Unit - 5

Special concrete

- Frequently, concrete can be used for a few unique causes for which unique houses are extra essential than the ones typically considered. Sometimes, it can be of fantastic significance to beautify one of the everyday houses.

- These unique programs regularly come to be obvious as new improvement the use of new substances or as upgrades the use of the fundamental substances. Some make use of unique aggregates (light-weight mixture, metal fiber, plastic fiber, glass fiber, and unique heavy mixture). Some unique houses — improved compressive and tensile power, water proofing, and progressed chemical resistance are finished with polymers, both as admixtures or floor remedy of hardened concrete.

- Admixtures for coloring concrete are to be had in all colors. The oldest and most inexpensive is possibly carbon black. Admixtures inflicting growth to be used in sealing cracks or beneathneath gadget bases, etc., consist of powdered aluminum and finely floor iron.

- Special admixtures are to be had to be used wherein the herbal mixture is alkali reactive, to neutralize this reaction. Proprietary admixtures are to be had that growth the tensile power or bond power of concrete. They are beneficial for making maintenance to concrete surfaces.

- Self-compacting concrete (SCC) has many advantages in phrases of manufacturing and site in comparison to conventional concrete namely, removal of outside or inner vibration for compaction, higher flowability, workability and pumpability, in addition to accelerated bonding with congested reinforcement.

- Moreover, the location of SCC is quicker and calls for much less labour. The appearance (floor finish), mechanical overall performance and sturdiness of SCC may be drastically higher than conventional concrete. However, the techniques of manufacturing, placement, best manipulate and completing are crucial for SCC. Constructability troubles might also additionally rise up for specifiers and contractors if associated standards, suggestions or practices aren't correctly observed for manufacturing and site. Self-compacting concrete is much less tolerant to abrupt adjustments in combination moisture content, chemical admixtures and water content.

- The sort of concrete mixer, delivery time and the techniques of concrete placement and completing can have an effect on the residences of SCC. Therefore, strong best manipulate measures ought to be in region in the course of the manufacturing and site of SCC. The high-quality flowability of SCC in comparison to conventional concrete makes pumping the quality approach of placement.

- However, there may be a excessive hazard of air entrainment because of a better glide rate, which could bring about bugholes and segregation. Normally SCC has much less floor imperfections in comparison to conventional concrete, however it'd be prone to bugholes, honeycombing and cracking if suggestions of manufacturing and site had been now no longer observed correctly.

- High-overall performance concrete (HPC) is concrete that has been designed to be greater long lasting and, if necessary, more potent than traditional concrete.

- HPC combinations are composed of basically the equal substances as traditional concrete combinations, however the proportions are designed, or engineered, to offer the energy and sturdiness wished for the structural and environmental necessities of the project. High-energy concrete is described as having a specific compressive energy of 8000 psi (fifty five MPa) or greater. The price of 8000 psi (fifty five MPa) became decided on as it represented a energy stage at which unique care is needed for manufacturing and trying out of the concrete and at which unique structural layout necessities can be wished.

- A concrete combination which has excessive workability, excessive energy, excessive modulus of bodily property, excessive density, excessive dimensional stability, low permeability and resistance to chemical assault is typically stated to be excessive overall performance concrete.

- The American Concrete Committee on High Performance Concrete consists of the subsequent six criteria:

Ease of placement

Long time period mechanical properties

Early-age energy

Toughness

Life in extreme environments

- Definition: a popular time period for a composite fabric comprising a polymer matrix bolstered with fibers withinside the shape of fabric, mat, strands, or some other fiber shape.- ACI Concrete Terminology

- Fiber-Reinforced Polymer (FRP) substances are composite substances that generally encompass robust fibers embedded in a resin matrix. The fibers offer energy and stiffness to the composite and typically deliver maximum of the carried out loads.

- The matrix acts to bond and guard the fibers and to offer for switch of strain from fiber to fiber via shear stresses. The maximum not unusualplace fibers are glass, carbon, and artificial fibers. FRP composites have very excessive energy traits and are nonconductive, noncorrosive, and lightweight.

- Fibre-bolstered polymer (FRP), additionally Fibre-bolstered plastic, is a composite fabric made from a polymer matrix bolstered with fibres. The fibres are commonly glass, carbon, or aramid, even though different fibres which includes paper or timber or asbestos were once in a while used. The polymer is commonly an epoxy, vinylester or polyester thermosetting plastic, and phenol formaldehyde resins are nevertheless in use.

- FRPs are generally used withinside the aerospace, automotive, marine, and creation industries. Composite substances are engineered or obviously taking place substances crafted from or extra constituent substances with considerably distinct bodily or chemical residences which continue to be separate and wonderful in the completed structure.

- Most composites have strong, stiff fibres in a matrix that's weaker and much less stiff. The goal is commonly to make a factor which is robust and stiff, frequently with a low density. Commercial fabric generally has glass or carbon fibres in matrices primarily based totally on thermosetting polymers, which includes epoxy or polyester resins. Sometimes, thermoplastic polymers can be preferred, because they're moldable after preliminary production.

- There are in addition instructions of composite wherein the matrix is a steel or a ceramic.

- For the maximum part, those are nevertheless in a developmental stage, with issues of excessive production charges but to be overcome . Furthermore, in those composites the motives for including the fibres (or, in a few cases, particles) are frequently alternatively complex; for example, upgrades can be sought in creep, wear, fracture toughness, thermal stability, etc .

- Fibre bolstered polymer (FRP) are composites utilized in nearly each kind of superior engineering structure, with their utilization starting from aircraft, helicopters and spacecraft thru to boats, ships and offshore systems and to automobiles, sports activities goods, chemical processing system and civil infrastructure which includes bridges and buildings.

- The utilization of FRP composites keeps to develop at an excellent price as those substances are used extra of their present markets and end up mounted in tremendously new markets which includes biomedical gadgets and civil structures.

