Unit - 1

Cement

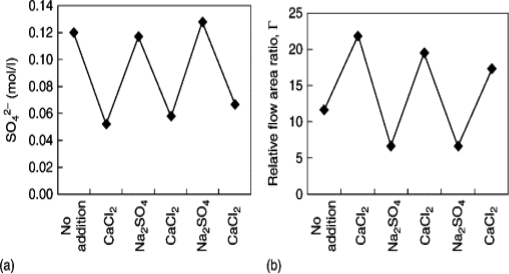

- Cement chemistry can have an effect on the dispersion performance of superplasticizers in numerous ways. One of those is thru the ionic composition of the aqueous section and particularly via the quantity of soluble sulfates.

- The milestone paper in this problem comes from Yamada and Hanehara (2001).

- As defined at the reversibility of polymer adsorption, they made opportunity additions of CaSO4 and Na2SO4 that changed the soluble sulfate concentration and the go with the drift spread, in addition to the adsorption.

- The essential step on this paper turned into to devise the relative go with the drift immediately with recognize to the polymer adsorption. This emphasizes the reversible nature of the polymer adsorption already mentioned above.

Fig: Chemistry of cement

Key takeaways:

- The milestone paper in this problem comes from Yamada and Hanehara (2001).

- Portland cement is made of 4 essential compounds: tricalcium silicate (3CaO · SiO2), dicalcium silicate (2CaO · SiO2), tricalcium aluminate (3CaO · Al2O3), and a tetra-calcium aluminoferrite (4CaO · Al2O3Fe2O3).

- In an abbreviated notation differing from the regular atomic symbols, those compounds are special as C3S, C2S, C3A, and C4AF, wherein C stands for calcium oxide (lime), S for silica, A for alumina, and F for iron oxide. Small quantities of uncombined lime and magnesia are also present, in conjunction with alkalies and minor quantities of different elements.

- The maximum vital hydraulic elements are the calcium silicates, C2S and C3S. Upon blending with water, the calcium silicates react with water molecules to shape calcium silicate hydrate (3CaO · 2SiO2 · 3H2O) and calcium hydroxide (Ca[OH]2).

- These compounds are given the shorthand notations C–S–H (represented with the aid of using the common components C3S2H3) and CH, and the hydration response may be crudely represented with the aid of using the subsequent reactions:

2C3S + 6H = C3S2H3 + 3CH

2C2S + 4H = C3S2H3 + CH

- During the preliminary degree of hydration, the discern compounds dissolve, and the dissolution in their chemical bonds generates a large quantity of heat. Then, for motives that aren't absolutely understood, hydration involves a stop. This quiescent, or dormant, length is extraordinarily critical withinside the placement of concrete. Without a dormant length there could be no cement trucks; pouring could should be accomplished right now upon mixing.

- Following the dormant period (that can remaining numerous hours), the cement starts to harden, as CH and C–S–H are produced. This is the cementitious cloth that binds cement and urban together. As hydration proceeds, water and cement are constantly consumed.

- Fortunately, the C–S–H and CH merchandise occupy nearly the identical extent because the authentic cement and water; extent is about conserved, and shrinkage is manageable.

- Although the formulation above deal with C–S–H as a selected stoichiometry, with the method C3S2H3, it does by no means shape an ordered shape of uniform composition. C–S–H is virtually an amorphous gel with a noticeably variable stoichiometry. The ratio of C to S, for example, can variety from 1:1 to 2:1, relying on blend layout and curing conditions.

Key takeaways:

- Portland cement is made of 4 essential compounds: tricalcium silicate (3CaO · SiO2), dicalcium silicate (2CaO · SiO2), tricalcium aluminate (3CaO · Al2O3), and a tetra-calcium aluminoferrite (4CaO · Al2O3Fe2O3).

- Calculate quantity of water in litre required for one bag of cement, as density of water is ready 1kg/ litre, so 20kg water = 20 litres and 30kg water = 30 litres, as a result you may want 20 to 30 litres of water in step with 50kg bag of cement. Regarding this, “how tons water required for 1 bag of cement?”, one 50kg bag of cement would require 20 to 30 litres of water, whilst one 25kg bag would require 10 to fifteen litres of water, a 20kg bag would require eight to twelve litres of water, one 40kg bag would require sixteen to 24 litres of water or a 94lb bag of Portland cement would require 4.five to 7 gallons of water.

- Regarding this, “how a whole lot water do I want for a 50kg bag of cement?”, its rely upon water cement ratio and form of grade of concrete, however commonly you'll want 20 to 30 litres of water blend with one 50kg bag of cement together with 2.five cubic toes of sand and 3.seventy five cubic toes of aggregate. This amount of water can be little extrade in keeping with climate circumstance or temperature.

- Cement is one of the maximum famous constructing fabric. It is used as a binder withinside the creation enterprise. It has each adhesion and brotherly love properties. It can bind debris right into a compact long lasting stable mass.

- Cement has a huge software withinside the creation enterprise along with: When cement is blended with sand and water to shape a paste, it's miles termed as mortar.

- The mortar is used to enroll in bricks or stones and in completing works along with plastering and pointing. When cement is blended with gravel (or beaten stones), sand and water, the composite product is known as concrete. The concrete is the second one maximum used fabric in this planet. It is used for building footings, beams, columns, slabs, stairs, etc. There are many kinds of cement which might be used as in keeping with their necessities and properties

- Fineness of Cement

The fineness of cement is the degree of the particle length of cement. The finer the cement, extra is the charge of a chemical reaction. This outcomes in a extra charge of electricity development. Very first-class cement is likewise undesirable. It generates extra warmness which leads to cracks in mortar or concrete. It also can result in a untimely setting.’

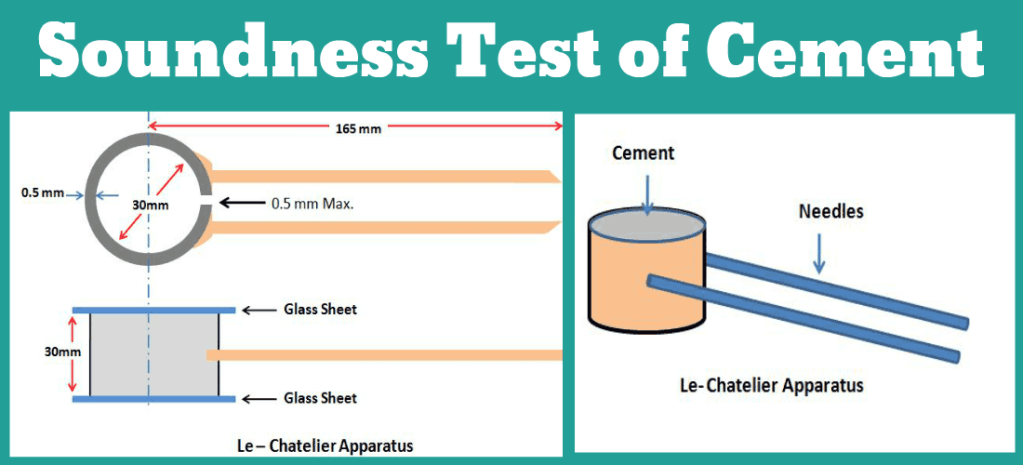

- Soundness of Cement

The phenomenon of cement to go through unwanted enlargement is called as unsoundness. When the cement does now no longer go through a huge alternate in volume, it will likely be known as sound cement. The unsound cement will fall apart because of volumetric adjustments as a result of the presence of unfastened lime and magnesia in cement. Unsound cement includes a few unfastened lime even after the very last grinding. This unfastened lime hydrates very slowly.

- The unfastened lime blanketed with the aid of using a skinny movie of cement. This prevents direct touch among lime and water. After the paste has set, moisture penetrates the unfastened lime, and hydration starts. The slaked lime occupies a huge volume. Hence enlargement takes place. Thus the mortar and urban crafted from unsound cement may also broaden cracks after a few time.

- Consistency of Cement: The bodily kingdom of cement paste is referred to as consistency.

- The motive of the consistency take a look at is to estimate the amount of blending water to shape a paste of everyday consistency. It is measured via way of means of the Vicat equipment Test. If the water content material withinside the cement paste is such that the Vicat’s plunger penetrates as much as five to 7 mm from the lowest of the mould, the cement paste is referred to as to be of everyday consistency.

Key takeaways:

- Cement is one of the maximum famous constructing fabric. It is used as a binder withinside the creation enterprise. It has each adhesion and brotherly love properties. It can bind debris right into a compact long lasting stable mass.

