Unit - 3

Fluidized bed boiler

Fluidized bed boiler

Fluidized mattress combustion (FBC) is a combustion generation used to burn strong fuels. In its maximum simple shape, gasoline debris are suspended in a hot, effervescent fluidity mattress of ash and different particulate materials (sand, limestone etc.) via which jets of air are blown to offer the oxygen required for combustion or gasification.

The resultant rapid and intimate blending of fuel line and solids promotes speedy warmness switch and chemical reactions in the mattress.

FBC flora are able to burning quite a few low-grade strong fuels, inclusive of maximum styles of coal, coal waste and woody biomass, at excessive performance and without the need for high priced gasoline preparation (e.g., pulverizing).

In addition, for any given thermal duty, FBCs are smaller than the equal traditional furnace, so might also additionally provide good sized blessings over the latter in phrases of value and flexibility. FBC reduces the quantity of sulfur emitted with inside the shape of SOx emissions.

Limestone is used to precipitate out sulfate all through combustion, which additionally lets in extra green warmness switch from the boiler to the equipment used to seize the warmth energy (commonly water tubes).

The heated precipitate coming in direct touch with the tubes (heating via way of means of conduction) will increase the performance. Since this lets in coal flora to burn at cooler temperatures, much less NOx is likewise emitted. However, burning at low temperatures additionally reasons expanded polycyclic fragrant hydrocarbon emissions.

FBC boilers can burn fuels aside from coal, and the decrease temperatures of combustion (800 °C / 1500 °F) produce other brought advantages as well.

“Fluidized mattress combustion (FBC) is a combustion generation used to burn strong fuels.”

A mattress of strong debris is stated to be fluidized whilst the pressurized fluid (liquid or fuel line) is exceeded via the medium and reasons the strong debris to act like a fluid below sure situations. Fluidization reasons the transformation of the nation of strong debris from static to dynamic.

Fluidized Bed Combustion

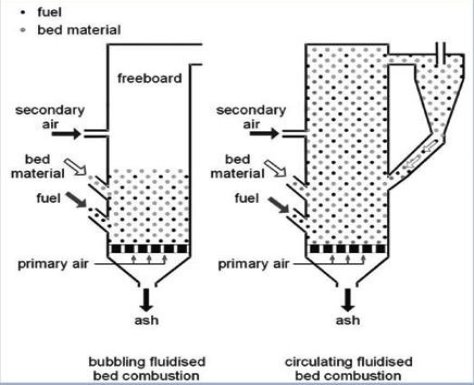

Is the ignition of a strong gasoline below the situations noted above? We, At Thermo dyne, Boiler Manufacture in India, We layout and manufacture Boilers with Bubbling Fluidized Bed Combustion (BFBC) Circulating Fluidized Bed Combustion (CFBC).

Bubbling FBC is used for Fuels with decrease heating values which include Rice Husk. Under such sort, the principle elements main to fluidization are as follows:

Solid Fuel

Particle Size

Air Fuel Mixture

Fluidized Bed Combustion takes location whilst the pressured draught fan substances air to the Furnace of the Boiler.

In the furnace, and is (used for Bubbling phenomenon) located at the Bed and is heated earlier than fluidization, the air enters the mattress from the nozzles equipped at the Furnace Bed.

And above the nozzles; the sand opposes the upward movement of the air. But at enough velocities, whilst the stress implemented via way of means of the air will become identical to the burden of the sand, fluidization of the sand occurs. Now the gasoline provided via way of means of gasoline conveyor is fed to the preheated effervescent sand and receives combusted away.

This phenomenon additionally guarantees entire combustion of the Fuel. The warmness launched all through combustion heats up the encircling boiler tubes and generates steam.

The fundamental blessings of Bubbling Fluidized Bed Combustion are the improved thermal performance, smooth ash removal. Another kind is the Circulating Fluidized Bed Combustion; its miles implemented to fuels with better heating values which include Petcock. In this, the unburned gasoline is fed once more to the furnace with the assist of a Forced Draught fan and ducts, making sure superior combustion and better heating and offers incredible gasoline flexibility.

Also, the fluidizing speed of Air in CFBC is relatively better than that of BFBC. One of the fundamental drawbacks is the strength consumption.

