Unit - 1

Introduction to layout of thermal power plant

Introduction to layout of thermal power plant

Almost 1/3 of power requirement of the sector is fulfilled by means of thermal energy flora (or thermal energy stations).

In those energy stations, steam is produced by means of burning a few fossil gasoline (e.g. Coal) after which used to run a steam turbine.

Thus, a thermal energy station can also additionally from time to time known as a Steam Power Station. After the steam passes via the steam turbine, it's far condensed in a condenser and once more fed returned into the boiler to come to be steam.

This is referred to as rating cycle. This article explains how power is generated in thermal energy flora. As majority of thermal energy flora use coal as their number one gasoline, this newsletter is targeted on a coal fired thermal energy plant.

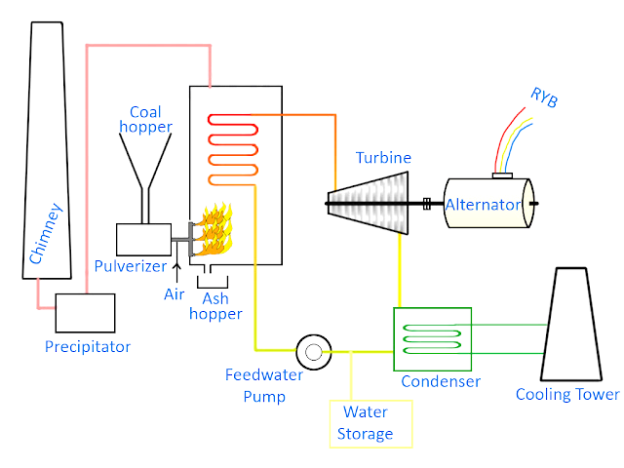

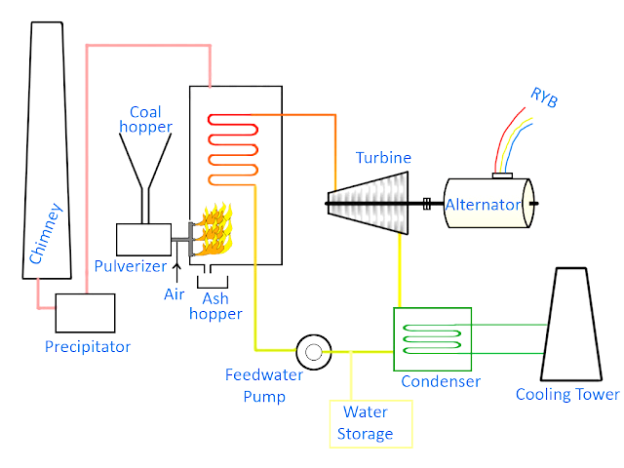

Typical Layout and Working of a Thermal Power Plant

A simplified format of a thermal energy station is proven below. Coal: In a coal primarily based totally thermal energy plant, coal is transported from coal mines to the producing station. Generally, bituminous coal or brown coal is used as gasoline.

The coal is saved in either 'lifeless garage' or in 'stay garage'. Dead garage is typically forty days backup coal garage that's used whilst coal deliver is unavailable.

Live garage is an uncooked coal bunker in boiler house. The coal is wiped clean in a magnetic purifier to clear out if any iron debris are gift which can also additionally purpose put on and tear with inside the equipment.

The coal from stay garage is first beaten in small debris after which taken into pulverize to make it in powdered form.

Fine powdered coal undergoes whole combustion, and for this reason pulverized coal improves performance of the boiler.

The ash produced after the combustion of coal is taken out of the boiler furnace after which nicely disposed.

Periodic elimination of ash from the boiler furnace is essential for the right combustion.

Boiler:

The aggregate of pulverized coal and air (generally preheated air) is taken into boiler after which burnt with inside the combustion zone.

On ignition of gasoline a massive fireball is shaped on the middle of the boiler and massive quantity of warmth electricity is radiated from it.

The warmth electricity is applied to transform the water into steam at excessive temperature and stress.

Steel tubes run alongside the boiler partitions wherein water is transformed in steam.

The flue gases from the boiler make their manner via super heater, economizer, and air preheater and ultimately get exhausted to the surroundings from the chimney.

Superheater:

The superheater tubes are hanged on the freshest a part of the boiler. The saturated steam produced with inside the boiler tubes is superheated to approximately 540 °C with inside the super heater.

The superheated excessive stress steam is then fed to the steam turbine.

Economizer:

An economizer is largely a feed water heater which heats the water earlier than presenting to the boiler.

Air pre-heater:

The number one air fan takes air from the surroundings and its far then warmed with inside the air pre-heater. Pre-heated air is injected with coal with inside the boiler. The gain of pre-heating the air is that it improves the coal combustion.

Steam turbine:

High stress extraordinary heated steam is fed to the steam turbine which reasons turbine blades to rotate. Energy with inside the steam is transformed into mechanical electricity with inside the steam turbine which acts because the top mover.

The stress and temperature of the steam falls to a decrease cost and it expands in extent because it passes via the turbine. The improved low stress steam is exhausted with inside the condenser.

Condenser:

The exhausted steam is condensed with inside the condenser through bloodless water circulation. Here, the steam loses it is stress in addition to temperature and it's far transformed returned into water.

Condensing is important because, compressing a fluid that's in gaseous country calls for a massive quantity of electricity with admire to the electricity required in compressing liquid. Thus, condensing will increase performance of the cycle.

Alternator:

The steam turbine is coupled to an alternator. When the turbine rotates the alternator, electric electricity is generated.

This generated electric voltage is then stepped up with the assist of a transformer after which transmitted wherein it's far to be applied.

Feed water pump:

The condensed water is once more fed to the boiler by means of a feed water pump.

Some water can be misplaced all through the cycle, that's definitely provided from an outside water source.

This became the fundamental operating precept of a thermal energy station and its regular components.

A sensible thermal plant own greater complex layout and more than one ranges of turbine which include

- High Pressure Turbine (HPT),

- Intermediate Pressure Turbine (IPT) and

- Low Pressure Turbine (LPT).

Principle of steam generation

Heat Exchange

Steam mills are utilized in numerous strategies to harness loose power with inside the shape of warmth and convert it right into a shape this is extra useful, inclusive of mechanical and electric power.

The warmth used is commonly produced deliberately to supply strength or is received as a byproduct of every other business process.

The on the spot supply of warmth is commonly dirty, inclusive of radioactive gasoline in a nuclear strength plant, so step one in steam strength era is to switch that warmth to smooth water with a warmth exchanger.

Steam Generation

The warm oil is circulated via the waters tub to generate steam. There are many one-of-a-kind geometric schemes for doing this, however the precept stays the same.

The heating liquid is diverted into numerous small pipes to boom its floor touch with water and facilitate speedy warmth trade and steam era.

The steam produced in cutting-edge nuclear and coal strength flora is frequently in supercritical situations or above the essential factor with inside the water section diagram (374 °C and 22 MPa).

Conversion of Heat to Electricity

Supercritical steam is loaded with power. Steams power is transformed into mechanical power through pressure with the aid of a steam turbine. The excessive strain of steam exerts strain at the angled blades of the turbine, inflicting the shaft to rotate.

This mechanical power is transformed into strength, the use of the strength with inside the shape of a rotating shaft to show an electric powered generator. The turbine being constructed with inside the picture can generate as much as sixty five MW of strength.

Compared to steams boilers, steams mills have much less metallic production of their layout, which makes use of an unmarried tube coil as opposed to numerous smaller diameter boiler tubes.

A unique feed water pump is used to constantly pump the feed water via the coil.

A steam generator makes use of a bar-via, compelled glide layout to transform incoming water into steam for the duration of an unmarried by skip via a water coil. As water passes via the coil, warmth is transferred from the recent gases, turning the water into steam.

Steam drums aren't used with inside the generator layout, in which the boiler steam has a dissipation region from the water, so accomplishing 99.5% steam pleasant calls for the usage of a steam/water separator.

Since mills do now no longer use a big pressurized vessel like a fire tube, they're frequently smaller and start-up quickly, making them perfect for brief on-call for situations.

However, this comes on the price of manufacturing power, as mills have a decrease turn-down price and are consequently much less capable of offer steam for the duration of intervals of variable call for.

Fuel for steam generators

The gasoline that has been used as a number one supply for energy for numerous years is coal.

It has now no longer been the handiest supply however has been useful to the energy enterprise because: coal has been the most inexpensive gasoline, on $ in keeping with million Btu basis; herbal fuelling has been strongly aggressive mostly in latest years; at one time (latest), 60% of U.S. Energy become generated in coal-fired flowers. Now ~40% from coal; about 80% of U.S. Coal manufacturing is burned in electric powered flowers.

However, the primary motive we're thinking about switching far from coal is burning coal is one of the maximum difficult environmental problems. For functions of the course, we keep in mind steam technology from coal as steam technology from biomass; each fuels are pretty similar.

We need an excessive warmness launch fee that is tied to the burning fee of gasoline. Since coal is a stable gasoline, it may not burn fast if it's miles in chunks. So, the manner to boom the burning fee is to boom the floor place of the coal; the manner to boom the floor place is to pulverize the coal into very small debris.

However, whilst the coal debris are small in size (something like flour), it makes it tough to handle.

It is tough to shovel something this is like dirt or to help it on a grate. Instead, it's miles simply blown into the boiler unit with a cutting-edge of air that is known as pulverized-coal firing or suspension firing.