Fig: Soundness test apparatus

- The soundness of cement suggests the steadiness of any cement throughout the extent extrade withinside the procedure of putting and hardening. In case the extent extrade in cement is volatile after putting and hardening, the concrete detail will crack, which could have an effect on the high-satisfactory of the shape or maybe motive critical accidents, referred to as terrible dimensional stability.

- The soundness take a look at of cement determines the enlargement of cement after it begins offevolved placing. Certain cement has been located to go through a huge enlargement after placing inflicting disruption of the set and hardened mass. This enlargement of cement can reason extreme issues for the sturdiness of systems whilst such cement is used.

- The soundness of cement is in particular measured through methods: EN-196 (1995), that's primarily based totally at the Le Châtelier take a look at method, and the autoclave take a look at (ASTM-C151, 2015), wherein strain is likewise implemented to the sample.

- Significance of Soundness of Cement

- The trying out of the stability of cement, to make sure that the cement does now no longer display any considerable next enlargement of high importance.

The unsoundness is taking place specifically because of an extra lime that might be mixed with acidic oxide on the kiln.

This is likewise because of insufficient burning or inadequate fineness of grinding or thorough blending of uncooked materials.

It is likewise may also arise because of too excessive share magnesium content material or calcium sulfate content material may also motive unsoundness in cement.

Types of cement:

- Ordinary Portland Cement (OPC)

- Portland Pozzolana Cement (PPC)

- Rapid Hardening Cement

- Quick setting cement

- Low Heat Cement

- Sulfates resisting cement

- Blast Furnace Slag Cement

- High Alumina Cement

- White Cement

- Colored cement

- Air Entraining Cement

- Expansive cement

- Hydrographic cement

- Ordinary Portland cement is the maximum extensively used form of cement, that's appropriate for all preferred concrete construction.

- It is the maximum generally produced and used form of cement across the world, with annual international manufacturing of round 3.eight million cubic meters in keeping with year.

- This cement is appropriate for all styles of concrete construction.

- Rapid hardening cement attains excessive power withinside the early days; it's miles utilized in concrete in which formworks are eliminated at an early degree and are much like everyday portland cement (OPC).

- This cement has elevated lime content material and carries better c3s content material and finer grinding, which offers better power improvement than OPC at an early degree.

- The power of fast hardening cement on the 3 days is much like 7 days power of OPC with the identical water-cement ratio. Thus, the benefit of this cement is that formwork may be eliminated earlier, which will increase the charge of creation and reduces the value of creation with the aid of using saving formwork value.

Key takeaways:

- Ordinary Portland cement is the maximum extensively used form of cement, that's appropriate for all preferred concrete construction.

- Blast furnace slag cement is acquired with the aid of using grinding the clinkers with approximately 60% slag and resembles greater or much less in residences of Portland cement.

- It may be used for works wherein monetary concerns are predominant.

- Low warmness cement is produced through keeping the proportion of tricalcium aluminate under 6% through growing the percentage of C2S.

- A small amount of tricalcium aluminate makes the concrete to supply low warmness of hydration.

- Low warmness cement appropriate for mass concrete production like gravity dams, because the low warmness of hydration, prevents the cracking of concrete because of warmness.

- This cement has expanded energy in opposition to sulphates and is much less reactive and preliminary putting time is more than OPC.

- Portland pozzolana cement is ready via way of means of grinding pozzolanic clinker with Portland cement. It is likewise produced via way of means of including pozzolana with the addition of gypsum or calcium sulfate or via way of means of in detail and uniformly mixing Portland cement and satisfactory pozzolana.

- This cement has a excessive resistance to diverse chemical assaults on concrete as compared with regular portland cement, and thus, it's far extensively used.

- It is utilized in marine structures, sewage works, sewage works, and for laying concrete underwater, along with bridges, piers, dams, and mass concrete works, etc

- Fly ash may be used as high cloth in lots of cement-primarily based totally products, along with poured concrete, concrete block, and brick. One of the maximum not unusualplace makes use of of fly ash is in Portland cement concrete pavement or PCC pavement.

- Road creation initiatives the use of PCC can use a extremely good deal of concrete, and substituting fly ash affords extensive monetary benefits. Fly ash has additionally been used as embankment and mine fill, and it has an increasing number of won reputation via way of means of the Federal Highway Administration.

- The fee of substitution—of fly ash for Portland cement—usually exact is 1 to at least one half kilos of fly ash for 1 pound of cement.1 Accordingly, the quantity of high-quality mixture withinside the concrete blend need to be decreased to deal with the extra quantity of the fly ash.

Key takeaways:

- It is utilized in marine structures, sewage works, sewage works, and for laying concrete underwater, along with bridges, piers, dams, and mass concrete works, etc

- Sulphate Resisting Cement is a sort of Portland Cement wherein the quantity of tricalcium aluminate (C3A) is confined to decrease than 5% and (2C 3A +C4AF) decrease than 25%, which reduces the formation of sulphate salts.

- The discount of sulphate salts lowers the opportunity of sulphate assault at the concrete.

- In this newsletter we look at approximately the composition, properties, characteristics, uses, blessings and downsides of sulphate resisting cement.

- Date of Manufacturing: As the power of cement reduces with age, the date of producing of cement baggage need to be checked. Cement Color: The colour of cement need to be uniform. It need to be common cement colour i.e. grey colour with a mild greenish shade.

- Whether Hard Lumps are Formed: Cement need to be unfastened from difficult lumps. Such lumps are shaped via way of means of the absorption of moisture from the atmosphere. T

- Temperature Inside Cement Bag: If the hand is plunged right into a bag of cement, it need to be cool in the cement bag. If hydration response takes area in the bag, it turns into warm.

- Smoothness Test: When cement is touched or rubbed in among fingers, it need to deliver a clean feeling. If it felt rough, it shows adulteration with sand.

- Water Sinking Test: If a small amount of cement is thrown into the water, it need to glide a while earlier than in the end sinking.

- The odor of Cement Paste: A skinny paste of cement with water need to sense sticky among the fingers. If the cement incorporates too much-pounded clay and silt as an adulterant, the paste will deliver an earthy odor.

- Glass Plate Test: A thick paste of cement with water is made on a chunk of a tumbler plate and it's miles stored below water for twenty-four hours. It need to set and now no longer crack.

- Block Test: A 25mm × 25mm × 200mm (1”×1”×8”) block of cement with water is made. The block is then immersed in water for 3 days. After removing, it's miles supported 150mm aside and a weight of 15kg uniformly positioned over it. If it suggests no signal of failure the cement is good.

- In mineralogy and petrology, a mixture is a mass of mineral crystals, mineraloid debris or rock debris. Examples are dolomite, that's an mixture of crystals of the mineral dolomite, and rock gypsum, an mixture of crystals of the mineral gypsum.

- Lapis lazuli is a form of rock composed of a mixture of crystals of many minerals consisting of lazurite, pyrite, phlogopite, calcite, potassium feldspar, wollastonite and a few sodalite institution minerals. In the development industry, an mixture (regularly called a creation mixture) is sand, gravel or overwhelmed rock that has been mined or quarried to be used as a constructing material. In pedology, an mixture is a mass of soil debris.

- If the mixture has shaped naturally, it may be referred to as a ped; if shaped artificially, it may be referred to as a clod.

- Aggregates are the maximum critical parts in concrete. They deliver frame to the concrete, lessen shrinkage and impact economy. Natural aggregates are inert granular substances along with sand, gravel stone or overwhelmed stone which might be used with a binding medium i.e. water, bitumen, portland cement, lime, etc. to shape compound substances i.e. asphalt concrete and portland cement concrete.

- Almost all of the herbal combination substances originate from mattress rocks. There are 3 kinds of rocks; igneous, sedimentary and metamorphic. These classifications are primarily based totally at the way of formation of rocks. It can be recalled that igneous rocks are fashioned through the cooling of molten magma or lava on the floor of the crest (lure and basalt) or deep below the crest (granite).

- They are hard, hard and dense.

- They can be acidic or fundamental relying upon the proportion of silica content.

- They can also additionally arise in mild hues or darkish hues. The sedimentary rocks are fashioned under the ocean mattress and finally lifted up. Sedimentary rocks range from smooth to hard, porous to dense and mild to heavy.

- The diploma of consolidation, the sort of cementation, the thickness of layers and contamination, those all are vital elements to decide the suitability of sedimentary rock for concrete aggregates.

- Metamorphic rocks are at first both igneous or sedimentary rocks which can be finally metamorphosed because of severe warmth and pressure. Many metamorphic rocks specially quartzite and gneiss were used for the manufacturing of right concrete aggregates.