The cars established with inside the Forced Draught Fan devour extra strength than the only established with inside the identical capability Boiler’s (wood/coal fired) Forced Draught Fan, due to multiplied ranges of draught requirement to create fluidization.

Bubbling fluidized bed boilers

High gasoline flexibility Generally, BFB combustion is characterized via way of means of preserving massive thermal capability of mattress material, and may stably hearth place numerous sorts of gasoline consisting of excessive-moisture or low-flammable gasoline.

By making use of the above combustion technology, Mitsubishi Power can deliver BFB boiler to make use of the numerous gasoline, that's coal, woody biomass like waste wood /production waste, and business waste consisting of the tire derived gasoline.

Reliable mattress drain discharge machine In order to save you volatile fluid mattress situation because of incombustible substances stagnation in furnace, Mitsubishi Power BFB boiler has the dependable mattress drain discharge machine consisting of suitable backside furnace shape and air nozzle, relying on gasoline property.

Low NOx combustion

The launch of pollution consisting of nitrogen oxides (NOx) may be decreased because of sufficiently low-temperature combustion (~900℃). B&W’s BFB boilers are designed to permit an extensive variety of fuels to be burned, one at a time or in combination.

The capacity to make use of numerous gasoline reasserts and brands presents proprietors with the power to take benefit of possibility fuels and manipulate gasoline costs. B&W’s benefit B&W’s BFB boiler is designed with reliability in mind.

Several functions integrate to offer low upkeep costs, excessive availability and long-time period reliability: An open backside layout lets in clean elimination of outsized or overseas material.

A water-cooled, fuel line-tight decrease furnace gets rid of the ability for fuel line leaks prompted from refractory damage.

Bottom-supported hoppers eliminate load from the boiler, lessen capital requirements, and decrease ability mechanical stresses among water-cooled and non-cooled components.

Incorporated in our layout are those functions to lessen upkeep costs: No put on parts No shifting parts No water-cooled screws or beams No cinder re-injection machine Long-lasting bubble caps

Fireside corrosion-erosion is the primary reason of metallic loss on furnace wall tubing in biomass and waste fired BFB boilers.

The price of metallic wastage is stimulated with the aid of using metallic temperature (boiler pressure), fuel line temperature (warmness flux).

And combustion environment.

The latter being a characteristic of gasoline chemistry and whether or not combustion is complete. Boiler furnace and very last steam layout temperatures are confined with the aid of using the combusted gasoline, as producers undertake precise firing strategies and temperature limits for given gasoline chemistry.

Chlorine without problems reacts with unstable alkali metals to supply alkali metallic chlorides, (Na+K)Cl, with inside the gaseous vapor phase.

Alkali chlorides without problems condense as ash deposits on fuel line tube metallic surfaces, in which it interacts with the commonly defensive oxide scales. The chloride-wealthy ash inhibits the boom of a dense, duplex oxide scale which could normally act as a ramification barrier to restrict in addition corrosion.

Frequently a chloride wealthy corrosion scale is located among the oxide scale and the metallic surface.

Under the impact of warmth flux, this ends in fast diffusion of corrodes and corrosion products.

In addition to the alkali metals observed in easy timber fuels, waste fuels regularly comprise heavy metals including lead and zinc.

These metals react without problems with chlorine and in addition make a contribution to the delivery of chloride wealthy ash to the tube metallic surface, growing the corrosively of the ash deposit and combustion environment.

Circulating fluidized bed boilers (Elementary treatment expected)

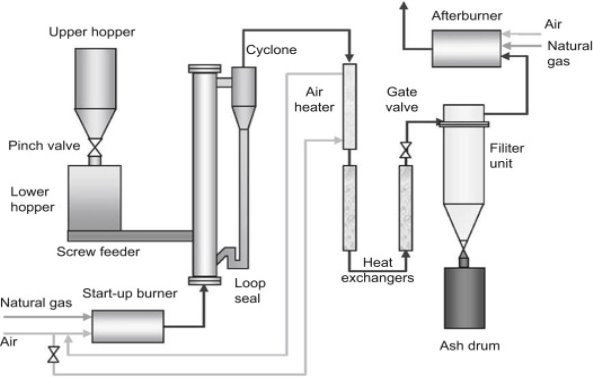

The circulating fluidized mattress (CFB) is a kind of Fluidized mattress combustion that makes use of a recirculating loop for even more performance of combustion.