This is now the same old for electric powered energy technology, abbreviated PC-fired water-tube boiler.

Burning the coal produces warmness; the warmth is used to boil the water to steam; the steam actions throughout the turbine to transport it; and the turbine turns the generator to supply energy

Through this series of transformations, the chemical capacity strength of gasoline (coal on this case) is transformed to excessive-capacity, excessive-voltage energy for distribution to consumers. If you keep in mind the internet performance from the coal pile to the cease of the plant, the plant performance is ~33%.

Plants constructed greater currently may be with inside the middle-excessive 30s range, at the same time as older flowers can be with inside the mid-20s.

The following steps are involved: Water is pumped at regular entropy to State 2 and into boiler.

Liquid is heated at regular stress State 3 (saturated steam). Steam expands at regular entropy via the turbine to State 4. Constant stress switch of warmth in condenser. The turbine turns the engine to supply energy.

The manner to decide the performance is to study the performance throughout every a part of the plant. Losses can arise at every step of the process

For a PC-fired present day energy plant, count on operation at 2500 psi, with a steam temperature of 540°C, then the general performance is 34%.

Losses at every element encompass 1 & 2) warmness losses in pipes and from the friction of the pump (performance of 92%); 3) warmness losses and friction with inside the turbine (performance of 44%); 4) warmness losses because the steam condenses returned to water (performance of 85%), and 5) little or no lack of performance from generator (performance of 99%).

For each 3 rail vehicles of coal used to generate energy, vehicles of coal are misplaced to waste warmness.

Necessity of water treatment

Water remedy is any manner that improves the high-satisfactory of water to make it suitable for a particular stop-use.

The stop use can be ingesting, commercial water supply, irrigation, river waft maintenance, water activity or many different uses, along with being competently lower back to the environment.

Water remedy eliminates contaminants and unwanted components, or reduces their awareness in order that the water turns into healthy for its preferred stop-use.

This remedy is vital to human fitness and lets in human beings to advantage from each ingesting and irrigation use. Water is the maximum vital compound for existence on Earth, and having drinkable water is a key global challenge for the twenty-first century. All dwelling matters require clean, uncontaminated water as a primary requirement. Water covers greater than seventy one percentage of the earth’s surface, however best round 1% of its miles drinkable in line with global requirements because of numerous contaminations.

Waste water discharge from industries, agricultural pollution, and municipal wastewater, environmental and worldwide modifications are the principle reasserts of water infection.

Even hint ranges of heavy metals, dyes, and microbes are dangerous to human fitness, aquatic structures, and the environment.

According to a Food and Agriculture Organization evaluation from 2007, absolute water shortage will have an effect on 1.eight billion humans dwelling in international locations, and water pressure would possibly have an effect on two-thirds of the worldwide population. To cope with water shortage issues, its miles required to get better water from contemporary wastewater or increase change water reasserts for human intake.

Domestic and commercial wastewater are the 2 styles of wastewater.

Domestic wastewater incorporates sewage, bacteria, viruses, dangerous and non-poisonous organisms, sanitary outputs, rubbish, detergents, and different strong and liquid discharges from non-production approaches.

Water infection is frequently resulting from the release of untreated wastewater from enterprises. The effluent from numerous enterprises, which includes various ranges of contaminants, is dumped into rivers or different water resources.

The wastewater might also additionally have an excessive share of natural and inorganic contaminants on the preliminary discharge.

Industries generate wastewater due to fabrication approaches, approaches coping with paper and pulp, textiles, chemicals, and from numerous streams which includes cooling towers, boilers, and manufacturing lines.

Typical ingesting water remedy approaches

Treatment for ingesting water manufacturing entails the elimination of contaminants and/or inactivation of any probably dangerous microbes from uncooked water to supply water this is natural sufficient for human intake with none brief time period or long time hazard of any damaging fitness effect.

In trendy terms, the best microbial dangers are related to ingestion of water this is infected with human or animal (along with bird) faces.

Faces may be a supply of pathogenic bacteria, viruses, protozoa and helminthes.

The elimination or destruction of microbial pathogens is essential, and typically entails using reactive chemical dealers which includes suspended solids, to eliminate bacteria, algae, viruses, fungi, and minerals along with iron and manganese.

Research along with Professor Linda Lawton's institution at Robert Gordon University, Aberdeen is operating to enhance detection of cyanobacteria.

These materials hold to reason excellent damage to numerous much less evolved international locations who do now no longer have get entry to powerful water purification structures.

Measures taken to make certain water high-satisfactory now no longer best relate to the remedy of the water, however to its conveyance and distribution after remedy.

It is consequently not unusual place exercise to maintain residual disinfectants with inside the handled water to kill bacteriological infection for the duration of distribution and to maintain the pipes clean.

Water furnished to home houses which includes for faucet water or different uses, can be in addition handled earlier than use, regularly the use of an in-line remedy manner. Such remedies can consist of water softening or ion exchange.

Many proprietary structures additionally declare to eliminate residual disinfectants and heavy metallic ions

Water is one of the crucial herbal assets on Earth. Water is the second one vital substance after air that's vital for the survival of all of the dwelling organisms in this planet.

There we've got come collectively and written this newsletter on Water remedy flora and why companies and governments have to consciousness extra on constructing extra water remedy flora for our world.

Most of Earth’s floor (71%) is included with the aid of using water and the sea holds approximately 97% of water that's saline and now no longer secure for consuming and different purposes.

Only 3% of the water is sparkling and appropriate for consuming.One-1/3 of the freshwater is saved with inside the shape of icebergs and polar ice caps and best a bit quantity is saved as groundwater and floor water.

The water which we use is floor water and it is largely to be had with inside the rivers, ponds, and lakes. But because the populace and developmental sports are growing the floor and groundwater have become infected day with the aid of using day.

The ever-growing pollutants has caused the creation of dangerous chemical substances and risky materials with inside the water system.

Today, it isn't always secure to at once use the water from rivers, reservoirs, and lakes because it includes numerous micro-organisms, pathogens, and different contaminants which have a detrimental impact at the fitness of humans, flora, and animals.

This scenario of dangerous and dangerous floor water has generated the want for the Water Treatment Plant.

Necessity:

- Water this is used for consuming water manufacturing incorporates water molecules and a big form of different substances. One of the residences of water is that it without problems dissolves different substances.

- Water that falls to earth for the duration of rain showers dissolves substances, debris and gasses along with oxygen, which may be located in air.

- Contaminants which might be found in air additionally dissolve in rain water. When floor water flows on the earth it additionally dissolves numerous extraordinary substances, along with sand debris, natural rely, microorganisms and minerals.

- Water that settles into the floor and will become groundwater regularly incorporates big quantities of dissolved minerals, because of touch with soils and rocks.

- Human activities, along with agriculture and business waste and sewer water discharge purpose some of pollution to go into the water. Water has the ability to cleanse itself.

- Contaminants are eliminated from water for the duration of organic processes.

- Contaminants are damaged down, or will live in the back of with inside the floor layer. The self-cleaning ability of water isn't always robust sufficient to provide smooth consuming water.

- This is an effect of the amount and form of business and agricultural contaminants which have entered floor and groundwater for lots decades.

- In the 1970’s it changed into found that business discharges and waste water discharges had been the purpose of water contamination.

- Immediately after this discovery measures had been taken to save you water pollution. Waste water ought to meet felony trendy earlier than it may be discharged.

- To meet the requirements water is purified earlier than its miles discharged. Despite of those measures water regularly nevertheless desires remedy earlier than its miles appropriate to be used as consuming water.

- During water purification waste water is dealt with to come to be consuming water which meets felony requirements with inside the bodily, bacteriological and chemical area.

- The water might not include an odor or flavor, and it ought to be vivid and chemically stable (non-corrosive).

- The type of remedy water desires, strongly relies upon the composition and high-satisfactory of the water. Water remedy incorporates method steps: bodily elimination of strong debris, in particular minerals and natural rely and chemical disinfection; killing or deactivating microorganisms in water.

Key takeaways:

- This became the fundamental operating precept of a thermal energy station and its regular components.

- Even hint ranges of heavy metals, dyes, and microbes are dangerous to human fitness, aquatic structures, and the environment.

- Water that settles into the floor and will become groundwater regularly incorporates big quantities of dissolved minerals, because of touch with soils and rocks.

Classification of steam generators

The creation of the steam generator, or boiler, converted normal existence lengthy earlier than digital improvements did, and arguably had an extra usual effect than greater current improvements inclusive of as on-line commerce, social media and wi-fi technology. It is difficult to realize now simply how a lot of a game-changer it became which will get from region to region without both private or animal (e.g., horse-drawn carriage) energy.

On its face, the manufacturing of steam on reason looks as if an odd choice.

Looking at the sector the manner a younger baby might, steam seems to be little greater than a compulsory watery waste fabricated from numerous tactics regarding warmness era, from cooking a container of pasta to warming the corridors of a building.

The first-class manner to narrate your thoughts to the price of nicely harnessed steam is to photo what takes place while something that has steam billowing from its miles abruptly capped or in any other case bodily averted from emitting that steam – for example, clamping a lid tightly down on a pot of boiling water for even a 2nd earlier than freeing it.

The Basics and Origins of Steam Power Steam is water vapor, or greater generally, the gaseous shape of the molecule.