- A key thing using the elevated packages of composites over the latest years is the improvement of latest superior types of FRP substances. This consists of tendencies in excessive overall performance resin structures and new forms of reinforcement, which includes carbon nanotubes and nanoparticles.

- Ferrocement or ferro-cement is a machine of production the usage of bolstered mortar or plaster (lime or cement, sand, and water) carried out over an "armature" of metallic mesh, woven, accelerated metallic, or metallic-fibers, and carefully spaced skinny metallic rods including rebar.

- The metallic generally used is iron or a few sort of metallic, and the mesh is made with cord with a diameter among 0.five mm and 1 mm. The cement is generally a completely wealthy blend of sand and cement in a 3:1 ratio; whilst used for making boards, no gravel is used, in order that the fabric isn't always concrete. Ferrocement is used to assemble fairly skinny, hard, sturdy surfaces and systems in lots of shapes including hulls for boats, shell roofs, and water tanks.

- Ferrocement originated withinside the 1840s in France and the Netherlands and is the foundation of bolstered concrete. It has a huge variety of different uses, inclusive of sculpture and prefabricated constructing components. The term "ferrocement" has been carried out via way of means of extension to different composite materials, inclusive of a few containing no cement and no ferrous fabric.

- Shotcrete, gunite or sprayed concrete is concrete or mortar conveyed via a hose and pneumatically projected at excessive pace onto a surface, as a production technique, first utilized in 1907 invented through Carl Akeley.

- It is generally strengthened through traditional metal rods, metal mesh, or fibers. Shotcrete is normally an all-inclusive time period for each the moist-blend and dry-blend variations invented through Carl Akeley.

- In pool production, however, shotcrete refers to moist blend and gunite to dry blend. In this context, those phrases aren't interchangeable. Shotcrete is located and compacted/consolidated on the identical time, because of the pressure with which it's miles ejected from the nozzle. It may be sprayed onto any kind or form of surface, consisting of vertical or overhead areas.

- Shotcrete, then called gunite, became invented in 1907 through American taxidermist Carl Akeley to restore the crumbling façade of the Field Columbian Museum in Chicago (the vintage Palace of Fine Arts from the World's Columbian Exposition).

- He used the technique of blowing dry fabric out of a hose with compressed air, injecting water on the nozzle because it became released. In 1911, he became granted a patent for his innovations, the "cement gun", the gadget used, and "gunite", the fabric that became produced.

- There isn't anyt any proof that Akeley ever used sprayable concrete in his taxidermy paintings, as is from time to time suggested. F. Trubee Davison blanketed this and different Akeley innovations in a unique problem of Natural History magazine.

- The dry-blend technique became used till the wet-blend technique became devised withinside the 1950s. In the 1960s, an opportunity technique for gunning dry fabric with a rotary gun appeared, the usage of a constantly fed open hopper.

- The nozzle is managed through hand on small jobs, inclusive of a modest swimming pool. On large paintings it's miles connected to mechanical palms and operated through handheld far flung control.

- Volume adjustments can arise in concrete at some point of the primary 24 hr and are commonly neglected in laboratory shrinkage evaluations. Unfortunately those early age extent adjustments are found in actual pavements and systems and may make contributions to the cracking conduct of the concrete at later ages.

- Early age extent adjustments can arise in forms: drying shrinkage earlier than the begin of curing and autogenous extent adjustments. Although those early age extent adjustments are frequently brushed off as being insignificant, latest paintings in Europe has diagnosed magnitudes for early age extent adjustments of a few concretes which can be same to or more than 28-day drying shrinkage measurements.

- Expansions have additionally been diagnosed in a few cases. The outcomes of a few investigations of extent adjustments in concrete at some point of the primary 24 hr beneathneath each drying and nondrying situations are presented.

- An instance of ability long-time period cracking beneathneath in part constrained situations (concrete slab-on-grade modeled via way of means of a concrete ring forged round a hole metallic ring) is used to demonstrate the significance of impact of early age extent adjustments on concrete cracking. Both take a look at approaches appoint nonstandard techniques to quantify the cracking ability of concrete.

- Drying shrinkage is a result of lack of moisture from hardened concrete to the environment. Due to the emptying of the satisfactory pores withinside the concrete, terrible capillary stress develops, which reasons a quantity discount of the concrete.

- If the concrete shrinkage is confined, tensile stresses broaden withinside the concrete (confined shrinkage).

- When the tensile stresses grow to be better than the tensile electricity of the concrete, cracks are generated. Cracks have a sizable effect at the sturdiness of a strengthened concrete member, considering they facilitate the ingress of dangerous substances.

- Shrinkage is an inherent asset of concrete. Shrinkage is as a result of the modifications in quantity both autogenous or caused and is one of the maximum negative homes of concrete affecting the aesthetics, strength, and sturdiness of systems because it usually finally ends up in cracks.

- It is virtually hard to make concrete which does now no longer cut back and crack, without the software of specialised components like shrinkage compensating admixtures and fibers.

- Hence, minor cracks are usually predicted and are best a query of the significance of the cracks. Shrinkage is assessed into plastic shrinkage, autogenous shrinkage, drying shrinkage and carbonation shrinkage and this text concentrates at the plastic shrinkage and its underlying mechanism. According to ACI 305R:

- “Plastic shrinkage cracking is regularly related to warm climate concreting in arid climates. It happens in uncovered concrete, broadly speaking in flat paintings however additionally in beams and footings and can broaden in different climates every time the evaporation charge is extra than the charge at which the water rises to the floor of lately positioned concrete through bleeding”.

- Plastic shrinkage develops because of the fast lack of moisture from the concrete floor because of evaporation or absorption through subgrade. Concrete usually bleeds however maximum of the time in a well-proportioned combination it now no longer seen and measurable.

