UNIT 4

POWER PLANT

Thermal energy is the major source of power generation in India. More than 60% of electric power is produced by steam plants in India. India has large deposit of coal (about 170 billion tonnes), 5th largest in world. Indian coals are classified as A-G grade coals.

In Steam power plants, the heat of combustion of fossil fuels is utilized by the boilers to raise steam at high pressure and temperature. The steam so produced is used in driving the steam turbines or sometimes steam engines couples to generators and thus in generating electrical energy.

Steam turbines or steam engines used in steam power plants not only act as prime movers but also as drives for auxiliary equipment, such as pumps, stokers fans etc. Steam power plants may be installed either to generate electrical energy only or generate electrical energy along with generation of steam for industrial purposes such as in paper mills, textile mills, sugar mills and refineries, chemical works, plastic manufacture, food manufacture etc.

The steam for process purposes is extracted from a certain section of turbine and the remaining steam is allowed to expand in the turbine. Alternatively the exhaust steam may be used for process purposes. Thermal stations can be private industrial plants and central station

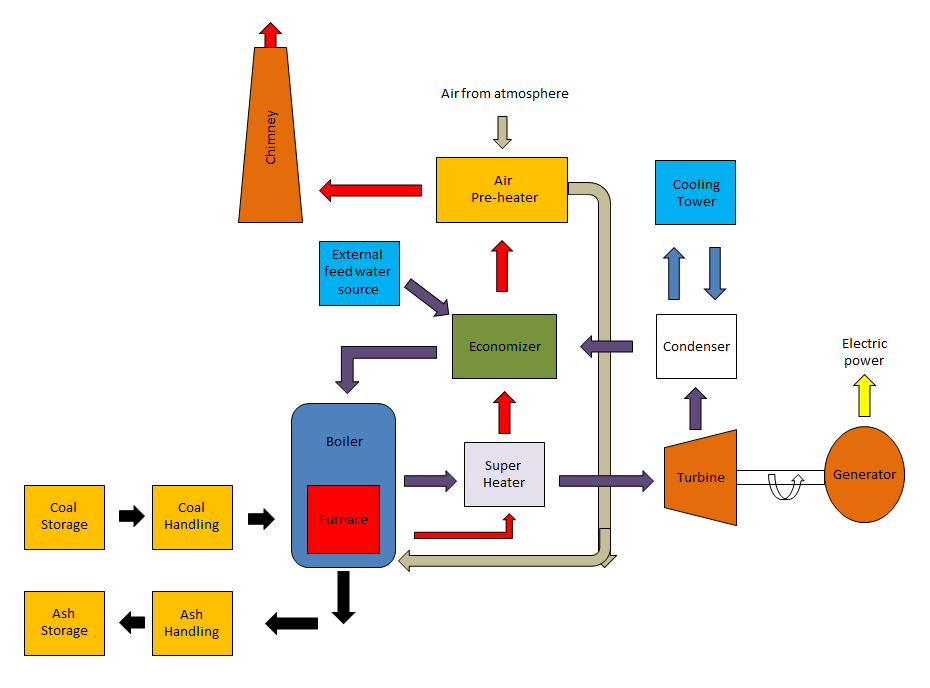

Components of Coal Fired Thermal Power Station:

Coal Preparation

i) Fuel preparation system:

In coal-fired power stations, the raw feed coal from the coal storage area is first crushed into small pieces and then conveyed to the coal feed hoppers at the boilers. The coal is next pulverized into a very fine powder, so that coal will undergo complete combustion during combustion process.

Pulverizer is a mechanical device for the grinding of many different types of materials. For example, they are used to pulverize coal for combustion in the steam-generating furnaces of fossil fuel power plants.

Types of Pulverisers: Ball and Tube mills; Ring and Ball mills; MPS; Ball mill; Demolition.

Ii) Dryers:

They are used in order to remove the excess moisture from coal mainly wetted during transport. As the presence of moisture will result in fall in efficiency due to incomplete combustion and also result in CO emission.

Iii) Magnetic separators:

Coal which is brought may contain iron particles. These iron particles may result in wear and tear. The iron particles may include bolts, nuts wire fish plates etc.

So these are unwanted and so are removed with the help of magnetic separators.

The coal we finally get after these above process are transferred to the storage site.

Purpose of fuel storage –

- Fuel storage is insurance from failure of normal operating supplies to arrive.