Water includes hydrogen and oxygen atoms and has a molecular system of H2O. Like different depend with a selected boiling point, water is capable of input the gaseous segment while it reaches that temperature (for water, a hundred C, or stages Celsius (212 F, or stages Fahrenheit) and receives a tiny electricity push so it could conquer its warmness of vaporization, a type of toll that depend normally has to pay to extrude among states (solid, liquid or Today, steam's maximum critical full-size function is with inside the era of electrical energy.

But lower back with inside the overdue 1600s, it became observed that it became less difficult to take away waste water from mines while it became condensed.

In the system, it became observed that the system of water condensing creates a vacuum (bad stress on the subject of anything lies out of doors the vicinity of condensation activity). This locating became ultimately included into cutting-edge steam engines and generators.

Types of Steam Generators

Fire tube.

These are most customarily utilized in tactics that want everywhere from 15 to 2,2 hundred horsepower (1 hp = 746 watts, or W). This sort of boiler is cylindrical, with the flame with inside the furnace hollow space itself and the combustion gases themselves stored inner a sequence of tubes. These are available in fundamental designs: dry lower back and moist lower back.

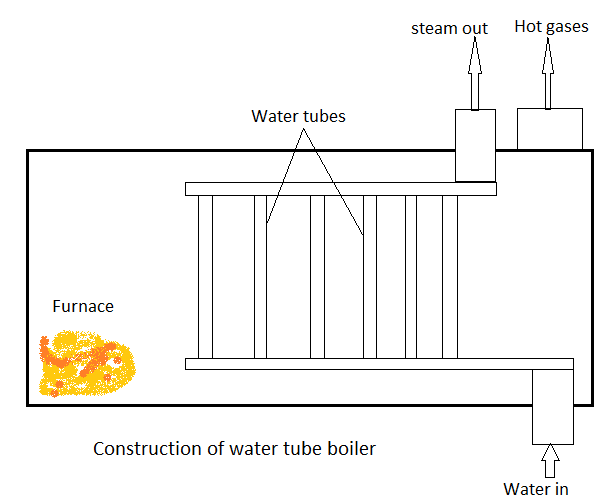

Water tube.

In this arrangement, tubes include steam, water or both, even as the goods of combustion by skip across the out of doors of tubes. These frequently have more than one units of drums, and due to the fact they use incredibly little water, those boilers provide strangely speedy steaming capabilities. Commercial. These normally characteristic combos of water tube, fire tube and electric powered-resistance designs.

They are famous in huge homes requiring a typically steady temperature, inclusive of colleges and libraries, workplace and authorities homes, airports, condo complexes, university and different studies laboratories hospitals, and so on.

Condensing.

Condensing boilers can attain thermal performance tiers of two ninety eight percentage, in comparison to 70 to eighty percentage plausible the usage of well-known boiler designs.

Typical performance tiers attain approximately ninety percentage while the go back water temperature is at a hundred and ten F or lower, and upward push with lowering water-go back temperature thereafter.

Flexible water tube (flex tube).

This production is in particular resistant to "warmness shock," making it an herbal choice for heating uses. Flexible water tube boilers are available in a huge variety of gasoline inputs and are well-ideal for low-stress packages the usage of both steam and warm water. (Not all "boilers" without a doubt boil water!) These also are pretty clean to maintain, with clean get right of entry to their operating components from the out of doors.

Electric.

These boilers are famously low-effect: clean, quiet, clean to install, and small on the subject of their utility. Because not anything is without a doubt burned (that is, there may be no flame to fear approximately), electric powered boilers are marvelously simple. There aren't any fuels or gasoline dealing with device with inside the mix, and subsequently no exhaust and no want for related pipes and ports. In addition, those have heating factors which can be clean to replace.

Heat restoration steam generator (HRSG).

This is a progressive electricity-restoration "warmness exchanger" that recovers warmness from a circulate of warm fuelling passing through. These create steam that may be used to power a selected a system or used to power a steam turbine to energy strength era the usage of an electromagnet. HRSGs are constructed on a basis of 3 number one components – an evaporator, a super heater and an economizer.

Steam as Nuclear Reactor Fuel

Nuclear energy plant life use electricity now no longer from the combustion of gasoline however through the mechanical separation of its tiniest components. That is a totally slight manner of describing nuclear fission, wherein atoms (on this case, the ones belonging to the detail uranium) are damaged into smaller atoms, freeing full-size quantities of electricity. The electricity launched through fission is captured and used to warmness and boil water, and the ensuing steam is used to energy a turbine for the reason of strength era.

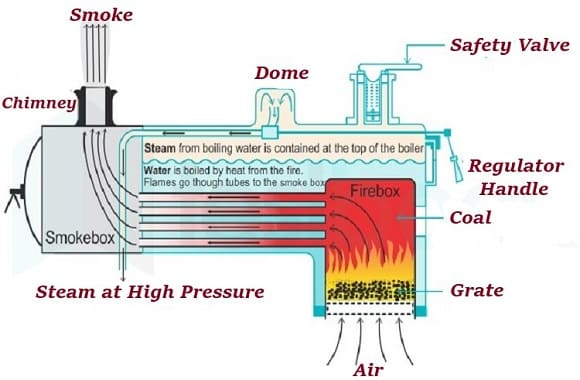

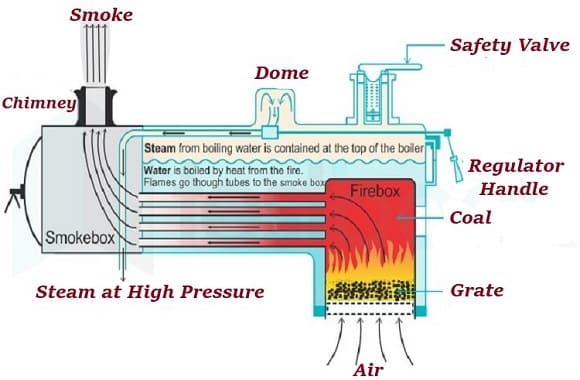

Fire tube boiler:

A hearth place-tube boiler is a kind of boiler wherein warm gases by skip from a hearth place via one or greater tubes strolling via a sealed field of water.

The warmth of the gases is transferred via the partitions of the tubes with the aid of using thermal conduction, heating the water and in the long run growing steam.

The hearth place-tube boiler advanced because the 0.33 of the 4 principal ancient forms of boilers: low-strain tank or "haystack" boilers, fluid boilers with one or massive flues, hearth place-tube boilers with many small tubes, and high-strain water-tube boilers.

Their benefit over fluid boilers with an unmarried massive flue is that the various small tubes provide some distance more heating floor place for the identical average boiler volume.

The well-known creation is as a tank of water penetrated with the aid of using tubes that bring the recent flue gases from the hearth place.

The tank is typically cylindrical for the maximum part

Being the most powerful sensible form for a pressurized field

And this cylindrical tank can be both horizontal and vertical.

This kind of boiler changed into used on without a doubt all steam locomotives with inside the horizontal "locomotive" shape. This has a cylindrical barrel containing the hearth place tubes, however additionally has an extension at one stop to residence the "firebox".

This firebox has an open base to offer a massive grate place and regularly extends past the cylindrical barrel to shape a square or tapered enclosure.

The horizontal hearth place-tube boiler is likewise regular of marine applications, the usage of the Scotch boiler; thus, those boilers are generally stated as "scotch-marine" or "marine" kind boilers.

Vertical boilers have additionally been constructed of the couple of hearth place-tube kind, even though those are relatively rare; maximum vertical boilers have been both fluid, or with pass water-tubes.

Fire Tube boiler is the best shape of the inner furnace, vertical hearth place tube boiler. Fire tube boilers are a transportable boiler and it calls for a small ground area. The steam score in hearth place tube boilers doesn’t exceed 2500 kg in line with hour and strain is restricted to ten bars.

A hearth place-tube boiler is a kind of boiler wherein warm gases by skip from a hearth place via one or (many) greater tubes strolling via a sealed field of water.

The hearth place-tube boiler advanced because the 0.33 of the 4 principal ancient forms of boilers: low-strain tank or “haystack” boilers, fluid boilers small tubes provide a miles more heating floor place for the identical average boiler volume.

The well-known creation is as a tank of water penetrated with the aid of using tubes that bring the recent flue gases from the hearth place.

This kind of boiler changed into used on without a doubt all steam locomotives with inside the horizontal “locomotive” shape.

This has a cylindrical barrel containing the hearth place tubes, however additionally has an extension at one stop to residence the “firebox”.

This firebox has an open base to offer a massive grate place and regularly extends past the cylindrical barrel to shape a square or tapered enclosure.

The horizontal hearth place-tube boiler is likewise regular of marine applications, the usage of the Scotch boiler; thus, those boilers are generally stated as “scotch-marine” or “marine” kind boilers.

Vertical boilers have additionally been constructed of the couple of hearth place-tube types, even though those are relatively rare; maximum vertical boilers have been both fluted or with pass water-tubes.

Fire Tube Boiler Construction

Fire tube boiler includes a vertical, cylindrical shell, prepared with a firebox with inside the bottom, water area with inside the center element and steam area with inside the higher element.

The hearth place grate is located at the lowest of the firebox and coal is fired on the firebox. An ash pit is positioned at the lowest of the grate to acquire the ash of burnt coal, that's periodically removed.

One or greater pass tubes are both flanged or riveted to the water area are positioned with inside the firebox to growth the heating floor place to enhance the water stream.

