The element which produces a signal relating to quantity being measured is termed as sensor. For example, for measuring change in temperature sensors transform input of temperature into change in resistance. Sensors are first and foremost requirement of any measuring system and control system. Transducers are elements which subjected to a physical change experience related change. Thus, the term transducer is often used in place of sensor. In measurement system transducer are used along with sensors to convert signals from one form to another form. If sensor/transducer gives an output which is analogue and so changes in a continuous way and typically has an output whose size is proportional to the size of the variable being measured then sensor/transducer is said to be analogue.

Performance terminology

Following terms are used to define performance of transducer and often measurement system as whole. Sensor specifications inform the user about deviations from the ideal behaviour of the sensors. Following are the various specifications of a sensor/transducer system.

Range

Range is the region between upper and lower limit within which instrument is design to operate for measuring, indicating, recording a physical quantity. For example, a thermometer has a scale from −40°C to 100°C. Thus, the range varies from −40°C to 100°C.

Span

Span is algebraic difference of upper and lower limit. For example, a thermometer, its scale goes from −40°C to 100°C. Thus, its span is 140°C.

Error

Error is defined as the difference between the result of the measurement and the true value of the quantity being measured. For example, displacement sensor shows displacement of 29.8 mm, but the actual displacement is 30 mm, therefore the error is - 0.2 mm.

Accuracy

Accuracy is closeness with which instrument reading approaches true value of variable under measurement. If the difference between reading and true value is very less then instrument it is said to be having high accuracy i.e. accuracy refers to how closely the measured value is close to its corresponding true value. It is often expressed as a percentage of the full range output or full–scale deflection. A piezoelectric transducer used to measure dynamic pressure is capable to detect pressures between 0.1 and 10,000 psig (0.7 KPa to 70 MPa). If it is specified with the accuracy of about±1% full scale, then the reading given can be expected to be within ± 0.7 MPa.

Sensitivity The ratio of change in output to the change in input of the instrument is known as sensitivity of instrument. For example, consider a voltmeter in which the input voltage  changes by 2 V, then the output reading should also change by 2 V. Therefore, the sensitivity is expressed as

changes by 2 V, then the output reading should also change by 2 V. Therefore, the sensitivity is expressed as  thus it represent how instrument respond to change in input.

thus it represent how instrument respond to change in input.

Nonlinearity

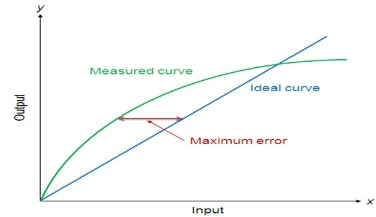

| |

Figure 1: Non-linearity error |

Maximum deviation of the actual measured curve of a sensor from the ideal curve is known as non-linearity error. Figure 1show graph between measured value and ideal values. Linearity is often specified in terms of percentage of nonlinearity, which is defined as:

Nonlinearity (%) = Maximum deviation in input ⁄ Maximum full-scale input |

|

The static nonlinearity depend on environmental factors, including temperature, vibration, acoustic noise level, and humidity. Therefore, it is important to know under what conditions the specification is valid.

Hysteresis

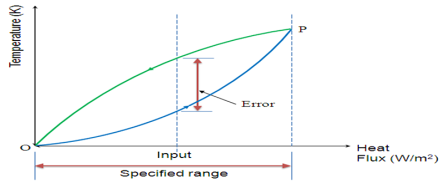

| |

Figure 2: Hysteresis error curve |

The hysteresis is an error of a sensor, which is defined as the maximum difference in output at any measurement value within the sensor's specified range when approaching the point first with increasing and then with decreasing the input parameter. Figure 2.1.2 shows the hysteresis error might have occurred during measurement of temperature using a thermocouple. The hysteresis error value is normally specified as a positive or negative percentage of the specified input range.

Resolution

Resolution is the smallest detectable incremental change of input parameter that can be detected in the output signal. Resolution can be expressed either as a proportion of the full-scale reading or in absolute terms. For example, if a LVDT sensor measures a displacement up to 20 mm or it provides an output as a number between 1 and 100 then the resolution of the sensor device is 0.2 mm.