- The concrete making homes of herbal aggregates are prompted to a degree on the idea of geological formation of the discern rock collectively with the following procedures of weathering and alteration.

Key takeaways:

- Temperature Inside Cement Bag: If the hand is plunged right into a bag of cement, it need to be cool in the cement bag. If hydration response takes area in the bag, it turns into warm.

- Classification of aggregates primarily based totally on: Grain Size If you separate aggregates through length, there are overriding categories:

- Fine Coarse

The length of first-class aggregates is described as four.75mm or smaller. That is, aggregates which may be surpassed thru quite a number four sieve, with a mesh length of four.75mm. Fine aggregates encompass matters inclusive of sand, silt and clay. Crushed stone and beaten gravel can also fall below this category.

- Typically, first-class aggregates are used to enhance workability of a concrete mix.

- Coarse aggregates degree above the four.75mm limit. These are much more likely to be herbal stone or gravel that has now no longer been beaten or processed. These aggregates will lessen the quantity of water wanted for a concrete mix, which might also lessen workability however enhance its innate strength.

- Classification of aggregates primarily based totally on:

Density: There are 3 weight-primarily based totally versions of aggregates: Light weight Standard High density Different density aggregates can have a whole lot exceptional applications. Lightweight and extremely light-weight aggregates are extra porous than their heavier counterparts, in order that they may be positioned to high-quality use in inexperienced roof construction, for example.

- They also are utilized in mixes for concrete blocks and pavements, in addition to insulation and fireproofing. High density aggregates are used to shape heavyweight concrete. They are used for whilst excessive strength, long lasting concrete systems are required – constructing foundations or pipework ballasting, for example.

| Scopes | Fine Aggregate (FA) | Coarse Aggregate (CA) |

1 | Definition | Fine aggregates are small size filler materials in construction. | Coarse aggregates are larger size filler materials in construction. |

2 | Size of Particles | Fine aggregates are the particles that pass through 4.75 mm sieve and retain on 0.075 mm sieve. | Coarse aggregates are the particles that retain on 4.75 mm sieve. |

3 | Materials | Sand, surki, stone screenings, burnt clays, cinders, fly ash, etc are used as fine aggregate in concrete. | Brick chips (broken bricks), stone chips (broken stones), gravels, pebbles, clinkers, cinders etc. are used as coarse aggregate in concrete. |

4 | Sources | River sand or machine sand, crushed stone sand, crushed gravel sand are the major sources of fine aggregate. | Dolomite aggregates, crushed gravel or stone, natural disintegration of rock are the major sources of coarse aggregate. |

5 | Surface Area | The surface area of fine aggregates is higher. | The surface area of coarse aggregate is less than fine aggregates. |

6 | Function in Concrete | The voids between the coarse aggregate are filled up by fine aggregate. | Coarse aggregate acts as inert filler material for concrete. |

7 | Uses | Fine aggregates are used in mortar, plaster, concrete, filling of road pavement layers, etc. | Coarse aggregates are mainly used in concrete, railway track ballast, etc. |

- Normal weight aggregates, used for most concretes, are naturally occurring gravels from land or marine sources, or crushed rocks, for example, limestone, granite or basalt.

- Used in maximum concrete construction, normal-weight aggregates are received with the aid of using draining riverbeds or mining and crunching formational cloth. Concrete made with normal-weight excellent and coarse aggregates usually weights approximately a hundred and forty four lb / ft3. Boulders and cobbles are usually now no longer used of their as-mined length however are overwhelmed to make numerous sizes of coarse mixture and synthetic sand and mineral filler.

- Gravels and clearly going on sand are produced with the aid of using the movement of water and weathering on glacial and river deposits. These substances have round, easy surfaces and particle-length distributions that require minimum processing.

- These substances may be provided in both coarse or excellent-mixture sizes. Fine aggregates have 100% in their cloth passing the 3â„8-in sieve. Coarse aggregates have the majority of the cloth retained at the No. Four sieve. Aggregates incorporate the finest extent percent in portland-cement concrete, mortar, or asphaltic concrete.

- In a portland-cement concrete blend, the coarse and excellent aggregates occupy approximately 60 to seventy five% of the overall blend extent. For asphaltic concrete, the aggregates constitute seventy five to 85% of the combinationture extent. Consequentially, the aggregates aren't inert filler substances. The person mixture homes have demonstrable consequences at the provider lifestyles and sturdiness of the cloth gadget wherein the mixture is used, along with portland-cement concrete, asphaltic concrete, mortar, or mixture base.

- The acceptability of a rough or excellent mixture to be used in concrete or mortar is judged with the aid of using many homes which includes gradation, quantity of excellent cloth passing the No. 2 hundred sieve, hardness, soundness, particle shape, extent stability, ability alkali reactivity, resistance to freezing and thawing, and natural impurities.

- For aggregates utilized in widespread constructing construction, belongings limits are supplied in ASTM C33, Specification for Concrete Aggregates, C637, Specification for Aggregates for Radiation-Shielding Concrete, and C330, Specification for Lightweight Aggregates for Structural Concrete.

- For different sorts of construction, along with highways and airports, requirements written with the aid of using numerous change or governmental agencies are available.

Key takeaways:

- Coarse aggregates degree above the four.75mm limit. These are much more likely to be herbal stone or gravel that has now no longer been beaten or processed. These aggregates will lessen the quantity of water wanted for a concrete mix, which might also lessen workability however enhance its innate strength.

- Concrete is a combination of cementious cloth, combination, and water. Aggregate is typically taken into consideration inert filler, which money owed for 60 to eighty percentage of the extent and 70 to eighty five percentage of the load of concrete.

- Although combination is taken into consideration inert filler, it's miles a vital aspect that defines the concrete’s thermal and elastic residences and dimensional stability.

- Aggregate is assessed as unique types, coarse and first-rate. Coarse combination is normally extra than four, seventy five mm (retained on a No. Four sieve), at the same time as first-rate combination is much less than four.seventy five mm (passing the No. Four sieve).

- The compressive combination power is an crucial thing withinside the choice of combination. When figuring out the power of regular concrete, maximum concrete aggregates are numerous instances more potent than the opposite additives in concrete and consequently now no longer a thing withinside the power of regular power concrete.

- Lightweight combination concrete can be extra inspired with the aid of using the compressive power of the aggregates. Other bodily and mineralogical residences of combination have to be acknowledged earlier than blending concrete to achieve a suited combination.

- These residences consist of form and texture, length gradation, moisture content, precise gravity, reactivity, soundness and bulk unit weight. These residences along side the water/cementitious cloth ratio decide the power, workability, and sturdiness of concrete.

- The form and texture of combination influences the residences of clean concrete extra than hardened concrete. Concrete is extra attainable whilst easy and rounded combination is used in preference to tough angular or elongated combination.

- Most herbal sands and gravel from riverbeds or beaches are easy and rounded and are superb aggregates. Crushed stone produces a lot extra angular and elongated aggregates, that have a better floor-to-extent ratio, higher bond traits however require extra cement paste to provide a attainable combination.

- The floor texture of combination may be both easy or tough. A easy floor can enhance workability, but a rougher floor generates a more potent bond among the paste and the combination growing a better power.

- The grading or length distribution of combination is an crucial feature as it determines the paste requirement for attainable concrete. This paste requirement is the thing controlling the cost, given that cement is the maximum highly-priced aspect.

- It is consequently suited to decrease the quantity of paste constant with the manufacturing of concrete that may be handled, compacted, and completed at the same time as presenting the vital power and sturdiness.

- The required quantity of cement paste relies upon the quantity of void area that have to be crammed and the whole floor location that have to be covered. When the debris are of uniform length the spacing is the greatest, however whilst a number of sizes is used the void areas are crammed and the paste requirement is lowered.

- The extra those voids are crammed, the much less attainable the concrete becomes, consequently, a compromise among workability and economic system is vital.

- Concrete workability essentially refers to how without difficulty freshly combined concrete may be placed, consolidated and completed with minimum lack of homogeneity.

- Generally the workability of concrete is decided through how fluid the combinationture is (i.e. the cement to water ratio).

- This is typically cited as "droop" (to discover extra approximately droop study our concrete droop check guide).

- Essentially - the extra fluid the concrete, the better the droop and while the droop is visible as a degree of water content, it's far commonly extensively utilized as a degree of concrete consistency.

- To offer long lasting concrete, it must be freed from segregation and the mortar must be in near touch with the coarse aggregate, reinforcement, and any adjoining faces to which it's far to be bonded.