- Storage permits some choice of the date of purchase, allowing the purchaser to take advantage of seasonal market conditions. Storage of coal is primarily a matter of protection against the coal strikes, failure of the transportation system & general coal shortages.

There are two types of storage:

- Live Storage (boiler room storage): storage from which coal may be withdrawn to supply combustion equipment with little or no remanding is live storage. This storage consists of about 24 to 30 hours of coal requirements of the plant and is usually a covered storage in the plant near the boiler furnace. The live storage can be provided with bunkers & coal bins. Bunkers are enough capacity to store the requisite of coal. From bunkers coal is transferred to the boiler grates.

- Dead storage- stored for future use. Mainly it is for longer period of time, and it is also mandatory to keep a backup of fuel for specified amount of days depending on the reputation of the company and its connectivity. There are many forms of storage some of which are –

- Stacking the coal in heaps over available open ground areas.

- As in (I). But placed under cover or alternatively in bunkers.

- Allocating special areas & surrounding these with high reinforced concerted retaking walls.

Boiler and auxiliaries

A Boiler or steam generator essentially is a container into which water can be fed and steam can be taken out at desired pressure, temperature and flow. This calls for application of heat on the container. For that the boiler should have a facility to burn a fuel and release the heat. The functions of a boiler thus can be stated as:-

- To convert chemical energy of the fuel into heat energy

- To transfer this heat energy to water for evaporation as well to steam for superheating.

The basic components of Boiler are: -

- Furnace and Burners

- Steam and Superheating

a. Low temperature super heater

b. Platen super heater

c. Final super heater

Economiser

It is located below the LPSH in the boiler and above pre heater. It is there to improve the efficiency of boiler by extracting heat from flue gases to heat water and send it to boiler drum.

Advantages of Economiser include

1) Fuel economy: – used to save fuel and increase overall efficiency of boiler plant.

2) Reducing size of boiler: – as the feed water is preheated in the economiser and enter boiler tube at elevated temperature. The heat transfer area required for evaporation reduced considerably.

Air Preheater

The heat carried out with the flue gases coming out of economiser are further utilized for preheating the air before supplying to the combustion chamber. It is necessary equipment for supply of hot air for drying the coal in pulverized fuel systems to facilitate grinding and satisfactory combustion of fuel in the furnace.

Reheater

Power plant furnaces may have a reheater section containing tubes heated by hot flue gases outside the tubes. Exhaust steam from the high pressure turbine is rerouted to go inside the reheater tubes to pick up more energy to go drive intermediate or lower pressure turbines.

Steam turbines

Steam turbines have been used predominantly as prime mover in all thermal power stations. The steam turbines are mainly divided into two groups: -

- Impulse turbine

- Impulse-reaction turbine

The turbine generator consists of a series of steam turbines interconnected to each other and a generator on a common shaft. There is a high pressure turbine at one end, followed by an intermediate pressure turbine, two low pressure turbines, and the generator. The steam at high temperature (536 ‘c to 540 ‘c) and pressure (140 to 170 kg/cm2) is expanded in the turbine.

Condenser

The condenser condenses the steam from the exhaust of the turbine into liquid to allow it to be pumped. If the condenser can be made cooler, the pressure of the exhaust steam is reduced and efficiency of the cycle increases.

The functions of a condenser are:-

1) To provide lowest economic heat rejection temperature for steam.

2) To convert exhaust steam to water for reserve thus saving on feed water requirement.

3) To introduce make up water.

We normally use surface condenser although there is one direct contact condenser as well. In direct contact type exhaust steam is mixed with directly with D.M cooling water.

Boiler feed pump

Boiler feed pump is a multi-stage pump provided for pumping feed water to economiser. BFP is the biggest auxiliary equipment after Boiler and Turbine. It consumes about 4 to 5 % of total electricity generation.

Cooling tower

The cooling tower is a semi-enclosed device for evaporative cooling of water by contact with air. The hot water coming out from the condenser is fed to the tower on the top and allowed to tickle in form of thin sheets or drops. The air flows from bottom of the tower or perpendicular to the direction of water flow and then exhausts to the atmosphere after effective cooling.

