Unit - 6

Fluid Machinery

TURBINES: Definition

Several bodily standards are hired through mills to acquire this power: Impulse mills alternate the course of waft of an excessive pace fluid or fuelling jet.

The ensuing impulse spins the turbine and leaves the fluid waft with faded kinetic power.

There isn't any strain alternate of the fluid or fuelling with inside the turbine blades (the transferring blades), as with inside the case of a steam or fuelling turbine, all of the strain drop takes vicinity with inside the desk bound blades (the nozzles). Before achieving the turbine, the fluid's strain head is modified to pace head through accelerating the fluid with a nozzle.

Pelton wheels and de Laval mills use this technique exclusively. Impulse mills do now no longer require a strain casement across the rotor for the reason that fluid jet is created through the nozzle previous to achieving the blades at the rotor. Newton's 2nd regulation describes the switch of power for impulse mills.

Impulse mills are maximum green to be used in instances in which the waft is low and the inlet strain is excessive. Reaction mills increase torque through reacting to the fuelling or fluid's strain or mass.

The strain of the fuelling or fluid modifications because it passes thru the turbine rotor blades. A strain casement is wanted to include the running fluid because it acts at the turbine stage(s) or the turbine have to be completely immersed with inside the fluid waft (along with wind mills).

The casing consists of and directs the running fluid and, for water mills, keeps the suction imparted through the draft tube. Francis mills and maximum steam mills use this concept.

For compressible running fluids, a couple of turbine ranges are typically used to harness the increasing fuelling efficiently. Newton's 1/3 regulation describes the switch of power for response mills.

Reaction mills are higher suitable to better waft velocities or packages in which the fluid head (upstream strain) is low. In the case of steam mills, along with might be used for marine packages or for land-primarily based totally strength generation, a Parsons-kind response turbine might require about double the wide variety of blade rows as a de Laval-kind impulse turbine, for the identical diploma of thermal power conversion.

Whilst this makes the Parsons Turbine lots longer and heavier, the general performance of a response turbine is barely better than the equal impulse turbine for the identical thermal power conversion.

In practice, present day turbine designs use each response and impulse standards to various stages on every occasion possible. Wind mills use an airfoil to generate a response carry from the transferring fluid and impart it to the rotor. Wind mills additionally advantage a few power from the impulse of the wind, through deflecting it at an angle.

Turbines with a couple of ranges can also additionally use both response and impulse blading at excessive strain. Steam mills have been historically extra impulse however hold to transport closer to response designs just like the ones utilized in fuelling mills.

At low strain the working fluid medium expands in extent for small discounts in strain. Under those conditions, blading will become strictly a response kind layout with the bottom of the blade completely impulse.

The motive is because of the impact of the rotation velocity for every blade. As the extent increases, the blade top increases, and the bottom of the blade spins at a slower velocity relative to the tip.

This alternate in velocity forces a fashion dressmaker to alternate from impulse at the bottom, to an excessive response-fashion tip.

Steam mills are used to pressure electric mills in thermal electricity plant life which use coal, gasoline oil or nuclear gasoline.

They have been as soon as used to without delay pressure mechanical gadgets which include ships' propellers (for instance the Turbine, the primary turbine-powered steam launch), however maximum such packages now use discount gears or an intermediate electric step, in which the turbine is used to generate electricity, which then powers an electric powered motor linked to the mechanical Turbo electric powered deliver equipment turned into in particular famous with inside the duration without delay earlier than and throughout World War II, in the main because of a loss of enough gear-slicing centers in US and UK shipyards. Aircraft fuelling turbine engines are now and again called turbine engines to differentiate among piston engines.

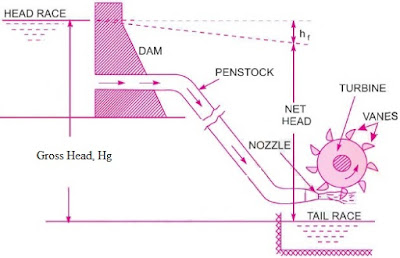

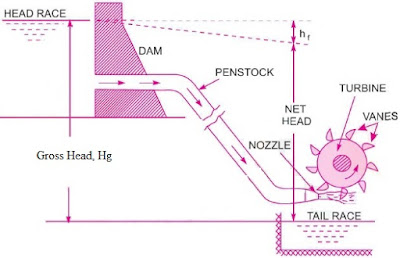

Gross and net heads

Now we can consciousness right here to apprehend a few critical terminologies related to a hydraulic turbine together with Gross head, Net head and efficiencies of a hydraulic turbine with the assist of this post. Will you be fascinated nowadays to discover those critical terminologies related to a hydraulic turbine? So allow us to begin right here with the subsequent critical terminologies

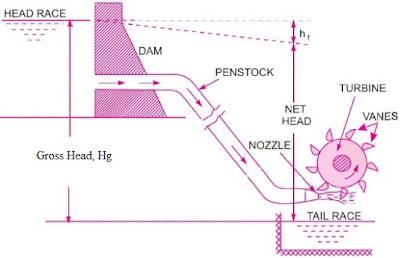

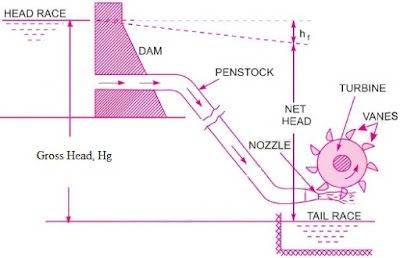

Gross Head

Gross head is largely described because the distinction among the pinnacle race stage and tail race stage whilst water isn't always flowing. Gross head may be indicated with the aid of using Hg as displayed right here in following figure.

Net Head

Net head is largely described as the pinnacle to be had on the inlet of the turbine. Net head is likewise in reality referred to as powerful head.

When water will waft from head race to the turbine, there may be a few losses of head because of friction among water and penstock.

There may also be different losses of head together with lack of head because of bend, fitting, at front of penstock etc. We should observe it right here that those losses may be very much less and will be left out whilst we evaluate with head loss because of friction.

Net head to be had on the inlet of turbine will be written as referred to right here.

Net head, H = Gross head (Hg) – head loss because of friction (hf) Loss of head because of friction may be given with the aid of using Darcy-Weisbach equation and we are able to discover it right here.

Different efficiencies

There are following crucial efficiencies that we are able to speak right here on this post.

Hydraulic performance

Mechanical Efficiency

Volumetric performance

Overall Efficiency

Hydraulic performance

Hydraulic performance is largely described because the ratio of electricity given with the aid of using water to the runner of turbine to the electricity provided with the aid of using the water on the inlet of the turbine.

Hydraulic performance may be indicated with the aid of using ηh.

Runner is largely a rotating element of a turbine and buckets or vanes may be constant on the circumference of the runner. Vanes or buckets constant at the runner aren't easy and therefore there may be hydraulic losses whilst water will waft thru those vanes of the turbine.

Therefore, electricity given with the aid of using water to the runner of the turbine may be much less than the electricity provided with the aid of using the water on the inlet of the turbine. Hydraulic performance of a turbine will be written as referred to right here

Hydraulic performance (ηh) = Power added to the runner of turbine / Power provided on the inlet of turbine

Hydraulic performance (ηh) = R.P/ W.P R.P = Power added to the runner of turbine

W.P = Power provided on the inlet of turbine or water electricity

Mechanical Efficiency

Mechanical performance is largely described because the ratio of electricity to be had on the shaft of the turbine to the electricity added to the runner of the turbine. Mechanical performance may be indicated with the aid of using ηm.

Power given with the aid of using water to the runner of turbine may be transmitted to the shaft of the turbine. Power to be had on the shaft of the turbine may be much less than the electricity added to the runner of the turbine because of mechanical losses.

Mechanical performance of a turbine will be written as referred to right here

Mechanical performance (ηm) = Power to be had on the shaft of the turbine / Power added to the runner of the turbine

Mechanical performance (ηm) = S.P/ R.P S.P = Power to be had on the shaft of the turbine R.P = Power added to the runner of turbine

Volumetric Efficiency

The quantity of the water placing the runner of a turbine may be barely much less than the quantity of the water provided to the turbine as a few quantity of water may be discharged to the tail race without placing the runner of the turbine.

Volumetric performance is largely described because the ratio of the quantity of the water honestly placing the runner of the turbine to the quantity of water provided to the turbine.

Volumetric performance may be indicated with the aid of using ηv.

Volumetric performance of a turbine will be written as referred to right here

Volumetric performance (ηv) = Volume of the water honestly placing the runner of the turbine / Volume of water provided to the turbine

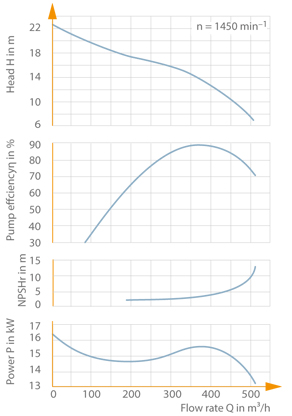

Overall Efficiency

Overall performance is largely described because the ratio of the electricity to be had on the shaft of the turbine to the electricity provided with the aid of using the water on the inlet of the turbine.

Overall performance may be indicated with the aid of using ηo.

Overall performance,

ηo = Power to be had on the shaft of the turbine / Power provided with the aid of using the water on the inlet of the turbine

Overall performance, ηo = S.P/W. P

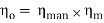

Overall performance is likewise described because the manufactured from mechanical performance and hydraulic performance

Overall performance = Mechanical performance x Hydraulic performance ηo = ηm x ηh

Classification of turbines

Types of Turbines Based on Energy Exchange among the water and the Machine

Considering how the fluid float acts at the turbine blades reasons hydro generators to be categorized into categories: impulse and response.

