Unit - 5

Ignition system

Battery and magneto ignition tool, spark plug, firing order, quality, quantity and hit and by skip over governing Ignition System:

Battery Ignition System:

The widest software for spark ignition internal combustion engines is in petrol (gasoline) road motors including motors and motorcycles. Compression ignition Diesel engines ignite the fuel-air mixture thru the warm temperature of compression and do now not need a spark. They generally have glow plugs that preheat the combustion chamber to allow starting in cold weather. Other engines may additionally use a flame, or a heated tube, for ignition.

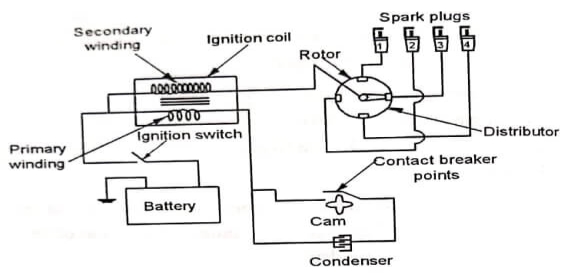

While this come to be now no longer unusual place for extraordinarily early engines it is now rare. The essential components with inside the ignition tool are a storage battery, an induction coil, a device to offer timed immoderate-voltage discharges from the induction coil, a distributor, and a set of spark plugs. The storage battery provides an electric powered current of low voltage (generally 12 volts) that is converted thru the tool to immoderate voltage (some 40,000 volts). The distributor routes the successive bursts of immoderate-voltage current to each spark plug with inside the firing order.

Many automobile engines now use a distributor-a lot much less ignition tool, or direct-ignition tool, in which a immoderate-voltage pulse is right now carried out to coils that sit down down on top of the spark plugs (called coil-on-plug). The most important components of these systems are a coil pack, an ignition module, a crankshaft reluctor ring, a magnetic sensor, and an virtual manipulate module. The ignition module controls the primary circuit to the coils, turning them on and off. The reluctor ring is set up on the crankshaft just so due to the fact the crankshaft rotates the magnetic sensor is delivered on thru notches with inside the reluctor ring. The magnetic sensor provides function statistics to the virtual manipulate module, which governs ignition timing.

A battery ignition gadget has a 6- or 12-volt battery charged with the resource of the use of an engine-driven generator to supply electricity, an ignition coil to boom the voltage, a device to interrupt modern from the coil, a distributor to direct modern to the ideal cylinder, and a spark plug projecting into each cylinder.

Parts of Battery Ignition System:

The main components of Battery Ignition system are listed below:

- Ignition switch

- Battery

- Ignition coil

- Ballast resistor

- Contact breaker

- Distributor

- Capacitor

- Spark Plug

Fig: Battery Ignition System

1. Ignition Switch:

It is used for ON or OFF the engine. One quit of the transfer is attached with the Primary Winding of Ignition Coil thru Ballast Resistor, and some other quit is attached with the Battery. Basically whilst the secret is placed interior it and became the transfer in ON function then the circuit is completed (Close Circuit), and whilst moved in the direction of the OFF function than its paintings as an open circuit. Nowadays, this transfer is changed via way of means of the Push Button, and this device is referred to as a keyless device.

2. Battery:

Although there are Zinc Acid Battery and Lithium-Ion Battery is carried out in contemporary-day vehicles. The voltage of the battery is between 6V to 12V or 24V.

3. Ignition coil:

t is running as a step-up transformer, and feature winds, one is number one that have a lesser turn, and the opposite one is secondary that have a better quantity of turn. It is the most important part of battery ignition system.

4. Ballast resistor:

This is used to restriction the modern-day with inside the ignition circuit and typically manufactured from Iron. It is located in collection among the Ignition Switch and Ignition Coil.

5. Contact Breaker:

The touch breaker is an electrical transfer that's regulated through the cam and while the breaker is open, modern flows thru the condenser and expenses it.

6. Distributor:

It is used with inside the multi-cylinder engine, and its reason is to modify spark in every spark plug at the appropriate sequence.

There are two types of distributors.

- Carbon Brush Type

- Gap Type

Carbon Brush Type:

It is consist of Carbon Brush which is slides over the metallic section inserted in the distributor cap.

Gap Type:

In this type, the rotor arm is surpassed via the steel phase of the distributor cap however it does now no longer contact the floor of the distributor cap. That’s why it's far referred to as Gap Type Distributor.

