Unit - 5

Boiling and Condensation

- Condensation is process in which the vapour changes into liquid at its saturation temperature corresponding to its vapour pressure.

- It occurs when vapour comes in contact with solid surface which is at temperature lower than saturation temperature of vapour.

Types of condensation

There are two types of condensation depending upon condition of surface.

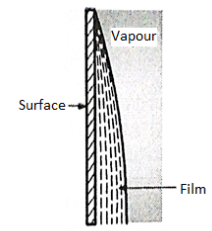

- Film wise condensation

The process of condensation of vapour while in contact with surface, it wets the surface and condensate flows down on entire surface forming film is called film wise condensation.

Fig1 Film wise condensation

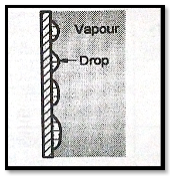

- Drop wise condensation

In case of condensate of the vapour does not wet the surface with which is in contact and the condensate collects in the form of droplets is called drop wise condensation.

Fig2 Drop wise condensation

Laminar film condensation on a vertical plate

Nusselt’s theory is widely accepted foe explanation of laminar film condensation on vertical plate.

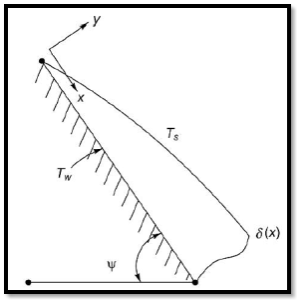

Fig3 Film condensation on vertical surface

Let us consider condensation of a vapour on a vertical plate as shown in Fig. Here xis the axial coordinate, measured downward along the plate, and y is the coordinate normal to the condensing surface. The condensate thickness is represented by  (x). Nusselt made the following assumptions:

(x). Nusselt made the following assumptions:

- The vapour is pure, dry and saturated.

- The condensate flow is under the action of gravity and is laminar.

- The vapour at the liquid-vapour interface is stagnant so that there is no shear stress or drag on the flow of condensate.

- The plate is maintained at a uniform temperature Tw that is less than the saturation temperature of the vapour Ts.

- The liquid temperature at the interface is that of saturated vapour.

- Fluid properties are constant.

- Heat transfer across the condensate layer is by pure conduction, and the liquid temperature profile is linear.

- Heat transfer is at steady state.

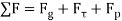

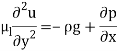

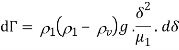

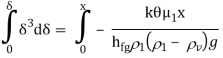

Let us take a lump of condensate of thickness dx at a distance x from the top of the plate and consider dy portion of this lump. The condensate drains out under the action of mechanical forces. Making a force balance on the element.

…(5.1)

…(5.1)

Where is the gravity force,

is the gravity force,  is the shear force and

is the shear force and is the pressure force exerted on the element. Here,

is the pressure force exerted on the element. Here,

Fτ = [ - Fτ1 + Fτ1 + /y (Fτ1) dy]

= /y [ (μ1 u/y ) b dx] dy

Fp = pb dy – pb dy - p/x dxb dy

= - p/x . Dxb dy

Where  =density,

=density, =acceleration due to gravity,

=acceleration due to gravity,  =viscosity of liquid,

=viscosity of liquid,

And  =viscosity of vapor,

=viscosity of vapor, =pressure,

=pressure,  =velocity.

=velocity.

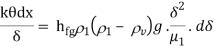

On substituting in 5.1

b dx dyg + μ1 2u/y2 b dx dy - p/x b dx dy = 0

On integrating

μ1 u/y = (p/x - g)y + B1

…(5.2)

When y = δ, u = U, du/dy = 0.

0 = (p/x - g) +B1

B1 = - (p/x - g)

μ1 du/dy = (p/x - g)(y – δ)

For y > δ, p = pv = v , du/dy =0, pv/x = vg

μ1 du/dy = (v - )g (y – δ)

μ1u = (v - )g(y2/2 – δy) + B2

When y = 0, u = 0, and therefore B2 = 0.

μ1 u = (v - )g (y2/2 – δy)

…(5.3)

At y = δ, u = U and since = 1

μ1U = (1 - v)g (δ2 – δ2/2)

= (1 - v)g δ2/2

…(5.4)

Dividing Eq.5.3 by 5.4

u/U = (δy – (y2/2))/(δ2/2) = 2y/δ – y2/δ2

…(5.5)

This is the velocity profile of the condensate across its thickness, which is parabolic.