The cooling towers are of four types: -

1. Natural Draft cooling tower

2. Forced Draft cooling tower

3. Induced Draft cooling tower

4. Balanced Draft cooling tower

Fan or draught system

In a boiler it is essential to supply a controlled amount of air to the furnace for effective combustion of fuel and to evacuate hot gases formed in the furnace through the various heat transfer area of the boiler. This can be done by using a chimney or mechanical device such as fans which acts as pump.

i) Natural draught

When the required flow of air and flue gas through a boiler can be obtained by the stack (chimney) alone, the system is called natural draught. When the gas within the stack is hot, its specific weight will be less than the cool air outside; therefore the unit pressure at the base of stack resulting from weight of the column of hot gas within the stack will be less than the column of extreme cool air. The difference in the pressure will cause a flow of gas through opening in base of stack. Also the chimney is form of nozzle, so the pressure at top is very small and gases flow from high pressure to low pressure at the top.

Ii) Mechanized draught

There are 3 types of mechanized draught systems

1) Forced draught system

2) Induced draught system

3) Balanced draught system

1) Forced draught: – In this system a fan called Forced draught fan is installed at the inlet of the boiler. This fan forces the atmospheric air through the boiler furnace and pushes out the hot gases from the furnace through super heater, reheater, economiser and air heater to stacks.

2) Induced draught: – Here a fan called ID fan is provided at the outlet of boiler, that is, just before the chimney. This fan sucks hot gases from the furnace through the superheaters, economiser, reheater and discharges gas into the chimney. This results in the furnace pressure lower than atmosphere and affects the flow of air from outside to the furnace.

3) Balanced draught:-In this system both FD fan and ID fan are provided. The FD fan is utilized to draw control quantity of air from atmosphere and force the same into furnace. The ID fan sucks the product of combustion from furnace and discharges into chimney. The point where draught is zero is called balancing point.

Ash handling system

The disposal of ash from a large capacity power station is of same importance as ash is produced in large quantities. Ash handling is a major problem.

i) Manual handling: While barrows are used for this. The ash is collected directly through the ash outlet door from the boiler into the container from manually.

Ii) Mechanical handling: Mechanical equipment is used for ash disposal, mainly bucket elevator, belt conveyer. Ash generated is 20% in the form of bottom ash and next 80% through flue gases, so called Fly ash and collected in ESP.

Iii) Electrostatic precipitator: From air preheater this flue gases (mixed with ash) goes to ESP. The precipitator has plate banks (A-F) which are insulated from each other between which the flue gases are made to pass. The dust particles are ionized and attracted by charged electrodes. The electrodes are maintained at 60KV.Hammering is done to the plates so that fly ash comes down and collect at the bottom. The fly ash is dry form is used in cement manufacture.

Generator

Generator or Alternator is the electrical end of a turbo-generator set. It is generally known as the piece of equipment that converts the mechanical energy of turbine into electricity. The generation of electricity is based on the principle of electromagnetic induction.

I) Sites selection criteria

The site of the thermal power plant is chosen with some specific conditions. The condition that must be fulfilled to build a thermal power is explained as below.

- Availability of Coal

A huge amount of coal is required for the generation of electrical energy. The thermal power station of 400 MW capacities requires 5000 to 6000 tons of coal per day. Therefore, thermal power stations should be located near to the coal mines to minimize the transportation cost.

- Ash Disposal Facilities

Ash produced after burning the coal is about 20 to 40% of the weight of the coal i.e. 1500 to 2000 tons per day. Thus, it becomes a more serious problem as it comes out in hot conditions and is highly corrosive. Therefore, there must be sufficient space available for the disposal of a large quantity of ash.

- Space Requirement

Space required for thermal power station is quite large for plant equipment, coal storage, ash disposal, staff colony, etc. The land available for the thermal power station must be available at low cost and with sufficient bearing capacity to withstand the load of machinery.

- Availability of Water

As the secondary requirement of the thermal power station is water.

The water is required for two purposes, firstly for conversation into steam for steam turbine and secondly for a condenser. Hence such power plants should be located near to the water resource such as river, lake, or canal.

- Transportation Facility

Power station should have the transportation facility such that as road and rail for transportation of material and machinery.

- Away from Populated Area

The thermal power station produces smoke and fumes by burning a huge amount of coal. This pollutes the atmosphere. Hence plants should be located at a considerable distance from the populated area.

- Near to the Load Center

Power stations should be located near to the load center to minimize the cost transmission system to transfer the electricity.