7. Capacitor:

A capacitor is a storing tool wherein electric electricity is stored. It is equipped parallel to the touch breaker, while the present day drops then it provided the extra present day in order that the spark is produced. It is made from metallic plates separated through air or every other insulating material.

8. Spark Plug:

It is very crucial and important part of system which able to ignite all system at its own.

Working Principle of Battery Ignition System:

In Battery Ignition System, while the Ignition Switch is became on then the modern will flows to the number one circuit thru ballast register, number one winding and call breaker The flowing modern brought about a magnetic area across the number one winding, the greater modern we deliver the greater magnetic field will generate. At a positive time, the touch breaker opens the modern is flowing thru the number one winding and fall. Due to this significant quantity of voltage the capacitor comes into the charging country while the capacitor charged completely then it begins off evolved turning in the modern toward the battery, because of this opposite flowing of the modern and already brought about magnetic area with inside the number one winding, a completely excessive voltage of 15000 V to 30000 V is generated with inside the secondary winding.

Advantages of Battery Ignition System:

These are the following advantages of Battery Ignition System:

• The depth of spark is good.

• It also can offer a excessive attention of spark even in low engine pace or beginning of Engine.

• The renovation of this ignition gadget may be very much less in comparison to others.

Disadvantages of Battery Ignition System:

The disadvantages are:

• Efficiency reduced with a discount in spark intensity.

• Occupies greater space.

• Efficiency reduced with a discount in spark intensity.

Applications of Battery Ignition System:

Here is the application of it:

- Battery Ignition System is used in Automobile (Car, Bus, Truck even in the Bike) to produce the Spark so that Combustion fuel can be burned.

Magneto Ignition System:

Magneto ignition device is an ignition device wherein magneto is used [produces high voltage] for the technology of energy and similarly that energy is utilized in numerous such things as to run the vehicles. This is essentially utilized in two-wheeler vehicles (Spark Ignition Engine) nowadays.

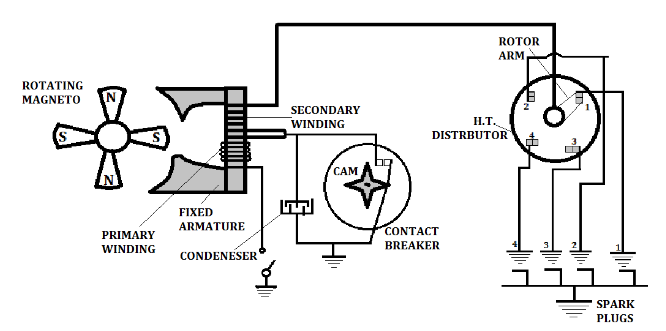

Fig. Magneto Ignition System

Parts of Magneto Ignition System:

The main parts of Magneto Ignition System are:

- Transformer core

- Contact Breaker

- Cam

- Capacitor

- Ignition Switch

- Distributor

- Spark Plug

1. Transformer core:

There are two types of winding we can see in Magneto Ignition System, those are:

- Primary Winding: The main function of this winding is to draw the power from the source.

- Secondary Winding: This winding has more turns of wire (the number is 1000 of turns of wire) as compared to the primary winding. This is connected to the Distributor (Which is having a rotor).

2. Contact Breaker:

The contact breaker is operated by cam and when breaker opens current flows through it.

3. Cam:

Cam is connected to the North and south magnet.

4. Capacitor:

Main work of it is to store charge. And here electric type capacitor issued.

5. Ignition switch:

For operating purpose like switch on and off this part is used.

6. Distributor:

This is connected to the spark plug and Distributor having the rotor.

7. Spark Plug:

The main work of the spark plug is firing the explosive mixture in the IC engine.

Working Principle of Magneto Ignition System:

When the engine of the machine starts, it permits the magneto to rotate and as a end result it’s producing the energy with inside the form of immoderate voltage then, one cease of the magneto is grounded thru a hint breaker, and the ignition capacitor is installed to its parallel. The contact breaker is regulated thru manner of way of the cam and while the breaker is open, current flows thru the capacitor and charges it. Now the capacitor is acting as a charger now, the primary current go with the flow is reduced, as a end result decreasing the overall magnetic field, generated with inside the machine. This will growth the voltage with inside the capacitor. This accelerated immoderate voltage with inside the capacitor will act as an EMF as a end result producing the spark, at the right spark plug thru the distributor. And on the start stage, the speed of the engine is low and consequently the voltage generated thru manner of way of the magneto is low. But due to the fact the rotating tempo of the engine will growth, it moreover will growth the voltage generated thru manner of way of the magneto as a end result the go with the flow of the current is also accelerated.