Stability

Stability is the ability of a sensor device to give same output when used to measure a constant input over a period of time. The term ‘drift’ is used to indicate the change in output that occurs over a period of time. It is expressed as the percentage of full range output.

Dead band/time

The dead band or dead space of a transducer is the range of input values for which there is no output. The dead time of a sensor device is the time duration from the application of an input until the output begins to respond or change.

Repeatability

It specifies the ability of a sensor to give same output for repeated applications of same input value. It is usually expressed as a percentage of the full range output:

Repeatability = (maximum – minimum values given) X 100/full range |

|

Response time

Response time describes the speed of change in the output on a step-wise change of the measurand. It is always specified with an indication of input step and the output range for which the response time is defined.

Classification of transducer

Classification based on energy generation

Classification based on type of output

Classification based on electrical principle involved

Displacement, position and proximity

The function of displacement sensors is to measurement of the amount by which object is moved. Position sensors are used to detect the position of object with some reference point. Proximity sensors are position sensors used to determine when an object has moved to within some particular critical distance of the sensor. Displacement sensors and position sensors are classified into two groups

In contact type linear displacement sensor usually there is a sensing shaft which in contact with objects being measured. Displacement of this shaft is monitored by sensor. This displacement of shaft cause changes in electrical voltage, resistance, capacitance or mutual inductance. In contact type angular displacement shaft is drive through gear mechanism, the rotation of transducer element. Change in air pressure in sensor or perhaps change in inductance or capacitance in object being measured is the principle behind non-contact displacement sensor. Following are examples of commonly used displacement sensors.

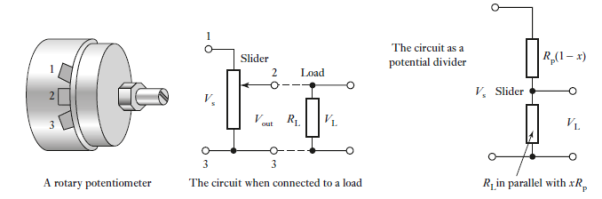

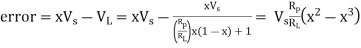

Potentiometer sensor

Potentiometer sensor consists of resistance element, sliding contact which moves over a length of element. Displacement is converted into potential difference. For rotary potentiometer rotatable sliding contact rotate over circular wire wound track or conductive plastic film as shown in figure 3. Input voltage  is supplied between terminal 1 and 3. Output voltage

is supplied between terminal 1 and 3. Output voltage  is measured between terminal 2 and 3.

is measured between terminal 2 and 3.  . Output is proportional to angle through which slider is rotated when wire wound track have constant resistance per unit length i.e., per unit angle. When slider moving from one turn to other causing voltage change in steps. Each step is being a movement of one turn. Resolution as percentage is 100/N for N turn of potentiometer. Thus resolution of wire track depends upon diameter of wire. For coarsely wound track diameter is about 0.15mm and 0.5mm for finely wound track. Load

. Output is proportional to angle through which slider is rotated when wire wound track have constant resistance per unit length i.e., per unit angle. When slider moving from one turn to other causing voltage change in steps. Each step is being a movement of one turn. Resolution as percentage is 100/N for N turn of potentiometer. Thus resolution of wire track depends upon diameter of wire. For coarsely wound track diameter is about 0.15mm and 0.5mm for finely wound track. Load  is connected across output and potential difference across load

is connected across output and potential difference across load  is directly proportional to

is directly proportional to  if load resistance is infinite. For finite load, effect of load is to transform linear relationship between output voltage and angle into a non-linear relationship.

if load resistance is infinite. For finite load, effect of load is to transform linear relationship between output voltage and angle into a non-linear relationship.  is parallel with fraction x of the potentiometer resistance

is parallel with fraction x of the potentiometer resistance  therefor combine resistance is

therefor combine resistance is

Voltage across load is fraction that resistance across the load is of total resistance across which the applied voltage is connected.

|

|

Figure 3: Rotary potentiometer

If the load is of infinite resistance then

|

Potentiometers are used as sensors in machine-tool controls, elevators, liquid-level assemblies, forklift trucks, automobile throttle controls. In manufacturing, potentiometers are used for control of injection moulding machines, woodworking machinery, printing, spraying, robotics, etc. These are also used in computer-controlled monitoring of sports equipment.