A brief chimney is attached on the pinnacle of the firebox to discharge the waste flue exhaust gases at a few more height.

Manhole and hand holes are supplied for cleansing the indoors of the boiler shell and pass tubes.

The boiler includes a strain gauge, water degree indicator, protection valve, steam forestall valve, and a manhole as mountings to offer protection and simplicity of working.

Fire Tube Boiler Working

Fuel burns at the grate with inside the firebox. The ensuing warm flue gases are allowed to by skip across the pass tubes.

The water surrounding the cylindrical firebox additionally gets warmth with the aid of using convection and radiation.

Thus steam is produced.

The water stream with inside the boiler relies upon at the density distinction in water, created with the aid of using the temperature distinction in water.

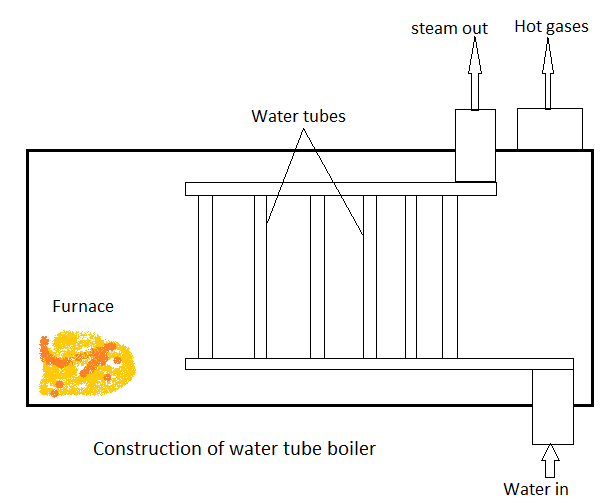

Water tube boilers:

Steam is one of the top notch reasserts of electricity for our contemporary-day age. We have used steam from the very starting of our first business revolution in human history.

It gives warmness for system heating, sterilization, and lots of different packages which can be more and more vital to business facilities, amongst others.

A boiler or steam generator is a tool used to create steam with the aid of using making use of warmness electricity to water.

Different kinds of boilers are to be had in numerous sizes and bureaucracy and discover their use in numerous packages.

The water tube boiler is one in all them this is implemented broadly in industries. In this article, we’re going to have an outline of water tube boilers along with operation, components, types, blessings, and drawbacks. Read this new weblog on Liquid to discover extra.

Water Tube Boilers Features

The water tube boiler represents one of the numerous pressurized gadget alternatives used to transform water into steam below managed conditions.

A manner to swiftly produce steam is to feed the water below stress right into a tube or tubes surrounded with the aid of using the combustion gases.

The earliest instance of this become evolved with the aid of using Goldsworthy Gurney with inside the overdue 1820s to be used in steam avenue carriages.

Modern excessive capability boilers are of water tube kind.

Basically, on this boiler, water may be flown with inside the tubes surrounded with the aid of using flue gases.

More steam is generated with the aid of using the usage of this boiler, so the general performance of the boiler is excessive.

The capacity of water tube boilers to be designed without using excessively massive and thick-walled stress vessels makes those boilers in particular appealing in packages that require:

An excessive steam output (as much as 500 kg/s) High-stress steam (as much as a hundred and sixty bar)

Superheated steam (as much as 550°C)

The water tube boiler is not unusual place in papermaking, sugar, and different Industries that call for electric electricity and steam.

Owing to their brilliant operating properties, using water tube boilers is surprisingly desired with inside the following main areas: Variety of system packages in industries Chemical processing divisions Pulp and Paper production plant life

The massive generators of application companies

Refining units Water Tube Boiler Components Here is evaluate of the water tube boiler components and functions.

Boiler Shell: This shell is the outside cylindrical a part of a stress container.

Steam drum: It is a set vessel for steam and water.

Mud drum: This is a cylindrical fashioned area at the bottom of the water area. It will collect impurities like dust, sediment, and others.

Water walls: It is a tubing association across the furnace to extract warmness from gasoline to generate steam.

Furnace: An enclosed area supplied for the combustion of gasoline.

Safety valve: It reveals a use for preventing the needless pressure from the development of a boiler.

Strainer: This is a form of tool as a clear out to keep strong factors permit a fluid deliver.

Sight glass: A glass tube is applied on steam kind boilers for giving observable symptoms and symptoms of the water degree in boilers.

Steam prevent valve: It controls the steam float deliver outside.

Feed take a look at valve: The excessive-pressure water flows thru this valve, which releases to the boiler actually and materials the water to the water kind boiler.

Burner: This is one form of tool for the start of air and gasoline right into a boiler on the desired velocity. It is the maximum important equipment for the firing of fuelling or oil.

Economizer: Accessory used to get better the warmth of flue fuelling that leaving the boiler with the aid of using heating feed water.

Superheater: It reveals use to growth the temperature of the steam. Working

Principle of Water Tube Boilers

Let’s realize approximately the operating precept of a water tube boiler, and it'll assist you to recognize its blessings and drawbacks clearly. The Feed Water is authorized with inside the steam drum with the aid of using a feed take a look at valve.

- The water travels to the dust drum wherein any undesirable debris will settle at the lowest of the dust drum.

- The water flow is maintained with the aid of using circulating tubes and steam stress is maintained with the aid of using equalizing tubes.

- The gasoline this is burnt with inside the firebox over the grate produces warm flue gases that journey over the water tubes giving its temperature.

- For the right passage of warm flue gases over the water tubes baffle plates are arranged.

- The heated water generates excessive-stress steam used for the manufacturing of Electricity.

- To growth the economic system of the boiler, exhaust gases additionally discover use to preheat combustion air blown into the burners and to heat the feed water deliver in an economizer.

Types of Water Tube Boilers

Here is a listing of water tube boiler types: Babcock and Wilcox boiler: Designed with the aid of using the American company of Babcock & Wilcox, this boiler reveals use in desk bound and marine engines. It completely reveals use whilst the stress above 10 bar and steam producing capability extra than 7000 kg/hr is required.

Sterling boiler:

This boiler is an early shape of water tube boilers, used to generate steam in massive land-primarily based totally desk bound plant life. They have become full-size in industries that produced flammable waste and required system steam. Sterling boilers are one in all the bigger preparations for a water tube boiler.

Simple vertical boiler:

These boilers discover use in steam electricity-pushed automobiles in addition to cell machines like railway steam engines, steam tractors, Steam shovels, and steam cranes.

Keep that during mind, opposite to famous perception that a locomotive boiler is a water tube boiler, you higher realize that it’s a hearth place tube boiler, and it isn't a water tube boiler instance.

Water Tube Boilers Pros

- Significant blessings of a water tube boiler gadget include:

- Safe and clean operation

- Fast response to steam call for

- Provides surprisingly green performance, as much as 90% with an economizer

- Rapid warmness transmission

- Requires much less ground place for a given output

- Can be effortlessly transported

- Easy get admission to all components for cleaning, inspecting, and repairing

- Can tolerate excessive steam pressures

- Large evaporative capacity

Water Tube Boilers Cons

Few obstacles related to using water tube boiler plant life include:

- High preservation cost

- Complicated and time-eating set up procedure

- Cannot be synthetic in packaged shape

- Uneconomical for small industries

High pressure boilers

An excessive stress boiler is a shell and tube warmness exchanger that use boiled water to create steam or excessive stress warm water. Using water crammed tubes in a metallic tank or enclosure, they devise electricity with the aid of using changing water into steam thru thermal power, that's used to electricity equipment.

The stress and steam of an excessive stress boiler is produced with the aid of using burning a gasoline, inclusive of coal, herbal fuelling, or petroleum.

The heated gases, from the burning gasoline, are circulated with the aid of using herbal convection or pressured with the aid of using a pump.

Forced circulate is produced with the aid of using a centrifugal pump to growth the evaporation charge to 210 ok of pressure in step with rectangular centimeter. Natural circulate is tons greater restricted and has a decrease pressure in step with rectangular centimeter. Two kinds of the boiler techniques are water tube and hearth place tube.

The majority of boilers paintings the usage of the equal precept of heated water generating steam.

The versions among the differing types is their geometric orientation, outside or inner hearth place, stress, water circulate, variety of tubes, and the circulate of gases. The geometric orientation of a boiler may be horizontal, vertical, or willing with hearth place outdoor or inside, relying at the boiler‘s design.

The department of mega Pascal stress (MPa) determines whether or not a boiler is low and excessive stress. Boilers that produce stress above eighty MPa are taken into consideration to be excessive stress. Low stress boilers have an MPa beneath eighty MPa.

Water circulate may be pressured or herbal. If the water is pumped, its miles pressured. If it's miles herbal, it's miles with the aid of using convection. Gas circulate is decided with the aid of using the form of tubing, which may be hearth place or tube. With hearth place tube, warmness movements thru tubes with inside the water.

In water tubing, water movements thru the tubes. Tubing for a boiler may be both unmarried and a couple of. The conventional Cornish boiler is an instance of an unmarried tube boiler because it has simplest one hearth place tube.

There is an extended listing of boilers which have a couple of tubes, that's current boiler design.

