Unit - 6

Measurement and Testing of IC engines

The performance of an engine is evaluated on the basis of the following;

(a) Specific Fuel Consumption.

(b) Brake Mean Effective Pressure.

(c) Specific Power Output.

(d) Specific Weight.

(e) Exhaust Smoke and Other Emissions.

Basic measurements

The essential measurements to be undertaken to evaluate the general overall performance of an engine on almost all assessments are the following:

(i) Indicated power (if possible);

(ii) Brake power;

(iii) Morse check for mechanical overall performance in case of multi-cylinder immoderate tempo engines; (

(iv) Rate of fuel consumption and its calorific value;

(v) Rate of flow of cooling water and its rise of temperature, for calculating the j warm temperature carried away thru jacket cooling water;

(vi) Heat carried away thru the exhaust gases - this is expected each immediately thru } exhaust fuel line calorimeter or thru measuring air consumption and temperature of M exhaust gases, and engine room temperature.

The approach of locating indicated electricity of 1 cylinder of a multi-cylinder I.C. Engine without using an excessive pace indicator is called the Morse test. The engine is first run beneathneath the specified circumstance of load, pace, temperature, etc., and the brake electricity is measured accurately.

Measurement of indicated power:

It is extraordinarily tough to decide the ti indicated power, specifically whilst slight or excessive engine speeds are used. The ratio of most if strain with inside the engine cylinder to the suggest strain at some stage in the cycle in an I.C. Engine * is an awful lot more than that of another warmness engine. Thus, to save you vibrations being set up, the spring used need to be stiff however on the identical time it have to supply sufficient top of the indicator diagram. The manufacturing of genuine quantity scale is frequently hindered through the absence or inaccessibility of any appropriate factor of attachment for the indicator cord, in order that it could transmit the piston movement, consisting of is supplied through the cross-head of a steam engine. Any miniature crank or cam tool connected to the crank shaft need to be phased with big accuracy, even as slackness, inertia and elasticity with inside the mechanism might also additionally supply very severe results. The piston and pencil detail utilized in steam engine exercise is vain besides at very low speeds, the price of strain upward thrust inflicting violent oscillations which can't be damped without introducing errors. The substitute of the piston through a diaphragm and using excessive optical or electric magnification of its deflection, lessen the oscillation hassle however fatigue of the diaphragm metallic and alternate of its calibration through warmness are each possibly to occur.

Measurement of brake power:

There may be very little problem in measuring this amount correctly if normal precautions are taken. This can be received via way of means of the usage of both a mechanical, electrical, hydraulic and air brake, etc. The distinction among the indicated energy and brake energy is referred to as the mechanical or friction loss, and consists of the poor loop of the indicator diagram. The following technique is followed to decide the friction energy in order that the indicated energy can be correctly determined.

Motoring test:

An approximate fee of friction energy can be located straight away following a length of strolling, via way of means of measuring the energy required to motor the engine (the engine is pushed via way of means of an electric powered motor) on the needful velocity and with the ignition switched Such a check must be performed as close to as most working temperature possible, the viscosity of the lubricant growing very significantly with a fall of temperature. Unfjprtunately the skinny movie of lubricant at the cylinder wall, the shearing of that is the motive of approximately 1/2 of the whole engine friction, suffers massive deterioration via way of means of warmness and oxidation at the same time as the engine is strolling, and on switching off the ignition, this broken oil on which the piston generally operates, is swiftly washed from the partitions and changed via way of means of oil in proper condition. The energy required to motor the engine therefore falls very swiftly inside possibly minutes, and then it starts offevolved to upward thrust slowly because of the cooling of wails. A affordable correct willpower of strolling friction is, therefore, very difficult, if now no longer not possible with ordinary check equipment.

“Morse” test for mechanical efficiency:

For multi-cylinder excessive pace engine the Morse check is available, and is much less open to objection that the easy motoring check. The technique of locating indicated electricity of 1 cylinder of a multi-cylinder I.C. Engine without using a excessive pace indicator is referred to as the Morse check. The engine is first run below the desired situation of load, pace, temperature, etc., and the brake electricity is measured accurately. Each cylinder is then cut-out in turn; the brake load being unexpectedly adjusted in every case to deliver the engine pace returned to the desired fee on the given attitude of enhance and throttle settling.