At the same time as attaining decrease emission of pollution.

Reports advocate that as much as 95% of pollution may be absorbed earlier than being emitted into the atmosphere.

The generation is constrained in scale however, because of its substantial use of limestone, and the reality that it produces waste byproducts.

Fluidization is the phenomenon via way of means of which stable debris are transported right into a fluid-like kingdom via suspension in a fuel line or liquid. The resultant blending of fuel line and solids promotes fast warmness switch and chemical reactions in the mattress.

Power flowers that use this generation are able to burning low grade fuels at excessive performance and without the want for highly-priced gasoline preparation.

They also are smaller than the equal traditional furnace, so can also additionally provide widespread benefits in phrases of value and flexibility.

Circulating fluidized mattress is a quite new generation with the capacity to obtain decrease emission of pollution.

Extensive studies has been performed in this generation in the beyond 15 years because of growing worries over pollutants as a result of conventional techniques of combusting coal and its sustainability.

The significance of this generation has grown currently due to tightened environmental policies for pollutant emission.

The Mercury and Air Toxic Standards (MATS) enacted in December 2011 with inside the United States via way of means of the Environmental Protection Agency have compelled all of the nations in Europe and America to strictly adhere to this policy.

This way that emissions inclusive of metals, acid gases, natural compound, flue fuel line acids and different pollution from strength flowers or commercial centers must meet the necessities set via way of means of EPA and enhancements must be completed for centers that don't meet the standards.

- As a result, the call for for circulating fluidized mattress generation is expected to rise. In 1923, Winkler's coal gasified represented the primary widespread huge-scale commercial utility of fluidized mattress (Kunii and Levenspiel, 1991).

- CFB combustion generation maintains to develop strongly in huge software strength plant packages as CFB boiler generation has grown from small-scale commercial packages to huge ultra-supercritical strength flowers in much less than 20 years

- Circulating fluidized mattress combustion (CFBC) strength era era has advanced unexpectedly with inside the final 30 years, and is now absolutely industrial and to be had at sizes as much as six hundred MW.

- However, pulverized coal (PC) boiler era stays the number one strength era for top class fuels and CFBC era is used in particular to hearth place fuels now no longer ideal for PC applications.

- The bankruptcy indicates that as much as 500 MW ability CFBC vegetation maintain a thermal and monetary gain over PC vegetation even if fired with top class fuels, and that this gain is more advantageous through their capacity to hearth place low-value ‘opportunity’ fuels.

- To hold their value competitiveness, CFBC vegetation want to development to the bigger sizes at which PC vegetation are to be had, 750 MW and above.

Coal handling

An easy coal managing format as proven with inside the figure. It is composed of Coal delivery Coal unloading.

- Preparation Transfer Outdoor garage.

- Covered garage.

- Implant managing.

- Weighing and measuring.

- Furnace firing.

- Coal managing format coal managing format

Requirements of Coal Handling Layout

- Low maintenance.

- Higher reliability.

- Should be easy and sound.

- It ought to require minimal operatives.

- Easy and clean in operation.

- Should deliver proper exceptional of gasoline with inside the proper time with inside the proper amount.

- Should have minimal put on in strolling the varieties of equipment.

Coal Handling Methods

Following are the one-of-a-kind coal managing techniques are used: Transportation through sea or river Rail Ropeways Road Pipeline

1. Transportation through Sea or River

The coal may be transported from the mines to the electricity stations by way of ships or massive boats via the sea or river. The unloaded coal from the deliver may be both dispatched to the garage backyard or at once to the conveyor device which at once to the combustion chamber hopper.

2. Transportation through Rail

In this case, the railway is used to move the coal from the mines at once to the electricity stations, maximum of the thermal electricity stations will acquire the coal from rail transport. The coal from the railway wagon is taken to the electricity station and is both brought to the garage backyard or near the factor of consumption.

3. Transportation through Ropeways

It is the maximum green technique of transporting coal from the mine to the electricity station. It is mainly used while the space among the electricity station and mine is much less than 10 km. The predominant gain of this type of device is, it components the coal constantly and unfastened from worker’s strike that's not unusual place with rain transport.