Impulse Turbines

If the turbine wheel is pushed through the kinetic electricity of the fluid that moves the turbine blades via the nozzle or otherwise, the turbine is called an impulse turbine. In those forms of generators, a hard and fast of rotating equipment operates at atmospheric stress. Impulse generators are commonly appropriate for excessive head and coffee float quotes.

Pelton, Turgo, and Cross-float generators are 3 forms of impulse generators. The production of the Pelton and Turgo generators is similar. However, the Cross-float turbine is a changed sort of impulse generators this is categorized as an impulse turbine because of the rotation of the runner at atmospheric stress and now no longer as a submerged turbine.

Reaction Turbines

If the sum of ability electricity and kinetic electricity of water which can be because of the stress and velocity, respectively reason the turbine blades to rotate, the turbine is classed as a response turbine. In those forms of generators, the whole turbine is immersed in water and adjustments in water stress in conjunction with the kinetic electricity of the water reason energy exchange. Applications of response generators are commonly at decrease heads and better float quotes than impulse generators.

The water passage via the turbine divides those generators into the subsequent 4 categories:

Radial Flow Turbine

These generators are divided into types: Inward radial float and outward radial float.

Inward Radial Flow Turbines

In those generators, water enters the turbine casing via the Penstock, and travels via the constant manual vanes to the rotor, and exits from there. Therefore, the internal and outer diameters are as the opening and the inlet, respectively. The Following determine suggests the course of the water in an inward radial float turbine. Water enters from the casing with inside the middle of the constant manual vanes.

Axial Flow Turbines

In this sort of turbine, the fluid flows parallel to the turbine shaft (turbine axis). Kaplan is this type of generators.

Mixed Flow Turbines

A turbine wherein the float enters the turbine radially and leaves it axially is a blended float turbine, like cutting-edge Francis generators.

Types of generators primarily based totally at the hydraulic running variety accordingly, water generators are of 3 categories:

Low Head Turbines

Hydraulic generators running with inside the head variety of fewer than forty five meters are taken into consideration low-head generators. Kaplan turbine is this type of generators. If the pinnacle is much less than three meters, it's far taken into consideration an ultra-low head.

Medium Head Turbines

The running variety for heads of forty five to 250 meters is called medium heads. Francis generators normally perform in such conditions.

High Head Turbines

With heads better than 250 meters are called excessive-head generators, Like the Pelton Turbine. In the determine beneath, you could see the running variety of various generators primarily based totally at the adjustments in head and float rate.Types of Turbines

Based on Specific Speed

The precise velocity of a turbine (denoted through Ns) is described as the velocity of a turbine with a geometrical similarity that could generate a unit of energy beneath a head unit. Based in this parameter, water generators are categorized into 3 classes:

Low Specific Speed Turbine

The values among 1 and 10 are low precise speeds. Impulse generators perform on this variety. For example, the Pelton turbine commonly operates at a selected velocity of approximately

Medium Specific Speed Turbine

Turbines that perform with inside the precise velocity variety of 10 to one hundred, along with Francis, have a medium precise velocity.

High Specific Speed Turbine

Specific speeds above one hundred are taken into consideration excessive values. Kaplan turbine works at an excessive precise velocity.

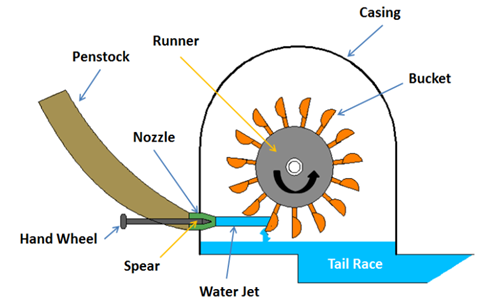

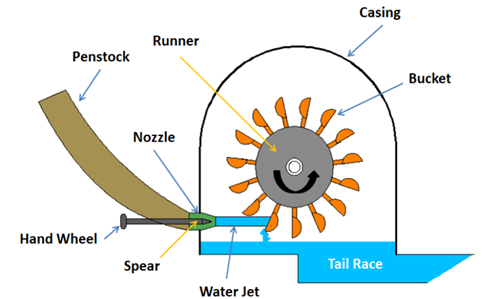

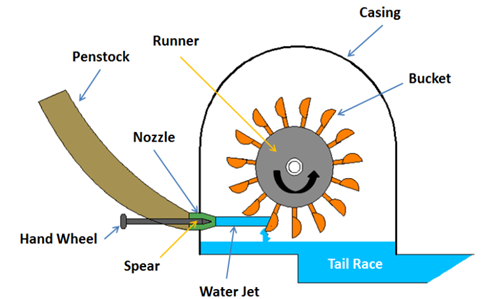

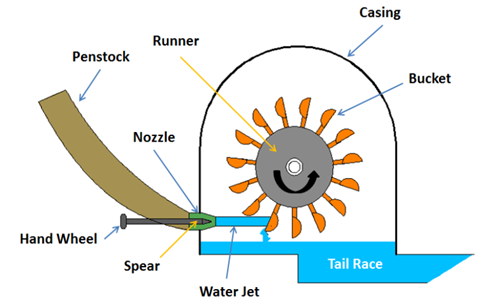

Component parts and working principles

Working Principle:

In those mills, the static stress in the runner is constant, and the turbine runner is at atmospheric stress.

The runner spins with inside the air, and the fluid is sprayed to the blades via the nozzle to change electricity with the turbine. A jet nozzle or a sequence of nozzles directs the excessive-velocity waft to the blades, which might be typically with inside the form of buckets or cups.

The software of the curved blades is to extrude the speed of the waft. This strike reasons a extrude in momentum and primarily based totally at the regulation of communique of electricity, a pressure is carried out to the turbine blades. .According to Newton’s 2nd regulation of movement, the pressure acquired via the movement of a fluid relies upon on factors: the mass of the fluid coming into the turbine and the adjustments in fluid speed among the turbine inlet and outlet.

Since no extrude in fluid mass occurs, most effective speed adjustments are taken under consideration in calculating the pressure carried out to the runner.

The saved water flows from a supply upstream via Penstock to be added to the nozzle. The capacity electricity of the water in the nozzle is transformed into kinetic electricity and injected into the blades or buckets; thus, the runner spins.

There is a mechanism to manipulate the waft of water injected into the runner. The spear typically performs a critical function on this procedure.

The generator connected to the shaft converts mechanical electricity into electric electricity. Impulse mills have the cap potential to take all of the kinetic electricity from the water for excessive efficiency.

Water is discharged into the environment from the lowest of the turbine housing after achieving the runner; therefore, there's no suction at the lowest of the turbine.

Here you may see schematically how an impulse turbine works with inside the procedure of extracting electricity from the kinetic electricity of water in addition to its additives.

Components of an Impulse Turbine

Impulse mills are composed of the subsequent additives.

Runner

The runner includes a round disk to which some of curved blades are connected and a cylindrical shaft with inside the center. Shafts and runners are typically product of chrome steel. In instances wherein the waft head is less, the runner is product of solid iron.

Buckets

Buckets are a fixed of spoon-fashioned cups which are hooked up across the runner to change electricity among the fluid and the turbine. The fluid jet hits those buckets after leaving the nozzle, making the turbine to rotate and exiting the outer fringe of the bucket.

The extrude with inside the course of the fluid in the course of the go out as compared to the perspective of effect varies relying at the layout of the turbine. To get the biggest momentum, this perspective need to be a hundred and eighty levels.

However, this perspective is restrained to angles of approximately a hundred and seventy levels because of concerns which include that the go out waft from one bucket does now no longer collide with the following bucket and does now no longer reason it to brake.

Nozzle

The nozzle is set up to alter and jet the fluid waft to strike the buckets. As stated earlier, it's miles the most effective a part of the impulse turbine meeting that the stress adjustments and the waft head are transformed into kinetic electricity.

The extent of water jet achieving the buckets is adjusted through an aspect referred to as a spear, that is a conical needle that actions inside and out of the nozzle through a hand wheel or automatically. By shifting this needle backward, the water waft increases, and through shifting forward, it decreases. The nozzle is usually crafted from tungsten carbide, which could be very difficult and may resist erosive particles.

Casing

The casing for an impulse turbine is a defend over the turbine to save you the water from splashing and additionally to manual it to the spillway, which exists for the greater water to guard the structural integrity of the dam. Normally, Cast iron is used to fabricate the casing.

Penstock

Penstocks in hydropower flowers are pipes and channels that deliver water from dams and reservoirs to mills. In general, they're product of steel. Water flows in those ducts beneath excessive pressures.

The discern under indicates the special additives of impulse mills and their positions. In addition to the principle additives stated above, a mechanism is typically used to save you the turbine from rotating.

When the water jet is stopped, the runner keeps to rotate because of the results of inertia.

In those instances, to save you this rotation, a jet of water is injected into the again of the buckets, that is referred to as a breaking jet.

Here you may schematically see how an impulse turbine works with inside the procedure of extracting electricity from the kinetic electricity of water in addition to its additives.

Selection of turbines on the basis of head and specific speed.

Initial turbine selection is usually based on the ratio of design variables known as the power specific speed. In U.S. Design practice this is given by

N = nP1/2 /H5/4

Wherein n is in revolutions in step with minute, P is the output in horsepower, and H is the pinnacle of water in ft. Turbine kinds may be categorized via way of means of their particular velocity, N, which usually applies on the factor of most performance.

If N stages from one to 20, similar to excessive heads and coffee rotational speeds, impulse mills are appropriate. For N among 10 and ninety, Francis-kind runners need to be selected, with slow-running, near-radial devices for the decrease N values and greater hastily rotating mixed-glide runners for better N values.

For N as much as 110, Deriaz mills can be suitable. If N stages from 70 to the most of 260, propeller or Kaplan mills are referred to as for. Using the particular velocity formula, a turbine designed to supply 100,000 horsepower (74, six hundred kilowatts) with a head of forty ft (12.2 meters) running at seventy two revolutions in step with minute could have a particular velocity of 226, suggesting a propeller or Kaplan turbine.