Measurement of rate of fuel consumption and its calorific value:

This could be very effortlessly measured for small capability engine via way of means of noting the time taken to devour a given quantity of gasoline, despite the fact that strictly speak me it's far the mass of the oil this is required. A easy device, wherein unique glass bulbs, one in every of approximately a hundred c.c. Capability and the alternative 2 hundred c.c. Capability, can be linked via way of means of three-manner cocks to the gasoline tank and the engine gasoline deliver line. Three-manner cocks assist to fill the only bulb whilst the alternative is feeding the engine. To lessen the gasoline intake to a mass basis, the precise gravity of the gasoline oil ought to be determined, on the temperature of the oil throughout the trial. For larger length oil engine, the best and the maximum correct approach of acquiring the gasoline intake is to help the gasoline tank on a weighing system and deliver gasoline to the engine. The fee of gasoline intake is then acquired via way of means of subtracting the mass of the gasoline and tank on the give up of the trial, from that on the beginning, the time taken to discharge this mass of gasoline being noted. The maximum dependable approach of measuring the fueloline intake of a fueloline engine is to byskip the fueloline via a graduated fueloline holder from which it's far drawn via way of means of the engine. This is greater correct than using a fueloline meter. The temperature and stress of the fueloline ought to be taken, in order that the quantity used can be decreased to regular or fashionable temperature and stress.

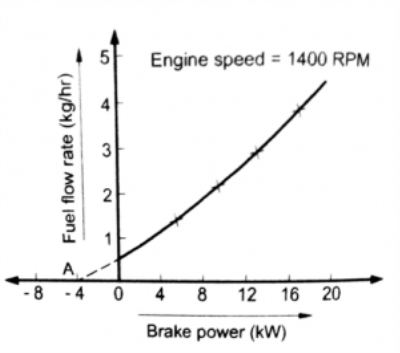

Fig. Willan’s line method

Willan’s line approach is likewise referred to as the gas price extrapolation approach. In this approach, we draw a graph in which we take brake electricity

• As proven with inside the figure, the graph is predicted again to 0 gas waft price of 0 gas in which it cuts at factor A at the terrible X-axis.

• Point A at the terrible X-axis suggests the friction electricity on the equal pace at the engine. When damage electricity will become 0, then gas intake on the equal electricity represents the gas fed on to triumph over the friction lack of the engine.

• As consistent with the graph, variant with inside the gas waft price and brake electricity is linear. It outcomes with inside the anticipation of the immediately a part of the primary curve as a terrible crossing at the X-axis at 0 gas waft price will constitute the friction electricity (F.P).

Limitations of Willans line method:

• Willan’s line approach is best used with inside the compression ignition (C.I) engine. It isn't always relevant to S.I engine.

• The friction strength given via way of means of this approach is approximate.

• Friction strength modifications even as an boom in engine velocity. That’s why the engine must run at a steady velocity at some stage in the Willan’s line test

Objectives of Testing

In general, the functions of trying out an inner combustion engine are:

(i) to achieve statistics approximately the engine which cannot be decided with the aid of using calculations,

(ii) to verify facts utilized in design, the validity of that is in doubt, and

(iii) To fulfill the client as to the rated strength output with the assured gas consumption

The majority of checks on inner combustion engines are accomplished for business functions so as to test the following:

(i) Rated strength (brake strength) with the assured gas consumption (kg/kW-hr.),

(ii) The amount of lubricating oil required on brake strength foundation in step with kW-hr.,

(iii) The amount of cooling water required on brake strength foundation in kg in step with kW-hr.

(iv) The stability of the engine while loaded at exclusive loads, and (v) The overload wearing ability of the engine.

Thermodynamic Tests:

Complete thermodynamic assessments are pretty exclusive from the economic assessments. They are executed for the motive of evaluating real effects with the theoretical or best performance. For such assessments it's far essential to degree losses similarly to the beneficial a part of the energy, and additionally to attract up a warmness stability account. Such trials have been ( the direct reason of, and incentive to, the development in warmness engines all through the duration in their development.

Power Testing:

For all strength exams with consequences to be plotted as opposed to velocity, a unmarried collection of stabilized runs at ascending velocity is enough. This collection of runs must development constantly from the bottom to the maximum. If the engine calls for to be idled among run to keep away from excessively excessive temperature, enough time must be allowed for the engine once more to attain to its stabilized situation earlier than taking readings. The brake load recorded must be regular and steady at some stage in the run.