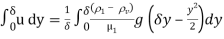

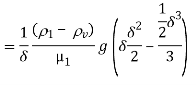

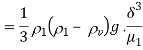

Let  =flow rate of condensate per unit width of plate

=flow rate of condensate per unit width of plate

=

Where  =density of liquid,

=density of liquid, =mean velocity and

=mean velocity and  =density of vapour

=density of vapour

From Eq.5.3

um =

…(5.6)

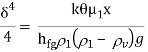

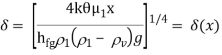

…(5.7)

This is the local film thickness of condensate layer. As x increases,  increases.

increases.

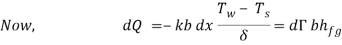

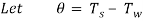

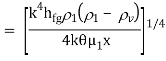

Now

…(5.8)

This is the local heat transfer coefficient. As x increases, hxdecreases. It can also be observed that as  decreases, hxincreases. The local Nusselt number at x is

decreases, hxincreases. The local Nusselt number at x is

…(5.9)

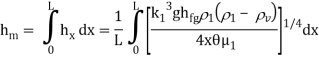

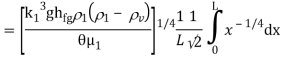

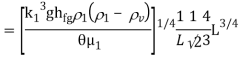

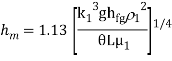

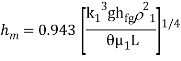

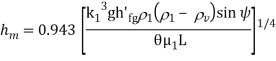

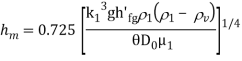

The average heat transfer coefficient is given by

…(5.10)

Since

…(5.11)

Equations (5.10) and (5.11) are the Nusselt’s equations for laminar film condensation on a vertical plate, which can also be applied to condensation outside a tube of large diameter. These give conservative values of heat transfer coefficient. McAdams suggested 20% increase over this value so that

…(5.12)

If the surface is inclined at an angle  with the horizontal (Fig.5.4), the average coefficient is

with the horizontal (Fig.5.4), the average coefficient is

…(5.13)

Fig4 Film wise condensation on inclined plate

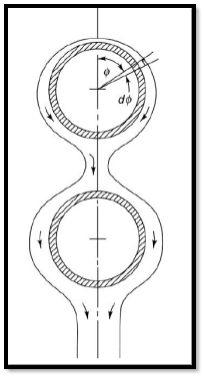

Laminar condensation on horizontal tube

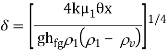

The condensate film on the outside of horizontal tubes flows around the tube and off the bottom in a sheet, as shown in Fig.5.5. The liquid film is very thin so that the above analysis applies here except that g is replaced by gsin and the average value of h follows from integration over the range of values from 0 to 180o, as given below:

and the average value of h follows from integration over the range of values from 0 to 180o, as given below:

Fig5 Condensate film on horizontal tubes

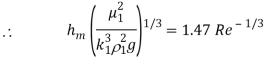

Reynold’s number

Reynolds number of the condensate flow is very important in determining condensation behaviour. It is often convenient to express the heat transfer coefficient directly in terms of Re.

Reynold’s number can be given as

Re = 4Γ/μ

…(5.14)

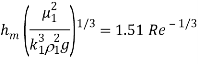

By performing basic mathematical operations Eq.5.11 can be expressed as

…(5.15)

Similarly for flow over horizontal tube

…(5.16)

- Boiling is convection heat transfer process in which the liquid changes its phase into vapour at liquid vapour interface.

- This process occurs when heat is transferred from solid surface to liquid in contact and surface temperature is maintained at temperature higher than the saturation temperature.

Modes of boiling

- Pool boiling:

It refers to a condition in which the heating surface is submerged beneath a free surface of liquid. Heat transfer takes place due to free convection only.

- Forced convection boiling:

In this case the fluid motion over a heated surface is provided by external means like pump in order to increase heat transfer coefficient.

- Sub-cooled or local boiling:

In a boiling process, the average liquid temperature may remain well below the saturation temperature with the wall temperature above saturation thus producing “local” boiling at the wall with subsequent condensation in the colder bulk of the liquid. This is known as Sub-cooled or local boiling.

- Saturated or bulk boiling:

Boiling in a liquid at saturation temperature is known as saturated or bulk boiling.