Environmental aspects for Site Selection of Thermal Power Plant

Air Pollution

Particulate meters SO2, NO2, and CO2 are emitted from the combustion of fuels in a thermal Power plant. If the uncontrolled, these affect humans, vegetation, buildings, and monuments, aquatic forest ecosystem.

The emission of large quantities of SO2 and NO2 from Thermal power plant may result in Acid-rain problems.

Waste Water Discharge

The large wastewater streams from Thermal power plant are cooling water below down, which can be either recycled or discharged to a surface water body, and then its chemical quality gets affected. Associated waste heat can impact ambient water temperature which in turn can radically alter aquatic plant and animal communities.

Other effluents from a Thermal power plant, like wastewater from de-mineralized backwash and resin regenerator wastewater, ash transport water and runoff from ash piles and sites, trace metals, acids and other chemicals in various combinations in the effluents, oil spills, etc. harm water quality.

Land Degradation

The thermal power stations are generally located on the non-forest land and do not involve much resettlement and rehabilitation problems.

However, its effects due to stack emission, etc. on flora and fauna, agricultural and other land have to be studied for any element percolation to groundwater through ash disposal in ash ponds are the serious effects of thermal power stations.

Noise Pollution

Some areas inside the plant will have noisy equipment such as crushers, belt conveyors, fans, pumps, milling plants, compressors, boiler, turbine, etc. Various measures to reduce the noise generation and exposure of workers to high noise levels in the plant area include silencers of fans, compressors, steam safety valves, etc., using noise absorbent materials, providing noise barriers for various areas, noise-proof control rooms.

II Advantage and disadvantage

Advantages The advantages of thermal power plants are listed below.

- The thermal power station has less initial cost as compared to the hydro-electric generating station.

- It requires less space as compared to the hydro power plant.

- The fuel cost is less as compared to a gas power plant.

- It can be installed at any location irrespective of coal mines. Coal can be transported to the site by road and rail.

- The huge amount of power can be generated by the thermal power station.

Disadvantages The disadvantages of thermal power plants are listed below.

- The running cost of the thermal power station is more as compared to the hydro generating station.

- It pollutes the atmosphere due to the production of a large amount of smoke and fumes.

- Maintenance cost is more.

- A skilled person is required for the Erection and Maintenance of the power station.

- Starting time is quite high (6 to 7 hours from the cold condition). Hence not suitable for peak loads.

- The overall efficiency of the thermal power station is very low (about 29%).

- Unavailability of good quality coal

- Maximum of heat energy lost

- Problem of ash removing

Hydroelectric power is developed from hydroelectric power plant or hydroelectric power station. It develops hydroelectricity to utilize the potential energy of water. In hydroelectric power plant, water is stored in a dam called hydroelectric dam which is located upper level from the ground especially any hilly areas. Water head is created by construction the dam across any river or lake.

This type of water head store huge potential energy. The water fall into water turbine and the potential energy of water is converted into kinetic energy. This kinetic energy is converted into mechanical energy at the turbine shaft. A hydroelectric generator or alternator is coupled with turbine shaft to convert mechanical energy into electrical energy.

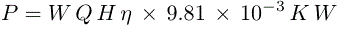

The power P is developed-

Here,

W = Specific weight of water in kg/m3

Q = Rate of flow of water in m3/s

H = Height of fall or head in meters

η = Overall efficiency of operation

Hydroelectric power plant is becoming very popular nowadays to full feel rapid increasing demand of electric power day by day. Every country is trying to develop more Hydro Electric Power Station to full fill their demand for electricity. In other hand fossils, fuels (coal, oil, and gas) are limited stock in the world and these fuels are expensive. So hydroelectricity may be a good alternative electrical source. So in a single word we can say, a generating Station which utilizes the potential energy of high-level water for the generating of electrical energy is known as hydropower plant or hydroelectric power plant.