4. Transportation through Road

The coal may be transported from mines to the electricity plant by way of trucks, tippers, tractors etc., via road, however its miles used best for small capability electricity stations. The predominant gain of this kind is that the coal may be carried at once into the powerhouse as much as the factor of consumption.

5. Transportation through Pipeline

In this technique, the coal with inside the shape of slurry is at once furnished from the far off mines to the strategically positioned thermal electricity flora via pipelining. This technique is the maximum green one.

It components a massive amount of coal constantly with none hassle and loss. This device is dearer than all different structures however maximum inexpensive in operation.

Elements of coal handling:

i) Coal delivery

The coal from deliver factors is introduced through ships or boats to strength stations located close to sea or river while coal is provided through rail or vehicles to the strength stations that are located far from sea or river. The transportation of coal through vehicles is used if the railway centers aren't available.

Ii) Unloading

The sort of system for use for unloading the coal acquired on the strength station relies upon on how coal is acquired on the strength station. If coal introduced through vehicles, there's no want of unloading tool because the vehicles might also additionally unload the coal to the outside garage.

Coal is without problems dealt with if the carry vehicles with scoop are used. In case the coal is delivered through railways wagons, ships or boats, the unloading can be performed through vehicle shakes, rotary vehicle dumpers, cranes, take hold of buckets and coal accelerators. Rotary vehicle dumpers even though steeply-priced are pretty green for unloading closed wagons.

(iii) Preparation

When the coal introduced is with inside the shape of large lumps and it isn't of right size, the education (sizing) of coal may be accomplished through crushers, breakers, sizers, driers and magnetic separators.

Iv)Transfer

After education coal is transferred to the useless garage with the aid of the subsequent systems.

1. Belt conveyors

2. Screw conveyors

3. Bucket elevators

4. Grab bucket elevators

5. Skip hoists

6. Flight conveyor

Belt Conveyor Figure indicates a belt conveyor. It includes an infinite belt shifting over a couple of stop drums (rollers). At far an assisting curler is supplied on the center.

The belt is made from rubber or canvas. Belt conveyor is appropriate for the switch of coal over lengthy distances. It is utilized in medium and big strength plants.

The preliminary value of machine isn't excessive and strength intake is likewise low. The inclination at which coal may be correctly accelerated through belt conveyor is set 20°. Average velocity favored than different types.

Advantages of belt conveyor

1. Its operation is easy and clean

2. It calls for much less strength in comparison to different styles of systems

3. Large portions of coal may be discharged fast and continuously.

4. Material may be transported on mild inclines.

2. Screw Conveyor

It includes an infinite helicoid screw suited to a shaft (figure). The screw even as rotating in a trough transfers the coal from feeding stop to the release stop.

This machine is appropriate, wherein coal is to be transferred over shorter distance and area boundaries exist. The preliminary value of the intake is excessive and there's substantial put on o screw. Rotation of screw varies among 75-one hundred twenty five p.m.

3. Bucket elevator

It includes buckets constant to a chain (figure). The chain movements over wheels. The coal is carried through the bucket from backside and discharged on the top.

4. Grab bucket elevator

It lifts and transfers coal on an unmarried rail or song from one factor to the different. The coal lifted through take hold of buckets is transferred to overhead bunker or garage. This machine calls for much less strength for operation and calls for minimal maintenance.

The take hold of bucket conveyor may be used with crane or tower as proven in figure. Although the preliminary value of this machine is excessive however working value is much less.

Storage of Coal

It is acceptable that enough amount of coal need to be saved. Storage of coal offers safety in opposition to the interruption of coal substances whilst there's put off in transportation of coal or because of strike in coal mines. Also whilst the charges are low, the coal may be bought and saved for destiny use.

The quantity of coal to be saved relies upon at the availability of area for garage, transportation centers, and the quantity of coal on the way to whether or not away and nearness to coal mines of the strength station.

Usually coal required for one month operation of strength plant is saved in case of strength stations are located at longer distance from the collieries while coal want for approximately 15 days is saved in case of strength station located close to collieries.

Storage of coal for longer intervals isn't tremendous as it blocks the capital and effects in deterioration of the excellent of coal.