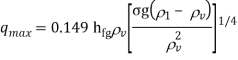

Regimes of boiling

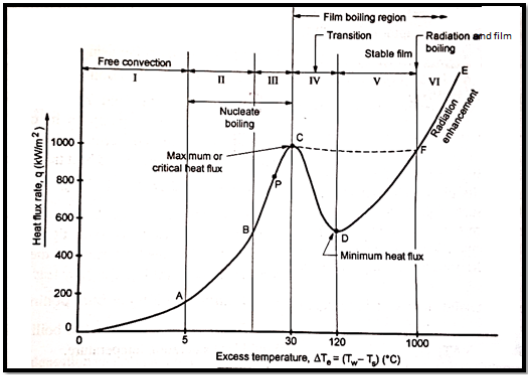

When boiling occurs as pool boiling, there are six different regimes which are represented by a graph known as pool boiling curve.

Pool boiling curve is plot of heat flux and excess temperature

Where,  is temperature of solid surface or solid wall and

is temperature of solid surface or solid wall and  is saturation temperature of liquid.

is saturation temperature of liquid.

Fig.6 Pool boiling curve of water

- Free convection boiling(Region 1):

In this regime the excess temperature is very small. The heat is transferred from wall to the liquid. Density of liquid at the decreases. Heating is by natural convection.

- Nucleate boiling(Regimes 2 and 3):

Heat flux increases rapidly with increase in excess temperature. Value of  is in range 5oC to 30oC. Nucleate boiling consist of two regimes viz. 2 and 3.

is in range 5oC to 30oC. Nucleate boiling consist of two regimes viz. 2 and 3.

During period A to B that is 2nd region of pool boiling, bubbles formed are very few in numbers. These bubbles condense in liquid and do not reach to the free surface. This region is also called unstable nucleate boiling due to instability of bubbles.

With further increase in temperature excess temperature in region 3, large number of bubbles are formed. These bubbles grow in size and rise to free surface of liquid. This region B to C is called stable nucleate boiling. As bubbles formed leave the surface almost immediately, the heating surface becomes available for new bubble formation. Hence, heat transfer continuously increases and reaches to a maximum value at point C. This maximum value is called critical heat flux.

- Transition boiling(Region 4):

With increasing temperature difference, bubble formation is very high. These bubbles form a blanket of vapour film on heating surface. It prevents fresh liquid from reaching to surface. In this region vapour film is not stable and collapses. Due to this part of surface will have film boiling and other part nucleate boiling. Hence, this region is called unstable film boiling.

- Stable film boiling(Region 5):

With further increase in excess temperature, bubble formation is so high that film becomes stable and covers entire surface. It offers more resistance to heat flow. The heat flux reduces to a minimum at D. Film is stable in this region. Hence it is called stable film boiling.

- Radiation enhancement(Region 6):

With further increase in excess temperature, heat flux starts rising. This is because radiation takes over convective heat transfer.

Forced convection boiling

Fig7 Forced convection boiling

Unlike pool boiling in forced convection boiling, directed motion is provided to fluid from external source. Various regions involved in forced convection boiling are

- Bubbly flow region:

In this region, bubbles formed at inner surface of the heated tube are mixed and carried by saturated liquid being forced to flow. The bubble growth depends on flow velocity.

- Slug flow region:

Individual bubbles combine to form larger bubbles or slugs of vapour. Volume of bubble keeps on increasing.

- Annular flow region:

In this region, vapour formed earlier combine and flow at larger velocity in central core of tube while fluid flows through annular passage around the curve.

- Mist flow region:

In this region, thickness of annular liquid ring keeps on decreasing and finally it is vanished. Vapour now flows with suspended liquid known as mist. Mist region continues until all the liquid is converted into vapour.

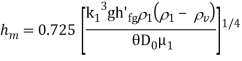

Important formulae

Local film thickness in laminar flow over vertical plate |  |

Average convective heat transfer coefficient in laminar flow over vertical plate |  |

Average convective heat transfer coefficient in laminar flow over inclined plate |  |

Average convective heat transfer coefficient in laminar flow over horizontal tube |  |

Nusselt’s number | Nu=  |

Critical heat flux |  |

Reynold’s number | Re = 4Γ/μ |

References:

- Bejan, Heat Transfer John Wiley, 1993

- J.P.Holman, Heat Transfer, Eighth Edition, McGraw Hill, 1997.

- F.P.Incropera, and D.P. Dewitt, Fundamentals of Heat and Mass Transfer, John Wiley,Sixth Edition, 2007.

- MassoudKaviany, Principles of Heat Transfer, John Wiley, 2002

- Yunus A Cengel, Heat Transfer: A Practical Approach, McGraw Hill, 2002