- Concrete must be deposited, as almost as practicable, in its very last position. Placement of concrete is achieved with buckets, hoppers, guide or motor-propelled buggies, chutes and drop pipes, conveyor belts, pumps, tremies, and paving equipment.

- Concrete also can be positioned with the aid of using the shotcrete procedure, wherein layers are implemented pneumatically.

- The shotcrete procedure is specially useful in which forming is inconvenient or impractical, get right of entry to or vicinity offers difficulties, or everyday casting strategies can't be employed.

- Sampling (in line with ASTM C 172) is step one in figuring out if the concrete located complies with specifications.

- The pointers are to take composite samples of enough overall volume (1 ft3 minimum) from the ready-blend truck after 10% and earlier than 90% of the burden has been discharged.

- These samples ought to be taken no extra than 15 mins aside and remixed to yield a composite sample.

- They are then protected to shield towards speedy evaporation and to keep away from contamination.

Key takeaways:

- The compressive combination power is an crucial thing withinside the choice of combination. When figuring out the power of regular concrete, maximum concrete aggregates are numerous instances more potent than the opposite additives in concrete and consequently now no longer a thing withinside the power of regular power concrete.

- Particle Shapes The shape of aggregate particles can be classified as either angular, subangular, subrounded or rounded. Each shape has advantages and disadvantages depending on the desired properties of the finished product.

- Effects

Strength of aggregate particles

Bond with cementitous materials

Resistance to sliding of one particle over another Angular particles with a rough surface texture

Can create a very strong matrix

Can also be very difficult to compact since the rough surface textures and angular particles can interlock together and resist compactive effort.

Rounded particles with smooth surface texture: Will compact readily, but Will be unstable under load since the particles will displace and slide against each other.

- Flat, thin, long, needle-shaped particles break easily • Want cubical or sphere-shaped particles instead Rough and fractured faces allow a better bond with asphalt and cements than rounded, smooth faces • More friction against sliding particles • Better interlocking of particles to create a strong framework to resist loads

- This paper evaluations the simple nature of the cement-mixture bond and its impact on concrete overall performance.

- The bond is a end result of mechanical interlocking furnished with the aid of using epitaxic increase of cement hydration merchandise at the mixture floor and of chemical reactions among the cement paste and mixture.

- The diploma to which the bond outcomes from every of those tactics isn't known.

- The impact of the bond on concrete overall performance is a topic of controversy; however, there appears to be a courting among concrete energy and bond energy, and it's miles recommended that the fine of the bond influences concrete durability.

- ‘Aggregate’ is a time period for any particulate material. It consists of gravel, beaten stone, sand, slag, recycled concrete and geosynthetic aggregates. Aggregate can be natural, synthetic or recycled.

- Aggregates make up a few 60 -80% of the concrete blend. They offer compressive electricity and bulk to concrete.

- Aggregates in any precise blend of concrete are decided on for his or her durability, electricity, workability and cappotential to acquire finishes.

- For an amazing concrete blend, aggregates want to be clean, hard, sturdy debris freed from absorbed chemical compounds or coatings of clay and different first-class substances that might purpose the deterioration of concrete.

- Aggregates are divided into either ‘coarse’ or ‘first-class’ categories. - Coarse aggregates are particulates which might be more than 4.75mm. The ordinary variety hired is among 9.5mm and 37.5mm in diameter. - Fine aggregates are generally sand or beaten stone which might be much less than 9.55mm in diameter.

- Typically the maximum not unusualplace length of combination utilized in creation is 20mm. A large length, 40mm, is extra not unusualplace in mass concrete.

- Larger combination diameters lessen the amount of cement and water needed.

- The unique gravity cost of any substance offers the concept approximately how heavy or mild is the substance in comparison to the usual substance. From the cost, we will decide it'll flow or sink in every other substance.

- All-herbal cloth and substance have their personal unique gravity cost. It typically tiers from 1 to 100. Water has a selected gravity of round 1and If the unique gravity of different cloth is extra than 1, then it sinks in water. If the unique gravity of the cloth is much less than 1 it floats in water.

- Therefore, the unique gravity of any cloth is an crucial assets to know. So that we will use it in a right way. Generally, the unique gravity of cement tiers from 3.1 to 3.sixteen g/cc. From this, we will say that the unique gravity of cement is greater than the unique gravity of water this is 1. It method cement will sink in water if we positioned it at the water.

- Also, we will say that cement is heavier than water. Cement particle has pore in it and they could take in moisture from the atmosphere. Considering this conduct of cement debris the unique gravity can both boom or decrease. While we're calculating cement for blend layout we bear in mind the unique gravity of cement as popular 3.14. So, any extrade in cement-unique gravity will have an effect on the combinationture layout.

- Hence, it's far important to check the unique gravity of the cement procured earlier than the combination process. This is the principle cause at the back of we reject the antique saved cement. Old cement has greater prone to keep outside moisture which leads to expanded unique gravity of cement.

- Bulk density is the burden of soil in a given volume. Soils with a bulk density better than 1.6 g/cm3 have a tendency to limition root growth. Bulk density will increase with compaction and has a tendency to growth with depth. Sandy soils are extra at risk of excessive bulk density. Bulk density may be used to calculate soil houses according to unit area (e.g. Kg/ha).

- The soil bulk density (BD), additionally referred to as dry bulk density, is the load of dry soil (Msolids) divided through the overall soil quantity (Vsoil). The general soil quantity is the blended quantity of solids and pores which may also incorporate air (Vair) or water (Vwater), or both (parent 1).

- The common values of air, water and stable in soil are without problems measured and are a beneficial indication of a soils bodily condition. Soil BD and porosity (the wide variety of pore spaces) displays the size, form and association of debris and voids (soil structure).

- Both BD and porosity (Vpores) deliver a terrific indication of the suitability for root boom and soil permeability and are vitally essential for the soil-plant-environment system (Cresswell and Hamilton, 2002; McKenzie et al., 2004). It is typically acceptable to have soil with a low BD (<1.five g/cm3) (Hunt and Gilkes, 1992) for maximum motion of air and water thru the soil.

- Aggregates commonly incorporate pores; those can be of numerous length and volume. Some aggregates have pores inside strong wherein different have commencing to the surface.

- Dear reader we can talk approximately pore length of various rock aggregates and their volume in our subsequent post. Here we need to give an explanation for affect of porosity, absorption in mixture at the homes of concrete.

- The porosity, permeability and absorption of mixture have affect on following homes of concrete. a. Bond among aggregates and surrounding hydrates paste of cement. b. Chemical balance of concrete

- As precise gravity is affected, for a particular mass of mixture, concrete manufacturing additionally affected. It is apparent that a porous mixture produce concrete of unit weight, as that of mild weight aggregates. Now-a-days light-weight mixture concretes are used for structural member, which yield giant energy with unique treatment.

- But while absorption is concerned, it'll impact water call for with in concrete and must be adjusted for water/cement ratio even as proportioning blend design. In our subsequent publish we can talk approximately pore sizes of herbal aggregates. Please live with us.

- Aggregates are porous substances able to each soaking up moisture internally and adsorbing moisture at the outside surface.

- Although we are trying to find out hard, dense, clean, sound, solid and non-reactive aggregates to be used in precast concrete, outstanding coarse mixture nevertheless comprise miniscule pores.

- These pores are able to retaining measurable quantities of moisture, that can substantially have an effect on a concrete mix. Fine mixture additionally want to be cautiously monitored in view that they're vulnerable to bulking, which reasons best mixture to preserve water among the mixture particles.

- Bulking of Sand takes place while sand comes in touch with moisture, which bureaucracy a skinny layer of water across the sand particle and this skinny layer of water exert an outward pressure on every different which reason the sand particle to transport farfar from every different and in the long run boom the quantity of sand.

- This phenomenon of the increasing volume of sand due to moisture in the sand is called “Sand Bulking “

- Abrasion Test is the degree of combination durability and abrasion resistance which includes crushing, degradation and disintegration. This check is recommended with the aid of using AASHTO T ninety six or ASTM C 131: Resistance to Degradation of Small-Size Coarse Aggregate with the aid of using Abrasion and Impact in Los Angeles Machine.

- The aggregates are used for the floor route of the motorway pavements and they may be subjected to carrying because of the motion of traffic. (Los Angeles abrasion check ASTM c131) When motors journey on the street, the soil debris gift among the pneumatic tires of the car and the street floor creates the abrasion impact on aggregates.