Types of High Pressure Boilers

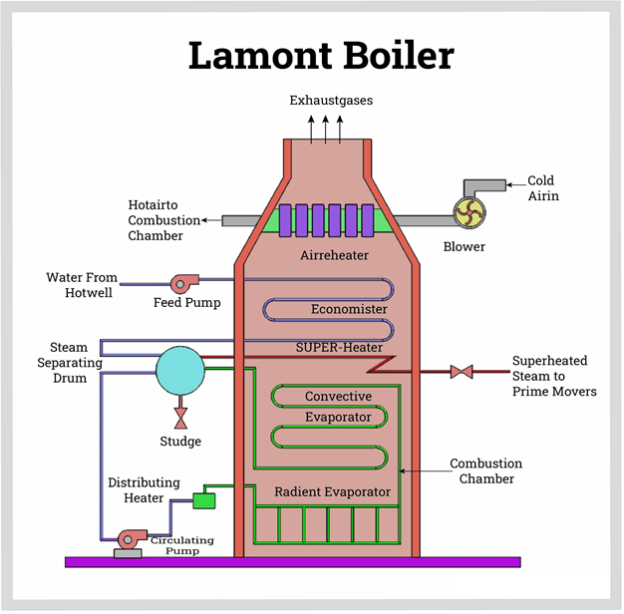

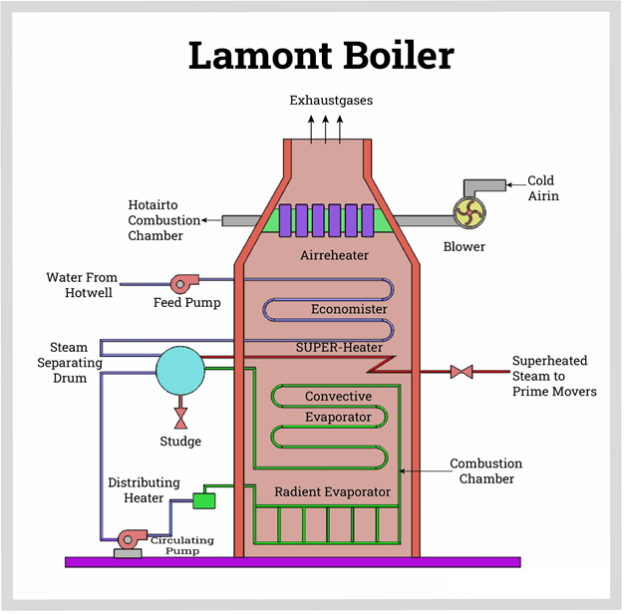

La Mont Boiler:

The Lamont boiler is a pressured convection water tube boiler that makes use of a pump to flow into water. It has an economizer to shop on power and growth efficiency, a boiler drum, super heater, evaporator, and air preheater. The combustion chamber for a La Mont Boiler is vertical.

Water is pumped thru the economizer and preheater into the boiler drum. The boiler drum serves as a steam separator. The pump pushes the water to a distributor header that has nozzles to ship the feed water into the evaporator tubes positioned with inside the partitions of the boiler to growth floor heating.

The water and steam pass into the boiler drum, wherein the steam is separated and exceeded to the super heater and directly to the turbine.

The super heater will increase the temperature of the saturated steam to save you water droplets from getting into the turbine.

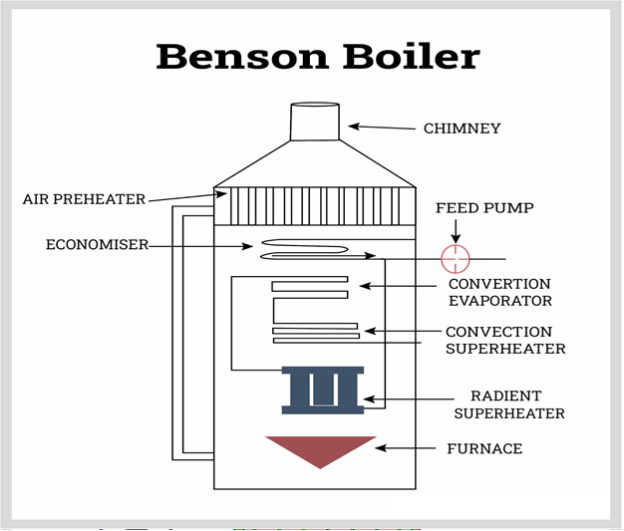

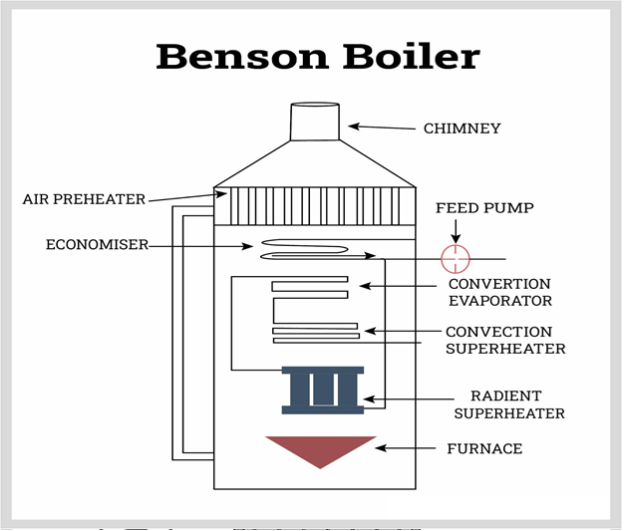

Benson Boiler:

The Benson boiler has a number of the equal functions because the La Mont boiler without a steam separator and works below essential stress.

It is a water tube, pressured circulate boiler, wherein the feed water is compressed to supercritical stress to save you the formation of bubbles with inside the water tube. The compressed water feed will increase the density of the water such that its density and that of the steam emerge as the equal, which reduces the latent warmness with inside the water to 0 making it less complicated to transform to steam.

The characteristic of the air preheater, economizer, super heater, evaporator, and combustion chamber are the equal. Unlike the La Mont boiler, the combustion chamber may be installed vertically or horizontally.

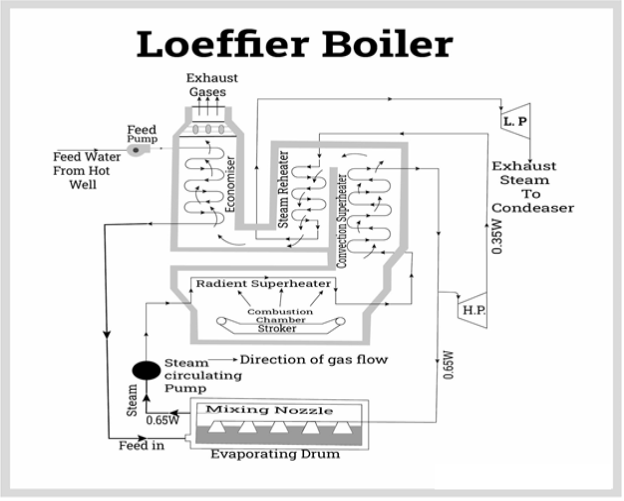

Loffler Boiler:

The Loffler boiler became advanced to solve a hassle with the La Mont boiler, which became salt and sediment buildup at the floor of the water tube and decreased warmness switch. Like the Benson boiler, water is circulated below excessive stress with inside the water tube. The Loffler boiler has radiant and convective super heaters that paintings collectively to distribute the steam to the turbine.

The radiant super heater heats the saturated steam the usage of radiant power produced with the aid of using the burning gasoline and is wherein warmness switch takes place.

The steam then passes thru the convective super heater this is heated with the aid of using the flue gases, which similarly heats the steam earlier than it passes directly to the turbine.

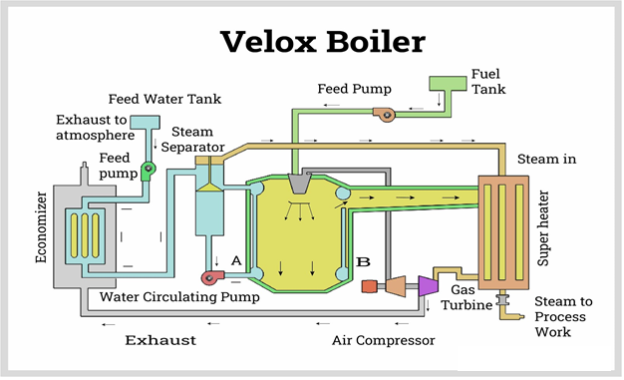

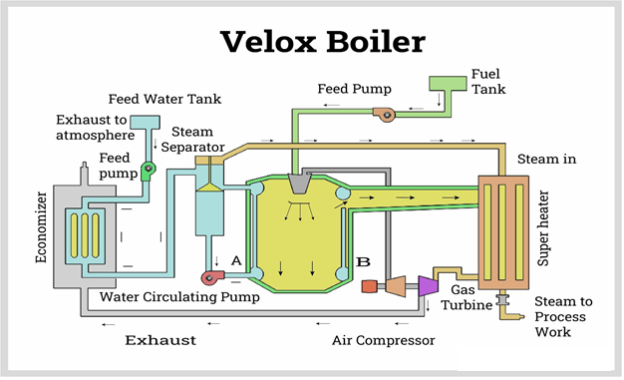

Velox Boiler:

The Velox boiler is a pressured circulate water tube boiler that makes use of excessive pace to unexpectedly produce steam.

The precept of the Velox boiler is constructed on the speed of the fuelling, which movements quicker than the velocity of sound and will increase the charge of warmth switch.