Strain gauge

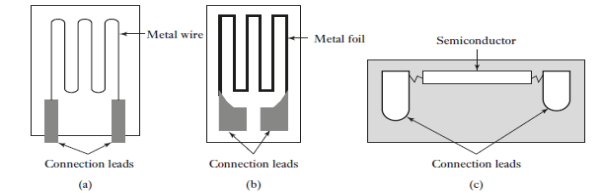

Electrical resistive type strain gauges are consists of metal wire or metal foil strip or semiconductor material strip which so thin like wafer and can be stuck onto surfaces as shown in figure 4. These strips are made of Constantan alloy (copper-nickel 55-45% alloy) and are bonded to a backing material plastic (ployimide), epoxy or glass fiber reinforced epoxy. The strain gauges are stuck to the work piece by using epoxy or Cyanoacrylate cement Eastman 910 SL. The strain in an element is a ratio of change in length in the direction of applied load to the original length of an element. Principle behind strain gauge is fractional change is resistance is proportional to strain.

where G, the constant of proportionality and called the gauge factor.

|

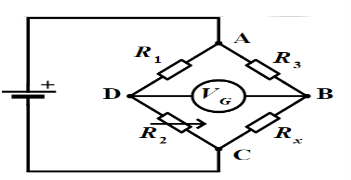

Due to external loading; work piece undergoes change in its shape the resistance of strain gauge element changes. This change in resistance is detected by Wheatstone’s resistance bridge as shown in figure 5. Wheatstone’s resistance bridge balance equation is given by

where Rx is resistance of strain gauge element, R2 is balancing/adjustable resistor, R1 and R3 are known constant value resistors. The measured deformation by the stain gauge is calibrated against change in resistance of adjustable resistor R2 which makes the voltage across nodes A and B equal to zero.

|

Figure 4: Strain gauges: (a) metal wire, (b) metal foil, (c) semiconductor.

The gauge factor G is generally taken about 2.0-4.0 and resistances are generally taken about 100 Ω.

|

Figure 5: Wheatstone's bridge

Strain gauges are widely used in experimental stress analysis and diagnosis on machines and failure analysis. They are basically used for multi-axial stress fatigue testing, proof testing, residual stress and vibration measurement, torque measurement, bending and deflection measurement, compression and tension measurement and strain measurement.

Strain gauges are primarily used as sensors for machine tools and safety in automotives. In particular. Strain gauges are also employed for force measurement in machine tools, hydraulic or pneumatic press and as impact sensors in aerospace vehicles.

Capacitive element based sensors

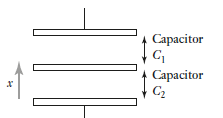

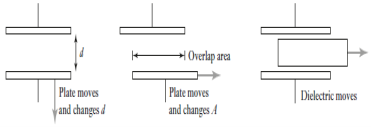

Capacitive sensors are non-contact based sensors used for measuring very short linear displacement from few millimeters to 100 millimeters. It consists of three plates as shown in figure 6A. Upper pair plates form one capacitor and lower pair plates for another capacitors. Linear displacement of plate is of three types (Figure 6)

|

Figure 6A: Three plate capacitive sensing element Figure 6B: Forms of capacitive sensing element

capacitance C of a parallel plate capacitor is given by

Where,

A = area of overlap between two plates d = plate separation |

If central plate moves downwards this increases the plate separation of the upper capacitor and decrease the separation of the lower capacitor. We thus have

|

When C1 and C2 are connected to a Wheatstone’s bridge, then the resulting out-of-balance voltage would be in proportional to displacement x.

Capacitive elements can also be used as proximity sensor. The approach of the object towards the sensor plate is used for induction of change in plate separation. This changes the capacitance which is used to detect the object (Figure 7).

