Unit - 7

Super charging

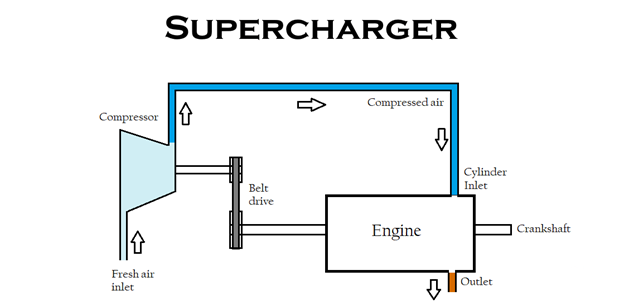

Supercharger, in piston-kind internal-combustion engines, air compressor or blower used to growth the consumption manifold stress of the engine. Higher stress will increase the mass of air drawn into the cylinders through the pumping movement of the pistons throughout every consumption stroke.

With the extra air, it's far viable to burn greater gasoline consistent with cycle, and the energy of the engine is as a consequence increased. Supercharging of IC Engines - It is the technique of growing the mass (or in different phrases density) of the air gasoline mixture (in spark ignition engines) or air (in compression ignition engines) brought about into the engine cylinder. This is typically completed with the assist of a compressor or blower called supercharger.

It has been experimentally determined that the supercharging will increase the energy advanced through the engine. It is broadly utilized in plane engines, because the mass of air sucked withinside the engine cylinder decreases at very excessive altitudes. This happens, due to the fact atmospheric stress decreases with the growth in altitude.

Following are the items of supercharging the engines:

1. To lessen mass of the engine consistent with brake energy (as required in plane engines).

2. To preserve energy of air craft engines at excessive altitudes wherein much less oxygen is to be had for combustion.

3. To lessen area occupied through the engine (as required in marine engines).

4. To lessen. Intake of lubricating oil (as required is all sorts of engines).

5. To growth the energy output of an engine whilst extra energy is required (as required in racing vehicles and different engines).

In plane piston engines, supercharging compensates for the decreased atmospheric stress at excessive altitudes. Development of the fueloline turbine, which calls for consistent waft of air and gasoline, delivered the advent of the turbosupercharger, or clearly turbocharger, a centrifugal blower pushed by means of a small fueloline turbine powered by means of the exhaust gases from the engine cylinders. A supercharger is an air compressor that will increase the stress or density of air provided to an inner combustion engine.

This offers every consumption cycle of the engine extra oxygen, letting it burn extra gasoline and do extra work, for that reason growing the energy output. Power for the supercharger may be supplied automatically through a belt, shaft, or chain linked to the engine's crankshaft.

Common utilization restricts the time period supercharger to automatically pushed units; whilst energy is as a substitute supplied by means of a turbine powered by means of exhaust fueloline, a supercharger is referred to as a turbocharger or only a turbo—or withinside the beyond a turbo supercharger.

Fig. 1 Schematical Representation of Supercharger

7.1.1. Types of Supercharger:

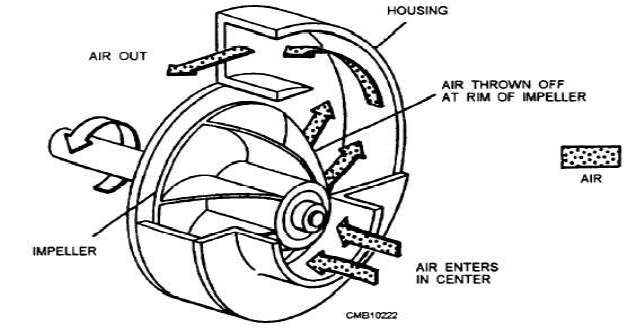

There are most important styles of superchargers described in keeping with the technique of fuel line transfer: advantageous displacement and dynamic compressors. Positive displacement blowers and compressors supply a nearly consistent stage of strain boom in any respect engine speeds (RPM). Dynamic compressors do now no longer supply strain at low speeds; above a threshold, velocity strain will increase exponentially.

A. Positive displacement

Positive-displacement pumps supply a almost constant quantity of air in keeping with revolution in any respect speeds (minus leakage, which is nearly consistent in any respect speeds for a given strain, as a result its significance decreases at better speeds).

Major styles of advantageous-displacement pumps include:

Fig. 2. Positive Type supercharger

• Roots

• Lysholm twin-screw

• Sliding vane

B. Compression type

Positive-displacement pumps are in addition divided into inner and outside compression kinds. Roots superchargers, together with excessive helix roots superchargers, produce compression externally.

• External compression refers to pumps that switch air at ambient stress.

Roots superchargers will be predisposed to be very robotically green at transferring air at low-stress differentials, at the identical time as at excessive-stress ratios, inner compression superchargers will be predisposed to be more robotically green. All the possibility kinds have a few diploma of inner compression.