Ash handling

Ash Handling System:

Boilers burning pulverized coal (PC) have backside furnaces. The massive ash debris are accrued below the furnace in a water-stuffed ash hopper, Fly ash is accrued in dirt creditors with both an electrostatic precipitator and a bughouse.

A PC boiler generates about 80% fly ash and 20 backside ash. Ash ought to be accrued and transported from numerous factors of the plant life as proven in figure. Pyrites, which might be the rejects from the pulverizes, are disposed of with the lowest ash device.

Three most important elements ought to be taken into consideration for ash disposal systems.

1. Plant

2. Fuel source

3. Environmental regulation

Needs for water and land are essential concerns for plenty ash dealing with systems. Ash portions to be disposed of rely upon the king of gas source. Ash garage and disposal web sites are guided through environmental regulations.

The sluice conveyor device is the maximum extensively used for backside ash dealing with, even as the hydraulic vacuum conveyor (figure) is the maximum regularly used for fly systems.

Bottom and slag can be used as filling cloth for avenue construction. Fly ash can partially update cement for making concrete. Bricks may be made with fly ash. These are long lasting and strong.

Ash dealing with Equipment

Mechanical method are required for the disposal of ash. The dealing with gadget ought to carry out the subsequent functions:

1. Capital investment, working and renovation costs of the gadget ought to be low.

2. It ought to be capable of take care of massive portions of ash.

3. Clinkers, shoot, dirt etc. create troubles. The gadget ought to be capable of take care of them smoothly.

4. The gadget used ought to do away with the ash from the furnace, load it to the conveying device to supply the ash to dumping web page or garage and in the end it ought to have method to get rid of the saved ash.

5. The gadget ought to be corrosion and put on resistant.

Classification of Ash Handling System

i) Hydraulic device

Ii) Pneumatic device

Iii) Mechanical device

The usually used ash discharge gadget is as follows:

i) Rail avenue vehicles

Ii) Motor truck

Iii) Barge

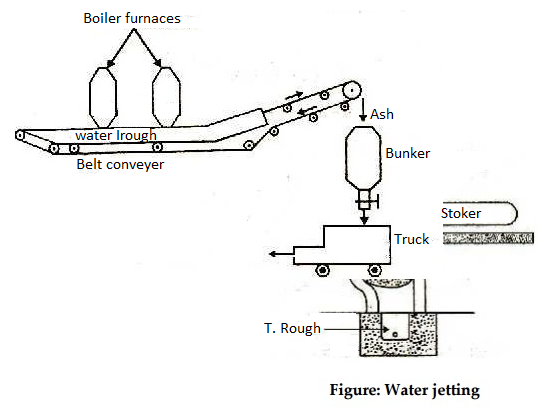

Hydraulic System

In this device, ash from the furnace grate falls right into a device of water owning excessive speed and is carried to the sumps. It is normally utilized in massive energy plant life. Hydraulic device is of types, namely, low strain hydraulic device used for intermittent ash disposal figure. Figure indicates hydraulic device.

Figure: Hydraulic device

In this technique water at enough strain is used to put off the ash to sump. Where water and ash are separated. The ash is then transferred to the unload web page in wagons, rail vehicles to trucks.

The loading of ash can be thru a belt conveyor, take hold of buckets. If there's an ash basement with ash hopper the ash can fall, at once in ash automobile or conveying device. Water jetting of ash is proven in figure. In this technique a low strain jet of water popping out of quenching nozzle is used to chill the ash. The ash falls into trough and is then eliminated.

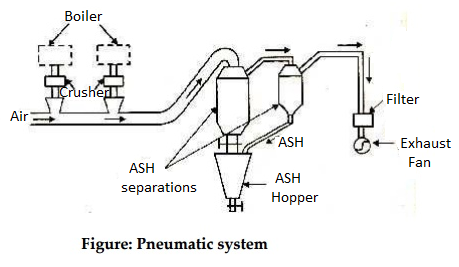

Pneumatic System

In this device ash from the boiler furnace outlet falls right into a crusher in which a beer ash debris are overwhelmed to small sizes.

The ash is then carried through an excessive speed air or steam to the factor of delivery.

Air leaving the ash separator is exceeded thru clear out out to do away with dirt etc. So that the exhauster handles smooth air with a purpose to defend the blades of the exhauster.