Applications of capacitive element sensors

|

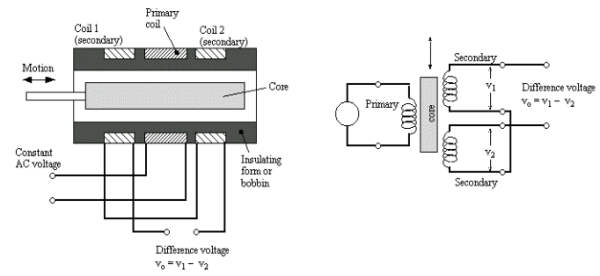

Linear variable differential transformer (LVDT) LVDT is primary transducer used for measuring liner displacement ranging from ± 2 to ± 400 mm consists of three coils symmetrically placed along insulated tube. The central coil is primary coil and other two coils are secondary coil. Secondary coils are connected in series so they can oppose their outputs. A magnetic core is attached to element of which displacement is to be measured and is placed inside the insulated tube as shown in figure 8.

|

Figure 7: LVDT

Alternating electro-magnetic forces (emfs) are generated in secondary coil because of alternating voltage input to primary coil. If core is displaced towards secondary coil 1 than in secondary coil 2, then more emf is generated in secondary one coil and there is a resultant voltage from the coils. As magnetic core is moves further value of resultant voltage increases in proportion with the displacement. With the help low pass filters and demodulators, precise displacement can be measured by using LVDT sensors. LVDT have good repeatability and reproducibility and high reliable.

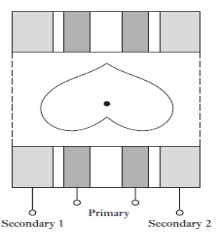

A rotary variable differential transformer (RVDT) can be used for the measurement of rotation (Figure 9). It operates on same principle as LVDT. Magnetic core is cardioid-shaped. Rotation causes more of it to pass into one secondary coil than the other. The range of operation is typically  40° with a linearity error of about

40° with a linearity error of about  0.5% of the range

0.5% of the range

|

Figure 8: RVDT

Applications of LVDT

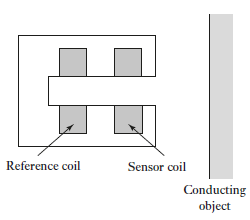

Eddy current proximity sensor

This sensors are used to detect non-magnetic but conductive materials. When an alternating current is passed thru this coil, an alternative magnetic field is generated. If a metal object comes in the close proximity of the coil, then eddy currents are induced in the object due to the magnetic field. These eddy currents create their own magnetic field which distorts the magnetic field responsible for their generation. As a result, impedance of the coil changes and so the amplitude of alternating current. This can be used to trigger a switch at some pre-determined level of change in current. Eddy current sensors are relatively inexpensive, available in small in size, highly reliable and have high sensitivity for small displacements. Figure 10 shows basic form of eddy current proximity sensors.

|

Figure 9: Eddy current proximity sensor

Applications of eddy current proximity sensors

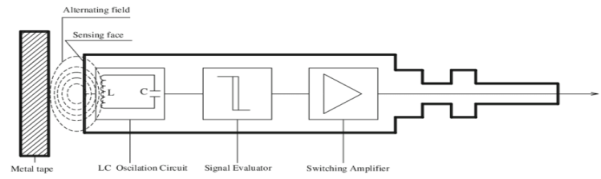

Inductive proximity switch

|

Figure 10: Schematic of proximity sensor

This sensors are used to detect metals espeacilly ferrous metals. Figure 11 shows schematic of proximity sensor.

It consists of four components coil, oscillator, detection circuit and output circuit. An alternating current is supplied to the coil which generates a magnetic field. When,a metal object comes closer to the end of the coil, inductance of the coil changes. This is continuously monitored by a circuit which triggers a switch when a preset value of inductance change is occurred.

Applications of inductive proximity switches

Optical sensors

Optical encoders provide digital output of linear or angular displacement. These are widely used in servomotors to measure rotation of shaft. It consists of disc with three concentric tracks of equally spaced holes. Three light sensors are used to detect the light passing thrugh the holes. These light sensors produce electric pulses which give the angular displacement of the mechanical element on which the Optical encoder is mounted. The inner track have only one hole which is used to locate the ‘home' position of the disc. The holes on the middle track offset from the holes of the outer track by one-half of the width of the hole. This arrangement provides the direction of rotation to be determined. When the disc rotates in clockwise direction, the pulses in the outer track lead those in the inner; in counter clockwise direction they lag behind. The resolution can be determined by the number of holes on disc. With 100 holes in one revolution, the resolution would be,

360°/100=3.6°.