- The metal plate wheels of animal-pushed motors additionally purpose tremendous abrasion of the street floor. Therefore, the aggregates utilized in street creation need to be tough sufficient to face up to abrasion. The resistance supplied through mixture to abrasion is decided withinside the laboratory through the Los Angeles Test machine. The Working precept of the Los Angeles abrasion check is to provide abrasive motion through use of preferred metal balls, which while blended with aggregates and turned around in a drum for a few precise time for a particular wide variety of revolutions additionally reasons an effect on aggregates. The percent put on of the pattern aggregates because of rubbing with metal balls is decided and is referred to as Los Angeles Abrasion Value.

- It is the capacity of aggregates that face up to surprising effect or surprise load on it. Also, it could be described because the resistance of combination to failure with the aid of using effect load. This effect load can smash combination into smaller portions and which ends withinside the failure of roads and pavements.

- The equipment as consistent with IS: 2386 (Part IV) - 1963 is composed of: (i) A checking out gadget weighing forty five to 60 kg and having a metallic base with a painted decrease floor of now no longer much less than 30 cm in diameter. It is supported on stage and aircraft concrete ground of minimal forty five cm thickness.

- The gadget ought to additionally have provisions for solving its base. (ii) A cylindrical metallic cup of inner diameter 102 mm, intensity 50 mm and minimal thickness 6.three mm. . (iii) A metallic hammer or tup weighing 13.five to 14.zero kg the decrease quit being cylindrical in shape, 50 mm long, 100.zero mm in diameter, with a 2 mm chamfer on the decrease part and case hardened. The hammer ought to slide freely among vertical publications and be concentric with the cup. Free fall of hammer ought to be inside 380±five mm. (iv) A cylindrical metallic degree having inner diameter seventy five mm and intensity 50 mm for measuring aggregates. (v) Tamping rod 10 mm in diameter and 230 mm long, rounded at one quit. (vi) A stability of ability now no longer much less than 500g, readable and correct as much as zero.1 g.

- A sieve evaluation is an analytical approach used to decide the particle length distribution of a granular fabric with macroscopic granular sizes. The sieve evaluation approach includes numerous layers of sieves with distinctive grades of sieve commencing sizes.

- The greatest sized sieve lies on the lowest of the stack with every layered sieve stacked above so as of growing sieve length. When a pattern of granular fabric is located at the pinnacle sieve and sifted, the man or woman debris of the fabric are separated onto the very last layer that the particle couldn't byskip through.

- The base of the tool consists of a shaker, which allows the filtering. Performing a sieve evaluation is essential whilst studying substances due to the fact their particle length distribution can have an effect on a extensive variety of houses which includes the energy of concrete, the solubility of a mixture, their floor place houses or even their taste.

- In a massive variety of industries which includes meals and pharmaceutics, conventional sieve evaluation is a popular manner for lots of manufacturing techniques and fine manipulate of powders and granules. Sieving is once in a while executed whilst deciding on media for abrasive blast cleaning. Some blessings of the sieve evaluation encompass smooth handling, low funding cost, correct effects in a fairly quick time frame and the opportunity of keeping apart the particle length fractions.

- Deleterious substances in combination are the ones materials which detrimentally impact the clean and hardened residences of concrete as an instance energy, workability, and long-time period overall performance of the concrete wherein such are used. Deleterious substances and fantastically unwanted constituents.

- Organic impurities, clay, silt and overwhelmed dust, salts, unsound particles, and alkali combination reactions.

- Adverse outcomes of deleterious substances on concrete consists of the growth of water call for in concrete, impair bond energy among cement and combination, lessen durability, bring about concrete popouts, and impair put on resistance.

- There are checks inclusive of colorimetric check endorsed with the aid of using ASTM C 40-ninety two that are used to decide combination natural content material. The colorimetric check does now no longer display the unfavourable impact of deleterious substances in combination.

- This is due to the fact excessive combination deleterious substance content material does now no longer infer that the combination isn't always match for usage this is why energy check primarily based totally on ASTM C 87-ninety is suggested for mortars with questionable sand.

- Organic impurities, commonly withinside the shape of tannic acid and its derivatives, are normally found in quality aggregates inclusive of sand.

- These may also intrude with the chemical response of hydration and might impact the electricity of the mortar or concrete in which the aggregates are used. The check approach for this willpower conforms to the opportunity method laid out in ASTM C40.

- If aggregate contains organic impurities it may not be suitable for inclusion in concrete. Organic impurities, usually tannic acid and its derivatives, may interfere with the chemical reactions of hydration. Impurities are more likely to be found in fine (sand) aggregate.

- The not unusualplace specs concerning pleasant of blending water is water need to be healthy for drinking. Such water need to have inorganic stable much less than a thousand ppm.

- This content material result in a stable amount 0.05% of mass of cement whilst w/c ratio is furnished 0.five ensuing small impact on power. But a few water which aren't potable can be utilized in making concrete with any considerable impact.

- Dark colour or terrible odor water can be used in the event that they do now no longer posses deleterious substances. PH of water to even nine is authorized if it now no longer tastes brackish.

- In coastal regions wherein neighborhood water is saline and don't have any exchange reassets, the chloride attention as much as a thousand ppm is even allowed for drinking. But this immoderate quantity of alkali carbonates and bicarbonates, in a few herbal mineral water, might also additionally motive alkali-silica reaction.

- Acceptable supply of water Besides potable water, numerous new and current reassets are to be had for blending water which may be used for whole and partial substitute of precious potable water.

- This includes • Ground water • Reclaimed water • Treated water from municipal sewer • Waste water of ready-blend concrete plant etc. In many areas of the arena there have shortage of water like Dubai and Qatar and the neighborhood government are searching out new reassets and reused water.

- There dealt with water are used for agricultural necessities and each day desires for creation industry. Like washing aggregates, as concrete blending water and curing of the same. Water from river and on occasion even sea are taken into consideration appropriate if it's far unfastened from brackish matter. In arid areas, brackish groundwater is blended with desalinated water and taken into consideration appropriate for concrete manufacturing and for concrete slurry too.

- Sampling guiding principle for blending water In addition to checking out on constituent of concrete like combination cementitious substances and admixtures etc., checking out of water is an vital a part of pleasant manage of concrete.

- A systematic checking out agenda for water checking out yields better performance of concrete and guarantee properly overall performance in regard of power and durability. Important issue to recollect is that water may be modified via way of means of chemical, bodily or organic reactions; such amendment might also additionally arise all through sampling and on the time of analyzing. So it need to be examined earlier than the usage of in concrete.

- For concrete grade higher than M-30, PSC works, bridge, roads, multi-storied buildings etc.

- For use in cold weather concreting.

- For marine structures but C3A should be between 5 – 8%.

Key takeaways:

- The unique gravity cost of any substance offers the concept approximately how heavy or mild is the substance in comparison to the usual substance. From the cost, we will decide it'll flow or sink in every other substance.

References:

1. Concrete Technology by Gambhir Mc. Graw Hill

2. Concrete Technology by A.M. Neville Pearson Education

3. Properties of Concrete by A.M. Neville Pearson Education

Unit - 1

Cement

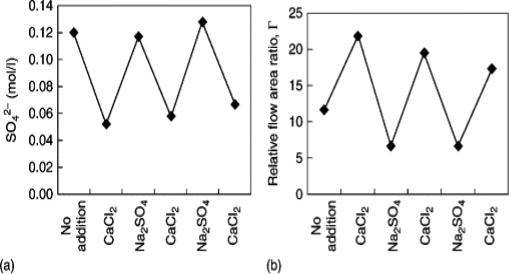

- Cement chemistry can have an effect on the dispersion performance of superplasticizers in numerous ways. One of those is thru the ionic composition of the aqueous section and particularly via the quantity of soluble sulfates.

- The milestone paper in this problem comes from Yamada and Hanehara (2001).

- As defined at the reversibility of polymer adsorption, they made opportunity additions of CaSO4 and Na2SO4 that changed the soluble sulfate concentration and the go with the drift spread, in addition to the adsorption.

- The essential step on this paper turned into to devise the relative go with the drift immediately with recognize to the polymer adsorption. This emphasizes the reversible nature of the polymer adsorption already mentioned above.

Fig: Chemistry of cement

Key takeaways:

- The milestone paper in this problem comes from Yamada and Hanehara (2001).

- Portland cement is made of 4 essential compounds: tricalcium silicate (3CaO · SiO2), dicalcium silicate (2CaO · SiO2), tricalcium aluminate (3CaO · Al2O3), and a tetra-calcium aluminoferrite (4CaO · Al2O3Fe2O3).