Speed Testing:

Engine speed should be held as constant as far as possible by means of applied dynamometer load at wide open throttle, or by throttle adjustment at part load.

Frictional Power:

The friction power shall follow immediately after the power test and if not possible then rest shall be conducted under conditions those for the power test.

Fuel Consumption:

Fuel intake will be measured concurrently with brake power; The gas intake dimension shall now no longer be began out till the engine is stabilized. A measuring c programming language of now no longer much less than 60 seconds will be used whilst measuring pace and gas intake. All particular gas intake figures will be primarily based totally upon found brake power.

Brake Thermal Efficiency:

- Brake-precise gas intake (BSFC) is a degree of the gas performance of any high mover that burns gas and produces rotational, or shaft energy. It is generally used for evaluating the performance of inner combustion engines with a shaft output. It is the charge of gas intake divided via way of means of the energy produced.

- Indicated thermal performance = B/A Brake thermal performance = C/A Energy misplaced in exhaust, coolant, and radiation Energy misplaced in friction, pumping etc.

- Compression ratio drastically improves the brake thermal performance. Warmth similarly improves the brake thermal performance. But, growing cut-off ratio resulted with decrease brake thermal performance.

- Diesel engines in private vehicles offer little engine braking as they're now no longer ready with a throttle frame and consequently can not draw a vacuum with inside the consumption manifold. This is called an exhaust brake and commonly determined on older trucks.

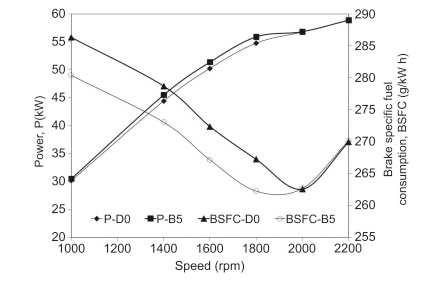

Brake power and brake specific fuel consumption of IC engines:

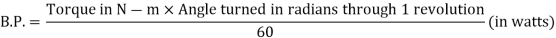

Brake Power:

The brake electricity (in brief written as B.P.) of an IC Engine is the electricity to be had on the crankshaft. The brake electricity of an I.C. Engine is, usually, measured by using a brake mechanism (prony brake or rope brake).

The beneficial electricity to be had on the crankshaft with inside the engine is referred to as wreck electricity (B.P.).

In case of prony brake, brake power of the engine,

where

where

W = Brake load in newtons,

l = Length of arm in metres, and

N = Speed of the engine in r.p.m.

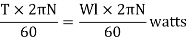

In case of rope brake, brake power of the engine,

…..[Considering diameter (d) of the rope]

…..[Considering diameter (d) of the rope]

Where

W = Dead load in newtons,

S = Spring balance reading in newtons,

D = Diameter of the brake drum in metres,

d = Diameter of the rope in metres, and

N = Speed of the engine in r.p.m.

Brake Specific Fuel Consumption of an IC Engine:

Specific gas intake is the quantity of gas fed on via way of means of a car for every unit of electricity output. The precise gas intake of an engine is the price of gas burnt to supply a unit of thrust.

Brake-precise gas intake (BSFC) is a degree of the gas performance of any top mover that burns gas and produces rotational, or shaft electricity. It is generally used for evaluating the performance of inner combustion engines with a shaft output.

It is the price of gas intake divided via way of means of the electricity produced. In conventional gadgets, it measures gas intake in kilos according to hour divided via way of means of the brake horsepower, lb/(hp⋅h); in SI gadgets, this corresponds to the inverse of the gadgets of precise strength, kg/J = s2/m2. It can also be notion of as electricity-precise gas intake, for this reason.

BSFC permits the gas performance of various engines to be without delay compared. To calculate the real performance of an engine calls for the strength density of the gas being used. Different fuels have unique strength densities described via way of means of the gas's heating value. The decrease heating value (LHV) is used for inner-combustion-engine-performance calculations due to the fact the warmth at temperatures underneath 150 °C (300 °F) can't be positioned to use.