It also can be proven that the glide fee ought to be approximately 24,500 cubic ft in step with second (694 cubic meters in step with second) at a turbine performance of ninety percent.

The runner diameter can be approximately 33 ft (10 meters).

This illustrates the massive sizes required for excessive-power, low-head installations and the low rotational velocity at which those mills ought to function to live inside the permissible particular velocity range.

Before constructing massive-scale installations, the layout need to be looked at with turbine version tests, the usage of geometrically comparable fashions of small and intermediate size, all running on the identical particular velocity.

Allowances have to be made for the consequences of friction, decided via way of means of the Reynolds number (density × rotational velocity × runner diameter squared/viscosity) and for feasible adjustments in scaled roughness and clearance dimensions.

Friction consequences are much less essential for massive devices, which have a tendency to be greater green than smaller ones.

Key Takeaways:

- Water enters from the casing with inside the middle of the constant manual vanes.

- The running variety for heads of forty five to 250 meters is called medium heads. Francis generators normally perform in such conditions.

- Since no extrude in fluid mass occurs, most effective speed adjustments are taken under consideration in calculating the pressure carried out to the runner.

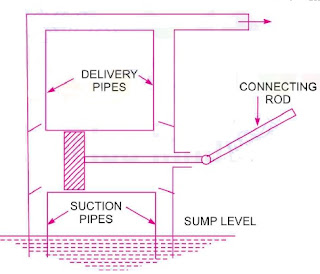

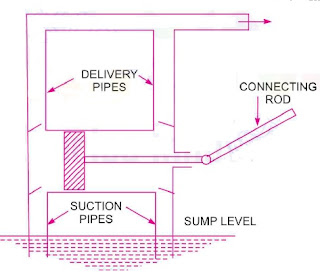

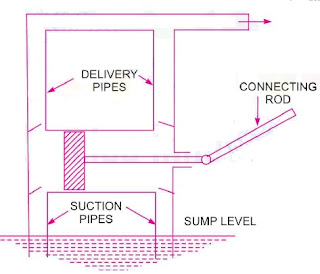

RECIPROCATING PUMPS, Components parts, working principle

Reciprocating pump is a tremendous displacement pump in which positive extent of liquid is accumulated in enclosed extent and is discharged the use of strain to the desired application.

Reciprocating pumps are extra appropriate for low volumes of waft at excessive pressures.

Components of Reciprocating Pump

The principal additives of reciprocating pump are as follows:

Suction Pipe

Suction pipe connects the supply of liquid to the cylinder of the reciprocating pump. The liquid is suck through this pipe from the supply to the cylinder.

Suction Valve

Suction valve is non-go back valve this means that simplest one directional waft is feasible on this kind of valve. This is located among suction pipe inlet and cylinder. During suction of liquid it's far opened and throughout discharge it's far closed.

Cylinder:

It is a whole cylinder fabricated from forged iron or metal alloy and it includes the association of piston and piston rod.

Piston and Piston rod:

For suction, the piston movements returned in the cylinder and for discharging of fluid, the piston movement’s with inside the ahead route. The Piston rod facilitates the piston to transport in a linear route i.e. both the ahead and the backward directions.

Crank and Connecting rod:

For rotation, the crank is attached to the strength supply like engine, motor, etc.

Delivery Pipe:

The characteristic of the transport pipe is to supply the water to the favored place from the cylinder.

Delivery valve:

Similar to the suction valve, a transport valve is likewise a Non-go back valve.

Working Principle of Reciprocating Pump:

When the strength deliver is given to the reciprocating pump, the crank rotates thru an electric powered motor. The attitude made with the aid of using the crank is answerable for the motion of the piston in the cylinder.

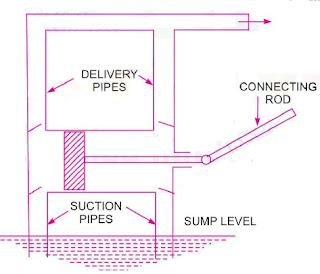

By regarding the above diagram, the piston movements closer to the intense left of the cylinder while the crank meets function A i.e. θ=zero.

Similarly, the piston movements closer to the intense proper of the cylinder while the crank meets the placement C i.e. θ=a hundred and eighty.

This is because of the presence of atmospheric stress at the sump liquid that is pretty much less than the stress in the cylinder. Therefore, because of the distinction in stress, the water enters into the cylinder thru a non-go back valve.

The water which remains with inside the extent of the cylinder must be dispatched to the release pipe thru discharge valve and this could be carried out while the crank is rotating from C to A i.e. (θ=a hundred and eighty to θ=360) which movements the piston with inside the ahead route.

Due to the motion of the piston in an ahead route, the stress will increase in the cylinder that is extra than the atmospheric stress. This consequences with inside the starting of the transport valve and last of the suction valve.

Once the water comes into the transport valve, it cannot flow returned to the cylinder due to the fact its miles a unidirectional valve or non-go back valve.

From there, it enters into the transport pipe in order that it could be dispatched to the specified function.

Therefore, on this way, the water is sucked and discharged from the sump to the favored place thru the piston in the cylinder.

Reciprocating Pump Advantages:

The benefits of Reciprocating Pump are as follows.

- It well-known shows a non-stop fee of discharge.

- It can paintings because of the linear motion of piston while the centrifugal pump works at the rotary pace of the impeller.

Reciprocating Pump Disadvantages:

The negative aspects of Reciprocating Pump are as follows.

- The protection price may be very excessive because of the presence of a huge wide variety of parts.

- The preliminary price of this pump is excessive.

- Flow fee is much less viscous fluids are tough to pump.

Applications of Reciprocating Pump:

The programs of Reciprocating Pump are as follows.

- Gas industries

- Petrochemical industries

- Oil refineries

- Vehicle water servicing facilities etc.

Work done of single & double acting pumps

Single acting pumps:

A pump is a tool that makes use of to switch distinctive fluids from one area to another. Pumps have a couple of kinds in keeping with distinctive applications. A reciprocating pump is a fava form of pump from the class of superb displacement pumps. In this article, we can deeply talk numerous elements of the reciprocating pump.

A reciprocating pump is a mechanical tool that modifications the mechanical strength of the fluid into hydraulic strength (strain strength). It makes use of a piston or plunger for pumping the fluid from one area to another. Because a reciprocating pump makes use of a piston or plunger for pumping purposes, therefore, it's also called a piston pump. In this pump, the piston reciprocates in an upward and downward role in the pump cylinder. As the piston actions in the direction of BDC, it sucks fluid at the same time as it pressurizes the fluid whilst it actions in the direction of TDC.

A hand pump is a maximum not unusual place instance of a reciprocating pump. A bicycle pump and syringe pump also are the maximum typically used examples of reciprocating pumps.

Slip in reciprocating pump is essentially described because the distinction among the theoretical discharge and real discharge of the reciprocating pump.

Actual discharge of a reciprocating pump might be much less than the theoretical discharge of the pump because of leakage of water in the course of operation of pump.

The distinction of the theoretical discharge and real discharge might be known as slip of reciprocating pump. Mathematically, we are able to explicit the slip in reciprocating pump as stated below

Slip = Qth – Qact

Slip is usually expressed as percentage slip and it will be given by following expression.

Percentage slip = (Qth – Qact)/Qth 100 = ( 1 – Qact/Qth) 100

= (1 – Cd) 100

Where, Cd = Co-efficient of discharge

Double acting pumps:

Water can be performing on each facet of the piston in case of double performing reciprocating pump as displayed right here in following figure.

Therefore, there can be suction and shipping pipes for double performing reciprocating pump as proven in following figure.

When there can be a suction stroke on one facet of the piston, identical time there can be a shipping stroke at the alternative facet of the piston.

Hence, in case of double performing reciprocating pump, there can be suction strokes and shipping strokes for one whole revolution of crank and water can be discharged via the shipping pipes at some stage in those shipping strokes.

Let us consider the following terms as mentioned below

D = Diameter of the piston

d = Diameter of the piston rod

Area on one side of the piston, A = (π/4) x D2

Area on other side of the piston where piston rod is connected with piston, A1 = (π/4) x [D2 -d2]

Work done by double acting reciprocating pump

Work done per second = Weight of water delivered x total height

Work done per second = 2g ALN/60 (hs + hd)

Negative slip

As we've got mentioned above that slip in reciprocating pump is essentially the distinction among the theoretical discharge and real discharge of the reciprocating pump.

If real discharge is greater than the theoretical discharge, slip of the reciprocating pump might be poor and it is able to be concluded via way of means of thinking about the equation of slip of reciprocating pump.

Negative slip will arise while suction pipe is long, shipping pipe is brief and pump is jogging at excessive speed.

So, we've got visible in short describe the reciprocating pump and essentially we've got mentioned right here the slip and poor slip in reciprocating pump.

You need to additionally discover the diverse critical posts as noted under and those are pretty critical and beneficial and consequently you ought to see those posts.

Positive and poor outcomes of friction, classifications of friction, coulomb's regulation of dry friction, a few tips for fixing frictional problems, idea of rolling resistance or rolling friction, wedge friction and idea of self- locking and the minimal preventing distance for a vehicle.

This is normally because of beginning and remaining of suction and transport valves because of water inertia. Please refer beneath photograph at the same time as studying in addition explanation.

Imagine End of suction inventory. Liquid is transferring (rushing) in the cylinder as piston is transferring outward (right here on this photograph proper facet of photograph).

As piston cannot circulate in addition as it’s already on its severe position, water will hammer transport valve. If this water hammer has sufficient pressure to raise transport valve than a few quantity of liquid will move in transport line

Before transport inventory commence. Due to this phenomena, transport inventory will throw more extent of liquid than swept extent of pump.

Air vessels – Working principle and necessity

Air vessel is a robust closed vessel as proven in figure. The pinnacle 1/2 of consists of compressed air and the decrease element consists of water or the fluid being pumped.