Fig. 3 Compression type supercharger

• Internal compression gadgets usually use a tough and rapid inner compression ratio. When the enhance stress is identical to the compression stress of the supercharger, the backflow is zero.

If the enhance stress exceeds that compression stress, backflow can but rise up as in a roots blower. The inner compression ratio of this form of supercharger may be matched to the anticipated enhance stress an great way to optimize mechanical efficiency.

A. Engine lubrication

The process of the lubrication gadget is to distribute oil to the shifting components to lessen friction among surfaces which rub towards every different. ... The oil then runs down withinside the crankcase to the principle bearings protecting the crankshaft. Oil is picked up and splashed onto the bearings to lubricate those surfaces. The procedure of lubrication in an inner combustion engine starts offevolved withinside the sump, typically known as the oil pan. From here, the oil is pulled thru a strainer, through the oil pump, disposing of large contaminants from the mass of the fluid. The oil then is going thru the oil filter. It is critical to notice that now no longer all filters carry out the same. A filter’s cappotential to get rid of debris depends upon many factors, along with the media material (pore size, floor location and intensity of filter), the differential strain throughout the media, and the go with the drift fee throughout the media.

Oil is pumped thru passageways to the numerous additives of the engine consisting of the cam, most important bearings, rod, pistons, etc. Gravity then pulls the oil back off to the lowest of the motor to empty returned into the sump, and the cycle repeats. To respect the whole effect of the engine lubrication procedure, you ought to recognize how oils are formulated. All engine oils have additives: components and base oil. The overall quantity of components in motor oil can variety from 20 to 30 percent, relying on brand, formula and application.

These components can enhance, suppress or upload residences to the bottom oil. A regular additive package deal determined in engine oil might encompass a detergent and a dispersant. These components paintings collectively to assist rid the engine gadget of deposits due to the burning of gas and contributed to through blow-through gases.

Dispersants and detergents are small debris which have a polar head and an oleophilic tail. The polar heads are interested in contaminants in the oil and surround them, forming a shape known as a micelle. Soot is a superb instance of a deposit this is managed through detergents and dispersants. Soot debris are enveloped through dispersant debris, forming a micelle, and are saved from attaching to steel surfaces.

They are moved on this kingdom thru the oil gadget till they're eliminated through the filter. This additionally prevents a procedure called congealing. During congealing, soot debris start to stack upon every different or congeal into a bigger particle. Smaller soot debris that would byskip thru additives with out interrupting the fluid movie can congeal to make large debris, which can also additionally disrupt the movie and harm surfaces.

Most car engines use a few shape of multi-grade oil. This form of oil has an additive known as a viscosity-index (VI) improver. A not unusualplace instance might be 10W-30 or 5W-40. These VI improvers are long-chain natural molecules that alternate form because the temperature in their surroundings changes. When in bloodless environments (engine startup), those molecules are tightly bound. As the oil heats up, they start to stretch out. This permits an oil to go with the drift greater simply at chillier temperatures however nonetheless preserve a suitable viscosity and, greater importantly, a lubricating layer withinside the working temperature variety.

Types of Lubrication System

Following are the 6 main types of lubrication system:

- Petrol system

- Splash system

- Pressure system

- Semi-pressure system

- Dry sump system

- Wet sump system

1. Petrol System

In those styles of the lubrication system, it's far generally used withinside the two-stroke petrol engines consisting of scooters and motorcycles. It is the best shape of the lubricating system. For lubrication purpose, it does now no longer have any separate component like an oil pump. But the lubricating oil is delivered to the petrol itself all through filling withinside the petrol tank of the automobile in a special ratio. When gasoline enters the crank chamber all through engine operation, oil debris cross down into the bearing surfaces and lubricate them. The piston rings, cylinder walls, piston pins, etc. are effortlessly lubricated withinside the identical way. If the engine is permitted to stay unused for a massive time, the lubricating oil separates off from petrol and begins offevolved to clogging of passages withinside the carburettor, happening in engine begin problems. Thus is the primary risks of this system.

2. Splash System

When the engine runs, the dipper dips withinside the oil as quick as in each revolution of the crankshaft and purpose the oil to splash at the cylinder walls. This movement impacts engine walls, piston rings, crankshaft bearings, and huge give up bearings. Splash machine often works in reference to the stress machine in an engine.