Some examples of lower heating values for vehicle fuels are:

Certification gasoline = 18,640 BTU/lb (0.01204 kW⋅h/g)

Regular gasoline = 18,917 BTU/lb (0.0122222 kW⋅h/g)

Diesel fuel = 18,500 BTU/lb (0.0119531 kW⋅h/g)

Thus a diesel engine's efficiency = 1/(BSFC × 0.0119531) and a gasoline engine's efficiency = 1/(BSFC × 0.0122225)

Importance:

BSFC is a measure of the fuel efficiency of any engine that burns fuel and produces rotational power output. The BSFC value indicates how efficiently the engine converts fuel supplied into useful work. One of the main parameters used to determine the characteristics of biodiesel on BSFC is calorific value.

Variable compression ratio is a era to regulate the compression ratio of an inner combustion engine at the same time as the engine is in operation. Variable compression engines permit the extent above the piston at pinnacle useless centre to be changed.

Advantage:

• Gasoline engines have a restrict at the most stress throughout the compression stroke, and then the gasoline/air combination detonates as opposed to burns.

• To acquire better electricity outputs on the equal speed, greater gasoline should be burned and consequently greater air is needed. To acquire this, turbochargers or superchargers are used to boom the inlet stress.

• This could bring about detonation of the gasoline/air combination until the compression ratio become decreased, i.e. the extent above the piston made extra. This may be completed to a extra or lesser volume with big will increase in electricity being possible.

• The down aspect of that is that beneath Neath mild loading, the engine can lack electricity and torque. The answer is which will range the inlet stress and regulate the compression ratio to suit.

• This offers the nice of each worlds, a small green engine able to extremely good electricity on demand. In addition, VCR lets in loose use of various fuels except petrol e.g. LPG or ethanol.

Compression ratios normally range among 1.05–7 in keeping with degree; however, a ratio of 3.5–4.zero in keeping with degree is taken into consideration most for maximum manner operations. Quite often, the temperature upward push of the fuelling throughout the compression dictates a restrict for the secure or affordable stress upward push.

Heat Balance Sheet of IC engines:

Heat Balance Sheet is an account of warmth provided and warmth applied in diverse methods with inside the IC engine. Heat stability sheet is used to get essential data concerning the overall performance of IC Engine. Heat stability sheet may be accomplished on 2d foundation or minute foundation or hour foundation. Since warmness stability sheet is account of warmth provided and warmth used by engine. So we need to maintain listing of warmth provided to engine and warmth used by engine.

The heat supplied to engine is only by combustion of fuel and is equal to :-

Qs = mf X CV

Where,

Mf = mass of fuel used in kg/min

CV = Calorific value of fuel in KJ/kg

List of heat which are utlized by the engines are:

1) Heat equivalent to brake power of engine.

2) Heat carried away by cooling water.

3) Heat exhausted with the exhaust gases

4) Unaccounted heat loss.

1) Heat equivalent to brake power of engine.

Q B.P = B.P X 60 = _ K J/Min

2) Heat carried away by cooling water.

Qw = Mw X CPw X ( Two – Twi ) in KJ/min

Where,

Mw =Mass of cooling water ciculated in Kg/Min

CPw = Specific heat of cooling water which is equal to 4.186 KJ/khK

Twi = Temperature of cooling water at inlet in °C.

Two= Temperature of cooling water at outlet of the engine in °C

3) Unaccounted heat losses:

A part of heat is lost by leakage of gases as well as by convection and radiation. Part of heat is also used to run other accessories like lubricating pump, cam shaft and water circulating pump. These part of heat cannot be measured accurately, so this is known as unaccounted heat. It is denoted by Qun.

Qun = Qs – (QB.P + Qw + Qg) in KJ / min

Now, we have values of heat supplied and heat utilized by the engine.From these values, we have to prepare a balance sheet.

Internal combustion engines generate unwanted emissions for the duration of the combustion process. In this, each SI and CI engines are similarly liable for the same.

The emissions exhausted into the environment pollute the ecosystem and reasons the subsequent problems

(i) worldwide warming

(ii) acid rain

(iii) smog

(iv) odors

(v) respiration and different fitness hazards

The primary reasons of those emissions are non-stoichiometric combustion, dissociation of nitrogen, and impurities with inside the gasoline and air. The emissions of challenge are: unburnt hydrocarbons (HC), oxides of carbon (COx), oxides of nitrogen (NOx), oxides of sulphur (SOx), and strong carbon particulates.