Air and water are separated via way of means of a bendy diaphragm which can move up or down relying at the difference in strain between the fluids.

The air charged at close to total transport strain/suction strain from the pinnacle and sealed. The air vessel is attached to the pipe traces very close to the pump, at almost the pump level.

On the transport aspect, whilst at the start and as much as the center of the transport stroke the top equals hs + hf + ha, better than the static and friction heads.

At this time a part of the water from pump will circulate the air vessel and the last will glide thru the transport pipe.

This will growth the compressed air strain. At the center stroke role the top can be enough to simply reason glide.

The entire of the glide from pump will guide to the transport pipe. At the second one 1/2 of the stroke the top can be identical to hs + hf - ha. At the placement the top can be now no longer enough to reason glide.

The compressed air strain will act at the water and water charged in advance into the air vessel will now glide out. Similar scenario prevails at the suction aspect.

At the begin and as much as the center of the suction stroke the top on the pump is better than static suction head via way of means of the quantity of acceleration head. The glide can be greater and component will circulate the air vessel.

The 2d 1/2 of the stroke water will glide out of the air vessel. In this system the rate of water with inside the transport pipe past the air vessel is uniform, and decrease than the most speed if air vessel isn't always fitted.

Necessity:

To stable the non-stop waft of liquid with uniform price of waft

To shop the suction and discharge pipe

To shop the significant quantity of labor in overcoming the frictional resistance with inside the suction and transport pipes

To run the reciprocating pump at an excessive velocity without separation

Working Principle:

Air vessel acts at the equal precept on the premise of which hydraulic accumulator and flywheel work.

When liquid will waft in to the vessel, air containing on the pinnacle of the chamber of air vessel could be compressed and whilst liquid will waft out from the vessel, air containing on the pinnacle of the chamber of air vessel could be expanded.

At begin of suction stroke of reciprocating pump or at some stage in first 1/2 of suction stroke, acceleration head could be most and therefore extra water could be required via suction pipe at some stage in beginning of suction stroke.

At the quilt of suction stroke, there could be retardation and therefore much less water could be required via the suction pipe and therefore extra water will waft to the air vessel and air vessel will save the power in phrases of water with the aid of using compressing the air contained with inside the pinnacle.

This saved power of air vessel could be applied at some stage in the begin of subsequent suction stroke.

At begin of transport stroke of reciprocating pump or at some stage in first 1/2 of transport stroke, acceleration head could be most and therefore extra water could be discharged to transport pipe of reciprocating pump at some stage in beginning of transport stroke.

In that case, extra water will waft to the air vessel and air contained above the water with inside the pinnacle of chamber could be compressed or we will say that power could be saved with inside the air vessel.

At the quilt of transport stroke, there could be retardation and therefore much less water could be discharged via the transport pipe and therefore extra water could be given with the aid of using the air vessel and air vessel will launch the power in phrases of water with the aid of using increasing the air contained with inside the pinnacle of the chamber.

Therefore, we've got visible right here the simple precept of air vessel in reciprocating pump and we've got additionally visible right here that how air vessel enables to preserve the uniform discharge with inside the operation of reciprocating pump.

Key Takeaways:

- Suction valve is non-go back valve this means that simplest one directional waft is feasible on this kind of valve. This is located among suction pipe inlet and cylinder.

- When there can be a suction stroke on one facet of the piston, identical time there can be a shipping stroke at the alternative facet of the piston.

- Before transport inventory commence. Due to this phenomena, transport inventory will throw more extent of liquid than swept extent of pump.

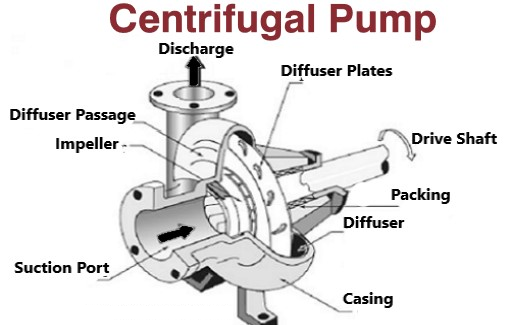

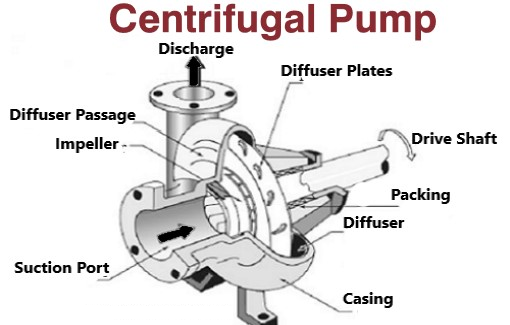

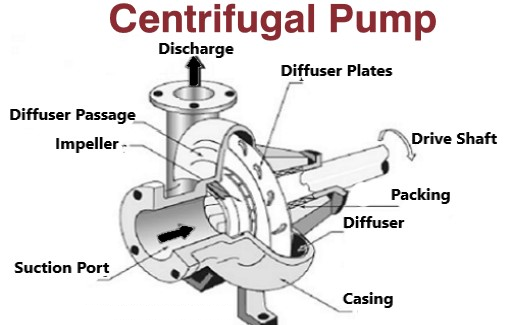

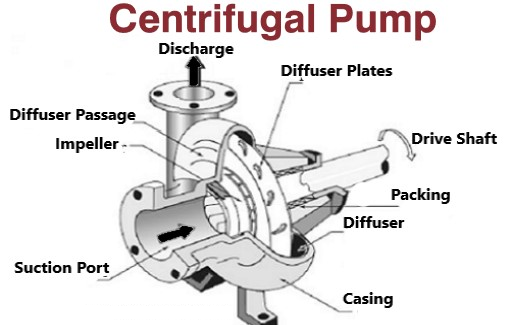

A. CENTRIFUGAL PUMP: Component parts; Working principle

The go with the drift of liquid takes vicinity in radial outward path that's opposite of the inward radial go with the drift response turbine. It is utilized in distinct regions in which fluid is wanted to higher from low degree to excessive degree.

Working Principle

It works at the precept of compelled vortex go with the drift. The compelled vortex go with the drift method while a sure mass of fluid or liquid is authorized to rotate through an outside torque than there's a upward thrust in stress head of the rotating liquid takes vicinity.

This upward thrust in stress head is used to supply water from one area to another. It is centrifugal pressure appearing at the fluid that makes it to go with the drift with inside the casing.

The upward thrust with inside the stress head of the rotating liquid at any factor is immediately proportional to the rectangular of the tangential speed of the rotating liquid.

Main Parts

The numerous predominant components of a centrifugal pump are:

Impeller

Casing

Suction pipe with a foot valve and strainer

Delivery pipe

Let’s speak approximately every one in every of them one through one

1. Impeller

It is the rotating a part of the pump. The impeller is set up on a shaft and the shaft of impeller is once more linked with the shaft of an electric powered motor. It is turned around through the motor and includes collection of backward curved blades.

2. Casing

It is an air tight passage which surrounds the impeller. The layout of the casing is executed in this kind of manner that its miles able to changing the kinetic electricity of the water discharging from the hole of the impeller into stress electricity earlier than it leaves the casing and enters into the shipping pipe.

Commonly 3 kinds of casing are utilized in centrifugal pump and those are

(i). Volute Casing: It is a spiral form of casing wherein the location of go with the drift will increase steadily. The boom in location of go with the drift decreases the rate and will increase the stress of the liquid that flows via the casing. The volute casing is proven in discern above:

(ii). Vortex Casing: In vortex casing, a round chamber is brought in among the impeller and casing. This is executed so that you can save you the lack of electricity because of formation of eddies. The performance of the vortex casing is extra than that of the volute casing.

(iii). Casing with Guide Blades: In this casing, the impeller is surrounded through collection of manual blades. The manual blades are set up on a hoop that's known as diffuser.

The layout of the manual vanes are saved as such that the water that's leaving the impeller enters the publications without shock. The location of the manual vanes will increase; this facilitates to lower the rate of the liquid and will increase its stress. After manual vanes, water passes via the encircling casing.

In maximum of the cases, the casing stays concentric with the impeller.

3. Suction Pipe with Foot Valve and Strainer

A pipe whose one stop is hooked up with the inlet of the impeller and the opposite stop is dipped into the sump of water is known as suction pipe. The suction pipe includes a foot valve and strainer at its decrease stop. The foot valve is a one manner valve that opens with inside the upward path. The strainer is used to clear out the undesirable particle gift with inside the water to save you the centrifugal pump from blockage.

4. Delivery Pipe

It is a pipe whose one stop is hooked up to the hole of the pump and different stop is hooked up to the desired top in which water is to be delivered

Static and monomeric heads

The static head, from time to time called the stress head, is a time period on the whole utilized in Hydraulics to indicate the static stress in a pipe, channel, or duct flow. It has the bodily dimensions of length (therefore the time period "head") and represents the flow-paintings in line with unit weight of fluid. In exercise the static head is equal to the vertical distance from a given stream tube to the piezometric head line or the hydraulic gradient line.

If P is the stress in a stream tube, the static head is described via way of means of P/ρg. Using this definition it's far obvious that during an open channel flow, wherein the stress is believed to be hydrostatic, the static head is the space from the stream tube to the water surface.

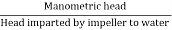

Monomeric heads

A centrifugal pump is a device which converts the kinetic strength of the water into strain strength earlier than the water leaves its casing. The glide of water leaving the impeller is unfastened vortex.

The impeller of a centrifugal pump may also have volute casing, vortex casing and volute casing with manual blades.

Blades. The following crucial factors can be mentioned for centrifugal pumps:

(a) The monomeric head is the real head of water in opposition to which a centrifugal pump has to work. It can be received with the aid of using the use of the subsequent relations, i.e.