Pneumatic Sensors

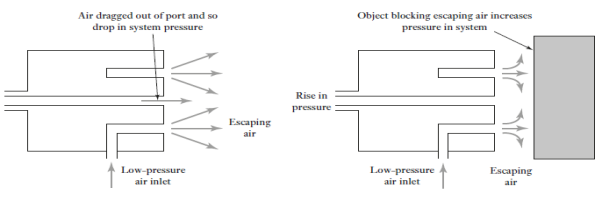

Pnematic sensors are used to measure displacement as well as proximity of object close to it. Principle behind pneumatic sensor is proximity of object or displacement is trasformed into change in air pressure. Figure 12 shows schematic of pneumatic sensor. As low pressure air is allowed to escape through port in front of sensor.As air escapes through port it reduces air pressure around the sensor output port. If object is present near low pressure, air cannot escape causing pressure increase in output port of sensor. This increase in presure is calibrated to measure displacement of object or to trigger the switch.

|

Figure 11: Pneumatic proximity sensor.

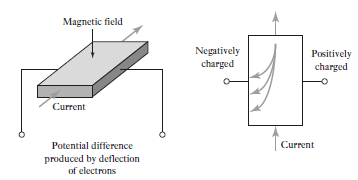

Hall effect sensors

|

Figure 12: Hall effect sensor

Figure 13 shows principle working of hall effect sensor. When beam of charged particles passes through a magnetic field, forces acts on these charged particles and beams gets deflected from its straight line path. Thus side of plate on which beam is deflected becomes negative charged and other becomes positive as electron directed away from this side. This charge separation produecs a potential difference which is the measure of distance of magnetic field from the disc carrying current.

Measurement of fluid level container is typical application of hall effect sensor. A magnet is attached on top of float of container and electric circuit with current carrying disc is mounted in casing. As fluid level rises magenet n float comes closer to disc and potential difference generates. This generated voltage triggers a switch to stop fluid source to fill up the container.

This sensor also used for mesauring displacement, detection of position of object.

Velocity and motion sensors

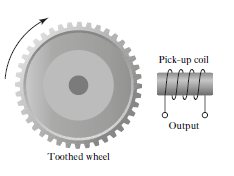

Tachogenerator

|

Figure 13: Variable reluctance tachogenerator.

Techogenerator is use to measure angular velocity. It works on the principle of variable reluctance. It consists of toothed wheel and magnetic circuit as shown in figure 14. This toothed wheel is mounted on shatf or element whose angular velocity is to be measured. And magnetic circuit is consists of a coil wound on ferromagnetic material core. When wheel rotates the air gap between wheel tooth and magnetic core changes causing cyclic change in flux linked with the coil. The alternating emf generated is the measure of angular motion. A pulse shaping signal conditioner is used to transform the output into a number of pulses which is counted by a counter.

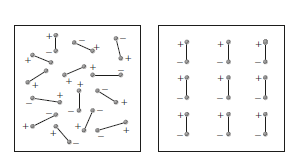

Pyroelectric sensors

This sensors works on principle of pyroelectricity. Which state that “Crystalline material such as lithium tantalate generates charge in response to heat flow.” Shown in figure 15.

|

Figure 14: Principle of pyroelectricity

When such crystalline material materials heats up just below the currie temperature in presense of electric field and material is cooled while remaining in field, its electric dipoles line up as shown in figure 15. This effect is known as polarization. When the electric field is removed, the material retains its polarisation. And when this polarized material is exposed to infrared radiation, its temperature rises and this reduces the amount of polarisation in the material, the dipoles being shaken up more and losing their alignment.