Air pollution due to SI engines

During that length the environment, with the assist of sunlight, stayed tremendously clean. As global populace grew, electricity plants, factories, and an ever-growing wide variety of vehicles started to pollute the air to the quantity that it changed into not acceptable. During the overdue 1940s, air pollutants as a hassle changed into first identified with inside the Los Angeles basin in California. Two reasons of this have been the huge populace density and the herbal climate situations of the area. Smoke and different pollution from many factories and vehicles blended with fog that changed into not unusualplace on this ocean area, and smog resulted. During the 1950s, the smog hassle elevated along side the boom in populace density and vehicle density. At this degree it changed into found out that the car changed into one of the primary participants to the hassle. By the Sixties emission requirements have been starting to be enforced in California.

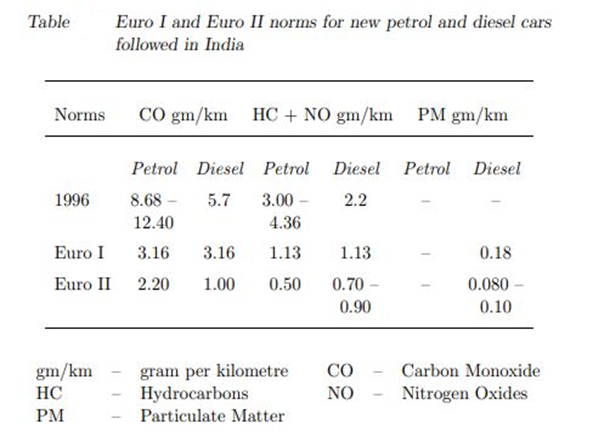

EURO I AND EURO II NORMS

As we know, the exhaust fueloline despatched into the environment with the aid of using the engine carries hydrocarbons (HC), carbon monoxide (CO) and nitrogen oxide (NOx) which can be especially liable for air pollution. These pollution are recognized to motive extreme fitness problems. Therefore there are legal guidelines on emission requirements, which restrict the quantity of every pollutant with inside the exhaust fueloline emitted with the aid of using an vehicle engine. Emission requirements had been observed for a while with inside the evolved

Countries. India is in prefer of the ”European Model” evolved with the aid of using the European countries. The European emission norms are called ’Euro Norms’, In India, vehicle industries have evolved the”Euro” norms. Euro I emission norms had been enforced with inside the New Delhi Capital Region from June 1999 and Euro II norms have taken impact from April 2000 at some point of India. The info of Euro I and Euro II norms tailored to Indian situations are given in Table.

Engine emissions

Engine emissions can be classified into two categories:

(i) exhaust emissions and

(ii) non-exhaust emissions.

Exhaust Emissions

As already referred to essential exhaust emissions are

(i) unburnt hydrocarbons, (HC)

(ii) oxides of carbon, (CO and CO2),

(iii) oxides of nitrogen, (NO and NO2)

(iv) Oxides of sulphur, (SO2 and SO3) (v) particulates (vi) Soot and smoke.

The first 4 are not unusual place to each SI and CI engines and the ultimate are particularly from CI engines. The essential non-exhaust emission is the unborn hydrocarbons from gasoline tank and crankcase blowby.

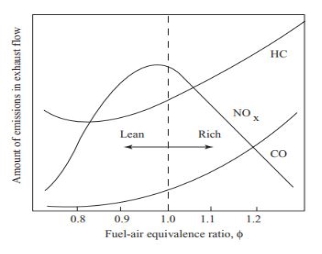

Figure indicates the variant of HC, CO and NOx emissions as a feature of equivalence ratio for an SI engine. It is certainly visible that each one the 3 emissions are a robust feature of equivalence ratio. As may be observed from the Fig that a wealthy combination does now no longer have sufficient oxygen to react with all of the carbon and hydrogen, and each HC and CO emissions boom. For φ < 0. 8, HC emissions additionally boom because of terrible combustion and misfire. The technology of nitrogen oxide emissions is a feature of the combustion temperature, maximum close to stoichiometric situations while temperatures are at the height value. Maximum NOx emissions arise at barely lean situations, wherein the combustion temperature is excessive and there may be an extra of oxygen to react with the nitrogen.