The Velox boiler has a fuelling turbine compressor that sends compressed air into the combustion chamber, wherein greater warmness is released. The extended charge of warmth launch complements the flue gases pace to the velocity of sound.

The flue gases by skip from the hearth place tubes at the lowest of the combustion chamber and surround water crammed tubes. Water is pressured from the economizer to the circulating pump at excessive pace inflicting the warmth to switch from the gases to the water very unexpectedly.

The water and steam pass to the water separator and directly to the super heater. As with the Loffler boiler, the flue gases are used to warmness the super heater.

Cornish Boiler:

The Cornish boiler is the most effective shape of boiler. It is a hearth place tube boiler that has an extended horizontal tube with an unmarried flue that carries the hearth place.

The cylindrical shell of a Cornish boiler is one to 2 meters in diameter and may be 4 to seven meters long.

The gasoline for a Cornish boil is loaded right into a grate thru a door, wherein it burns to supply warm gases that pass into the hearth place tube this is surrounded with the aid of using water, wherein the water is heated to supply steam.

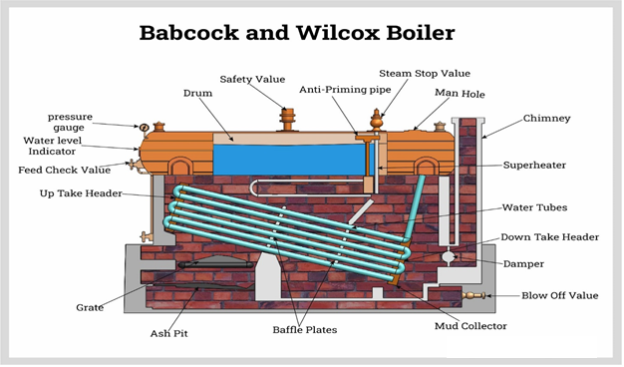

Cornish Boiler Babcock and Wilcox Boiler:

The Babcock and Wilcox boiler is a water tube horizontal boiler with herbal draft circulate and a couple of tubing. Water enters the tubes with the aid of using a down take header, is heated with the aid of using warm flue gases and movements in a zigzag style pressured with the aid of using baffle plates.

The steam with inside the tubes movements to an uptake header, wherein its miles accumulated in a boiler drum.

An anti-priming pump filters the steam to get rid of any water droplets in order that simplest steam is dispatched to the super heater, which will increase the temperature of the steam. The steam from the super heater is accumulated or dispatched directly to the turbine.

Boiler mountings and accessories.

The boiler mountings are fittings which might be installed at the boiler for its right functioning.

Mountings are water stage indicator, protection valve, stress gauge, etc.

It can be mentioned that a boiler cannot characteristic thoroughly without the mountings.

The boiler add-ons are the gadgets, which shape an essential a part of a boiler however aren't installed on it.

They consist of super heater, economizer, feed pump etc.

It can be mentioned the add-ons assist in controlling and going for walks the boiler efficiently.

Boiler Mountings

Following are the essential boiler mountings:

- Water stage indicator

- Pressure gauge

- Safety valve

- Stop valve

- Blow off

- Feed take a look at valve

- Fusible plug

Water Level Indicator

It is a protection tool upon which secure running of the boiler depends. Water stage indicator diagram

Working Principle

Water-tube indicator the water includes a vertical tough glass tube G that is geared up with gunmetal tubes A and B.

The tubes A connects the steam area of the boiler with the glass tube and the tube B connects the water area of the boiler with the glass tube. The tube A is supplied with a valve ‘S’, referred to as a steam valve, and tube B is geared up with any other valve ‘W’, referred to as a water valve.

In addition to those valves, a 3rd valve, referred to as drain valve, is suited for the water stage indicator via which water collectively with condensed steam from the gunmetal tube A is tired from time to time.

Pressure Gauge

Pressure gauges are used to degree the stress of steam interior a steam boiler. The stress gauge is constant in the front of a steam boiler. Pressure Gauge diagram

Working Principle

The stress gauge proven in fig is bourdon stress gauge. It includes a round spring tube A.

One give up of the bourdon tube is closed and related to a hyperlink L and the opposite give up is squared to a Hollow block B.

The hyperlink L connects the closed give up of the tube to the toothed region C that is hinged at O.

The toothed region gears with pinion D which includes a pointer P. The pointer actions on a dial graduated in stress units.

Safety valves

These are the gadgets connected with inside the steam boiler for stopping explosions because of immoderate inner stress of steam.

Safety Valve diagram

The protection valve is a device which prevents the boiler stress from growing above its ordinary running stress with the aid of using routinely beginning whilst the boiler stress exceeds the ordinary running stress,

Thus permitting extra steam to break out into the environment till the stress comes right all the way down to its ordinary valve.

Thus, a protection valve guarantees protection to a boiler from being broken because of immoderate steam stress.

- The protection valves usually used are:

- Deadweight protection valve,

- Lever protection valve,

- Spring-loaded protection valve,

- Steam prevent valve

The characteristic of a prevent valve is to govern the float of the steam from with inside the boiler and to prevent it absolutely whilst required.

A prevent valve or junction valve is used to adjust the float of steam from the boiler.

Steam Stop Valve diagram

The valves installed at the boilers, which alternate the route of float of steam with the aid of using 90° are referred to as junction valves, even as valves geared up in pipelines which permitting the steam with inside the identical route are referred to as prevent valve.

Blow-off Valve

The characteristic of a blow-off valve is to take away periodically the sediments deposited at the lowest of the boiler even as the boiler is in operation and to drain the boiler even as its miles being wiped clean or inspected.

Blow off Valve or Cock –

Boiler Mountings and Accessories When the blow-off valve is opened the water that is beneathneath the stress of steam, rushes out with high-quality speed accordingly wearing out the sediments together with it.

Feed Check Valve

When the extent of water with inside the boiler falls, its miles added returned to the desired stage with the aid of using providing the extra water referred to as feed water.

The stress in the boiler could be excessive consequently the stress of the feed water must be raised with the aid of using a pump earlier than its miles fed into the boiler.

The feed water beneathneath excessive stress is fed into the boiler via the feed take a look at valve.

The characteristic of a feed take a look at valve is to govern the float of water from the feed pump to the boiler and to save you the backflow of water from the boiler to the pump whilst the pump stress is much less than the stress or whilst the feed pump ceases to work.

Evidently feed take a look at valve is located on the boiler give up of the transport pipe of the feed pump. Fusible Plug

Fusible Plug –

The plug is made from tin or leads alloy, which has a low melting point.

The characteristic of the fusible plug is to put-off the hearth place with inside the furnace of the boiler whilst the water stage falls beneathneath and risky stage and accordingly avoids the explosion, which might also additionally take region because of overheating of the tubes and the shell. It is geared up over the crown of the furnace or the combustion chamber.

Boiler Accessories

The boiler add-ons are required to enhance the performance of the steam energy plant and to allow for the right running of the boiler.

The boiler add-ons aren’t installed at once at the boiler. The vital boiler add-ons are:

- Economizer

- Air pre-heater

- Superheater

- Feed pump

- Steam Separator

- Steam trap

Economizer

The combustion gases popping out of the boiler include a massive amount of warmth. Therefore the most quantity of warmth from the gases have to be recovered earlier than it escapes to the chimney. Economizer - Boiler Mountings and Accessories In the economizer, heating the feed water does the recuperation of warmth with inside the flue gases.

The economizer is located with inside the direction of the gases. They enhance the general performance of the boiler with the aid of using decreasing gasoline consumption.

Air Pre-heater

The air preheater is an accent that recovers the warmth with inside the exhaust fuelling with the aid of using heating the air provided to the furnace of the boiler. Supplying preheated air into the furnace produces an excessive furnace temperature and hurries up the combustion of the gasoline.

Thus the thermal performance of the plant could be increased.

The benefits of air pre-heater are, Increase with inside the steam technology rate. Better combustion with much less soot, smoke and ash, and Low-grade fuels may be used.

Superheater

The superheater is utilized in boilers to boom the temperature of the steam above the saturation temperature.

The dry saturated steam generated with inside the boiler is handed via a hard and fast of tubes located with inside the direction of the flue gases, wherein it'll be heated in addition with the aid of using the recent fuelling to boom its temperature approximately the saturation temperature.

Feed Pump

A feed pump is a boiler accent required to pressure the feed water at excessive stress into the boiler. Commonly used pumps are, Reciprocating pumps Rotary pumps

The reciprocating pumps are pushed at once with the aid of using coupling them to the steam engine.

The rotary pumps are pushed with the aid of using the steam mills or with the aid of using electric powered motors.

Key Takeaways:

- Water is pressured from the economizer to the circulating pump at excessive pace inflicting the warmth to switch from the gases to the water very unexpectedly.

- The boiler add-ons are the gadgets, which shape an essential a part of a boiler however aren't installed on it.

- The characteristic of a prevent valve is to govern the float of the steam from with inside the boiler and to prevent it absolutely whilst required.

References:

1. Thermal Engineering, Mathur & Mehtra, Jain Brothers Publications, New Delhi.

2. Heat Engineering, V.P. Vasandani & D.S. Kumar, Metropolian Book Publishers.

3. Power Plant Engineering, A.K. Raja, Shrivastava and Dwivedi, New age International Publishers.

4. Fluidized Bed Combustion, S. Oka and E. Anthony, Marcel Dekker Inc.

5. Power Plant Engineering, M. M. EI- Wakil, McGraw Hill International.

Unit - 1

Introduction to layout of thermal power plant

Introduction to layout of thermal power plant

Almost 1/3 of power requirement of the sector is fulfilled by means of thermal energy flora (or thermal energy stations).