- Bleeding is because of self-weight consolidation of solids withinside the sparkling concrete below gravity, because of their better density as compared to that of pore water. When the evaporation charge exceeds the bleeding charge, the water saturation degree sinks under the concrete floor degree, developing a capillary region of low pressure, and leaving the floor dry which ends up in shrinkage and next cracking.

- Hence, concrete made micro silica is pretty liable to plastic shrinkage cracking because it does now no longer bleed and precise interest is needed to keep away from floor drying at some stage in placement.

- The mechanism at the back of the shrinkage and shrinkage cracking isn't as easy as precise above. In order to apprehend it, we ought to begin with the fundamental homes of water like floor tension, cohesion, adhesion and capillarity.

- Cement Content:

As a popular rule, the growth withinside the richness of concrete blend which results in drying shrinkage.

- Water Content:

Briefly, it may be stated that the extra the water amount used withinside the concrete blend, extra is the shrinkage. Thus a moist blend has greater shrinkage than a dry blend that's in any other case similar.

- Aggregate:

By the use of the biggest feasible most length of aggregates in concrete and making sure top grading, the requirement of water for the preferred workability is decreased and urban consequently received has much less shrinkage due to discount withinside the porosity of the hardened concrete.

- Curing:

Curing additionally performs a critical component in restricting shrinkage. If right curing is began out as quickly because the preliminary set has taken vicinity and it's far endured for as a minimum 7-10 days shrinkage is relatively much less.

- Presence of Excessive Fines in Aggregates:

The presence of immoderate fines which include silt, clay, and dirt in aggregates has a tremendous impact at the volume of shrinkage in concrete. Presence of fines will increase particular floor vicinity of combination and therefore the water requirement.

- Chemical Composition of Cement:

The chemical composition of cement used for concrete & mortar additionally has a few impact on shrinkage. Rapid hardening cement has extra shrinkage than Ordinary Portland Cement.

- Temperature:

A critical element which impacts the water requirement of concrete and consequently its shrinkage is the temperature of sparkling concrete. Concreting executed in slight wintry weather have tons much less cracking tendency than the concreting executed in warm summer time season months.

- Humidity:

The volume of shrinkage additionally relies upon at the relative humidity of ambient air. Thus, shrinkage is tons much less in coastal regions wherein relative humidity stays excessive all through the year. Low relative humidity may additionally motive plastic shrinkage in concrete.

- Curing situations have an effect on significantly the very last enlargement due to the fact water is in reality essential to attain an enlargement.

- Therefore, to be able to completely broaden the capability of enlargement, it's miles essential to offer curing situations that offer enough water curing. Figure 22.nine gives the restricted enlargement of concretes having a water–binder ratio (w/b) same to 0.38 containing, respectively, 16% of a calcium sulphoaluminate-primarily based totally expansive agent (a) and 8% of a calcium-oxide primarily based totally expansive agent (b) (Bissonnette et al., 2014). A first collection of concrete became cured at 100% relative humidity (RH) at some point of 7 days and afterward at 50% RH.

- A 2nd collection of concrete became cured in air after the demolding simply 6 h after their casting.

- The have an effect on of the curing on expansive reactions really seems for the 2 sorts of expansive agents.

- For the calcium sulphoaluminate-primarily based totally expansive agent, the absence of water curing (curing in air) did now no longer produce nearly any enlargement.

- For the calcium-primarily based totally expansive agent, the absence of water curing produced an enlargement, however it became best same to 30% of the enlargement received below water curing.

- The non-uniform moisture distribution in concrete reasons the differential drying shrinkage. From this form of differential drying shrinkage, tensile pressure happens at the uncovered floor of concrete systems and can bring about crack formation.

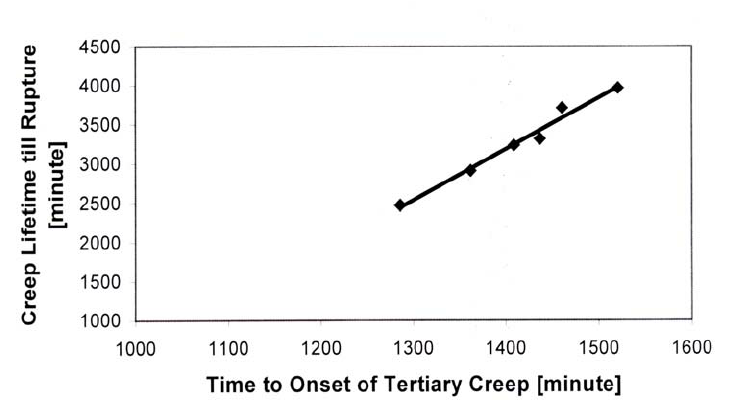

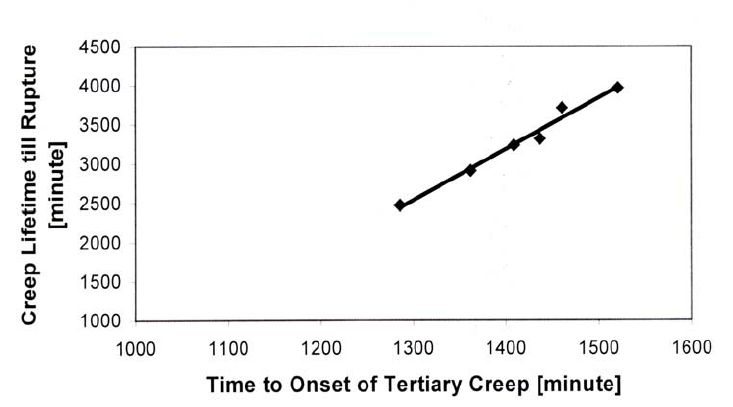

- This residual pressure is appreciably stricken by the creep of concrete. In this study, for the reason of predicting the differential drying shrinkage, the evaluation approach became suggested, wherein the creep of concrete became additionally considered. In addition, the differential drying shrinkage pressure became measured at numerous positions in concrete through the use of embedded pressure gauges.