- In an abbreviated notation differing from the regular atomic symbols, those compounds are special as C3S, C2S, C3A, and C4AF, wherein C stands for calcium oxide (lime), S for silica, A for alumina, and F for iron oxide. Small quantities of uncombined lime and magnesia are also present, in conjunction with alkalies and minor quantities of different elements.

- The maximum vital hydraulic elements are the calcium silicates, C2S and C3S. Upon blending with water, the calcium silicates react with water molecules to shape calcium silicate hydrate (3CaO · 2SiO2 · 3H2O) and calcium hydroxide (Ca[OH]2).

- These compounds are given the shorthand notations C–S–H (represented with the aid of using the common components C3S2H3) and CH, and the hydration response may be crudely represented with the aid of using the subsequent reactions:

2C3S + 6H = C3S2H3 + 3CH

2C2S + 4H = C3S2H3 + CH

- During the preliminary degree of hydration, the discern compounds dissolve, and the dissolution in their chemical bonds generates a large quantity of heat. Then, for motives that aren't absolutely understood, hydration involves a stop. This quiescent, or dormant, length is extraordinarily critical withinside the placement of concrete. Without a dormant length there could be no cement trucks; pouring could should be accomplished right now upon mixing.

- Following the dormant period (that can remaining numerous hours), the cement starts to harden, as CH and C–S–H are produced. This is the cementitious cloth that binds cement and urban together. As hydration proceeds, water and cement are constantly consumed.

- Fortunately, the C–S–H and CH merchandise occupy nearly the identical extent because the authentic cement and water; extent is about conserved, and shrinkage is manageable.

- Although the formulation above deal with C–S–H as a selected stoichiometry, with the method C3S2H3, it does by no means shape an ordered shape of uniform composition. C–S–H is virtually an amorphous gel with a noticeably variable stoichiometry. The ratio of C to S, for example, can variety from 1:1 to 2:1, relying on blend layout and curing conditions.

Key takeaways:

- Portland cement is made of 4 essential compounds: tricalcium silicate (3CaO · SiO2), dicalcium silicate (2CaO · SiO2), tricalcium aluminate (3CaO · Al2O3), and a tetra-calcium aluminoferrite (4CaO · Al2O3Fe2O3).

- Calculate quantity of water in litre required for one bag of cement, as density of water is ready 1kg/ litre, so 20kg water = 20 litres and 30kg water = 30 litres, as a result you may want 20 to 30 litres of water in step with 50kg bag of cement. Regarding this, “how tons water required for 1 bag of cement?”, one 50kg bag of cement would require 20 to 30 litres of water, whilst one 25kg bag would require 10 to fifteen litres of water, a 20kg bag would require eight to twelve litres of water, one 40kg bag would require sixteen to 24 litres of water or a 94lb bag of Portland cement would require 4.five to 7 gallons of water.

- Regarding this, “how a whole lot water do I want for a 50kg bag of cement?”, its rely upon water cement ratio and form of grade of concrete, however commonly you'll want 20 to 30 litres of water blend with one 50kg bag of cement together with 2.five cubic toes of sand and 3.seventy five cubic toes of aggregate. This amount of water can be little extrade in keeping with climate circumstance or temperature.

- Cement is one of the maximum famous constructing fabric. It is used as a binder withinside the creation enterprise. It has each adhesion and brotherly love properties. It can bind debris right into a compact long lasting stable mass.

- Cement has a huge software withinside the creation enterprise along with: When cement is blended with sand and water to shape a paste, it's miles termed as mortar.

- The mortar is used to enroll in bricks or stones and in completing works along with plastering and pointing. When cement is blended with gravel (or beaten stones), sand and water, the composite product is known as concrete. The concrete is the second one maximum used fabric in this planet. It is used for building footings, beams, columns, slabs, stairs, etc. There are many kinds of cement which might be used as in keeping with their necessities and properties

- Fineness of Cement

The fineness of cement is the degree of the particle length of cement. The finer the cement, extra is the charge of a chemical reaction. This outcomes in a extra charge of electricity development. Very first-class cement is likewise undesirable. It generates extra warmness which leads to cracks in mortar or concrete. It also can result in a untimely setting.’

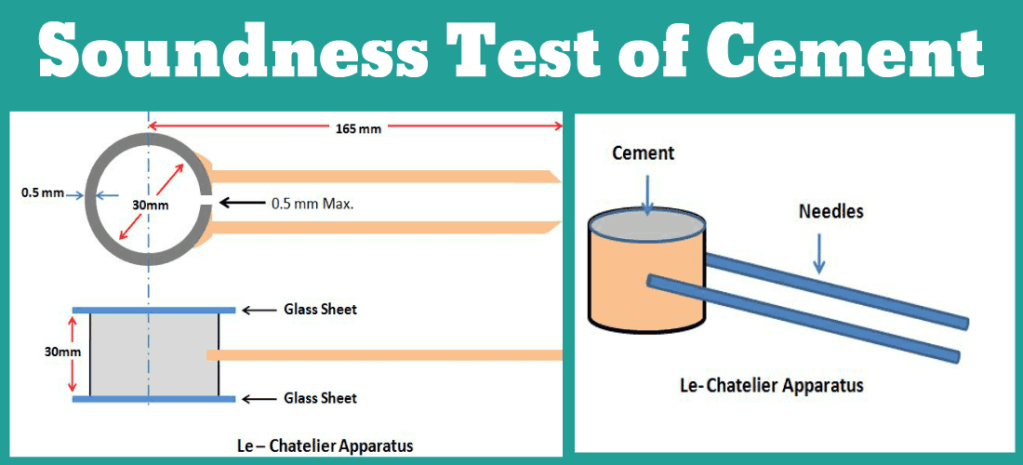

- Soundness of Cement

The phenomenon of cement to go through unwanted enlargement is called as unsoundness. When the cement does now no longer go through a huge alternate in volume, it will likely be known as sound cement. The unsound cement will fall apart because of volumetric adjustments as a result of the presence of unfastened lime and magnesia in cement. Unsound cement includes a few unfastened lime even after the very last grinding. This unfastened lime hydrates very slowly.

- The unfastened lime blanketed with the aid of using a skinny movie of cement. This prevents direct touch among lime and water. After the paste has set, moisture penetrates the unfastened lime, and hydration starts. The slaked lime occupies a huge volume. Hence enlargement takes place. Thus the mortar and urban crafted from unsound cement may also broaden cracks after a few time.

- Consistency of Cement: The bodily kingdom of cement paste is referred to as consistency.

- The motive of the consistency take a look at is to estimate the amount of blending water to shape a paste of everyday consistency. It is measured via way of means of the Vicat equipment Test. If the water content material withinside the cement paste is such that the Vicat’s plunger penetrates as much as five to 7 mm from the lowest of the mould, the cement paste is referred to as to be of everyday consistency.

Key takeaways:

- Cement is one of the maximum famous constructing fabric. It is used as a binder withinside the creation enterprise. It has each adhesion and brotherly love properties. It can bind debris right into a compact long lasting stable mass.

Fig: Soundness test apparatus

- The soundness of cement suggests the steadiness of any cement throughout the extent extrade withinside the procedure of putting and hardening. In case the extent extrade in cement is volatile after putting and hardening, the concrete detail will crack, which could have an effect on the high-satisfactory of the shape or maybe motive critical accidents, referred to as terrible dimensional stability.

- The soundness take a look at of cement determines the enlargement of cement after it begins offevolved placing. Certain cement has been located to go through a huge enlargement after placing inflicting disruption of the set and hardened mass. This enlargement of cement can reason extreme issues for the sturdiness of systems whilst such cement is used.

- The soundness of cement is in particular measured through methods: EN-196 (1995), that's primarily based totally at the Le Châtelier take a look at method, and the autoclave take a look at (ASTM-C151, 2015), wherein strain is likewise implemented to the sample.

- Significance of Soundness of Cement

- The trying out of the stability of cement, to make sure that the cement does now no longer display any considerable next enlargement of high importance.

The unsoundness is taking place specifically because of an extra lime that might be mixed with acidic oxide on the kiln.

This is likewise because of insufficient burning or inadequate fineness of grinding or thorough blending of uncooked materials.

It is likewise may also arise because of too excessive share magnesium content material or calcium sulfate content material may also motive unsoundness in cement.

Types of cement:

- Ordinary Portland Cement (OPC)

- Portland Pozzolana Cement (PPC)

- Rapid Hardening Cement

- Quick setting cement

- Low Heat Cement

- Sulfates resisting cement

- Blast Furnace Slag Cement

- High Alumina Cement

- White Cement

- Colored cement

- Air Entraining Cement

- Expansive cement

- Hydrographic cement

- Ordinary Portland cement is the maximum extensively used form of cement, that's appropriate for all preferred concrete construction.