In those energy stations, steam is produced by means of burning a few fossil gasoline (e.g. Coal) after which used to run a steam turbine.

Thus, a thermal energy station can also additionally from time to time known as a Steam Power Station. After the steam passes via the steam turbine, it's far condensed in a condenser and once more fed returned into the boiler to come to be steam.

This is referred to as rating cycle. This article explains how power is generated in thermal energy flora. As majority of thermal energy flora use coal as their number one gasoline, this newsletter is targeted on a coal fired thermal energy plant.

Typical Layout and Working of a Thermal Power Plant

A simplified format of a thermal energy station is proven below. Coal: In a coal primarily based totally thermal energy plant, coal is transported from coal mines to the producing station. Generally, bituminous coal or brown coal is used as gasoline.

The coal is saved in either 'lifeless garage' or in 'stay garage'. Dead garage is typically forty days backup coal garage that's used whilst coal deliver is unavailable.

Live garage is an uncooked coal bunker in boiler house. The coal is wiped clean in a magnetic purifier to clear out if any iron debris are gift which can also additionally purpose put on and tear with inside the equipment.

The coal from stay garage is first beaten in small debris after which taken into pulverize to make it in powdered form.

Fine powdered coal undergoes whole combustion, and for this reason pulverized coal improves performance of the boiler.

The ash produced after the combustion of coal is taken out of the boiler furnace after which nicely disposed.

Periodic elimination of ash from the boiler furnace is essential for the right combustion.

Boiler:

The aggregate of pulverized coal and air (generally preheated air) is taken into boiler after which burnt with inside the combustion zone.

On ignition of gasoline a massive fireball is shaped on the middle of the boiler and massive quantity of warmth electricity is radiated from it.

The warmth electricity is applied to transform the water into steam at excessive temperature and stress.

Steel tubes run alongside the boiler partitions wherein water is transformed in steam.

The flue gases from the boiler make their manner via super heater, economizer, and air preheater and ultimately get exhausted to the surroundings from the chimney.

Superheater:

The superheater tubes are hanged on the freshest a part of the boiler. The saturated steam produced with inside the boiler tubes is superheated to approximately 540 °C with inside the super heater.

The superheated excessive stress steam is then fed to the steam turbine.

Economizer:

An economizer is largely a feed water heater which heats the water earlier than presenting to the boiler.

Air pre-heater:

The number one air fan takes air from the surroundings and its far then warmed with inside the air pre-heater. Pre-heated air is injected with coal with inside the boiler. The gain of pre-heating the air is that it improves the coal combustion.

Steam turbine:

High stress extraordinary heated steam is fed to the steam turbine which reasons turbine blades to rotate. Energy with inside the steam is transformed into mechanical electricity with inside the steam turbine which acts because the top mover.

The stress and temperature of the steam falls to a decrease cost and it expands in extent because it passes via the turbine. The improved low stress steam is exhausted with inside the condenser.

Condenser:

The exhausted steam is condensed with inside the condenser through bloodless water circulation. Here, the steam loses it is stress in addition to temperature and it's far transformed returned into water.

Condensing is important because, compressing a fluid that's in gaseous country calls for a massive quantity of electricity with admire to the electricity required in compressing liquid. Thus, condensing will increase performance of the cycle.

Alternator:

The steam turbine is coupled to an alternator. When the turbine rotates the alternator, electric electricity is generated.

This generated electric voltage is then stepped up with the assist of a transformer after which transmitted wherein it's far to be applied.

Feed water pump:

The condensed water is once more fed to the boiler by means of a feed water pump.

Some water can be misplaced all through the cycle, that's definitely provided from an outside water source.

This became the fundamental operating precept of a thermal energy station and its regular components.

A sensible thermal plant own greater complex layout and more than one ranges of turbine which include

- High Pressure Turbine (HPT),

- Intermediate Pressure Turbine (IPT) and

- Low Pressure Turbine (LPT).

Principle of steam generation

Heat Exchange

Steam mills are utilized in numerous strategies to harness loose power with inside the shape of warmth and convert it right into a shape this is extra useful, inclusive of mechanical and electric power.

The warmth used is commonly produced deliberately to supply strength or is received as a byproduct of every other business process.

The on the spot supply of warmth is commonly dirty, inclusive of radioactive gasoline in a nuclear strength plant, so step one in steam strength era is to switch that warmth to smooth water with a warmth exchanger.

Steam Generation

The warm oil is circulated via the waters tub to generate steam. There are many one-of-a-kind geometric schemes for doing this, however the precept stays the same.

The heating liquid is diverted into numerous small pipes to boom its floor touch with water and facilitate speedy warmth trade and steam era.

The steam produced in cutting-edge nuclear and coal strength flora is frequently in supercritical situations or above the essential factor with inside the water section diagram (374 °C and 22 MPa).

Conversion of Heat to Electricity

Supercritical steam is loaded with power. Steams power is transformed into mechanical power through pressure with the aid of a steam turbine. The excessive strain of steam exerts strain at the angled blades of the turbine, inflicting the shaft to rotate.

This mechanical power is transformed into strength, the use of the strength with inside the shape of a rotating shaft to show an electric powered generator. The turbine being constructed with inside the picture can generate as much as sixty five MW of strength.

Compared to steams boilers, steams mills have much less metallic production of their layout, which makes use of an unmarried tube coil as opposed to numerous smaller diameter boiler tubes.

A unique feed water pump is used to constantly pump the feed water via the coil.

A steam generator makes use of a bar-via, compelled glide layout to transform incoming water into steam for the duration of an unmarried by skip via a water coil. As water passes via the coil, warmth is transferred from the recent gases, turning the water into steam.

Steam drums aren't used with inside the generator layout, in which the boiler steam has a dissipation region from the water, so accomplishing 99.5% steam pleasant calls for the usage of a steam/water separator.

Since mills do now no longer use a big pressurized vessel like a fire tube, they're frequently smaller and start-up quickly, making them perfect for brief on-call for situations.

However, this comes on the price of manufacturing power, as mills have a decrease turn-down price and are consequently much less capable of offer steam for the duration of intervals of variable call for.

Fuel for steam generators

The gasoline that has been used as a number one supply for energy for numerous years is coal.

It has now no longer been the handiest supply however has been useful to the energy enterprise because: coal has been the most inexpensive gasoline, on $ in keeping with million Btu basis; herbal fuelling has been strongly aggressive mostly in latest years; at one time (latest), 60% of U.S. Energy become generated in coal-fired flowers. Now ~40% from coal; about 80% of U.S. Coal manufacturing is burned in electric powered flowers.

However, the primary motive we're thinking about switching far from coal is burning coal is one of the maximum difficult environmental problems. For functions of the course, we keep in mind steam technology from coal as steam technology from biomass; each fuels are pretty similar.

We need an excessive warmness launch fee that is tied to the burning fee of gasoline. Since coal is a stable gasoline, it may not burn fast if it's miles in chunks. So, the manner to boom the burning fee is to boom the floor place of the coal; the manner to boom the floor place is to pulverize the coal into very small debris.

However, whilst the coal debris are small in size (something like flour), it makes it tough to handle.

It is tough to shovel something this is like dirt or to help it on a grate. Instead, it's miles simply blown into the boiler unit with a cutting-edge of air that is known as pulverized-coal firing or suspension firing.

This is now the same old for electric powered energy technology, abbreviated PC-fired water-tube boiler.

Burning the coal produces warmness; the warmth is used to boil the water to steam; the steam actions throughout the turbine to transport it; and the turbine turns the generator to supply energy

Through this series of transformations, the chemical capacity strength of gasoline (coal on this case) is transformed to excessive-capacity, excessive-voltage energy for distribution to consumers. If you keep in mind the internet performance from the coal pile to the cease of the plant, the plant performance is ~33%.

Plants constructed greater currently may be with inside the middle-excessive 30s range, at the same time as older flowers can be with inside the mid-20s.

The following steps are involved: Water is pumped at regular entropy to State 2 and into boiler.

Liquid is heated at regular stress State 3 (saturated steam). Steam expands at regular entropy via the turbine to State 4. Constant stress switch of warmth in condenser. The turbine turns the engine to supply energy.

The manner to decide the performance is to study the performance throughout every a part of the plant. Losses can arise at every step of the process

For a PC-fired present day energy plant, count on operation at 2500 psi, with a steam temperature of 540°C, then the general performance is 34%.

Losses at every element encompass 1 & 2) warmness losses in pipes and from the friction of the pump (performance of 92%); 3) warmness losses and friction with inside the turbine (performance of 44%); 4) warmness losses because the steam condenses returned to water (performance of 85%), and 5) little or no lack of performance from generator (performance of 99%).

For each 3 rail vehicles of coal used to generate energy, vehicles of coal are misplaced to waste warmness.

Necessity of water treatment

Water remedy is any manner that improves the high-satisfactory of water to make it suitable for a particular stop-use.

The stop use can be ingesting, commercial water supply, irrigation, river waft maintenance, water activity or many different uses, along with being competently lower back to the environment.

Water remedy eliminates contaminants and unwanted components, or reduces their awareness in order that the water turns into healthy for its preferred stop-use.