Applications of Pyroelectric sensors

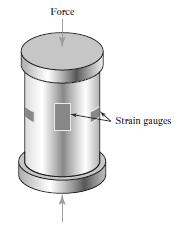

Strain Gauge as force Sensor

Working of strain gauges are based on principle of change in electrical resistance. When element is subjected to load casuses tension or compression depending on load direction this causes change in resistance of material. Figure 16 shows strain gauge load cell. It consists of cylindrical tube to which strain gauges are attached. A load applied on the top collar of the cylinder compress the strain gauge element which changes its electrical resistance. Generally strain gauges are used to measure forces up to 10 MN.

|

Figure 15: Strain gauge load cell

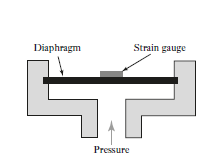

Fluid Pressure

It necessary to measure pressure of system regularly for pertoleum, chemical, power industries. There are various types instruments such as diaphragms, capsules, and bellows are used to monitor the fluid pressure. Figure shows 17 specially designed strain gauges doped in diaphragms which is speacilly used in automobile to measure inlet manifold pressure.

|

Figure 16: Diaphragm pressure gauge

Pressurized fluid displaces the diaphragm and this displacement is measured by strain gauge which placed above diaphragm.

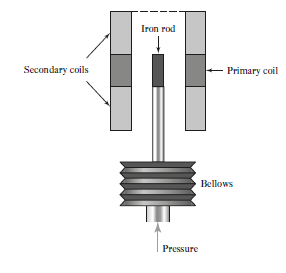

Capsules are formed by combining two corrugated diaphragm ( figure 18 ) which increase the sensitivity as compare to diaphragm. A stack of capsules is called as Bellows. Bellows with a LVDT sensor measures the fluid pressure in terms of change in resultant voltage

|

Figure 17: Schematic of Capsule (a) and Bellow (b)

|

Figure 18: LVDT with bellows

Figure 19 show schematic arrangement of LVDT with bellows which is used to measure Fluid pressure. The principle behind this sensor is change in pressure is measured interms of change in resultant voltage across secondary coil.

Tactile sensors

This sensors are used to sense the contact of fingertips of robot with object. They are also used in manufacturing CNC’s touch display screens of visual display units (VDUs). Figure 20 shows schematic of piezo-electric polyvinylidene fluoride (PVDF) tactile sensor. It consists of two PVDF layer separated by soft film which tansfer vibrations. An alternating current is supplied to lower PVDF Layer which generates vibration due to reverse piezoelectric effect. And this vibrations are transmitted to upper PVDF layer via soft film. This transferred vibrations generated alternating voltage in upper layer of PVDF. When pressure is applied on upper PVDF layer then these transferred vibrations gets affected and change the output voltage. This triggers a switch or an action in robots or touch displays.

|

Figure 19: PVDF tectile sensor

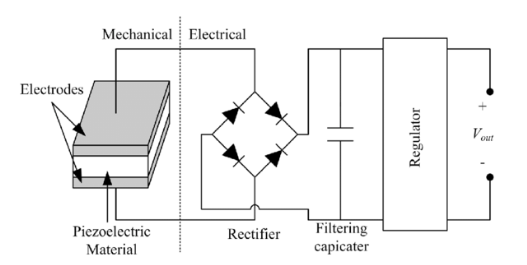

Piezoelectric sensor

These sensors are used measure pressure, acceleration, oscillations, impact or high speed compression or tension. This sensors are consists of piezoelectric ionic crystal material as shown in figure 21. When force or pressure is applied this metaerials get stretched or compressed. Due to this the charge over the material changes and redistributes and one face of the material becomes positively charged and the other face becomes negatively charged. The net charge q on the surface is proportional to the amount x by which the charges have been displaced. The displacement is proportion to force. Mathematically,

q = kx = SF

Where k is constant and S is a constant termed the charge sensitivity.

|

Figure 20: Piezoelectric sensor

Liquid flow

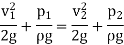

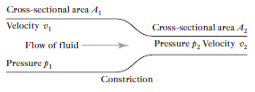

Liquid flow measuremment is generally based on Bernoulli’s principle of fluid flow through constriction (figure 22). Quantity of fluid flow is measured by using pressure drop when fluid flows through constriction. For horizontal tube Bernoulli’s equation given as

where v1=fluid velocity p1= pressure A1=cross-sectional area of the tube prior to the constriction v2= the velocity p2= pressure A2=cross-sectional area at constriction, |

|

Figure 21: Fluid flow through constriction

mass of liquid passing per second through the tube prior to the constriction must equal that passing through the tube at the constriction,

we have

Where Q = quantity liquid passing through the tube per second |

Orifice plate

Orifice plate is simply as disc with hole at its center which is placed in the tube through which the fluid is flowing (Figure 23). The pressure difference is measured between a point equal to the diameter of the tube upstream and a point equal to the half the diameter downstream. Orifice plate is inexpensive and simple in construction with no moving parts. It exhibits nonlinear behavior and does not work with slurries. It has accuracy of ± 1.5%.