3. Pressure System

In those sorts of lubrication device, engine components are lubricated beneathneath pressure feed. The lubricating oil is saved in a separate tank or the sump, from which an oil pump gets the oil thru a strainer and transfers it thru a easy out out to the precious oil gallery at a pressure of 2-four kg/cm2. Four. Semi-pressure System. It is the combination of a dash device and pressure device of the lubrication device. Some components are lubricated thru way of method of splash device and a few components thru way of method of a pressure device. Almost all four-stroke engines are oiled or lubricated thru way of method of this semi-pressure device. The most important deliver of oil on this device is placed withinside the lowest of the crank chamber. A easy out out is extracted from the lowest of the sump thru oil and brought thru a device pump at a pressure of one bar. Larger bearing ends are lubricated thru a nozzle spray. Consequently, the oil furthermore oils or lubricates crankshaft bearings, cams, cylinder partitions and timing gears. The oil deliver is measured with the assist of oil pressure gauges. This device is an entire lot a whole lot much less expensive to install. This permits excessive bearing masses and engine tempo to be carried out than the splash device. The oil from the principle gallery is going to the principle bearings, after lubricating the principle bearing, a number of it's far going returned to the sump, a few is splattered to lubricate the cylinder partitions and the relaxation is going from a hollow into the crank pin. From the crankpin, it's far going thru a hollow withinside the connecting rod net to the piston pin, in which it lubricates the piston rings. To lubricate the timing gears and camshaft, the oil is led thru a separate oil line from the oil gallery. The valve tape is lubricated thru way of method of attaching the principle oil gallery to the tappet manual surfaces thru drilled holes. An oil pressure gauge at the tool panel shows the oil pressure withinside the device. The oil filters and strainers withinside the device clean off the oil from dust, metal debris and exclusive volatile debris.

5. Dry Sump System

The device wherein lubricating of oil collects withinside the oil sump is referred to as a moist sump device as a stress device. But the device wherein the lubricating oil isn't always positioned withinside the oil sump is referred to as the dry pump device. In this device, the vanes sweep the oil from the inlet to the opening side. As the drum is carried out in an eccentric manner, the extent among the drum and the casting constantly decreases and the oil stress at the opening increases.

6. Wet Sump System

In this tool, oil is transported to numerous engine additives with a sump strainer. In this wet sump tool, oil pressure is of about 4 to 5 kg/cm2. After lubrication, the oil is carried once more to the oil sump. Therefore, it is known as a wet sump lubrication tool. The advantages of a wet sump tool are its simplicity. And the oil is close to wherein it will be applied, doesn’t have hundreds of additives to repair, and is pretty steady to assemble in a car.

B. Cooling of Engine:

Cooling system

Almost all motors hire liquid cooling structures for his or her engines. A standard automobile cooling device incorporates (1) a sequence of channels solid into the engine block and cylinder head, surrounding the combustion chambers with circulating water or different coolant to hold away immoderate warmth, (2) a radiator, including many small tubes ready with a honeycomb of fins to radiate warmth rapidly, which gets and cools warm liquid from the engine, (3) a centrifugal-kind water pump with which to flow into coolant, (4) a thermostat, which continues regular temperature with the aid of using routinely various the quantity of coolant passing into the radiator, and (5) a fan, which pulls sparkling air thru the radiator. For operation at temperatures under 0 °C (32 °F), it's miles essential to save you the coolant from freezing. This is commonly accomplished with the aid of using including a few compound, which include ethylene glycol, to depress the freezing factor of the coolant. By various the quantity of additive, it's miles feasible to guard in opposition to freezing of the coolant right all the way down to any minimal temperature typically encountered.

Coolants include corrosion inhibitors designed to make it essential to empty and top off the cooling device simplest each few years. Air-cooled cylinders perform at better, extra green temperatures, and air cooling gives the crucial benefit of putting off now no longer simplest freezing and boiling of the coolant at temperature extremes however additionally corrosion harm to the cooling device.

Control of engine temperature is extra tough, however, and excessive-temperature-resistant ceramic elements are required whilst layout running temperatures are drastically expanded. Pressurized cooling structures were used to boom powerful running temperatures. Partially sealed structures the usage of coolant reservoirs for coolant growth if the engine overheats have been delivered withinside the early 1970s

Specially formulated coolants that don't go to pot over the years cast off the want for annual replacement. Electrical device The electric device incorporates a garage battery, generator, beginning (cranking) motor, lights device, ignition device, and numerous add-ons and controls. Originally, the electric device of the car turned into constrained to the ignition equipment. With the appearance of the electrical starter on a 1912 Cadillac model, electric powered lighting fixtures and horns commenced to update the kerosene and acetylene lighting fixtures and the bulb horns. Electrification turned into fast and complete, and, with the aid of using 1930, 6-volt structures have been general everywhere.

Increased engine speeds and better cylinder pressures made it more and more more tough to satisfy excessive ignition voltage necessities. The large engines required better cranking torque. Additional electrically operated features—which include radios, window regulators, and multispeed windshield wipers—additionally introduced to device necessities.