Advantages of Magneto Ignition System:

These are the following advantages of Magneto Ignition System:

• This gadget calls for much less preservation in comparison to the Battery ignition gadget.

• This is extra beneficial due to the fact no battery is used.

• It occupies much less space.

• An electric powered circuit is generated with the aid of using the magneto

• No battery is needed, so no trouble of battery discharge

• Efficiency improves because of high-depth spark.

Disadvantages of Magneto Ignition System:

Although there are some disadvantages:

• During starting, the best of spark is negative because of low speed.

• This is a bit costly compared to some other ignition system.

Applications of Magneto Ignition System:

Magneto Ignition System nowadays widely used in:

• This machine is used for the era of electricity (In case of Battery machine their Battery is used) and to run the vehicles.

• This is largely utilized in two-wheeler vehicles (SI Engine) nowadays.

• A rotating magnet produces excessive voltage.

• And additionally that is utilized in diverse locations like: Tractors, Outboard Motors, Washing Machines, Buses, Power Units, Marine Engines, and Natural Gas Engines.

Firing order:

The firing order of an internal combustion engine is the collection of ignition for the cylinders. In a spark ignition (e.g. Fuel/petrol) engine, the firing order corresponds to the order in which the spark plugs are operated.

Four-stroke engines must moreover time the valve openings relative to the firing order, due to the fact the valves do now not open and close to on every stroke.

The numbering tool for cylinders is commonly based totally definitely on the cylinder numbers developing from the the front to the rear of an engine (See engine orientation below).

Straight engine

Cylinders numbered from front (#1 cylinder) to rear.

V engine

V engine with cylinder numbering primarily based totally on crankshaft function (rather than following every cylinder financial institution) The front most cylinder is generally #1, but there are not unusual place approaches:

• Numbering the cylinders in every financial institution sequentially (e.g. 1-2-3-four alongside the left financial institution and 5-6-7-eight alongside the proper financial institution). This method is usually utilized by V8 engines from Audi, Ford and Porsche.

• Numbering the cylinders primarily based totally on their function alongside the crankshaft (e.g. 1-3-5-7 alongside the proper financial institution and 2-for-6-eight alongside the left financial institution). This method is usually utilized by V8 engines from General Motors, and Chrysler. The choice of whether or not the number one cylinder is at the left financial institution or proper financial institution generally relies upon on which financial institution is in the direction of the front of the crankshaft.

However, the Ford Flathead V8 and Pontiac V8 engine truly have the number one cylinder at the back of the cylinder from the alternative financial institution.

His become executed so that everyone Ford engines might have cylinder #1 at the proper financial institution and all Pontiac engines might have cylinder #1 at the left financial institution, to simplify the system of figuring out the cylinders.

Radial engine

The cylinders are numbered around the circle, in clockwise direction with the #1 cylinder at the top.

Quality, Quantity and hit and miss governing:

Governing:

The manner of imparting any arrangement, a good way to maintain the engine velocity constant (in keeping with the converting load conditions) is called governing of I.C. Engines. The manner of imparting any arrangement, a good way to maintain the engine velocity though there are numerous strategies for the governing of I.C. Engines, but the subsequent are important:

- Hit and miss governing.

In this gadget of governing, each time the engine begins offevolved strolling at better speed (because of reduced load), a few explosions are neglected or missed. This is achieved with the assist of a centrifugal governor. This technique of governing is extensively used for I. C. Engines of smaller capability or fueloline engines.

2. Qualitative governing.

In this machine of governing, a manage valve is outfitted with inside the gas shipping pipe, which controls the amount of gas to be blended with inside the charge. The motion of manage valve is regulated with the aid of using the centrifugal governor thru rack and pinion arrangement.

3. Quantitative governing.

In this gadget of goverliing, the exceptional of charge (i.e. air-fuel ratio of the mixture) is stored constant. But the quantity of mixture provided to the engine cylinder is numerous with the aid of using the usage of a throttle valve this is regulated via the centrifugal governor through rack and pinion arrangement.

4. Combination system of governing.

In this system of governing, the qualitative and quantitative methods of governing are combined together.