Fig: Exhaust Emissions

Hydrocarbons (hc)

Exhaust gases leaving the combustion chamber of an SI engine comprise as much as 6000 ppm of hydrocarbon additives, the equal of 1-1.5% of the gasoline. About 40% of that is unburned additives of the gasoline. The different 60% includes in part reacted additives that had been now no longer gift with inside the unique gasoline. These include small no equilibrium molecules, which might be shaped whilst big gasoline molecules ruin up (thermal cracking) at some point of the combustion reaction. It is regularly handy to deal with those molecules as though they contained one carbon atom, as CH1. Hydrocarbon emissions might be specific for every fuel blend, relying at the unique gasoline additives. Combustion chamber geometry and engine running parameters additionally have an impact on the HC factor spectrum.

The reasons for hydrocarbon emissions from SI engine are:

• Incomplete combustion

• Crevice volumes and go with the drift in crevices

• Leakage beyond the exhaust valve

• Valve overlap

• Deposits on walls

• Oil on combustion chamber walls

Incomplete Combustion

There are numerous motives for this. Complete and homogeneous blending of gas and air is nearly impossible. The incomplete combustion is because of:

(i) Improper blending: Due to incomplete blending of the air and gas a few gas debris do now no longer locate oxygen to react with. This reasons HC emissions.

(ii) Flame quenching: As the flame is going very near the partitions it receives quenched on the partitions leaving a small extent of unreacted air-gas combination. The thickness of this unburned layer is of the order of one hundred microns.

However, it can be stated that a number of this combination close to the wall that doesn't at the start get burned because the flame the front passes will burn later with inside the combustion procedure because of extra blending, swirl and turbulence.

Air pollution due to IC engines:

Carbon monoxide, nitrogen oxides, and hydrocarbons are launched whilst gasoline is burned in an inner combustion engine and whilst air/gasoline residuals are emitted thru the automobile tailpipe. Gasoline vapors additionally get away into the surroundings at some stage in refueling and whilst gasoline vaporizes from engines and gasoline structures because of automobile operation or warm weather. The pollution in automobile emissions are regarded to harm lung tissue, and may result in and worsen breathing diseases, together with asthma. Motor automobile pollutants additionally contributes to the formation of acid rain and provides to the greenhouse gases that motive weather change. Pollutants emitted immediately from motors aren't the handiest motive for concern.

In many city areas, motor motors are the unmarried biggest contributor to ground-stage ozone that's a not unusual place element of smog. Ozone reasons coughing, wheezing and shortness of breathe, and may bring about everlasting lung harm, making it a motive of vital public fitness problems. Hence, CNG fueloline is used to manipulate the air pollutants. Compressed herbal fueloline, or CNG, is herbal fueloline below strain which stays clear, odorless, and non-corrosive. Although motors can use herbal fueloline as both a liquid or a fueloline, maximum motors use the gaseous shape compressed to excessive pressures.

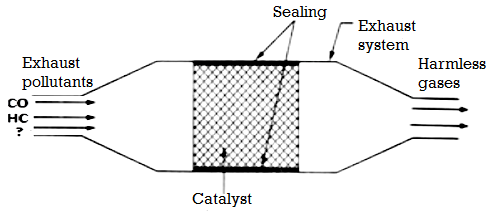

Catalytic Convertor:

A catalytic converter is an exhaust emission manipulate tool that converts poisonous gases and pollution in exhaust fueloline from an inner combustion engine into less-poisonous pollution with the aid of using catalyzing a redox response. Catalytic converters are normally used with inner combustion engines fueled with the aid of using gas or diesel, together with lean-burn engines, and once in a while on kerosene warmers and stoves. A catalytic converter makes use of a chamber referred to as a catalyst to extrade the damaging compounds from an engine’s emissions into secure gases, like steam.

Fig: Catalytic Convertor

It works to cut up up the hazardous molecules with inside the gases that a vehicle produces earlier than they get launched into the air. The catalytic converter is positioned on the bottom of a car and seems like a huge steel box. There are pipes popping out of it. The convertor makes use of those pipes and the catalyst at some stage in the procedure of creating the gases secure to be expelled. Gases are introduced in from the “input” pipe related to the engine of a car. These are blown over the catalyst, which reasons a chemical response that breaks aside the pollution.