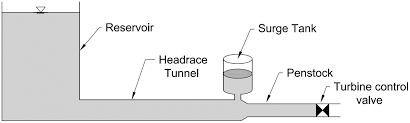

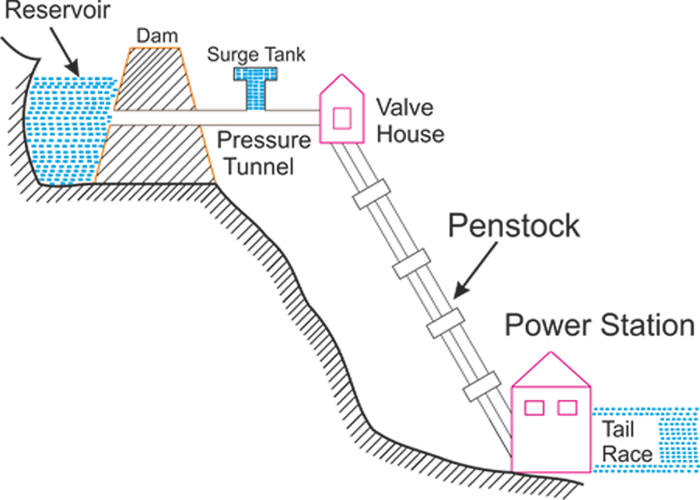

Constituents of a hydro-electric plant

The constituents of hydro-electric power station can be divided mainly into three categories 1) hydraulic structure 2) water turbines 3) electrical equipment.

Hydraulic structure:

Hydraulic structure of hydro-electric power station includes a dam, spillways, head works, surge tank, and penstock.

1) Dam:

The place where the water can be store and creates water head. Dams are mostly built of concrete or stone masonry, the type and arrangement depend on the location of the site. The type of dam also depends on the foundation condition, local material, and transportation available. The dam should not be very expensive.

2) Spillways:

There are times when the water head exceeds the storage capacity of the reservoir. Such situation can affect the whole process. In order to discharge the surplus water from the storage area into the river downstream. A concrete path constructed alongside the dam called spillways is used to drain the excess water.

3) Headwork’s:

The headwork’s consist of the diversion structures at the head of an intake. It controls the flow of water into and through headwork’s should be as smooth as possible to avoid heat loss.

4) Surge tank:

When the open conduit is used to carry water to the turbine it requires no protection but when the closed conduit is used it needs protection to limit the pressure in the conduit. For this reason, a surge tank is used for closed conduit. The surge tank is a small reservoir or tank in which water level rises or falls to reduce the pressure.

5) Penstock:

Penstocks are open or closed conduits which carry water to the turbines. They are mostly made of reinforced concrete or steel.

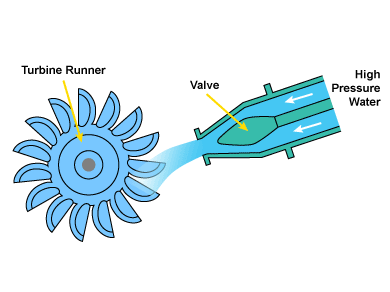

Water turbines:

Those devices which convert water’s kinetic energy into mechanical energy are called water turbines. There are so many turbines used to generate mechanical effort.1) impulse turbines 2) reaction turbines.

Reaction turbine has two types 1) Francis turbines 2) Kaplan turbines

Electrical equipment:

Every power station consists of different electrical types of equipment. There are so many types of equipment can be used for example alternator, exciter, Dc batteries, relays, circuit breakers, measuring devices, controlling devices, electrical motors etc.

WORKING PRINCIPLE OF HYDROELECTRIC POWER PLANT

Working principle of hydroelectric power plant depends on the conversion of hydraulic energy into electrical energy. To get this hydroelectricity, hydroelectric power plant needs some arrangements for proper working and efficiency. The block diagram of hydroelectric power plant is shown below:

Hydroelectric power station needs huge amount of water at sufficient head all the time. So a hydroelectric dam is constructed across the river or lake.an artificial storage reservoir where water is stored, is placed back side of the dam. This reservoir creates sufficient water head. A pressure tunnel is placed in between the reservoir to valve house and water is coming from reservoir to penstock via this tunnel. An automatic controlling sluice valve is placed in valve house and it controls water flow to the power station and the letter cuts off supply of water in case the penstock bursts. Penstock is a huge steel pipe in which water is taken from valve house to turbine. A surge tank is also provided just before the valve house for better regulation of water pressure in the system. Now water turbine converts hydraulic energy into mechanical energy and an alternator which is couple to the water turbine converts this mechanical energy into electrical energy.

I) Site selection criteria

- Water Availability:

Main fuel of this plant is water. So, such plant should be located nearer to river, canal etc. where sufficient water is available all the time.