Lubrication and cooling system:

Lubricating structures are structures used to help the easy and wholesome operation of rotating equipment components like gears, bearings, dies, chains, spindles, cables, pumps, and rails.

• Without lubricating structures, many commercial enterprise and manufacturing strategies may want to place on down from friction, overheating, and generally require maintenance lots more quickly. (Without lubrication, commercial enterprise bearings rarely closing more than 10% of their functionality lifestyles span.)

• Machinery that requires constant maintenance will growth production downtime and negatively influences commercial enterprise productivity usual. Some US-based absolutely estimates feature a hint over 50% of usual commercial enterprise bearing screw ups to a lack of proper lubrication.

Wet Sump Lubrication System

The moist sump machine is not unusual place and popular oil sump in an vehicle engine. It’s referred to as moist-sump as it incorporates oil in only the sump, serving as a reservoir and it makes use of a unmarried oil pump. Oil circulating method appears to speedy on this lubricating machine due to the fact the oil is pumped from at once to the transferring parts. The sump is fabricated from skinny formed stainless metallic that is used to cowl the engine beneath. It collects the oil while the engine is at rest. Wet sumps are formed into deeper segment and it’s installed at the lowest of the crankcase serving as oil storage/reservoir. Though oil staving regularly takes place there are approaches to save you it.

The engine is cowl completely, stopping outside dust from getting into. Oil sumps additionally assist with inside the cooling of lubricating warm oil because the automobile moves. There is airflow below the sump, which allows to chill the recent oil earlier than getting into the engine for lubrication. There are cooling fins with inside the sump which growth its floor area. Oil sumps assist to maintain massive dust and save you them from getting into the engine. Small dust is saved with the aid of using the oil filter. The oil it incorporates is used for lubrication, cooling, and cleansing of the engine. With a dipstick, oil sump permits the oil to be a gauge. Oil pan/sump permits oil to empty out so new oil may be installed.

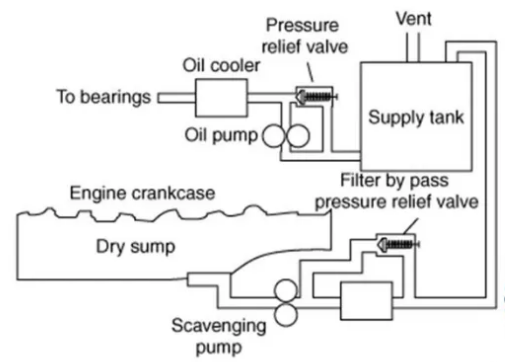

Dry Sump Lubrication

In a dry-sump lubricating system, there's a further oil reservoir apart from the oil pan. It’s a manner to manipulate lubricating oil in each two-stroke and four-stroke inner combustion engine. Oil is pumped at special ranges with inside the system, at at the very least two, with as many as five or 6. The subsequent degree is scavenging the oil out of the dry-sump pan and returning the oil and gases to the outside reservoir.

Fig: Dry Sump Lubrication System

Cooler is typically used the various inline of the scavenge shops and the outdoor reservoir. A Gilmer or High Torque Drive (HTD) timing belt and pulleys are generally used to pressure the pump. The motive for the severa ranges is to ensure all oil is scavenged from the pan and moreover to ensure more air from the crankcase is remove. Dry sump tool is in fashionable used on massive diesel engines much like those applied in ships. It is also used on gasoline engines applied in racing cars, aerobatic aircraft further to excessive-general overall performance motorcycles. They are used on excessive-general overall performance engines due to their reliability, oil capacity, an awful lot much less oil starvation, etc.

Crankcase Ventilation

A crankcase air flow machine gets rid of undesirable gases from the crankcase of an inner combustion engine. The machine normally includes a tube, a one-manner valve and a vacuum source (which include the consumption manifold). The undesirable gases, called "blow-with the aid of using", are gases from the combustion chamber that have leaked beyond the piston rings. Early engines launched those gases to the ecosystem truly with the aid of using them leaking via the crankcase seals. The first precise crankcase air flow machine changed into the street draught tube, which used a partial vacuum to attract the gases via a tube and launch them to the ecosystem.

Two-stroke engines with a crankcase compression layout do now no longer want a crankcase air flow machine, due to the fact ordinary operation of the engine entails sending the crankcase gases to the combustion chamber.