- The inner drying shrinkage pressure differs appreciably in step with the intensity from uncovered floor.

- Carbonation shrinkage takes place while the concrete is uncovered to air containing carbon dioxide. When the hardened concrete is uncovered to this sort of air, the load increases, and the concrete undergoes irreversible carbonation shrinkage.

- The carbonation shrinkage can be as awesome because the shrinkage because of air drying at seventy tiers Fahrenheit, fifty- percentage relative humidity, and a saturated condition.

- The carbonation method proceeds slowly and generally produces small shrinkage at relative humidities beneath twenty 5 percentage, or close to saturation. The most impact of carbonation takes area while the concrete is in a dry surroundings with a relative humidity of approximately fifty percentage. Carbonation in freshly located concrete generally takes place while the concrete is located in bloodless climate situations that use unvented fueloline heaters.

- When the carbon monoxide reacts with the clean concrete close to the surface, it produces a soft, chalky surface, generally 0.00254 to 0.00762 meters thick.

- Creep may be described because the elastic and long-time period deformation of concrete below a non-stop load. Generally, a long time stress modifications the form of concrete shape and the deformation takes place alongside the course of the carried out load.

- When the non-stop load is removed, the pressure is reduced immediately. The quantity of the reduced pressure is same to the elastic pressure on the given age. This brief healing is then accompanied through a non-stop lower in pressure, called creep healing this is part of general creep pressure suffered through the concrete.

- Creep Coefficient: The ratio of the closing creep pressure to the elastic pressure on the age of loading is named as creep coefficient.

- Factors Affecting Creep Of Concrete: The elements that have an effect on creep of concrete are much like the elements affecting shrinkage that are as following:

1. Water-cement Ratio: The fee of creep is accelerated with growing water cement ratio.

2. Humidity: It is motivated through humidity and drying circumstance of the atmosphere.

3. Age Of Concrete: The fee of creep swiftly decreases with time. The time taken through a concrete shape to attained creep is five years.

4. Aggregate: Aggregates with moisture motion and coffee elastic modulus motive a big quantity of creep.

- The fee of creep typically decreases with the boom of the scale of aggregates. Five. Admixtures: Some admixtures (specially accelerators) also are accountable for inflicting creep in concrete.

- When concrete is loaded, the shape undergoes elastic and inelastic deformations. Elastic deformations arise without delay after the concrete is subjected to a given load, in keeping with Hooke’s Law. Inelastic deformations boom with time because the concrete studies a sustained load.

- This inelastic deformation, additionally referred to as creep, will increase at a reducing charge in the course of the loading period. During the primary month of sustained loading, about one-fourth to one-1/3 of the final creep takes place. As time proceeds, generally one-1/2 of to three-fourths of the final creep happens in the course of the primary 1/2 of year.

- The quantity of creep that the concrete undergoes relies upon 1) the importance of the sustained loading, 2) the age and power of the concrete whilst the pressure is applied, and 3) the full quantity of time that the concrete is stressed.

- When the concrete is loaded, the specimen undergoes inner homes inclusive of closure of voids withinside the concrete, viscous waft of the cement-water paste, crystalline waft in aggregates, and water flowing out of the cement "gel" because of drying and loading.

- Aggregates play a vital position in each creep and shrinkage. A properly graded, coarser combination with a low voids content material decreases the results of creep and shrinkage. Also, hard, dense aggregates that aren't absorptive and feature a excessive modulus of elasticity are ideal for low shrinkage and creep rates.

- Another vital thing to decreasing creep is the kind of curing manner completed previous to loading. Very little creep happens whilst a excessive-strain steamed curing manner is used.

- Atmospheric and excessive-strain steam curing produces little creep whilst in comparison to the seven-day wet curing method. These styles of curing lessen the drying shrinkage through 1/2 of as tons as they lessen creep. Other elements affecting creep consist of kind of cement, quantity of cement paste, length and form of concrete, quantity of reinforcement (rebar), volume-to-floor ratio, temperature, and humidity.

Fig: Relation between time and creep

- Concrete creep is described as: deformation of shape beneathneath sustained load. Basically, long time strain or pressure on concrete could make it alternate shape. This deformation commonly takes place withinside the route the pressure is being implemented. Like a concrete column getting greater compressed, or a beam bending.

- Creep does now no longer always purpose concrete to fail or destroy apart. When a load is implemented to concrete, it stories a right away elastic stress which develops into creep stress if the burden is sustained. Aggregate undergoes little or no creep. It is truly the paste that is answerable for the creep. However, the combination affects the creep of concrete via a restraining impact at the importance of creep.

- The paste that is creeping beneathneath load is constrained with the aid of using combination which do now no longer creep. The more potent the combination the greater is the restraining impact and subsequently the much less is the importance of creep.

- A growth from sixty five to 75 % of volumetric content material of the combination will lower the creep with the aid of using 10 %. The modulus of elasticity of combination is one of the vital elements influencing creep. It may be without problems imagined that the better the modulus of elasticity the much less is the creep. Light weight combination indicates significantly better creep than everyday weight combination The quantity of paste content material and its fine is one of the maximum vital elements influencing creep. A poorer paste shape undergoes better creep.

- Therefore, it is able to be stated that creep will increase with growth in water/cement ratio. In different words, it is able to additionally be stated that creep is inversely proportional to the power of concrete. Broadly speaking, all different elements which can be affecting the water/cement ratio also are affecting the creep.

- Creep and shrinkage of concrete are bodily homes of concrete. The creep of concrete, which originates from the calcium silicate hydrates (C-S-H) withinside the hardened Portland cement paste (that's the binder of mineral aggregates), is essentially distinct from the creep of metals and polymers.

- Unlike the creep of metals, it happens in any respect strain ranges and, in the carrier strain range, is linearly depending on the strain if the pore water content material is constant.