2. Water Storage:

Storage of water in a suitable reservoir or dam has to be placed by a careful geological study of the area to get the maximum advantage of that water. Dam should be located across the river to get continuous water supply throughout the year specially in a dry season. The storage capacity of dam can be determined by hydrograph or mass curve or using analytical method. Adequate facilities of erection a dam and storage of water are two important matters for site selection of hydroelectric power plant.

3. Water Head:

It is an important point for site selection of hydroelectric power plant. Water head is directly related to the cost of generation of electric power. If effective head is increased, water storage has to be reduced as well as capital cost of the plant is reduced.

4. Distance from the load center:

Since it is located away from the load center, more transmission line is required to supply the power. To avoid the line loss and economical power supply, distance of such plant should need more attention.

5. Transportation Facilities:

Good transportation facilities must be available to any hydroelectric power plant, so that necessary equipment should be reached easily.

6. Availability of land:

Hydroelectric power plant needs enough space. It should be kept in mind that land cost must be cheap.

II) Advantage and disadvantage

ADVANTAGES & DISADVANTAGES OF HYDROELECTRIC POWER PLANT

Advantages

There are lots of advantages in Hydroelectric Power Plant:

1. Since water is the main source of energy, so no fossil fuels are required.

2. This plant is neat and clean and no smoke or as disposal is required.

3. It is the cheapest operating and maintenance cost as compared to the other power plants because water is freely available in the world.

4. It is very reliable, robust and has a longer life app rocks 45 to 60 years.

5. This plant can start instantly.

6. It can start hydroelectric power with fluctuating load demand.

7. The efficiency does not fall at the age of this plant.

8. There is no standby loss in this plant.

9. At the initial time of construction highly skilled engineers are required and after that only few experience persons can run the plant.

10. This plant also serves to help in irrigation and Flood control etc.

11. Since this plants are located remote area so land is available and competitively cheaper rates.

Disadvantages

There are some Disadvantages in hydro power plant:

1. Such plant requires large area

2. High construction cost is required due to construction of dam.

3. When experience skilled engineers are required to build this plant

4. Scenes such plant is located as from the load areas, long transmission line is required to transmit this hydroelectric power.

4. It doesn't supply constant hydroelectricity due to the availability of water. In transition, power supply is most affected.

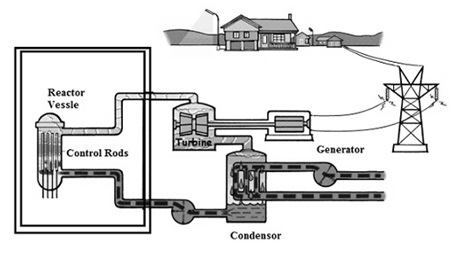

The heat energy in the nuclear power plant can be generated through a nuclear reaction or nuclear fission. The heavy elements of nuclear fission are Uranium/Thorium is carried out within a special device called a nuclear reactor. A huge amount of energy can be generated because of nuclear fission. The rest parts within the nuclear, as well as conventional thermal plants, are the same. The fission of 1 Kg Uranium generates heat energy which is equal to the energy generated through 4500 tons of high-grade coal. This significantly decreases the fuel transportation cost, so it is a major benefit of these plants. Worldwide, there are huge deposits of fuels existing; therefore, these plants can supply electrical energy continuously for hundreds of years. Nuclear power plants generate 10% of the electricity from the whole electricity in the world.

The power plant that is used to warm the water to generate steam, then this steam can be used for rotating huge turbines for generating electricity. These plants use the heat to warm the water which is generated by nuclear fission. So the atoms in the nuclear fission will split into different smaller atoms for generating energy.

Nuclear Power Plant Working Principle

In the power plant, the fission takes place in the reactor and the middle of the reactor is known as the core that includes uranium fuel, and this can be formed into pellets of ceramic. Every pellet generates 150 gallons of oil energy. The total energy generated from the pellets is stacked in metal fuel rods. A bunch of these rods is known as a fuel assembly and a reactor core includes several fuel assemblies.

During nuclear fission, the heat can be generated within the core of the reactor. This heat can be used to warm the water into steam so that turbine blades can be activated. Once the turbine blades activated then they drive the generators to make electricity. In a power plant, a cooling tower is available to cool the steam into the water otherwise they use the water from different resources. Finally, the cooled water can be reused to generate steam.

Components of Nuclear Power Plant

In the above nuclear power plant block diagram, there are different components which include the following.