Lubrication of Engine components:

Components of Engine Lubrication System:

- Oil Sump.

- Engine oil filter.

- Piston cooling nozzles.

- Oil Pump.

- The Oil Galleries.

- Oil Cooler.

- The Oil pressure indicator/light.

Cooling System:

Cooling machine, equipment hired to hold the temperature of a shape or tool from exceeding limits imposed via way of means of desires of protection and efficiency. If overheated, the oil in a mechanical transmission loses its lubricating capacity, at the same time as the fluid in a hydraulic coupling or converter leaks beneath Neath the stress created. In an electric powered motor, overheating reasons deterioration of the insulation.

Cooling structures are hired in automobiles, commercial plant machinery, nuclear reactors, and plenty of different sorts of machinery. (For a remedy of the cooling dealers usually hired are air and a liquid (normally water or an answer of water and antifreeze), both on my own or in combination. In a few cases, direct touch with ambient air (unfastened convection) can be sufficient; in different cases, it is able to be vital to hire forced-air convection, created both via way of means of a fan or via way of means of the herbal movement of the recent body.

In a transmission, if the floor vicinity of the housing (container) is adequately big in comparison with the energy lost, or if the transmission is in a transferring vehicle, there may be normally good enough unfastened convection and no want for synthetic cooling. To increase the cooling impact via way of means of growing the floor vicinity, the housing can be supplied with skinny steel fins. On a few desk bound mechanical transmissions, it is able to be vital to flow into the lubricating oil via pipes surrounded via way of means of bloodless water or to apply a fan to blow air via pipes surrounded via way of means of the oil with inside the reservoir. On many electric powered motors, a fan is hooked up to the rotating detail to create a modern-day of cooling air via the housing.

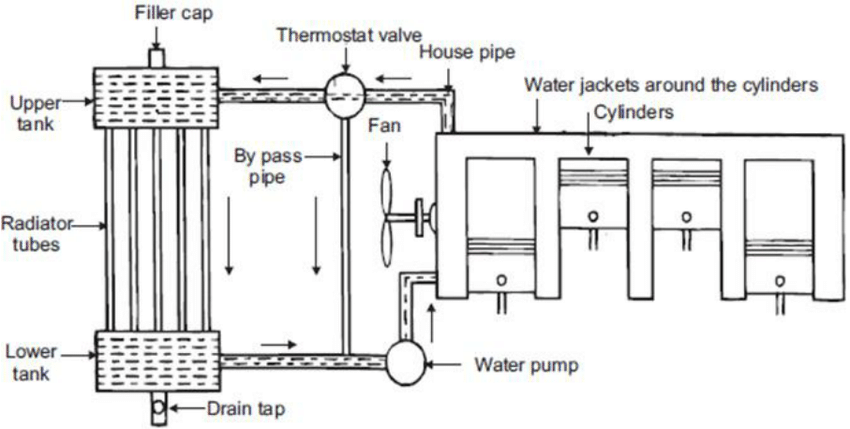

Liquid cooling system:

Liquid cooling is the discount of warmth in digital and mechanical gadgets via exploiting the residences of liquids. Liquid cooling is a firmly set up cooling technique in lots of contemporary technologies. Automobiles, mainframes and the structures of laptop fanatics have used water cooling for lots years. The techniques and coolants can vary among and inside those categories. In laptop cooling, the maximum not unusual place shape of liquid cooling entails a closed machine of tubes that incorporates the liquid from one factor worried in cooling to another. These structures are usually known as loops.

The pump pushes the liquid eleven though a loop and need to be primed with a view to begin circulating the liquid. Pumps burn out whilst spinning empty as they too depend upon the fluid they flow into for cooling. The tubing is maximum generally bendy plastic, frequently clean however on occasion colored or even UV reactive.

Some customers have used difficult plastic or copper pipe with bend fittings or fashioned tender copper piping. After the pump, the tubing commonly incorporates the liquid to the radiator wherein it's miles cooled of the pumps warmth load. Then the liquid movements directly to the additives that want cooling. The liquid is administered via water blocks.

A water block is comparable in characteristic to a warmth sink however the cooled floor vicinity is enclosed in the block. Thermal touch with additives is improved through thermal compound. Due to the liquid’s thermal capacity (approximately 30 instances that of air), the floor vicinity internal is a good deal smaller than today’s commonly massive high-stop air cooling warmth sinks. Water blocks exist for lots laptop additives except the CPU and the GPU.