Monomeric head = Work done in keeping with kg of water - Losses with inside the impeller

= Energy in keeping with kg at outlet of impeller - Energy in keeping with kg at inlet of impeller

= Suction lift + Loss of head in suction pipe because of friction + Delivery lift + Loss of head in shipping pipe because of friction + Velocity head with inside the shipping pipe.

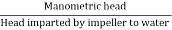

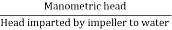

Different efficiencies

Efficiency of a centrifugal pump is 3 types.

1) Monomeric performance (ηman)

2) Mechanical performance (ηm)

3) Overall performance (ηo)

In a centrifugal pump, Power is transmitted from the shaft of the electrical motor to the shaft of the pump after which to the Impeller and from the Impeller the energy is given to the water. So energy is reducing from the shaft of the pump to the Impeller after which to the water. Read paintings achieved with the aid of using a centrifugal pump on water. In this page, we can speak the 3 kinds of performance of a centrifugal pump.

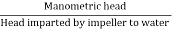

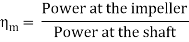

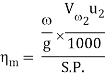

1) Monomeric performance ( ηman ): The energy on the Impeller of the pump is extra then the energy given to the water at outlet of the pump. The ratio of the energy given to water at outlet of the pump to the energy to be had on the impeller is called monomeric performance. Mathematically, monomeric performance system is written as:

ηman =

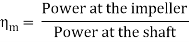

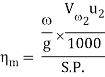

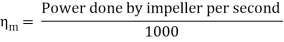

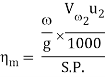

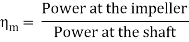

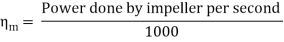

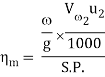

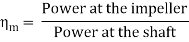

2) Mechanical performance ( ηm ):

Mechanical performance of a centrifugal pump is the ratio of the energy to be had on the impeller to the energy on the shaft of the centrifugal pump. The energy on the shaft of the centrifugal pump is extra than the energy to be had on the impeller of the pump.

Mathematically, mechanical performance system is written as: mechanical performance system of centrifugal pump

The energy on the impeller in kW

The power at the impeller in kW

Where S.P. = Shaft power

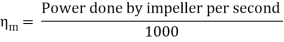

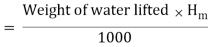

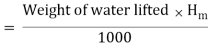

3) Overall performance ( ηo ):

Overall performance of a centrifugal pump is the ratio of the energy output of the pump to the energy enter to the pump. The energy output of the pump in kW

Power input to the pump = Power supplied to the electric motor = S.P. Of the pump

B. Priming & priming devices

Priming perhaps performed manually or automatically. Not all pumps require priming however normally do.

There are Self-Priming Pumps and additionally a few format conditions in which priming isn't required. Same may be mentioned in this text because it progresses.

Priming a pump might be the primary and one of the maximum essential issue one have to do earlier than working it. Not priming a pump or now no longer doing it nicely makes majority of pump problems.

Any hassle in pump because of loss of priming can also additionally reason monetary effect because of pump protection and the downtime of piping machine because of a malfunctioning pump.

Why Priming is required? Priming reduces the threat of pump harm at some point of begin-up because it prevents the pump impeller to turns into gas-sure and consequently incapable of pumping the preferred liquid.

For dependable operation, pumps should first be primed; this is, air or gases to be expelled from the suction and impeller eye location and changed with liquid to be pumped. The pump could now no longer characteristic nicely whilst now no longer absolutely full of liquid.

Along with compromised performance, now no longer priming the pump and allowed to run without fluid, it's going to overheat the pump machine and there may be a threat of harm to essential inner pump components. Centrifugal Pumps are designed to pump drinks now no longer gases.

Centrifugal Pump cannot suck the liquid, however it pushes the liquid from suction to discharge. Due to stress distinction created with the aid of using the liquid driven to the release with an extra push on liquid from the atmospheric stress with inside the garage tank linked to pump suction piping, greater liquid input with inside the suction facet of pump supplied suction line is absolutely full of liquid (primed).

Its form of that pushes the liquid out and pulling impact isn't so prominent. During the begin up of the pump if any air pocket is gift on the suction facet, then pump will push the air.

As an end result air gift with inside the suction facet will try and increase and it's going to block the liquid from getting into the centrifugal pump.

As an end result air gift with inside the suction facet will try and increase and it's going to block the liquid from getting into the centrifugal pump. Also defined in different words, in Centrifugal Pump the pinnacle evolved (in meters of liquid this is pumped) relies upon at the velocities decided with the aid of using diameter of the impeller and the impeller speed (rpm.).

As the stress evolved is associated with the pinnacle with the aid of using the equation head = pr / sp. Weight, the stress to be had may be proportional to the particular weight of the liquid.

This method that the stress (or stress distinction) created with air may be simplest round 1/800 instances that with water (density of water = a thousand kg/ m3 and dry air at S.T.P has a density of 1.2 kg/m3).

Therefore, if the pump isn't primed, the suction stress created will now no longer be enough to raise water. Whereas in Positive Displacement Pump, at some point of suction phase, piston actions backward and shape a low stress area withinside the pump. This stress distinction among suction & garage tank is massive sufficient to drag the liquid, although air pocket is gift withinside the suction line. In short, it creates a excessive preliminary vacuum at some point of the begin of suction stroke.

Positive displacement pumps can evacuate all of the air in its cylinder with the aid of using distinctive feature of its movement and consequently a higher stress (vacuum) is likewise generated. So we want now no longer have priming operation in nice displacement pumps.

Priming with Separator

In this approach of pump priming, air-water separation chamber is furnished at the shipping facet of pump and a dishonest suction pipe component is furnished on the inlet of the pump.

The air escapes via the pump discharge nozzle even as the fluid drops go into reverse and is all over again entrained with the aid of using the impeller. The suction line is for that reason constantly evacuated. This layout has predominant drawbacks.

Priming with Ejector

In this approach of pump priming, ejector is furnished at the suction facet of pump.

Ejectors require a Compressed Air Supply as a strength input. Priming with the aid of using Installing Foot Valve In this approach of pump priming, a foot valve (functioning as a NRV) is mounted with inside the suction piping to insure that the liquid will now no longer drain from the pump casing and suction piping as soon as the pump stops operating.

A foot valve is a shape of take a look at valve mounted on the bottom, or foot, of a suction line. When the pump stops and the ports of the foot valve close, the liquid can't drain lower back from pump suction if the valve seats tightly. Keep in thoughts that those foot valves have an uncongenial dependency of leaking.

Priming via way of means of Installing Foot Valve

In this technique of pump priming, a foot valve (functioning as a NRV) is established with inside the suction piping to insure that the liquid will now no longer drain from the pump casing and suction piping as soon as the pump stops operating.

A foot valve is a shape of test valve established on the bottom, or foot, of a suction line. When the pump stops and the ports of the foot valve close, the liquid cannot drain again from pump suction if the valve seats tightly. Keep in thoughts that those foot valves have an unpleasant addiction of leaking.

Specific speed

Specific velocity Ns, is used to symbolize turbo machinery velocity. Common industrial and commercial practices use dimensioned variations that are of identical utility.

Specific velocity is maximum normally utilized in pump programs to outline the suction unique velocity —a quasi-non-dimensional range that categorizes pump impellers as to their kind and proportions. In Imperial devices it's far described as the rate in revolutions in keeping with minute at which a geometrically comparable impeller could function if it had been of this type of length as to supply one gallon in keeping with minute in opposition to one foot of hydraulic head.

In metric devices waft can be in l/s or m³/s and head in m, and care have to be taken to nation the devices used.

Performance is described because the ratio of the pump or turbine in opposition to a reference pump or turbine, which divides the real overall performance determine to offer a unit less determine of merit. The ensuing determine could greater descriptively be referred to as the "perfect-reference-tool-unique overall performance.

This ensuing unit less ratio might also additionally loosely be expressed as a "velocity," handiest due to the fact the overall performance of the reference perfect pump is linearly depending on its velocity, in order that the ratio of [device-performance to reference-device-performance] is likewise the extended velocity at which the reference tool could want to function, so one can produce the overall performance, rather than its reference velocity of "1 unit.

Specific velocity is an index used to are expecting favored pump or turbine overall performance. I.e. it predicts the overall form of a pump's impeller. It is that this impeller's "form" that predicts its waft and head traits in order that the clothier can then choose a pump or turbine maximum suitable for a selected application. Once the favored unique velocity is known, fundamental dimensions of the unit's additives may be without problems calculated.

C. Theoretical aspects of multistage pumps

The head of a single-level centrifugal pump is essentially ruled via way of means of the form of impeller and the circumferential pace. If the rotational pace can't be multiplied because of different running situations and a bigger impeller diameter might result in very low unique speeds ensuing in uneconomical efficiencies, becoming numerous levels in collection (additionally see Series operation) may be an financial choice of growing the head.

If the wide variety of levels is altered at unchanged dimensions and speeds, the waft charge of one of these multistage pump stays regular at the same time as the energy enter and head growth proportionally to the wide variety of levels. An instance of a pump with numerous level casings of the identical kind equipped in tandem association is the ring-phase pump.

This form of pump is regularly utilized in energy station programs, e.g. As a boiler feed pump and in commercial programs requiring excessive pressures. The character levels of a multistage pump do now no longer always need to be organized in tandem.

The balancing of axial thrust may be greater via way of means of arranging the levels lower back to lower back in pairs or groups (see Back-to-lower back impeller pump).

A normal instance will be the pipeline pump. Multistage pumps are a financial way of masking the better stress levels of pump collection choice charts. Further blessings are that multistage pumps can without problems be tapped downstream of a level or that dummy levels may be equipped for destiny stress increases.

A drawback of very massive numbers of levels is the growing sensitivity of the pump rotor to outside or herbal vibrations. Each level includes an impeller, a diffuser and go back manual vanes (generally mixed with the diffuser), which might be all positioned inside one and the identical level casing.