1) Nuclear Reactor

In a power plant, a nuclear reactor is an essential component like a heat source that includes the fuel & its reaction of nuclear chain including the waste products of nuclear. The nuclear fuel used in the nuclear reactor is Uranium & its reactions are heat generated in a reactor. Then, this heat can be transferred to the coolant of the reactor to generate heat to all the parts in the power plant.

There are different types of nuclear reactors that are used in the manufacturing of plutonium, ships, satellites & aircraft for research as well as medical purposes. The power plant includes not only includes the reactor and also includes turbines, generators, cooling towers, a variety of safety systems.

2) Steam Generation

In all the power plants, the production of steam is general; however, the way of generating will change. Most of the plants use water reactors by using two loops of rotating water to generate steam. The primary loop carries very hot water for heating an exchange once water at a low-pressure is circulated, then it warms the water to generate the steam to transmit to the turbine section.

3) Generator & Turbine

Once the steam is generated, then it travels with high pressures to speed up the turbine. The rotating of the turbines can be used to rotate an electric generator for generating electricity that is transmitted to the electrical grid.

4) Cooling Towers

In a nuclear power plant, the most essential part is a cooling tower which is used to reduce the heat of the water. Please refer to this link to know more about what is a cooling tower – components, construction & applications

Working of Nuclear Power Plant

The elements like Uranium or Thorium are sued nuclear fission reaction of a nuclear reactor. Because of this fission, a huge amount of heat energy can be generated and it is transmitted to the coolant reactor. Here, the coolant is nothing but water, liquid metal otherwise gas. The water is heated to flow in a heat exchanger so that it changes into high-temperature steam. Then the steam which is produced is permitted to make a steam turbine run. Again the steam can be changed back into the coolant & recycled to use for the heat exchanger. So, the turbine and alternator are connected to produce electricity. By using a transformer, the electricity which is produced can be increased to use in long-distance communication.

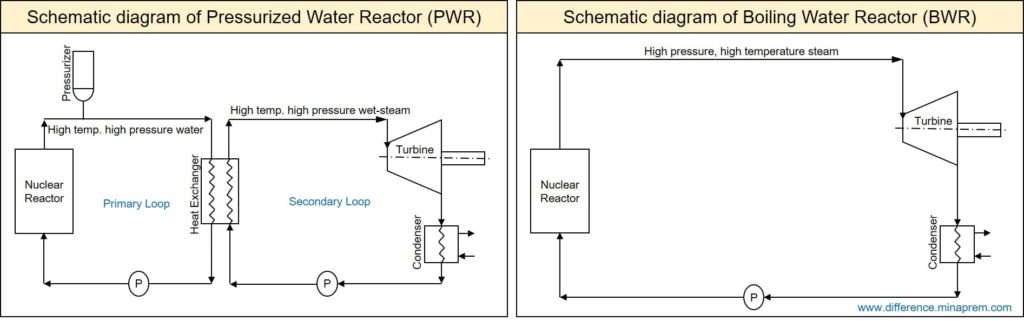

I) PWR and BWR

Pressurized Water Reactor (PWR) | Boiling Water Reactor (BWR) |

Pressurized Water Reactor (PWR) power plants consist of two loops—(i) primary loop or coolant loop that takes away heat from reactor, and (ii) secondary loop or working fluid loop that drives the turbine. A heat exchanger (HE) is employed to transfer heat from primary loop to the secondary loop. | Boiling Water Reactor (BWR) power plants consist of a single loop where the coolant that takes away heat from the reactor is directly fed to the turbine. Thus no heat exchanger is desired. |

In the primary loop, normal water (H2O) acts as coolant-cum-moderator. In the secondary loop, the normal water acts as working fluid. However, water from one loop is not allowed to mix with the water of other loop. | Since it has only one loop, so normal water (H2O) serves all three purposes – cooling, moderation, and working fluid. |

Normal water in the primary loop that acts as moderator-cum-coolant is not allowed to boil. That means the water remains in liquid phase throughout the cycle of primary loop. However, the water in the secondary loop is allowed to boil. | Here the normal water (H2O) is allowed to change its phase. Thus the water (liquid phase) is first converted into steam (gaseous phase) within the reactor, and then the steam is again condensed to water before pumping back to reactor. |