The less-dangerous gases now journey thru the second one pipe, or the “output,” this is related to a vehicle’s tailpipe. So what's a catalytic converter made of? The catalyst internal a catalytic converter is made commonly from platinum or a comparable steel, together with rhodium or palladium. Gases go with the drift thru a ceramic honeycomb shape positioned in the cat housing. This is coated with metals which have particular jobs that play a function in decreasing emissions. There are essential varieties of catalysts that is probably featured in a vehicle:

• Reduction catalysts: Help lessen nitrogen oxide pollutants via way of means of casting off oxygen. Nitrogen oxides are damaged up into nitrogen and oxygen gases, which on their very own are harmless.

• Oxidation catalysts: Used to extrade carbon monoxide into carbon dioxide thru an contrary manner of including oxygen.

This allows a car run on a greater green air/gas ratio, permitting the engine to deliver the converter with sufficient oxygen to finish the oxidation manner.

Types of Catalytic Converters

As referred to before, there are number one catalysts – discount and oxidation – that may be used inside an exhaust device to address particular gases. Depending at the yr of the car and the sort of catalytic converter it has, there may not be a discount catalyst in place. There are number one types of catalytic converters:

- Two-way: They handiest have oxidation catalysts, which assist extrade carbon monoxide to carbon dioxide. Hydrocarbons (that's unburned and in part burned fuel) are modified to carbon dioxide and water.

- Three-way: As said earlier, that is used to extrade nitrogen oxides to nitrogen and oxygen gases. Diesel engines appoint using -manner catalysts, and the converters also are in particular designed to paintings with diesel exhausts. The converters for those kinds of engines try to goal particulates referred to as soluble natural fractions. These are crafted from hydrocarbons sure to soot.

Diesel engines rent the usage of two-manner catalysts, and the converters also are specially designed to paintings with diesel exhausts. The converters for those kinds of engines try to goal particulates called soluble natural fractions. These are crafted from hydrocarbons certain to soot.

Advanced IC Engine Concepts:

n inner combustion engine (ICE or IC engine) is a warmness engine wherein the combustion of a gas takes place with an oxidizer (normally air) in a combustion chamber this is an fundamental a part of the operating fluid float circuit. This pressure movements the thing over a distance, reworking chemical electricity into beneficial kinetic electricity and is used to propel, circulate or electricity regardless of the engine is connected to. In contrast, in outside combustion engines, inclusive of steam or Stirling engines, electricity is introduced to a operating fluid now no longer consisting of, blended with, or infected through combustion products. While there are numerous desk bound programs, maximum ICEs are utilized in cell programs and are the dominant electricity deliver for cars inclusive of cars, plane and boats.

Application:

• Where excessive energy-to-weight ratios are required, inner combustion engines seem with inside the shape of combustion mills or Wankel engines.

• Powered plane normally makes use of an ICE which can be a reciprocating engine. Airplanes can rather use jet engines and helicopters can rather appoint turboshafts; each of which can be sorts of mills.

• In addition to presenting propulsion, airliners may also appoint a separate ICE as an auxiliary energy unit. Wankel engines are suited to many unmanned aerial vehicles.

• ICEs power big electric powered turbines that energy electric grids.

• They are observed with inside the shape of combustion mills with a normal electric output with inside the variety of a few one hundred MW. Combined cycle energy vegetation use the excessive temperature exhaust to boil and superheat water steam to run a steam turbine.

• Thus, the performance is better due to the fact greater strength is extracted from the gas than what might be extracted with the aid of using the combustion engine alone. Combined cycle energy vegetation obtain efficiencies with inside the variety of 50% to 60%. In a smaller scale, desk bound engines like Gas engine or Diesel turbines are used for backup or for presenting electric energy to regions now no longer linked to an electric powered grid.

References:

1. Obert E. F, “Internal Combustion Engines and Air Pollution”, Harper and Row Publication Inc. NY, 1973.

2. Heisler H, “Advanced Engine Technology”, Edward Arnold, 1995.

3. Heywood J. B, “Internal Combustion Engine Fundamentals”, McGraw Hill Book Co. NY, 1989

4. Heldt P. M, “High Speed Combustion Engines”, Oxford & IBH publishing Co. India, 1985.

5. Stockel M W, Stockel T S and Johanson C, “Auto Fundamentals”, The Goodheart, Wilcox Co.

6. Inc., Illinois, 1996.