Irrespective of the wide variety of levels an inlet casing with radial or axial inlet nozzle is organized upstream of the primary level, and the final level is equipped with inside the discharge casing containing the balancing tool and a shaft seal. Only the not unusual place pump shaft, tie bolts and baseplate need to be adjusted to deal with the desired wide variety of levels.

Trouble & remedies

If the motor is used because the high mover, first use the fingers to replace the cooling fan of the motor to look whether or not the rotation is flexible. If flexible, it can be the begin capacitor failure or potential discount which wishes to update.

If die, it explains the rotor is caught. It ought to cleansing rust upload lubricating grease, or do away with the caught rotor overseas body.

Reverse rotation of pump

This is a not unusual place trouble while first used which ought to straight away stop. If the motor for energy, it ought to update three-segment energy deliver any two-segment.

The operation can alternate the path of rotation of the pump. If the diesel engine for energy which ought to recollect the manner the belt connection. After pump rotation, no water out If the rotation is everyday however the water out, the feasible motives are:

1) The inlet is blocked with the aid of using sundries, the clear out ought to be hooked up after cleansing.

2) the suction pipe or device is leaking, which can be from welding seam, the pipe has a sand hollow or crack, the joint gasket seal isn't good, etc. 3) the suction peak is just too high, reduce.

4) The Impeller cavitation.

5) The quantity of water injected into the pump isn't enough.

6) there's air with inside the pump, the emptying approach is to shut the pump outlet regulating valve, open the loop valve.

7) The opening resistance is just too large, ought to test the period of the water pipe or easy the opening pipe.

8) The pump velocity isn't enough, ought to boom the pump velocity. Abnormal sound or immoderate vibration

When the pump running every day, the complete pump device ought to be stable, and the sound ought to be every day. If there's noise or atypical vibration of the unit, it's far frequently the precursor of pump failure. We ought to straight away test to cast off hidden dangers. The purpose for the pump unit vibration may be very complicated. From the purpose of vibration, it's far especially mechanical, hydraulic, and electric and so on.

From the mechanism of vibration, it's far specially introduced vibration pressure is just too large, tension is inadequate, and resonance. Bearing overheating when running, if the bearing is hot, the motives ought to be checked and treated from the subsequent aspects:

1) Inadequate lubricating oil or bad oil circulation.

2) Bad exceptional lubricating oil and impurities make the bearing rust, put on and rotation aren't flexible.

3) Extreme bearing put on.

4) The pump and motor aren't the equal center.

5) The bearing internal ring and the pump shaft neck suit too loosely or too tightly.

6) The belt is just too tight while using with the belt.

7) The axial thrust is just too large, the stability hollow on every impeller ought to be dredged.

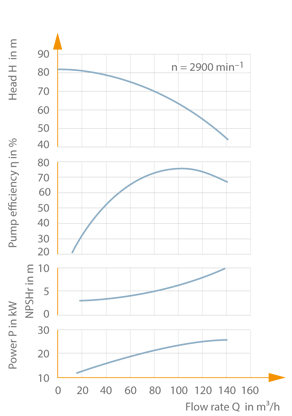

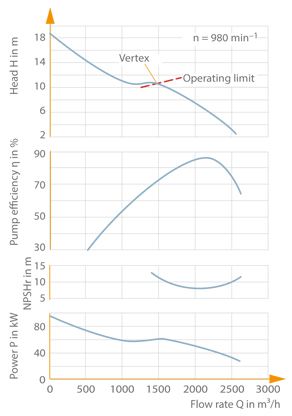

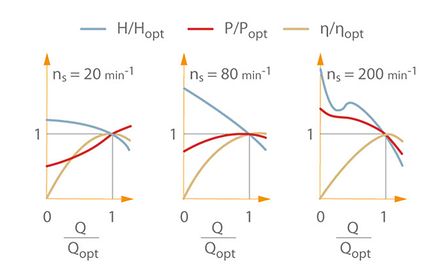

Operating characteristics curves.

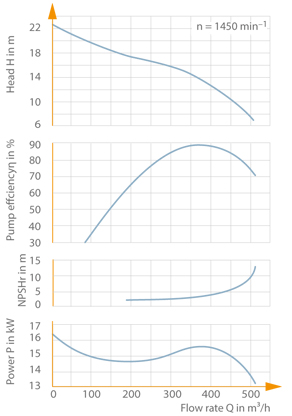

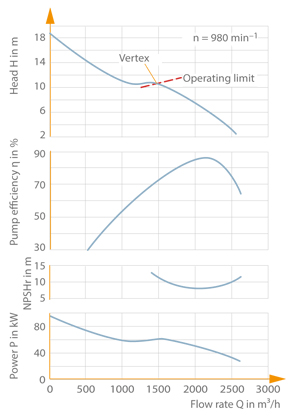

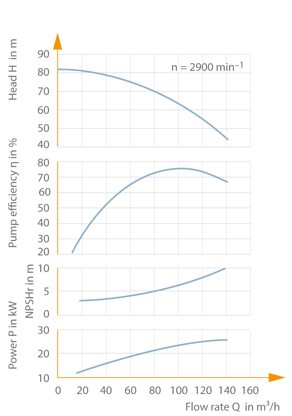

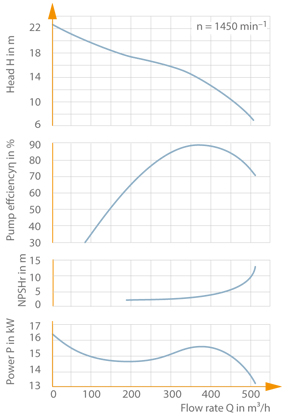

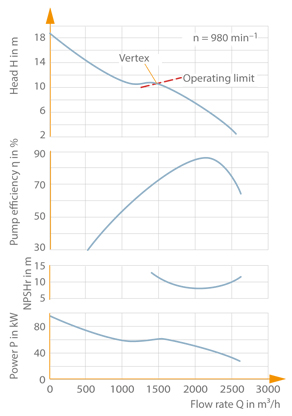

The feature curves of centrifugal pumps plot the route of the subsequent parameters towards waft rate (Q): head (H) (see H/Q curve), electricity enter (P), pump performance (η) and NPSHr, i.e. the NPSH required with the aid of using the pump. The feature curve's form is frequently decided with the aid of using the pump type (i.e. impeller, pump casing or precise velocity. Secondary impacts inclusive of cavitation, production tolerances, length and bodily houses of the fluid handled (e.g. viscosity, solids delivery or pulp pumping aren't taken under consideration in those diagrams.

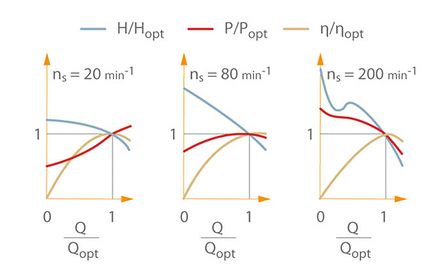

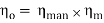

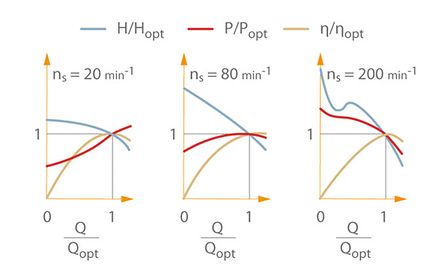

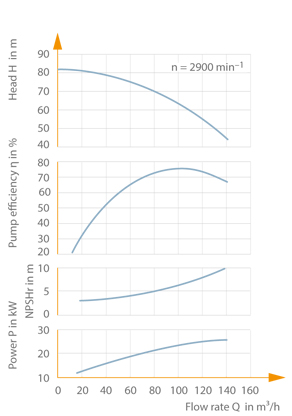

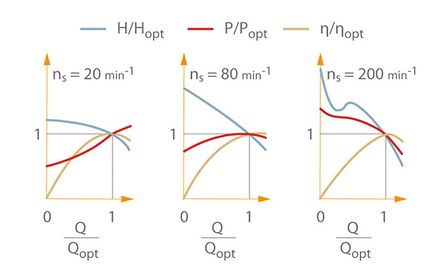

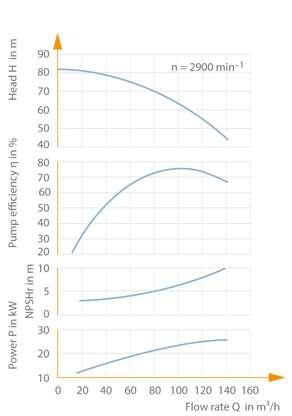

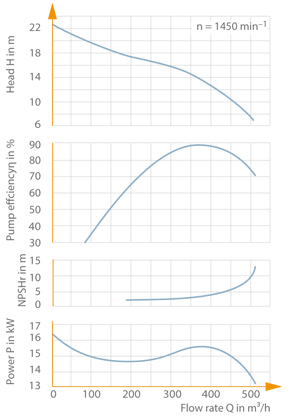

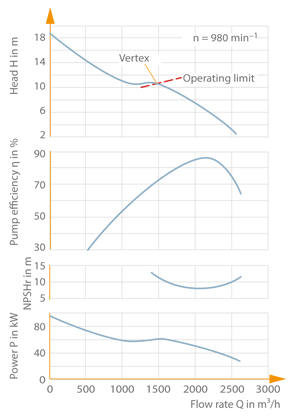

Figs. 1 to 4 Characteristic curve

Fig. 1 Characteristic curve: Centrifugal pump curves for various specific speeds. Curves plotted in percentage ratios referred to the best efficiency point (ns increasing from left to right)

Fig. 2 Characteristic curve: Radial flow centrifugal pump, specific speed

Fig. 3 Characteristic curve: Mixed flow centrifugal pump, specific speed nS 80 rpm

Fig. 4 Characteristic curve: Axial flow centrifugal pump, specific speed nq ~ 200 rpm

As the precise velocity increases, the (negative) slope of the H/Q curve will become steeper. In the case of centrifugal pumps with a low precise velocity, the performance curve is surprisingly flat with inside the vertex, while the performance curve of excessive precise velocity pumps is greater pointed (see High precise velocity).