There are blocks for motherboards, northbridge, southbridge, chips and electricity uptake circuitry inclusive of MOSFETs, RAM and difficult drives. The liquid utilized in cooling can be deionised water or an electrically nonconductive and non-capacitive engineered fluid, of which there are some of patented formulations. You can’t use faucet water because the ions dissolved in it are probable to corrode the water blocks. For the equal cause it’s inadvisable to combine metals in a cooling loop. You additionally need to bear in mind algae and microorganism boom that would clog a machine, so a few biocide marketers ought to be included.

Fig: Liquid Cooling System

Often fanatics select de-ionised water due to its performance, prepared availability and occasional cost. There are different elective elements as well. A loop might also additionally use a reservoir (a tank of liquid) or a 3 manner tailored T-line with a fill port. It might also additionally have water blocks for difficult drives and ram as well. The liquid can also be actively cooled through thermo-electric- or section change-primarily based totally water chillers in severe cases.

In those extremes, there are extra issues past leaks, just like the opportunities of condensation or freezing the liquid. Liquid cooling helps more going for walks speeds and quieter going for walks. Among fanatics, there may be a sure delight in the advent and status of ones cooling answer as well. Liquid cooling was the close to special area of the laptop fanatic and overclockers. Because contemporary CPUs and GPUs run at better speeds, they produce greater warmth than ever. Pre-packaged closed liquid cooling comes with a few high-stop CPUs and GPUs. This may be a consolation to folks that nevertheless are cautious of the concept of building their personal cooling loops.

Air Cooling System:

In the air cooling system, the warm temperature is dissipated right away to the air after being completed through the cylinder walls. The essential principle involved in this method is to have a current of air flowing continuously over the heated ground of the engine from wherein the warm temperature is to be removed. The amount of heat dissipated based totally mostly on the following factors.

- The floor vicinity of metallic into touch with air.

- The fee of air flow.

- A temperature distinction among the heated floor and the air.

- The conductivity of the metallic.

For entire use of air-cooling, the floor vicinity of the metallic which comes in touch with air is progressed via way of means of imparting fins over the cylinder barrels. More the floor vicinity in a touch with air, greater the warmth is dissipated.

Fig: Air cooling System

Higher the price of air flow, better the warmth is dissipated. Similarly better the temperature distinction among the heated floor and the air, better could be the warmth dissipation. A metallic having conductivity dissipates greater quantity of heat.

Advantage of Air Cooling System Engine

- Lighter in weight because of there's no radiator, cooling jackets and coolant.

- No topping up the cooling gadget

- No leaks to shield against.

- Anti-freeze now no longer required.

- Engine warms-up quicker than with water-cooled design.

- This gadget may be paintings in bloodless climates in which water can also additionally freeze.

- Can be utilized in regions in which there's an absence of cooling water.

Disadvantages of Air Cooling System Engine

1. Less green cooling system, due to the coefficient of warmth switch for air is much less than that for water.

2. It isn't always clean to hold even cool across the cylinder, the cylinder deformation can occur.

3. More noisy operation.

4. Limited use in motorcycles, and scooters in which the cylinders are uncovered to the air stream.

Comparison between Air and Liquid cooling System:

Advantages of air cooling | Advantages of water cooling |

Eliminate the use of water hence smaller engine size and weight. | Due to higher latent heat of water, more heat can be removed from locally heated spots. |

Simpler engine design | Higher volumetric efficiency |

Less sensitive to climatic changes | Higher specific output engines becomes possible and poses no problems with water cooling |

Better warm-up performance | Water-cooled engine can be placed anywhere in the vehicle |

Reduced carbon deposits due to higher cylinder temperature. |

|

Easier control of cooling system |

|

Can tolerate some degree of damage |

|

References:

1. Obert E. F, “Internal Combustion Engines and Air Pollution”, Harper and Row Publication Inc. NY, 1973.

2. Heisler H, “Advanced Engine Technology”, Edward Arnold, 1995.

3. Heywood J. B, “Internal Combustion Engine Fundamentals”, McGraw Hill Book Co. NY, 1989

4. Heldt P. M, “High Speed Combustion Engines”, Oxford & IBH publishing Co. India, 1985.

5. Stockel M W, Stockel T S and Johanson C, “Auto Fundamentals”, The Goodheart, Wilcox Co.

6. Inc., Illinois, 1996.