- It is the maximum generally produced and used form of cement across the world, with annual international manufacturing of round 3.eight million cubic meters in keeping with year.

- This cement is appropriate for all styles of concrete construction.

- Rapid hardening cement attains excessive power withinside the early days; it's miles utilized in concrete in which formworks are eliminated at an early degree and are much like everyday portland cement (OPC).

- This cement has elevated lime content material and carries better c3s content material and finer grinding, which offers better power improvement than OPC at an early degree.

- The power of fast hardening cement on the 3 days is much like 7 days power of OPC with the identical water-cement ratio. Thus, the benefit of this cement is that formwork may be eliminated earlier, which will increase the charge of creation and reduces the value of creation with the aid of using saving formwork value.

Key takeaways:

- Ordinary Portland cement is the maximum extensively used form of cement, that's appropriate for all preferred concrete construction.

- Blast furnace slag cement is acquired with the aid of using grinding the clinkers with approximately 60% slag and resembles greater or much less in residences of Portland cement.

- It may be used for works wherein monetary concerns are predominant.

- Low warmness cement is produced through keeping the proportion of tricalcium aluminate under 6% through growing the percentage of C2S.

- A small amount of tricalcium aluminate makes the concrete to supply low warmness of hydration.

- Low warmness cement appropriate for mass concrete production like gravity dams, because the low warmness of hydration, prevents the cracking of concrete because of warmness.

- This cement has expanded energy in opposition to sulphates and is much less reactive and preliminary putting time is more than OPC.

- Portland pozzolana cement is ready via way of means of grinding pozzolanic clinker with Portland cement. It is likewise produced via way of means of including pozzolana with the addition of gypsum or calcium sulfate or via way of means of in detail and uniformly mixing Portland cement and satisfactory pozzolana.

- This cement has a excessive resistance to diverse chemical assaults on concrete as compared with regular portland cement, and thus, it's far extensively used.

- It is utilized in marine structures, sewage works, sewage works, and for laying concrete underwater, along with bridges, piers, dams, and mass concrete works, etc

- Fly ash may be used as high cloth in lots of cement-primarily based totally products, along with poured concrete, concrete block, and brick. One of the maximum not unusualplace makes use of of fly ash is in Portland cement concrete pavement or PCC pavement.

- Road creation initiatives the use of PCC can use a extremely good deal of concrete, and substituting fly ash affords extensive monetary benefits. Fly ash has additionally been used as embankment and mine fill, and it has an increasing number of won reputation via way of means of the Federal Highway Administration.

- The fee of substitution—of fly ash for Portland cement—usually exact is 1 to at least one half kilos of fly ash for 1 pound of cement.1 Accordingly, the quantity of high-quality mixture withinside the concrete blend need to be decreased to deal with the extra quantity of the fly ash.

Key takeaways:

- It is utilized in marine structures, sewage works, sewage works, and for laying concrete underwater, along with bridges, piers, dams, and mass concrete works, etc

- Sulphate Resisting Cement is a sort of Portland Cement wherein the quantity of tricalcium aluminate (C3A) is confined to decrease than 5% and (2C 3A +C4AF) decrease than 25%, which reduces the formation of sulphate salts.

- The discount of sulphate salts lowers the opportunity of sulphate assault at the concrete.

- In this newsletter we look at approximately the composition, properties, characteristics, uses, blessings and downsides of sulphate resisting cement.

- Date of Manufacturing: As the power of cement reduces with age, the date of producing of cement baggage need to be checked. Cement Color: The colour of cement need to be uniform. It need to be common cement colour i.e. grey colour with a mild greenish shade.

- Whether Hard Lumps are Formed: Cement need to be unfastened from difficult lumps. Such lumps are shaped via way of means of the absorption of moisture from the atmosphere. T

- Temperature Inside Cement Bag: If the hand is plunged right into a bag of cement, it need to be cool in the cement bag. If hydration response takes area in the bag, it turns into warm.

- Smoothness Test: When cement is touched or rubbed in among fingers, it need to deliver a clean feeling. If it felt rough, it shows adulteration with sand.

- Water Sinking Test: If a small amount of cement is thrown into the water, it need to glide a while earlier than in the end sinking.

- The odor of Cement Paste: A skinny paste of cement with water need to sense sticky among the fingers. If the cement incorporates too much-pounded clay and silt as an adulterant, the paste will deliver an earthy odor.

- Glass Plate Test: A thick paste of cement with water is made on a chunk of a tumbler plate and it's miles stored below water for twenty-four hours. It need to set and now no longer crack.

- Block Test: A 25mm × 25mm × 200mm (1”×1”×8”) block of cement with water is made. The block is then immersed in water for 3 days. After removing, it's miles supported 150mm aside and a weight of 15kg uniformly positioned over it. If it suggests no signal of failure the cement is good.

- In mineralogy and petrology, a mixture is a mass of mineral crystals, mineraloid debris or rock debris. Examples are dolomite, that's an mixture of crystals of the mineral dolomite, and rock gypsum, an mixture of crystals of the mineral gypsum.

- Lapis lazuli is a form of rock composed of a mixture of crystals of many minerals consisting of lazurite, pyrite, phlogopite, calcite, potassium feldspar, wollastonite and a few sodalite institution minerals. In the development industry, an mixture (regularly called a creation mixture) is sand, gravel or overwhelmed rock that has been mined or quarried to be used as a constructing material. In pedology, an mixture is a mass of soil debris.

- If the mixture has shaped naturally, it may be referred to as a ped; if shaped artificially, it may be referred to as a clod.

- Aggregates are the maximum critical parts in concrete. They deliver frame to the concrete, lessen shrinkage and impact economy. Natural aggregates are inert granular substances along with sand, gravel stone or overwhelmed stone which might be used with a binding medium i.e. water, bitumen, portland cement, lime, etc. to shape compound substances i.e. asphalt concrete and portland cement concrete.

- Almost all of the herbal combination substances originate from mattress rocks. There are 3 kinds of rocks; igneous, sedimentary and metamorphic. These classifications are primarily based totally at the way of formation of rocks. It can be recalled that igneous rocks are fashioned through the cooling of molten magma or lava on the floor of the crest (lure and basalt) or deep below the crest (granite).

- They are hard, hard and dense.

- They can be acidic or fundamental relying upon the proportion of silica content.

- They can also additionally arise in mild hues or darkish hues. The sedimentary rocks are fashioned under the ocean mattress and finally lifted up. Sedimentary rocks range from smooth to hard, porous to dense and mild to heavy.

- The diploma of consolidation, the sort of cementation, the thickness of layers and contamination, those all are vital elements to decide the suitability of sedimentary rock for concrete aggregates.

- Metamorphic rocks are at first both igneous or sedimentary rocks which can be finally metamorphosed because of severe warmth and pressure. Many metamorphic rocks specially quartzite and gneiss were used for the manufacturing of right concrete aggregates.

- The concrete making homes of herbal aggregates are prompted to a degree on the idea of geological formation of the discern rock collectively with the following procedures of weathering and alteration.

Key takeaways:

- Temperature Inside Cement Bag: If the hand is plunged right into a bag of cement, it need to be cool in the cement bag. If hydration response takes area in the bag, it turns into warm.

- Classification of aggregates primarily based totally on: Grain Size If you separate aggregates through length, there are overriding categories:

- Fine Coarse

The length of first-class aggregates is described as four.75mm or smaller. That is, aggregates which may be surpassed thru quite a number four sieve, with a mesh length of four.75mm. Fine aggregates encompass matters inclusive of sand, silt and clay. Crushed stone and beaten gravel can also fall below this category.

- Typically, first-class aggregates are used to enhance workability of a concrete mix.

- Coarse aggregates degree above the four.75mm limit. These are much more likely to be herbal stone or gravel that has now no longer been beaten or processed. These aggregates will lessen the quantity of water wanted for a concrete mix, which might also lessen workability however enhance its innate strength.

- Classification of aggregates primarily based totally on:

Density: There are 3 weight-primarily based totally versions of aggregates: Light weight Standard High density Different density aggregates can have a whole lot exceptional applications. Lightweight and extremely light-weight aggregates are extra porous than their heavier counterparts, in order that they may be positioned to high-quality use in inexperienced roof construction, for example.