The electricity enter curve of a low precise velocity pump has its minimal price at Q = 0 (shut-off point), while the electricity enter of a excessive precise velocity pump reaches a most at Q = 0. The presentation of parameters in a feature curve can provide Qualitative data See Fig. 1 Characteristic curve Quantitative data on current centrifugal pumps of numerous precise speeds See Figs. 2 to 4

Characteristic curve

Even a given precise velocity the feature curve's form can nevertheless be prompted thru the choice of the correct head coefficient. The better the pinnacle coefficient for given running data, the smaller the impeller diameter is, the flatter the H/Q curve and the steeper the P/Q curve. It is for this reason feasible to suit the pump's feature curve to the precise structures requirements. See Fig. 5

Characteristic curve

For the everyday running variety of centrifugal pumps (n, Q and Hall positive), its miles enough to plan the feature curve with inside the first quadrant of the H/Q coordinate system.

These include, for instance, operation in turbine mode, the pump's behavior following a pressure failure or start-up (beginning torque at opposite path of rotation).

A centrifugal pump's entire traits chart (four-quadrant feature curves choice chart) is frequently set up on the idea of experiments and relies upon at the pump type. Figure 6 indicates an instance of a double-suction centrifugal pump with ns = 35 rpm (in step with Stepanoff).

D. Selection of pumps, system head curves and pump head curves. Model testing of pumps:

Selection of pumps

Liquid name

Knowing the liquid which you are pumping is important because it permits us to make sure that we provide a pump made out of well-matched substances; consequently heading off capacity corrosion and abrasion issues. What is the chemical make up? Are there any solids present, in that case what's the most particle length and concentration?

Flow fee

This will decide the dimensions of the pump required. A better go with the drift fee calls for a bigger pump.

Pressure

The strain on the inlet and outlet of the pump will decide the sort and regularly the dimensions of pump required. Knowing the strain you're pumping towards permits us to pick the maximum appropriate pump technology.

If you're uncertain of your differential strain; we will assist to calculate it

Viscosity

There are many devices of size for viscosity but we generally tend to paintings in centipoise cP or centistokes cSt. Viscosity is a degree of a liquid’s resistance to deformation as a result of stress, or extra plainly; the ‘thickness’ of a liquid. Viscosity is generally better for thicker liquids, for example; water has a viscosity of one cp at 20 degC while honey has a viscosity of about ten thousand cp.

Viscosity impacts the sort and length of the pump required, with better viscosities generally requiring high quality displacement devices jogging at decrease speeds in preference to centrifugal pump solutions.

Density

The density or unique gravity of the pumping liquid on the working temperature will have an effect on how an awful lot strength is needed to obtain the desired duty.

This in flip will assist us length an appropriate power or motor to function the pump without a problem.

Temperature

This can have an effect on the substances of creation for the pump, and the form of pump offered.

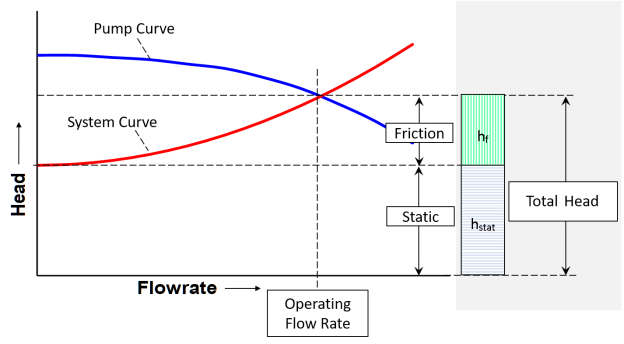

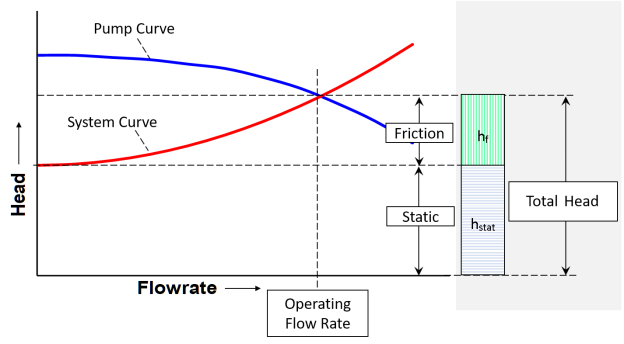

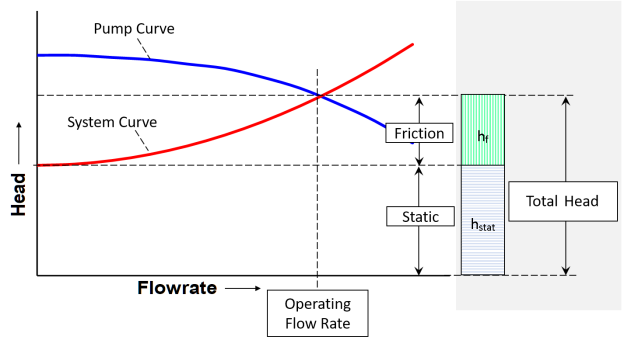

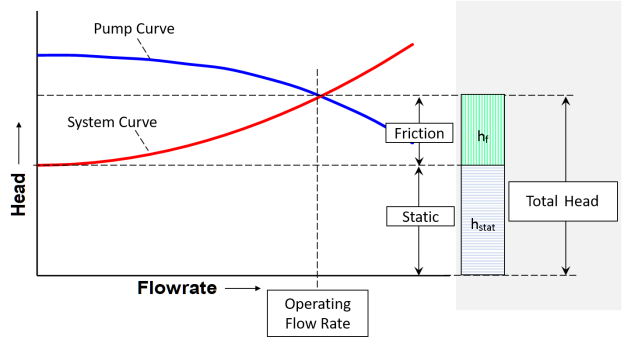

System head curves and pump head curves

System head curves

It combines factors of the performance (H-Q) curve of the unique pump below attention with the mixed static, working, and frictional loss heads (the entire dynamic head or TDH) of the machine below layout.

The intersection factor of those curves is usually taken into consideration because the real working factor or the situation of service (COS) for the pump. System head curves may be a precious device for studying pumping structures with distinct pumps, a couple of or variable head situations, a couple of pump speeds, or numerous impeller trims at the identical sheet of paper.

They are adaptable for low or excessive head situations, a couple of float situations, or with one or extra pumping units. Formerly, machine head curves have been evolved with the aid of using the use of a tedious manner related to the plotting of numerous pump curve situations towards an alternating set of machine potential vs. Head situations.

Advancements in pc era now allow the identical kind of machine head plotting in a far shorter time and with advanced accuracy. A machine head curve is plotted in a comparable style as a pump curve, however the number one distinction entails the plotting of the machine situations.

Both curves usually observe the identical conference of plotting potential at the “x” axis towards head at the “y” axis. The unique nature of the 2 curves dictates the curve ascends, beginning with the static head, with growing head values alongside the “y” axis for the machine head curve, and descends, beginning with the pump’s shutoff head, alongside the identical axis for the pump curve.

Pump head curves

The performance curve indicates the η (performance) of the pump. Efficiency is measured in %. All pumps have a ‘quality point’ (ηmax), indicating in which the pump is operating maximum efficiently.

The performance of the pump relies upon at the pump length and the high-satisfactory of the construction/production. Small pumps generally have a decrease performance than big pumps.

The pump overall performance curve indicates the correlation among media flow (Q) and the strain differential or head (H) that the pump creates.

The gadgets for Q are generally [m3/h] or [l/s]

The unit for H is generally [m] H (head) may be recalculated top (strain) with the aid of using the usage of the subsequent equation:

p = ρ x g x H [pa] p = strain [pa] ρ = density [kg/m3] g = acceleration because of gravity [m/s2] H = head [m] Flow is generally given in m3/h or l/s.

For variable-velocity pumps, the overall performance curve is given at minimal and most RPM. When numerous pumps are linked, the very last overall performance curve is carried out with the aid of using combining the traits of the person pumps.

Parallel-linked pumps are delivered horizontally to growth Q. For equal pumps, the most Q will double, but most H might be the same. This precept is usually utilized in pump systems. Series-linked pumps are delivered vertically to growth H. For equal pumps, the most H will double.

Maximum Q will stay the same. This precept is usually utilized in multi-degree pumps. The overall performance curve is used collectively with the gadget traits whilst dimensioning and choosing pumps.

Fig: System and pump head curves

Model testing of pumps

In instances wherein technical or monetary factors (for instance length, rotational pace and material/fluid properties) make checking out on an item or system infeasible beneath authentic situations, measurements also can be made with the aid of version checking out.

Particularly with inside the case of hydraulic turbo machinery (centrifugal pumps, water turbines, hydraulic torque converters) version checking out may be conducted: on decreased scale models, and/or with decreased rotational pace, and the usage of a replacement fluid as appropriate.

The blessings of version checking out are: decreased dimensions of the check item and the check facility, decrease strength input/running charges for the duration of checking out, probably less complicated coping with of the fluid (e.g. Bloodless water in place of warm water or toxic, flammable fluids), more precision whilst shifting the consequences of particularly specific version checking out than whilst operating with measurements taken beneath authentic situations with inside the system.

When planning, appearing and comparing version assessments and shifting the consequences to the authentic-length gadget and/or the authentic running situations, the affinity legal guidelines should be located and applied. Key issues are:

Geometric similarity should be maintained, inclusive of clearance hole widths, and, wherein possible, floor roughness.

Changes in period because of elastic and thermal deformations should additionally be located.

Test consequences should be transformed on the idea of version legal guidelines.