- Unlike the creep of polymers and metals, it well-knownshows multi-months aging, due to chemical hardening because of hydration which stiffens the microstructure, and multi-yr aging, due to long-time period rest of self-equilibrated micro-stresses withinside the nano-porous microstructure of the C-S-H. If concrete is absolutely dried, it does now no longer creep, however it's far subsequent to not possible to dry concrete absolutely with out extreme cracking.

- Concrete creep is described as: deformation of shape below sustained load. Basically, long time stress or strain on concrete could make it extrade shape. This deformation commonly happens withinside the path the pressure is being implemented. Like a concrete column getting greater compressed, or a beam bending. Creep does now no longer always purpose concrete to fail or spoil apart.

- When a load is implemented to concrete, it reports a direct elastic stress which develops into creep stress if the burden is sustained.

References:

1. Concrete Technology by Gambhir Mc. Graw Hill

2. Concrete Technology by A.M. Neville Pearson Education

3. Properties of Concrete by A.M. Neville Pearson Education

Unit - 5

Special concrete

- Frequently, concrete can be used for a few unique causes for which unique houses are extra essential than the ones typically considered. Sometimes, it can be of fantastic significance to beautify one of the everyday houses.

- These unique programs regularly come to be obvious as new improvement the use of new substances or as upgrades the use of the fundamental substances. Some make use of unique aggregates (light-weight mixture, metal fiber, plastic fiber, glass fiber, and unique heavy mixture). Some unique houses — improved compressive and tensile power, water proofing, and progressed chemical resistance are finished with polymers, both as admixtures or floor remedy of hardened concrete.

- Admixtures for coloring concrete are to be had in all colors. The oldest and most inexpensive is possibly carbon black. Admixtures inflicting growth to be used in sealing cracks or beneathneath gadget bases, etc., consist of powdered aluminum and finely floor iron.

- Special admixtures are to be had to be used wherein the herbal mixture is alkali reactive, to neutralize this reaction. Proprietary admixtures are to be had that growth the tensile power or bond power of concrete. They are beneficial for making maintenance to concrete surfaces.

- Self-compacting concrete (SCC) has many advantages in phrases of manufacturing and site in comparison to conventional concrete namely, removal of outside or inner vibration for compaction, higher flowability, workability and pumpability, in addition to accelerated bonding with congested reinforcement.

- Moreover, the location of SCC is quicker and calls for much less labour. The appearance (floor finish), mechanical overall performance and sturdiness of SCC may be drastically higher than conventional concrete. However, the techniques of manufacturing, placement, best manipulate and completing are crucial for SCC. Constructability troubles might also additionally rise up for specifiers and contractors if associated standards, suggestions or practices aren't correctly observed for manufacturing and site. Self-compacting concrete is much less tolerant to abrupt adjustments in combination moisture content, chemical admixtures and water content.

- The sort of concrete mixer, delivery time and the techniques of concrete placement and completing can have an effect on the residences of SCC. Therefore, strong best manipulate measures ought to be in region in the course of the manufacturing and site of SCC. The high-quality flowability of SCC in comparison to conventional concrete makes pumping the quality approach of placement.

- However, there may be a excessive hazard of air entrainment because of a better glide rate, which could bring about bugholes and segregation. Normally SCC has much less floor imperfections in comparison to conventional concrete, however it'd be prone to bugholes, honeycombing and cracking if suggestions of manufacturing and site had been now no longer observed correctly.

- High-overall performance concrete (HPC) is concrete that has been designed to be greater long lasting and, if necessary, more potent than traditional concrete.

- HPC combinations are composed of basically the equal substances as traditional concrete combinations, however the proportions are designed, or engineered, to offer the energy and sturdiness wished for the structural and environmental necessities of the project. High-energy concrete is described as having a specific compressive energy of 8000 psi (fifty five MPa) or greater. The price of 8000 psi (fifty five MPa) became decided on as it represented a energy stage at which unique care is needed for manufacturing and trying out of the concrete and at which unique structural layout necessities can be wished.

- A concrete combination which has excessive workability, excessive energy, excessive modulus of bodily property, excessive density, excessive dimensional stability, low permeability and resistance to chemical assault is typically stated to be excessive overall performance concrete.

- The American Concrete Committee on High Performance Concrete consists of the subsequent six criteria:

Ease of placement

Long time period mechanical properties

Early-age energy

Toughness

Life in extreme environments

- Definition: a popular time period for a composite fabric comprising a polymer matrix bolstered with fibers withinside the shape of fabric, mat, strands, or some other fiber shape.- ACI Concrete Terminology

- Fiber-Reinforced Polymer (FRP) substances are composite substances that generally encompass robust fibers embedded in a resin matrix. The fibers offer energy and stiffness to the composite and typically deliver maximum of the carried out loads.

- The matrix acts to bond and guard the fibers and to offer for switch of strain from fiber to fiber via shear stresses. The maximum not unusualplace fibers are glass, carbon, and artificial fibers. FRP composites have very excessive energy traits and are nonconductive, noncorrosive, and lightweight.

- Fibre-bolstered polymer (FRP), additionally Fibre-bolstered plastic, is a composite fabric made from a polymer matrix bolstered with fibres. The fibres are commonly glass, carbon, or aramid, even though different fibres which includes paper or timber or asbestos were once in a while used. The polymer is commonly an epoxy, vinylester or polyester thermosetting plastic, and phenol formaldehyde resins are nevertheless in use.

- FRPs are generally used withinside the aerospace, automotive, marine, and creation industries. Composite substances are engineered or obviously taking place substances crafted from or extra constituent substances with considerably distinct bodily or chemical residences which continue to be separate and wonderful in the completed structure.