- They also are utilized in mixes for concrete blocks and pavements, in addition to insulation and fireproofing. High density aggregates are used to shape heavyweight concrete. They are used for whilst excessive strength, long lasting concrete systems are required – constructing foundations or pipework ballasting, for example.

| Scopes | Fine Aggregate (FA) | Coarse Aggregate (CA) |

1 | Definition | Fine aggregates are small size filler materials in construction. | Coarse aggregates are larger size filler materials in construction. |

2 | Size of Particles | Fine aggregates are the particles that pass through 4.75 mm sieve and retain on 0.075 mm sieve. | Coarse aggregates are the particles that retain on 4.75 mm sieve. |

3 | Materials | Sand, surki, stone screenings, burnt clays, cinders, fly ash, etc are used as fine aggregate in concrete. | Brick chips (broken bricks), stone chips (broken stones), gravels, pebbles, clinkers, cinders etc. are used as coarse aggregate in concrete. |

4 | Sources | River sand or machine sand, crushed stone sand, crushed gravel sand are the major sources of fine aggregate. | Dolomite aggregates, crushed gravel or stone, natural disintegration of rock are the major sources of coarse aggregate. |

5 | Surface Area | The surface area of fine aggregates is higher. | The surface area of coarse aggregate is less than fine aggregates. |

6 | Function in Concrete | The voids between the coarse aggregate are filled up by fine aggregate. | Coarse aggregate acts as inert filler material for concrete. |

7 | Uses | Fine aggregates are used in mortar, plaster, concrete, filling of road pavement layers, etc. | Coarse aggregates are mainly used in concrete, railway track ballast, etc. |

- Normal weight aggregates, used for most concretes, are naturally occurring gravels from land or marine sources, or crushed rocks, for example, limestone, granite or basalt.

- Used in maximum concrete construction, normal-weight aggregates are received with the aid of using draining riverbeds or mining and crunching formational cloth. Concrete made with normal-weight excellent and coarse aggregates usually weights approximately a hundred and forty four lb / ft3. Boulders and cobbles are usually now no longer used of their as-mined length however are overwhelmed to make numerous sizes of coarse mixture and synthetic sand and mineral filler.

- Gravels and clearly going on sand are produced with the aid of using the movement of water and weathering on glacial and river deposits. These substances have round, easy surfaces and particle-length distributions that require minimum processing.

- These substances may be provided in both coarse or excellent-mixture sizes. Fine aggregates have 100% in their cloth passing the 3â„8-in sieve. Coarse aggregates have the majority of the cloth retained at the No. Four sieve. Aggregates incorporate the finest extent percent in portland-cement concrete, mortar, or asphaltic concrete.

- In a portland-cement concrete blend, the coarse and excellent aggregates occupy approximately 60 to seventy five% of the overall blend extent. For asphaltic concrete, the aggregates constitute seventy five to 85% of the combinationture extent. Consequentially, the aggregates aren't inert filler substances. The person mixture homes have demonstrable consequences at the provider lifestyles and sturdiness of the cloth gadget wherein the mixture is used, along with portland-cement concrete, asphaltic concrete, mortar, or mixture base.

- The acceptability of a rough or excellent mixture to be used in concrete or mortar is judged with the aid of using many homes which includes gradation, quantity of excellent cloth passing the No. 2 hundred sieve, hardness, soundness, particle shape, extent stability, ability alkali reactivity, resistance to freezing and thawing, and natural impurities.

- For aggregates utilized in widespread constructing construction, belongings limits are supplied in ASTM C33, Specification for Concrete Aggregates, C637, Specification for Aggregates for Radiation-Shielding Concrete, and C330, Specification for Lightweight Aggregates for Structural Concrete.

- For different sorts of construction, along with highways and airports, requirements written with the aid of using numerous change or governmental agencies are available.

Key takeaways:

- Coarse aggregates degree above the four.75mm limit. These are much more likely to be herbal stone or gravel that has now no longer been beaten or processed. These aggregates will lessen the quantity of water wanted for a concrete mix, which might also lessen workability however enhance its innate strength.

- Concrete is a combination of cementious cloth, combination, and water. Aggregate is typically taken into consideration inert filler, which money owed for 60 to eighty percentage of the extent and 70 to eighty five percentage of the load of concrete.

- Although combination is taken into consideration inert filler, it's miles a vital aspect that defines the concrete’s thermal and elastic residences and dimensional stability.

- Aggregate is assessed as unique types, coarse and first-rate. Coarse combination is normally extra than four, seventy five mm (retained on a No. Four sieve), at the same time as first-rate combination is much less than four.seventy five mm (passing the No. Four sieve).

- The compressive combination power is an crucial thing withinside the choice of combination. When figuring out the power of regular concrete, maximum concrete aggregates are numerous instances more potent than the opposite additives in concrete and consequently now no longer a thing withinside the power of regular power concrete.

- Lightweight combination concrete can be extra inspired with the aid of using the compressive power of the aggregates. Other bodily and mineralogical residences of combination have to be acknowledged earlier than blending concrete to achieve a suited combination.

- These residences consist of form and texture, length gradation, moisture content, precise gravity, reactivity, soundness and bulk unit weight. These residences along side the water/cementitious cloth ratio decide the power, workability, and sturdiness of concrete.

- The form and texture of combination influences the residences of clean concrete extra than hardened concrete. Concrete is extra attainable whilst easy and rounded combination is used in preference to tough angular or elongated combination.

- Most herbal sands and gravel from riverbeds or beaches are easy and rounded and are superb aggregates. Crushed stone produces a lot extra angular and elongated aggregates, that have a better floor-to-extent ratio, higher bond traits however require extra cement paste to provide a attainable combination.

- The floor texture of combination may be both easy or tough. A easy floor can enhance workability, but a rougher floor generates a more potent bond among the paste and the combination growing a better power.

- The grading or length distribution of combination is an crucial feature as it determines the paste requirement for attainable concrete. This paste requirement is the thing controlling the cost, given that cement is the maximum highly-priced aspect.

- It is consequently suited to decrease the quantity of paste constant with the manufacturing of concrete that may be handled, compacted, and completed at the same time as presenting the vital power and sturdiness.

- The required quantity of cement paste relies upon the quantity of void area that have to be crammed and the whole floor location that have to be covered. When the debris are of uniform length the spacing is the greatest, however whilst a number of sizes is used the void areas are crammed and the paste requirement is lowered.

- The extra those voids are crammed, the much less attainable the concrete becomes, consequently, a compromise among workability and economic system is vital.

- Concrete workability essentially refers to how without difficulty freshly combined concrete may be placed, consolidated and completed with minimum lack of homogeneity.

- Generally the workability of concrete is decided through how fluid the combinationture is (i.e. the cement to water ratio).

- This is typically cited as "droop" (to discover extra approximately droop study our concrete droop check guide).

- Essentially - the extra fluid the concrete, the better the droop and while the droop is visible as a degree of water content, it's far commonly extensively utilized as a degree of concrete consistency.

- To offer long lasting concrete, it must be freed from segregation and the mortar must be in near touch with the coarse aggregate, reinforcement, and any adjoining faces to which it's far to be bonded.

- Concrete must be deposited, as almost as practicable, in its very last position. Placement of concrete is achieved with buckets, hoppers, guide or motor-propelled buggies, chutes and drop pipes, conveyor belts, pumps, tremies, and paving equipment.

- Concrete also can be positioned with the aid of using the shotcrete procedure, wherein layers are implemented pneumatically.

- The shotcrete procedure is specially useful in which forming is inconvenient or impractical, get right of entry to or vicinity offers difficulties, or everyday casting strategies can't be employed.

- Sampling (in line with ASTM C 172) is step one in figuring out if the concrete located complies with specifications.

- The pointers are to take composite samples of enough overall volume (1 ft3 minimum) from the ready-blend truck after 10% and earlier than 90% of the burden has been discharged.

- These samples ought to be taken no extra than 15 mins aside and remixed to yield a composite sample.

- They are then protected to shield towards speedy evaporation and to keep away from contamination.

Key takeaways:

- The compressive combination power is an crucial thing withinside the choice of combination. When figuring out the power of regular concrete, maximum concrete aggregates are numerous instances more potent than the opposite additives in concrete and consequently now no longer a thing withinside the power of regular power concrete.

- Particle Shapes The shape of aggregate particles can be classified as either angular, subangular, subrounded or rounded. Each shape has advantages and disadvantages depending on the desired properties of the finished product.

- Effects

Strength of aggregate particles

Bond with cementitous materials

Resistance to sliding of one particle over another Angular particles with a rough surface texture

Can create a very strong matrix

Can also be very difficult to compact since the rough surface textures and angular particles can interlock together and resist compactive effort.

Rounded particles with smooth surface texture: Will compact readily, but Will be unstable under load since the particles will displace and slide against each other.