Dynamic similarity cannot typically be fulfilled. If infringement is unavoidable, practice corrections to the transformed consequences, e.g. performance scale-up in instances wherein the Reynolds range equivalence is comprised in version checking out and authentic situations. Cavitation version checking out: have a look at the fluid properties (germ count, fuel line content).

Key Takeaways:

- If die, it explains the rotor is caught. It ought to cleansing rust upload lubricating grease, or do away with the caught rotor overseas body.

- The opening resistance is just too large, ought to test the period of the water pipe or easy the opening pipe.

- System head curves may be a precious device for studying pumping structures with distinct pumps, a couple of or variable head situations, a couple of pump speeds, or numerous impeller trims at the identical sheet of paper.

References:

1. Hydraulics & Fluid Mechanics- Dr.Modi& Dr. Seth

2. Fluid Mechanics-Streeter & Wylie

3. Fluid Mechanics- Dr. A.K.Jain

4. Fluid Mechanics through problems- Garde

5. Theory and applications of Fluid Mechanics- K. Subramanya

6. Foundation of Fluid Mechanics-Yuan

7. Flow through open channel – K.G.Rangaraju

Unit - 6

Fluid Machinery

TURBINES: Definition

Several bodily standards are hired through mills to acquire this power: Impulse mills alternate the course of waft of an excessive pace fluid or fuelling jet.

The ensuing impulse spins the turbine and leaves the fluid waft with faded kinetic power.

There isn't any strain alternate of the fluid or fuelling with inside the turbine blades (the transferring blades), as with inside the case of a steam or fuelling turbine, all of the strain drop takes vicinity with inside the desk bound blades (the nozzles). Before achieving the turbine, the fluid's strain head is modified to pace head through accelerating the fluid with a nozzle.

Pelton wheels and de Laval mills use this technique exclusively. Impulse mills do now no longer require a strain casement across the rotor for the reason that fluid jet is created through the nozzle previous to achieving the blades at the rotor. Newton's 2nd regulation describes the switch of power for impulse mills.

Impulse mills are maximum green to be used in instances in which the waft is low and the inlet strain is excessive. Reaction mills increase torque through reacting to the fuelling or fluid's strain or mass.

The strain of the fuelling or fluid modifications because it passes thru the turbine rotor blades. A strain casement is wanted to include the running fluid because it acts at the turbine stage(s) or the turbine have to be completely immersed with inside the fluid waft (along with wind mills).

The casing consists of and directs the running fluid and, for water mills, keeps the suction imparted through the draft tube. Francis mills and maximum steam mills use this concept.

For compressible running fluids, a couple of turbine ranges are typically used to harness the increasing fuelling efficiently. Newton's 1/3 regulation describes the switch of power for response mills.

Reaction mills are higher suitable to better waft velocities or packages in which the fluid head (upstream strain) is low. In the case of steam mills, along with might be used for marine packages or for land-primarily based totally strength generation, a Parsons-kind response turbine might require about double the wide variety of blade rows as a de Laval-kind impulse turbine, for the identical diploma of thermal power conversion.

Whilst this makes the Parsons Turbine lots longer and heavier, the general performance of a response turbine is barely better than the equal impulse turbine for the identical thermal power conversion.

In practice, present day turbine designs use each response and impulse standards to various stages on every occasion possible. Wind mills use an airfoil to generate a response carry from the transferring fluid and impart it to the rotor. Wind mills additionally advantage a few power from the impulse of the wind, through deflecting it at an angle.

Turbines with a couple of ranges can also additionally use both response and impulse blading at excessive strain. Steam mills have been historically extra impulse however hold to transport closer to response designs just like the ones utilized in fuelling mills.

At low strain the working fluid medium expands in extent for small discounts in strain. Under those conditions, blading will become strictly a response kind layout with the bottom of the blade completely impulse.

The motive is because of the impact of the rotation velocity for every blade. As the extent increases, the blade top increases, and the bottom of the blade spins at a slower velocity relative to the tip.

This alternate in velocity forces a fashion dressmaker to alternate from impulse at the bottom, to an excessive response-fashion tip.

Steam mills are used to pressure electric mills in thermal electricity plant life which use coal, gasoline oil or nuclear gasoline.

They have been as soon as used to without delay pressure mechanical gadgets which include ships' propellers (for instance the Turbine, the primary turbine-powered steam launch), however maximum such packages now use discount gears or an intermediate electric step, in which the turbine is used to generate electricity, which then powers an electric powered motor linked to the mechanical Turbo electric powered deliver equipment turned into in particular famous with inside the duration without delay earlier than and throughout World War II, in the main because of a loss of enough gear-slicing centers in US and UK shipyards. Aircraft fuelling turbine engines are now and again called turbine engines to differentiate among piston engines.

Gross and net heads

Now we can consciousness right here to apprehend a few critical terminologies related to a hydraulic turbine together with Gross head, Net head and efficiencies of a hydraulic turbine with the assist of this post. Will you be fascinated nowadays to discover those critical terminologies related to a hydraulic turbine? So allow us to begin right here with the subsequent critical terminologies

Gross Head

Gross head is largely described because the distinction among the pinnacle race stage and tail race stage whilst water isn't always flowing. Gross head may be indicated with the aid of using Hg as displayed right here in following figure.

Net Head

Net head is largely described as the pinnacle to be had on the inlet of the turbine. Net head is likewise in reality referred to as powerful head.

When water will waft from head race to the turbine, there may be a few losses of head because of friction among water and penstock.

There may also be different losses of head together with lack of head because of bend, fitting, at front of penstock etc. We should observe it right here that those losses may be very much less and will be left out whilst we evaluate with head loss because of friction.

Net head to be had on the inlet of turbine will be written as referred to right here.

Net head, H = Gross head (Hg) – head loss because of friction (hf) Loss of head because of friction may be given with the aid of using Darcy-Weisbach equation and we are able to discover it right here.

Different efficiencies

There are following crucial efficiencies that we are able to speak right here on this post.

Hydraulic performance

Mechanical Efficiency

Volumetric performance

Overall Efficiency

Hydraulic performance

Hydraulic performance is largely described because the ratio of electricity given with the aid of using water to the runner of turbine to the electricity provided with the aid of using the water on the inlet of the turbine.

Hydraulic performance may be indicated with the aid of using ηh.

Runner is largely a rotating element of a turbine and buckets or vanes may be constant on the circumference of the runner. Vanes or buckets constant at the runner aren't easy and therefore there may be hydraulic losses whilst water will waft thru those vanes of the turbine.

Therefore, electricity given with the aid of using water to the runner of the turbine may be much less than the electricity provided with the aid of using the water on the inlet of the turbine. Hydraulic performance of a turbine will be written as referred to right here

Hydraulic performance (ηh) = Power added to the runner of turbine / Power provided on the inlet of turbine

Hydraulic performance (ηh) = R.P/ W.P R.P = Power added to the runner of turbine

W.P = Power provided on the inlet of turbine or water electricity

Mechanical Efficiency

Mechanical performance is largely described because the ratio of electricity to be had on the shaft of the turbine to the electricity added to the runner of the turbine. Mechanical performance may be indicated with the aid of using ηm.

Power given with the aid of using water to the runner of turbine may be transmitted to the shaft of the turbine. Power to be had on the shaft of the turbine may be much less than the electricity added to the runner of the turbine because of mechanical losses.

Mechanical performance of a turbine will be written as referred to right here

Mechanical performance (ηm) = Power to be had on the shaft of the turbine / Power added to the runner of the turbine

Mechanical performance (ηm) = S.P/ R.P S.P = Power to be had on the shaft of the turbine R.P = Power added to the runner of turbine

Volumetric Efficiency

The quantity of the water placing the runner of a turbine may be barely much less than the quantity of the water provided to the turbine as a few quantity of water may be discharged to the tail race without placing the runner of the turbine.

Volumetric performance is largely described because the ratio of the quantity of the water honestly placing the runner of the turbine to the quantity of water provided to the turbine.

Volumetric performance may be indicated with the aid of using ηv.

Volumetric performance of a turbine will be written as referred to right here

Volumetric performance (ηv) = Volume of the water honestly placing the runner of the turbine / Volume of water provided to the turbine

Overall Efficiency

Overall performance is largely described because the ratio of the electricity to be had on the shaft of the turbine to the electricity provided with the aid of using the water on the inlet of the turbine.

Overall performance may be indicated with the aid of using ηo.

Overall performance,

ηo = Power to be had on the shaft of the turbine / Power provided with the aid of using the water on the inlet of the turbine

Overall performance, ηo = S.P/W. P

Overall performance is likewise described because the manufactured from mechanical performance and hydraulic performance

Overall performance = Mechanical performance x Hydraulic performance ηo = ηm x ηh

Classification of turbines

Types of Turbines Based on Energy Exchange among the water and the Machine

Considering how the fluid float acts at the turbine blades reasons hydro generators to be categorized into categories: impulse and response.

Impulse Turbines

If the turbine wheel is pushed through the kinetic electricity of the fluid that moves the turbine blades via the nozzle or otherwise, the turbine is called an impulse turbine. In those forms of generators, a hard and fast of rotating equipment operates at atmospheric stress. Impulse generators are commonly appropriate for excessive head and coffee float quotes.

Pelton, Turgo, and Cross-float generators are 3 forms of impulse generators. The production of the Pelton and Turgo generators is similar. However, the Cross-float turbine is a changed sort of impulse generators this is categorized as an impulse turbine because of the rotation of the runner at atmospheric stress and now no longer as a submerged turbine.

Reaction Turbines

If the sum of ability electricity and kinetic electricity of water which can be because of the stress and velocity, respectively reason the turbine blades to rotate, the turbine is classed as a response turbine. In those forms of generators, the whole turbine is immersed in water and adjustments in water stress in conjunction with the kinetic electricity of the water reason energy exchange. Applications of response generators are commonly at decrease heads and better float quotes than impulse generators.