- Most composites have strong, stiff fibres in a matrix that's weaker and much less stiff. The goal is commonly to make a factor which is robust and stiff, frequently with a low density. Commercial fabric generally has glass or carbon fibres in matrices primarily based totally on thermosetting polymers, which includes epoxy or polyester resins. Sometimes, thermoplastic polymers can be preferred, because they're moldable after preliminary production.

- There are in addition instructions of composite wherein the matrix is a steel or a ceramic.

- For the maximum part, those are nevertheless in a developmental stage, with issues of excessive production charges but to be overcome . Furthermore, in those composites the motives for including the fibres (or, in a few cases, particles) are frequently alternatively complex; for example, upgrades can be sought in creep, wear, fracture toughness, thermal stability, etc .

- Fibre bolstered polymer (FRP) are composites utilized in nearly each kind of superior engineering structure, with their utilization starting from aircraft, helicopters and spacecraft thru to boats, ships and offshore systems and to automobiles, sports activities goods, chemical processing system and civil infrastructure which includes bridges and buildings.

- The utilization of FRP composites keeps to develop at an excellent price as those substances are used extra of their present markets and end up mounted in tremendously new markets which includes biomedical gadgets and civil structures.

- A key thing using the elevated packages of composites over the latest years is the improvement of latest superior types of FRP substances. This consists of tendencies in excessive overall performance resin structures and new forms of reinforcement, which includes carbon nanotubes and nanoparticles.

- Ferrocement or ferro-cement is a machine of production the usage of bolstered mortar or plaster (lime or cement, sand, and water) carried out over an "armature" of metallic mesh, woven, accelerated metallic, or metallic-fibers, and carefully spaced skinny metallic rods including rebar.

- The metallic generally used is iron or a few sort of metallic, and the mesh is made with cord with a diameter among 0.five mm and 1 mm. The cement is generally a completely wealthy blend of sand and cement in a 3:1 ratio; whilst used for making boards, no gravel is used, in order that the fabric isn't always concrete. Ferrocement is used to assemble fairly skinny, hard, sturdy surfaces and systems in lots of shapes including hulls for boats, shell roofs, and water tanks.

- Ferrocement originated withinside the 1840s in France and the Netherlands and is the foundation of bolstered concrete. It has a huge variety of different uses, inclusive of sculpture and prefabricated constructing components. The term "ferrocement" has been carried out via way of means of extension to different composite materials, inclusive of a few containing no cement and no ferrous fabric.

- Shotcrete, gunite or sprayed concrete is concrete or mortar conveyed via a hose and pneumatically projected at excessive pace onto a surface, as a production technique, first utilized in 1907 invented through Carl Akeley.

- It is generally strengthened through traditional metal rods, metal mesh, or fibers. Shotcrete is normally an all-inclusive time period for each the moist-blend and dry-blend variations invented through Carl Akeley.

- In pool production, however, shotcrete refers to moist blend and gunite to dry blend. In this context, those phrases aren't interchangeable. Shotcrete is located and compacted/consolidated on the identical time, because of the pressure with which it's miles ejected from the nozzle. It may be sprayed onto any kind or form of surface, consisting of vertical or overhead areas.

- Shotcrete, then called gunite, became invented in 1907 through American taxidermist Carl Akeley to restore the crumbling façade of the Field Columbian Museum in Chicago (the vintage Palace of Fine Arts from the World's Columbian Exposition).

- He used the technique of blowing dry fabric out of a hose with compressed air, injecting water on the nozzle because it became released. In 1911, he became granted a patent for his innovations, the "cement gun", the gadget used, and "gunite", the fabric that became produced.

- There isn't anyt any proof that Akeley ever used sprayable concrete in his taxidermy paintings, as is from time to time suggested. F. Trubee Davison blanketed this and different Akeley innovations in a unique problem of Natural History magazine.

- The dry-blend technique became used till the wet-blend technique became devised withinside the 1950s. In the 1960s, an opportunity technique for gunning dry fabric with a rotary gun appeared, the usage of a constantly fed open hopper.

- The nozzle is managed through hand on small jobs, inclusive of a modest swimming pool. On large paintings it's miles connected to mechanical palms and operated through handheld far flung control.

- Volume adjustments can arise in concrete at some point of the primary 24 hr and are commonly neglected in laboratory shrinkage evaluations. Unfortunately those early age extent adjustments are found in actual pavements and systems and may make contributions to the cracking conduct of the concrete at later ages.

- Early age extent adjustments can arise in forms: drying shrinkage earlier than the begin of curing and autogenous extent adjustments. Although those early age extent adjustments are frequently brushed off as being insignificant, latest paintings in Europe has diagnosed magnitudes for early age extent adjustments of a few concretes which can be same to or more than 28-day drying shrinkage measurements.

- Expansions have additionally been diagnosed in a few cases. The outcomes of a few investigations of extent adjustments in concrete at some point of the primary 24 hr beneathneath each drying and nondrying situations are presented.

- An instance of ability long-time period cracking beneathneath in part constrained situations (concrete slab-on-grade modeled via way of means of a concrete ring forged round a hole metallic ring) is used to demonstrate the significance of impact of early age extent adjustments on concrete cracking. Both take a look at approaches appoint nonstandard techniques to quantify the cracking ability of concrete.

- Drying shrinkage is a result of lack of moisture from hardened concrete to the environment. Due to the emptying of the satisfactory pores withinside the concrete, terrible capillary stress develops, which reasons a quantity discount of the concrete.

- If the concrete shrinkage is confined, tensile stresses broaden withinside the concrete (confined shrinkage).

- When the tensile stresses grow to be better than the tensile electricity of the concrete, cracks are generated. Cracks have a sizable effect at the sturdiness of a strengthened concrete member, considering they facilitate the ingress of dangerous substances.

- Shrinkage is an inherent asset of concrete. Shrinkage is as a result of the modifications in quantity both autogenous or caused and is one of the maximum negative homes of concrete affecting the aesthetics, strength, and sturdiness of systems because it usually finally ends up in cracks.