This is accomplished with the aid of using a circuit that begins off evolved with the battery, one aspect of that's grounded at the chassis and leads thru the ignition transfer to the number one winding of the ignition coil and lower back to the floor thru an interrupter transfer. Interrupting the number one circuit induces a excessive voltage throughout the secondary terminal of the coil. The excessive-voltage secondary terminal of the coil results in a distributor that acts as a rotary transfer, alternately connecting the coil to every of the wires main to the spark plugs. Solid-country or transistorized ignition structures have been delivered withinside the 1970s.

These distributor structures furnished expanded sturdiness with the aid of using putting off the frictional contacts among breaker factors and distributor cams.

The breaker factor turned into changed with the aid of using a revolving magnetic-pulse generator wherein alternating-present day pulses cause the excessive voltage wished for ignition by using an amplifier digital circuit. Changes in engine ignition timing are made with the aid of using vacuum or digital manage unit (microprocessor) connections to the distributor.

The supply of power for the numerous electric gadgets of the car is a generator, or alternator, this is belt-pushed from the engine crankshaft. The layout is commonly an alternating-present day kind with integrated rectifiers and a voltage regulator to in shape the generator output to the electrical load and additionally to the charging necessities of the battery, no matter engine velocity. A lead-acid battery serves as a reservoir to save extra output of the generator.

This presents power for the beginning motor and electricity for running different electric powered gadgets whilst the engine isn't always going for walks or whilst the generator velocity isn't always sufficiently excessive for the load.

For water-cooled engines on plane and floor vehicles, waste warmth is transferred from a closed loop of water pumped via the engine to the encircling surroundings with the useful resource of the usage of a radiator.

Water has a better warmth functionality than air, and may consequently go along with the float warmth extra speedy far far from the engine, however a radiator and pumping gadget upload weight, complexity, and cost. Higher-strength engines generate extra waste warmth, however can go along with the float extra weight, which means they'll be commonly water-cooled.

Radial engines permit air to go along with the float round every cylinder directly away, giving them a bonus for air cooling over at once engines, flat engines, and V engines. Rotary engines have a comparable configuration, however the cylinders furthermore usually rotate, growing an air go along with the float even though the car is stationary. Aircraft layout extra strongly favors decrease weight and air-cooled designs. Rotary engines had been famous on plane till the prevent of World War I, however had crucial balance and standard overall performance problems. Radial engines had been famous till the prevent of World War II, till fueloline turbine engines in large detail changed them. Modern propeller-pushed plane with internal-combustion engines are in spite of the truth that during large detail air-cooled.

Transition from air cooling:

The extrude of air cooling to liquid cooling passed off on the begin of World War II at the same time as America navy favored dependable vehicles. From steam engines, wherein water loss is accepted, considering that steam engines already use up big volumes of water. Because the pump seal leaked mainly at the same time as the pump turn out to be on foot and the engine turn out to be hot, the water loss evaporated inconspicuously, leaving at awesome a small rusty hint at the same time as the engine stopped and cooled, thereby no longer revealing large water loss. Automobile radiators (or warmth exchangers) have an outlet that feeds cooled water to the engine and the engine has an outlet that feeds heated water to the pinnacle of the radiator.

Water movement is aided through a rotary pump that has first-class a slight impact, having to art work over this shape of sizeable shape of speeds that its impeller has first-class a minimum impact as a pump.

While on foot, the leaking pump seal tired cooling water to some extent wherein the pump need to no longer by skip lower once more water to the pinnacle of the radiator, so water movement ceased and water with inside the engine boiled.

However, considering that water loss added about overheat and similarly water loss from boil-over, the right water loss turn out to be hidden.

After setting apart the pump problem, vehicles and vehicles constructed for the struggle fare effort (no civilian vehicles had been constructed throughout that time) had been prepared with carbon-seal water pumps that did no longer leak and brought about no greater geysers. Meanwhile, air cooling superior in reminiscence of boiling engines... However the reality that boil-over turn out to be no longer a now no longer unusual place problem.

Air-cooled engines have turn out to be famous ultimately of Europe.

The reality that new water-cooled vehicles no longer boiled over, however the ones vehicles supplied nicely. Emissions had been passed, unleaded fuel line changed leaded fuel line and leaner fuel line combinations have turn out to be the norm. Subaru determined on liquid-cooling for his or her EA series (flat) engine even as it turn out to be brought in 1966.

References:

1. Obert E. F, “Internal Combustion Engines and Air Pollution”, Harper and Row Publication Inc. NY, 1973.

2. Heisler H, “Advanced Engine Technology”, Edward Arnold, 1995.

3. Heywood J. B, “Internal Combustion Engine Fundamentals”, McGraw Hill Book Co. NY, 1989

4. Heldt P. M, “High Speed Combustion Engines”, Oxford & IBH publishing Co. India, 1985.

5. Stockel M W, Stockel T S and Johanson C, “Auto Fundamentals”, The Goodheart, Wilcox Co. Inc., Illinois, 1996.