|

Figure 22: Orifice plate

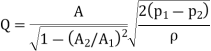

Turbine meter

Turbine meter consists of multiblade rotor supported at center of pipeline through which flow is to be measured (Figure 24). As fluid flows through pipe so causing rotation of rotor. Angular velocity of is approximatly proportional to flow rate. A magnetic pick up coil is placed near the pipe which can determine rate of revolution of rotor. Turbine meter is expensive with accuracy of  .

.

|

Figure 23: Turbine flowmeter

Fluid level

Floats

Monitoring the movement of floats as fluid level rises or falls is direct method to measure fluid level. Figure 25 shows schematic arrangement of simple float system. As float displace causes a lever arm to rotate and therefore slider moves across a potentiometer. The result is an output of a voltage related to the height of liquid. Other forms of this involve the lever causing the core in an LVDT to become displaced, or stretch or compress a strain-gauged element.

|

Figure 24: Float system

Differential pressure

Figure 25 shows the differential pressure cell which helps to determine pressure difference between liquid at base of vessel and atomspheric pressure, the vessel is open to atomspheric pressure.

|

Figure 25: Using a differential pressure sensor

Temperature

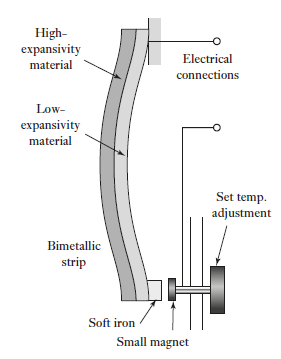

Bimetallic strips

It consists of two metal strips bonded together (Figure 26). These metals have different coefficients of expansion and when the temperature changes the composite strip bends into a curved strip, the higher coefficient metal is on the outside of the curve. This sensor can be used as controlling switch to control temperature rising above pre-set value. When the strips bend, the soft iron comes closer to magnet and further touches. Then the electric circuit completes and generates an alarm.

|

Figure 26: Bimetallic strips

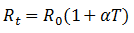

Resistance temperature detectors (RTDs)

Electric resistance of a metal changes due to change in its temperature; this is the principle behind working RTDs. On heating up metals up to certain their resistance increases and follows a linear relationship as given below

Where Rt = Resistance at temperature T (°C) and R0 = Temperature at 0°C α = Temperature coefficient of resistance. Figure 27 shows Variation of resistance with temperature for metals. |

|

Figure 27: Variation of resistance with temperature for metals

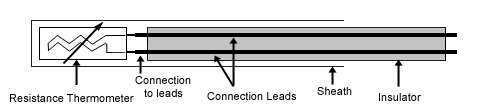

RTDs are simple resistive elements in the form of coils of wire of metals such as platinum, nickel or nickel–copper alloys; platinum is the most widely used due to its linear variation of resistance as temperature change thin-film platinum elements are often made by depositing the metal on a suitable substrate, wire-wound elements involving a platinum wire held by a high-temperature glass adhesive inside a ceramic tube (Figure 28). Such detectors are highly stable and give reproducible responses over long periods of time. They tend to have response times of the order of 0.5 to 5 s or more.

|

Figure 28: Construction of RTD

Applications of RTD

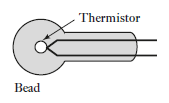

Thermistors

Thermistors are made from mixture of metal oxide such as those of chromium, cobalt, iron, manganese and nickel. These oxides are semiconductor. Materials are formed into various forms such as beads, discs and rods as shown in figure 29.

|

Figure 29: Common forms of Thermistors.