- It is virtually hard to make concrete which does now no longer cut back and crack, without the software of specialised components like shrinkage compensating admixtures and fibers.

- Hence, minor cracks are usually predicted and are best a query of the significance of the cracks. Shrinkage is assessed into plastic shrinkage, autogenous shrinkage, drying shrinkage and carbonation shrinkage and this text concentrates at the plastic shrinkage and its underlying mechanism. According to ACI 305R:

- “Plastic shrinkage cracking is regularly related to warm climate concreting in arid climates. It happens in uncovered concrete, broadly speaking in flat paintings however additionally in beams and footings and can broaden in different climates every time the evaporation charge is extra than the charge at which the water rises to the floor of lately positioned concrete through bleeding”.

- Plastic shrinkage develops because of the fast lack of moisture from the concrete floor because of evaporation or absorption through subgrade. Concrete usually bleeds however maximum of the time in a well-proportioned combination it now no longer seen and measurable.

- Bleeding is because of self-weight consolidation of solids withinside the sparkling concrete below gravity, because of their better density as compared to that of pore water. When the evaporation charge exceeds the bleeding charge, the water saturation degree sinks under the concrete floor degree, developing a capillary region of low pressure, and leaving the floor dry which ends up in shrinkage and next cracking.

- Hence, concrete made micro silica is pretty liable to plastic shrinkage cracking because it does now no longer bleed and precise interest is needed to keep away from floor drying at some stage in placement.

- The mechanism at the back of the shrinkage and shrinkage cracking isn't as easy as precise above. In order to apprehend it, we ought to begin with the fundamental homes of water like floor tension, cohesion, adhesion and capillarity.

- Cement Content:

As a popular rule, the growth withinside the richness of concrete blend which results in drying shrinkage.

- Water Content:

Briefly, it may be stated that the extra the water amount used withinside the concrete blend, extra is the shrinkage. Thus a moist blend has greater shrinkage than a dry blend that's in any other case similar.

- Aggregate:

By the use of the biggest feasible most length of aggregates in concrete and making sure top grading, the requirement of water for the preferred workability is decreased and urban consequently received has much less shrinkage due to discount withinside the porosity of the hardened concrete.

- Curing:

Curing additionally performs a critical component in restricting shrinkage. If right curing is began out as quickly because the preliminary set has taken vicinity and it's far endured for as a minimum 7-10 days shrinkage is relatively much less.

- Presence of Excessive Fines in Aggregates:

The presence of immoderate fines which include silt, clay, and dirt in aggregates has a tremendous impact at the volume of shrinkage in concrete. Presence of fines will increase particular floor vicinity of combination and therefore the water requirement.

- Chemical Composition of Cement:

The chemical composition of cement used for concrete & mortar additionally has a few impact on shrinkage. Rapid hardening cement has extra shrinkage than Ordinary Portland Cement.

- Temperature:

A critical element which impacts the water requirement of concrete and consequently its shrinkage is the temperature of sparkling concrete. Concreting executed in slight wintry weather have tons much less cracking tendency than the concreting executed in warm summer time season months.

- Humidity:

The volume of shrinkage additionally relies upon at the relative humidity of ambient air. Thus, shrinkage is tons much less in coastal regions wherein relative humidity stays excessive all through the year. Low relative humidity may additionally motive plastic shrinkage in concrete.

- Curing situations have an effect on significantly the very last enlargement due to the fact water is in reality essential to attain an enlargement.

- Therefore, to be able to completely broaden the capability of enlargement, it's miles essential to offer curing situations that offer enough water curing. Figure 22.nine gives the restricted enlargement of concretes having a water–binder ratio (w/b) same to 0.38 containing, respectively, 16% of a calcium sulphoaluminate-primarily based totally expansive agent (a) and 8% of a calcium-oxide primarily based totally expansive agent (b) (Bissonnette et al., 2014). A first collection of concrete became cured at 100% relative humidity (RH) at some point of 7 days and afterward at 50% RH.

- A 2nd collection of concrete became cured in air after the demolding simply 6 h after their casting.

- The have an effect on of the curing on expansive reactions really seems for the 2 sorts of expansive agents.

- For the calcium sulphoaluminate-primarily based totally expansive agent, the absence of water curing (curing in air) did now no longer produce nearly any enlargement.

- For the calcium-primarily based totally expansive agent, the absence of water curing produced an enlargement, however it became best same to 30% of the enlargement received below water curing.

- The non-uniform moisture distribution in concrete reasons the differential drying shrinkage. From this form of differential drying shrinkage, tensile pressure happens at the uncovered floor of concrete systems and can bring about crack formation.

- This residual pressure is appreciably stricken by the creep of concrete. In this study, for the reason of predicting the differential drying shrinkage, the evaluation approach became suggested, wherein the creep of concrete became additionally considered. In addition, the differential drying shrinkage pressure became measured at numerous positions in concrete through the use of embedded pressure gauges.

- The inner drying shrinkage pressure differs appreciably in step with the intensity from uncovered floor.

- Carbonation shrinkage takes place while the concrete is uncovered to air containing carbon dioxide. When the hardened concrete is uncovered to this sort of air, the load increases, and the concrete undergoes irreversible carbonation shrinkage.

- The carbonation shrinkage can be as awesome because the shrinkage because of air drying at seventy tiers Fahrenheit, fifty- percentage relative humidity, and a saturated condition.

- The carbonation method proceeds slowly and generally produces small shrinkage at relative humidities beneath twenty 5 percentage, or close to saturation. The most impact of carbonation takes area while the concrete is in a dry surroundings with a relative humidity of approximately fifty percentage. Carbonation in freshly located concrete generally takes place while the concrete is located in bloodless climate situations that use unvented fueloline heaters.

- When the carbon monoxide reacts with the clean concrete close to the surface, it produces a soft, chalky surface, generally 0.00254 to 0.00762 meters thick.