Here steam is generated in a heat exchanger outside the nuclear reactor. | Here steam is generated within the reactor itself. |

Here the water in the primary loop is maintained at high pressure (15 – 17 MPa) to avoid boiling at reactor exit. | Here water pressure remains comparatively low (7 – 8 MPa) as it is allowed to boil. |

A pressurizer is required to use mandatorily to maintain water pressure in such a way that it does not evaporate even at very high temperature. | No such pressurizer is employed as evaporation of the water is desired. |

The temperature of the water at the reactor exit is kept around 310°C (corresponding to the working pressure to avoid boiling). | Steam temperature at reactor exit remains comparatively low (around 285°C). |

PWR has comparatively low thermal efficiency owing to two different loops. | BWR offers higher thermal efficiency. |

In PWR, the control rods are inserted from the top of the nuclear reactor. | In BWR, the control rods are inserted from the bottom of the nuclear reactor. |

Since the fluid is maintained at high pressure, so the PWR core volume is less. | For the same power generation, core volume of the BWR is comparatively larger. |

Since the working fluid loop is separated from the primary loop, so PWR is less risky in spreading of radioactive materials owing to leakage. | Since same fluid passes through the reactor and turbine in BWR plants, so any leakage in the turbine can spread radioactive elements into the atmosphere. |

II) Site Selection for Nuclear Power Plant

The selection of the site for nuclear PowerPoint can be done by considering the technical requirement. The arrangement and working of a nuclear power plant mainly depend on the characteristics of the site.

While designing the plant, the risks from the site must be considered. The plant design has to handle with tremendous natural occurrence & human-induced actions, without damaging the operational security of the plant.

Each site has to give needed necessities like discarded and decay heat sinks, power supply availability, excellent communications and efficient crisis management, etc. For a power plant, the estimate of the site typically occupies different stages like selection, characterization, pre-operational, and operational.

The purpose of characterisation of any particular area during the site selection stage is to determine the suitability of particular site for setting up a Nuclear Power Project (NPP). In this stage, geological, geo-morphological and geo-technical aspects are considered and regions or areas are usually identified that are excluded from further consideration. Subsurface information for this stage is usually obtained from current and historical documents, field reconnaissance, including geological surveys. In the recent past, remote sensing played great role in obtaining detailed and accurate information with minimum effort within least possible time frame. For a nuclear power plant, site evaluation typically involves the following stages,

a. Selection stage: One or more preferred candidate sites are selected after investigation of a large region, rejection of unsuitable sites, and screening and comparison of the remaining sites.

b. Characterization stage: This stage is further subdivided into:

• Verification-In which the suitability of the site to host a nuclear power plant is verified mainly according to predefined site exclusion criteria;

• Confirmation-In which the characteristics of the site necessary for the purposes of analysis and detailed design are determined.

c. Pre-operational stage: Studies and investigations from the previous stages are continued to refine the assessment of site characteristics. Data obtained from site allow a final assessment of simulation models used in the ultimate design of foundation and superstructure as well.

d. Operational stage: Selected investigations are pursued over the lifetime of the plant, to ensure that the variation of engineering properties are not varying significantly during the operating life of the plan

III) Advantages and disadvantages

Advantages

The advantages of nuclear power plants include the following.

1) It uses less space compared with other power plants

2) It is extremely economical and generates huge electric power.

3) These plants are located near the load center because there is no requirement of huge fuel.

4) It generates a huge amount of power in the process of each nuclear fission

5) It uses less fuel to generate huge energy

6) Its operation is reliable

7) When compared with steam power plants, it is very clean and neat

8) The operating cost is small

9) It doesn’t produce polluting gases

Disadvantages

The disadvantages of nuclear power plants include the following.

1) The cost of primary installation is extremely high when compared with other power stations.

2) The nuclear fuel is expensive so recovering is difficult

3) High capital cost compare with other power plants

4) Technical knowledge is required to operate this plat. So maintenance, as well as salary, will be high.

5) There is a chance of radioactive pollution

6) The response is not efficient

7) The requirement of cooling water is double compare with a steam power plant.

Applications

The applications of nuclear power plants include the following.

Nuclear energy is used in different industries all over the world for desalination of ocean water, production of hydrogen, district cooling/heating, the removal of tertiary oil resources & used in heat process applications like cogeneration, conversion of coal to liquids & help in the chemical feedstock synthesis.