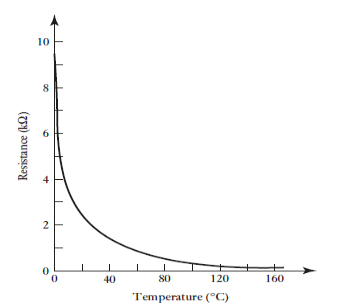

As temperature increases resistance of conventional metal-oxide thermistors decreases in non-linear manner (Figure 30). This is the principle behind working of Thermistors. And these Thermistors are known as negative temperature coefficient (NTCs). The resistance–temperature relationship can be describe mathematically as follows

|

Where

= resistance at temperature t

= resistance at temperature t

K and  = constants

= constants

Applications of Thermistors

|

Figure 30: Typical variation of resistance with temperature

Thermocouples

Thermocouple works on the fact that when a junction of dissimilar metals heated, it produces an electric potential related to temperature. As per Thomas Seebeck (1821), when two wires composed of dissimilar metals are joined at both ends and one of the ends is heated, then there is a continuous current which flows in the thermoelectric circuit. Figure 31. shows the schematic of thermocouple circuit. The net open circuit voltage (the Seebeck voltage) is a function of junction temperature and composition of two metals. It is given by,

ΔVAB = αΔT

Where α, the Seebeck coefficient, is the constant of proportionality.

|

Figure 31: Thermocouple circuit

Applications of Thermocouples

Light sensors

Photoresistor

Photoresistor are also known as light dependant resistor (LDR). When incident light intensity is increases resistance of resistor in photoresistor decreases. This is working principle of photoresistor. It is made of a high resistance semiconductor material, cadmium sulfide (CdS). The resistance of a CdS photoresistor varies inversely to the amount of light incident upon it. Photoresistor follows the principle of photoconductivity which results from the generation of mobile carriers when photons are absorbed by the semiconductor material. Figure 32 shows basic construction of photoresistor.

|

Figure 32: Construction of a photo resistor

The CdS resistor coil is mounted on a ceramic substrate. This assembly is encapsulated by a resin material. The sensitive coil electrodes are connected to the control system though lead wires. On incidence of high intensity light on the electrodes, the resistance of resistor coil decreases which will be used further to generate the appropriate signal by the microprocessor via lead wires.

Applications of photo resistor

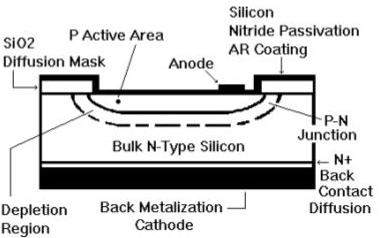

Photodiodes

Photodiode is a solid-state device which converts incident light into an electric current. Photodiodes are semiconductor junction diodes connected into a circuit in reverse bias, so they give very high resistance. When there is no incident light, the reverse current is negligible and is termed the dark current. When light falls on the junction, extra hole–electron pairs are produced and there is an increase in the reverse current and the diode resistance drops. The reverse current is very nearly proportional to the intensity of the light. A photodiode can thus be used as a variable resistance device controlled by the light incident on it. Photodiodes have a very fast response to light.

|

Figure 33: Construction photo diode detector

It is constructed from single crystal silicon wafers. It is a p-n junction device. The upper layer is p layer. It is very thin and formed by thermal diffusion or ion implantation of doping material such as boron. Depletion region is narrow and is sandwiched between p layer and bulk n type layer of silicon. Light irradiates at front surface, anode, while the back surface is cathode. The incidence of light on anode generates a flow of electron across the p-n junction which is the measure of light intensity.

Applications of photo diodes

Camera: Light Meters, Automatic Shutter Control, Auto-focus, Photographic Flash Control

Medical: CAT Scanners - X ray Detection, Pulse Oximeters, Blood Particle Analysers

Industry

Safety Equipment

Automotive

Communications

References:

1. Instrumentation and control systems by W. Bolton, 2nd edition, Newnes, 2000.

2. Thomas G. Beckwith, Roy D. Marangoni, John H. Lienhard V, Mechanical Measurements (6th Edition) 6th Edition, Pearson Education India, 2007.

3. Gregory K. McMillan, Process/Industrial Instruments and Controls Handbook, Fifth Edition, McGraw-Hill: New York, 1999.