- Creep may be described because the elastic and long-time period deformation of concrete below a non-stop load. Generally, a long time stress modifications the form of concrete shape and the deformation takes place alongside the course of the carried out load.

- When the non-stop load is removed, the pressure is reduced immediately. The quantity of the reduced pressure is same to the elastic pressure on the given age. This brief healing is then accompanied through a non-stop lower in pressure, called creep healing this is part of general creep pressure suffered through the concrete.

- Creep Coefficient: The ratio of the closing creep pressure to the elastic pressure on the age of loading is named as creep coefficient.

- Factors Affecting Creep Of Concrete: The elements that have an effect on creep of concrete are much like the elements affecting shrinkage that are as following:

1. Water-cement Ratio: The fee of creep is accelerated with growing water cement ratio.

2. Humidity: It is motivated through humidity and drying circumstance of the atmosphere.

3. Age Of Concrete: The fee of creep swiftly decreases with time. The time taken through a concrete shape to attained creep is five years.

4. Aggregate: Aggregates with moisture motion and coffee elastic modulus motive a big quantity of creep.

- The fee of creep typically decreases with the boom of the scale of aggregates. Five. Admixtures: Some admixtures (specially accelerators) also are accountable for inflicting creep in concrete.

- When concrete is loaded, the shape undergoes elastic and inelastic deformations. Elastic deformations arise without delay after the concrete is subjected to a given load, in keeping with Hooke’s Law. Inelastic deformations boom with time because the concrete studies a sustained load.

- This inelastic deformation, additionally referred to as creep, will increase at a reducing charge in the course of the loading period. During the primary month of sustained loading, about one-fourth to one-1/3 of the final creep takes place. As time proceeds, generally one-1/2 of to three-fourths of the final creep happens in the course of the primary 1/2 of year.

- The quantity of creep that the concrete undergoes relies upon 1) the importance of the sustained loading, 2) the age and power of the concrete whilst the pressure is applied, and 3) the full quantity of time that the concrete is stressed.

- When the concrete is loaded, the specimen undergoes inner homes inclusive of closure of voids withinside the concrete, viscous waft of the cement-water paste, crystalline waft in aggregates, and water flowing out of the cement "gel" because of drying and loading.

- Aggregates play a vital position in each creep and shrinkage. A properly graded, coarser combination with a low voids content material decreases the results of creep and shrinkage. Also, hard, dense aggregates that aren't absorptive and feature a excessive modulus of elasticity are ideal for low shrinkage and creep rates.

- Another vital thing to decreasing creep is the kind of curing manner completed previous to loading. Very little creep happens whilst a excessive-strain steamed curing manner is used.

- Atmospheric and excessive-strain steam curing produces little creep whilst in comparison to the seven-day wet curing method. These styles of curing lessen the drying shrinkage through 1/2 of as tons as they lessen creep. Other elements affecting creep consist of kind of cement, quantity of cement paste, length and form of concrete, quantity of reinforcement (rebar), volume-to-floor ratio, temperature, and humidity.

Fig: Relation between time and creep

- Concrete creep is described as: deformation of shape beneathneath sustained load. Basically, long time strain or pressure on concrete could make it alternate shape. This deformation commonly takes place withinside the route the pressure is being implemented. Like a concrete column getting greater compressed, or a beam bending.

- Creep does now no longer always purpose concrete to fail or destroy apart. When a load is implemented to concrete, it stories a right away elastic stress which develops into creep stress if the burden is sustained. Aggregate undergoes little or no creep. It is truly the paste that is answerable for the creep. However, the combination affects the creep of concrete via a restraining impact at the importance of creep.

- The paste that is creeping beneathneath load is constrained with the aid of using combination which do now no longer creep. The more potent the combination the greater is the restraining impact and subsequently the much less is the importance of creep.

- A growth from sixty five to 75 % of volumetric content material of the combination will lower the creep with the aid of using 10 %. The modulus of elasticity of combination is one of the vital elements influencing creep. It may be without problems imagined that the better the modulus of elasticity the much less is the creep. Light weight combination indicates significantly better creep than everyday weight combination The quantity of paste content material and its fine is one of the maximum vital elements influencing creep. A poorer paste shape undergoes better creep.

- Therefore, it is able to be stated that creep will increase with growth in water/cement ratio. In different words, it is able to additionally be stated that creep is inversely proportional to the power of concrete. Broadly speaking, all different elements which can be affecting the water/cement ratio also are affecting the creep.

- Creep and shrinkage of concrete are bodily homes of concrete. The creep of concrete, which originates from the calcium silicate hydrates (C-S-H) withinside the hardened Portland cement paste (that's the binder of mineral aggregates), is essentially distinct from the creep of metals and polymers.

- Unlike the creep of metals, it happens in any respect strain ranges and, in the carrier strain range, is linearly depending on the strain if the pore water content material is constant.

- Unlike the creep of polymers and metals, it well-knownshows multi-months aging, due to chemical hardening because of hydration which stiffens the microstructure, and multi-yr aging, due to long-time period rest of self-equilibrated micro-stresses withinside the nano-porous microstructure of the C-S-H. If concrete is absolutely dried, it does now no longer creep, however it's far subsequent to not possible to dry concrete absolutely with out extreme cracking.

- Concrete creep is described as: deformation of shape below sustained load. Basically, long time stress or strain on concrete could make it extrade shape. This deformation commonly happens withinside the path the pressure is being implemented. Like a concrete column getting greater compressed, or a beam bending. Creep does now no longer always purpose concrete to fail or spoil apart.

- When a load is implemented to concrete, it reports a direct elastic stress which develops into creep stress if the burden is sustained.

References:

1. Concrete Technology by Gambhir Mc. Graw Hill

2. Concrete Technology by A.M. Neville Pearson Education

3. Properties of Concrete by A.M. Neville Pearson Education