This remedy is vital to human fitness and lets in human beings to advantage from each ingesting and irrigation use. Water is the maximum vital compound for existence on Earth, and having drinkable water is a key global challenge for the twenty-first century. All dwelling matters require clean, uncontaminated water as a primary requirement. Water covers greater than seventy one percentage of the earth’s surface, however best round 1% of its miles drinkable in line with global requirements because of numerous contaminations.

Waste water discharge from industries, agricultural pollution, and municipal wastewater, environmental and worldwide modifications are the principle reasserts of water infection.

Even hint ranges of heavy metals, dyes, and microbes are dangerous to human fitness, aquatic structures, and the environment.

According to a Food and Agriculture Organization evaluation from 2007, absolute water shortage will have an effect on 1.eight billion humans dwelling in international locations, and water pressure would possibly have an effect on two-thirds of the worldwide population. To cope with water shortage issues, its miles required to get better water from contemporary wastewater or increase change water reasserts for human intake.

Domestic and commercial wastewater are the 2 styles of wastewater.

Domestic wastewater incorporates sewage, bacteria, viruses, dangerous and non-poisonous organisms, sanitary outputs, rubbish, detergents, and different strong and liquid discharges from non-production approaches.

Water infection is frequently resulting from the release of untreated wastewater from enterprises. The effluent from numerous enterprises, which includes various ranges of contaminants, is dumped into rivers or different water resources.

The wastewater might also additionally have an excessive share of natural and inorganic contaminants on the preliminary discharge.

Industries generate wastewater due to fabrication approaches, approaches coping with paper and pulp, textiles, chemicals, and from numerous streams which includes cooling towers, boilers, and manufacturing lines.

Typical ingesting water remedy approaches

Treatment for ingesting water manufacturing entails the elimination of contaminants and/or inactivation of any probably dangerous microbes from uncooked water to supply water this is natural sufficient for human intake with none brief time period or long time hazard of any damaging fitness effect.

In trendy terms, the best microbial dangers are related to ingestion of water this is infected with human or animal (along with bird) faces.

Faces may be a supply of pathogenic bacteria, viruses, protozoa and helminthes.

The elimination or destruction of microbial pathogens is essential, and typically entails using reactive chemical dealers which includes suspended solids, to eliminate bacteria, algae, viruses, fungi, and minerals along with iron and manganese.

Research along with Professor Linda Lawton's institution at Robert Gordon University, Aberdeen is operating to enhance detection of cyanobacteria.

These materials hold to reason excellent damage to numerous much less evolved international locations who do now no longer have get entry to powerful water purification structures.

Measures taken to make certain water high-satisfactory now no longer best relate to the remedy of the water, however to its conveyance and distribution after remedy.

It is consequently not unusual place exercise to maintain residual disinfectants with inside the handled water to kill bacteriological infection for the duration of distribution and to maintain the pipes clean.

Water furnished to home houses which includes for faucet water or different uses, can be in addition handled earlier than use, regularly the use of an in-line remedy manner. Such remedies can consist of water softening or ion exchange.

Many proprietary structures additionally declare to eliminate residual disinfectants and heavy metallic ions

Water is one of the crucial herbal assets on Earth. Water is the second one vital substance after air that's vital for the survival of all of the dwelling organisms in this planet.

There we've got come collectively and written this newsletter on Water remedy flora and why companies and governments have to consciousness extra on constructing extra water remedy flora for our world.

Most of Earth’s floor (71%) is included with the aid of using water and the sea holds approximately 97% of water that's saline and now no longer secure for consuming and different purposes.

Only 3% of the water is sparkling and appropriate for consuming.One-1/3 of the freshwater is saved with inside the shape of icebergs and polar ice caps and best a bit quantity is saved as groundwater and floor water.

The water which we use is floor water and it is largely to be had with inside the rivers, ponds, and lakes. But because the populace and developmental sports are growing the floor and groundwater have become infected day with the aid of using day.

The ever-growing pollutants has caused the creation of dangerous chemical substances and risky materials with inside the water system.

Today, it isn't always secure to at once use the water from rivers, reservoirs, and lakes because it includes numerous micro-organisms, pathogens, and different contaminants which have a detrimental impact at the fitness of humans, flora, and animals.

This scenario of dangerous and dangerous floor water has generated the want for the Water Treatment Plant.

Necessity:

- Water this is used for consuming water manufacturing incorporates water molecules and a big form of different substances. One of the residences of water is that it without problems dissolves different substances.

- Water that falls to earth for the duration of rain showers dissolves substances, debris and gasses along with oxygen, which may be located in air.

- Contaminants which might be found in air additionally dissolve in rain water. When floor water flows on the earth it additionally dissolves numerous extraordinary substances, along with sand debris, natural rely, microorganisms and minerals.

- Water that settles into the floor and will become groundwater regularly incorporates big quantities of dissolved minerals, because of touch with soils and rocks.

- Human activities, along with agriculture and business waste and sewer water discharge purpose some of pollution to go into the water. Water has the ability to cleanse itself.

- Contaminants are eliminated from water for the duration of organic processes.

- Contaminants are damaged down, or will live in the back of with inside the floor layer. The self-cleaning ability of water isn't always robust sufficient to provide smooth consuming water.

- This is an effect of the amount and form of business and agricultural contaminants which have entered floor and groundwater for lots decades.

- In the 1970’s it changed into found that business discharges and waste water discharges had been the purpose of water contamination.

- Immediately after this discovery measures had been taken to save you water pollution. Waste water ought to meet felony trendy earlier than it may be discharged.

- To meet the requirements water is purified earlier than its miles discharged. Despite of those measures water regularly nevertheless desires remedy earlier than its miles appropriate to be used as consuming water.

- During water purification waste water is dealt with to come to be consuming water which meets felony requirements with inside the bodily, bacteriological and chemical area.

- The water might not include an odor or flavor, and it ought to be vivid and chemically stable (non-corrosive).

- The type of remedy water desires, strongly relies upon the composition and high-satisfactory of the water. Water remedy incorporates method steps: bodily elimination of strong debris, in particular minerals and natural rely and chemical disinfection; killing or deactivating microorganisms in water.

Key takeaways:

- This became the fundamental operating precept of a thermal energy station and its regular components.

- Even hint ranges of heavy metals, dyes, and microbes are dangerous to human fitness, aquatic structures, and the environment.

- Water that settles into the floor and will become groundwater regularly incorporates big quantities of dissolved minerals, because of touch with soils and rocks.

Classification of steam generators

The creation of the steam generator, or boiler, converted normal existence lengthy earlier than digital improvements did, and arguably had an extra usual effect than greater current improvements inclusive of as on-line commerce, social media and wi-fi technology. It is difficult to realize now simply how a lot of a game-changer it became which will get from region to region without both private or animal (e.g., horse-drawn carriage) energy.

On its face, the manufacturing of steam on reason looks as if an odd choice.

Looking at the sector the manner a younger baby might, steam seems to be little greater than a compulsory watery waste fabricated from numerous tactics regarding warmness era, from cooking a container of pasta to warming the corridors of a building.

The first-class manner to narrate your thoughts to the price of nicely harnessed steam is to photo what takes place while something that has steam billowing from its miles abruptly capped or in any other case bodily averted from emitting that steam – for example, clamping a lid tightly down on a pot of boiling water for even a 2nd earlier than freeing it.

The Basics and Origins of Steam Power Steam is water vapor, or greater generally, the gaseous shape of the molecule.

Water includes hydrogen and oxygen atoms and has a molecular system of H2O. Like different depend with a selected boiling point, water is capable of input the gaseous segment while it reaches that temperature (for water, a hundred C, or stages Celsius (212 F, or stages Fahrenheit) and receives a tiny electricity push so it could conquer its warmness of vaporization, a type of toll that depend normally has to pay to extrude among states (solid, liquid or Today, steam's maximum critical full-size function is with inside the era of electrical energy.

But lower back with inside the overdue 1600s, it became observed that it became less difficult to take away waste water from mines while it became condensed.

In the system, it became observed that the system of water condensing creates a vacuum (bad stress on the subject of anything lies out of doors the vicinity of condensation activity). This locating became ultimately included into cutting-edge steam engines and generators.

Types of Steam Generators

Fire tube.

These are most customarily utilized in tactics that want everywhere from 15 to 2,2 hundred horsepower (1 hp = 746 watts, or W). This sort of boiler is cylindrical, with the flame with inside the furnace hollow space itself and the combustion gases themselves stored inner a sequence of tubes. These are available in fundamental designs: dry lower back and moist lower back.

Water tube.

In this arrangement, tubes include steam, water or both, even as the goods of combustion by skip across the out of doors of tubes. These frequently have more than one units of drums, and due to the fact they use incredibly little water, those boilers provide strangely speedy steaming capabilities. Commercial. These normally characteristic combos of water tube, fire tube and electric powered-resistance designs.

They are famous in huge homes requiring a typically steady temperature, inclusive of colleges and libraries, workplace and authorities homes, airports, condo complexes, university and different studies laboratories hospitals, and so on.

Condensing.

Condensing boilers can attain thermal performance tiers of two ninety eight percentage, in comparison to 70 to eighty percentage plausible the usage of well-known boiler designs.

Typical performance tiers attain approximately ninety percentage while the go back water temperature is at a hundred and ten F or lower, and upward push with lowering water-go back temperature thereafter.

Flexible water tube (flex tube).