Figure: Pneumatic device

Mechanical device

Figure indicates a mechanical ash dealing with device. In this device ash cooled through water seal falls at the belt conveyor and is executed constantly to the bunker. The ash is then eliminated to the dumping web page from the ash banker with the assist of trucks.

Key takeaways:

- This way that emissions inclusive of metals, acid gases, natural compound, flue fuel line acids and different pollution from strength flowers or commercial centers must meet the

- The coal from the railway wagon is taken to the electricity station and is both brought to the garage backyard or near the factor of consumption.

Cogeneration: Introduction to cogeneration

Cogeneration

The technique of the usage of steam to show generators and generate energy — permits a plant to lessen its reliance on outside electric power purchases. This article discusses exceptional practices for the selection, operation, integration, and manipulate of steam cogeneration structures.

A normal fossil-gasoline energy plant has a median thermal-to-energy performance of 35–45%, due to the fact its steam turbine can best extract a lot electric power from excessive-stress steam, and due to the fact the low-stress steam that exits the turbine can't be used.

Therefore, the steam exiting the turbine need to be condensed, and its capacity power is lost. Industrial vegetation, however, have an aggressive benefit over energy vegetation due to the fact they have got numerous technique gadgets which can use the lower-stress outlet steam, which removes the want for inefficient steam condensing.

In a cogeneration system, steam that passes via the generators is maintained at an outlet stress excessive sufficient to be utilized by technique gadgets. Because power on the turbine outlet is re-used, cogeneration structures have usual efficiencies that may be better than 85%, which permits commercial vegetation to generate electric energy at lower-than-marketplace costs.

Cogeneration or blended warmness and energy (CHP) is the usage of a warmness engine or energy station to generate energy and beneficial warmness on the identical time.

Cogeneration is a greater green use of gasoline or warmness, due to the fact in any other case-wasted warmness from energy era is placed to a few effective use.

Combined warmness and energy (CHP) vegetation get better in any other case wasted thermal power for heating.

This is likewise known as blended warmness and energy district heating. Small CHP vegetation are an instance of decentralized power.

By-product warmness at mild temperatures (100–180 °C, 212–356 °F) also can be utilized in absorption fridges for cooling.

Cogeneration turned into practiced in a number of the earliest installations of electrical era. Before relevant stations disbursed energy, industries producing their very own energy used exhaust steam for technique heating.

Large workplace and rental buildings, hotels, and shops usually generated their very own energy and used waste steam for constructing warmness.

Due to the excessive price of early bought energy, those CHP operations persevered for decades after application energy have become available.

Need:

- Need for Cogeneration enables to enhance the performance of the plant.

- Cogeneration lessen air emissions of particulate matter, nitrous oxides, sculpture dioxide, mercury and carbon dioxide which might in any other case ends in greenhouse effect.

- It reduces fee of manufacturing and enhance productivity.

- Cogeneration gadget enables to shop water intake and water costs.

- Cogeneration gadget is greater not pricey in comparison to traditional energy plant.

- In congenital energy plant, with 100 % strength enter, handiest 45 % of strength is used and relaxation 55 % is wasted however with cogeneration, the whole strength used is 80% and strength wasted is handiest 20%.

- Thermal energy flora are a primary supply of energy deliver in India.

- The traditional approach of energy era and deliver to the client is wasteful with inside the feel that handiest approximately a 3rd of the number one strength fed into the energy plant is clearly made to be had to the consumer with inside the shape of energy

- In traditional energy plant, performance is handiest 35% and closing 65% of strength is lost.

- Also in addition losses of round 10-15% are related to the transmission and distribution of energy with inside the electric grid.

- For instance with inside the scheme, an enterprise calls for 24 gadgets of electrical strength and 34 gadgets of warmth strength.

- Through separate warmth and energy course the number one strength enter in energy plant may be 60 gadgets (24/0.forty).

- If a separate boiler is used for steam era then the gasoline enter to boiler may be forty gadgets (34/0.eighty five).

- If the plant had cogeneration then the gasoline enter may be handiest sixty eight gadgets (24+34)/0.eighty five to satisfy each electric and thermal strength requirements.

- It may be found that the losses, which had been forty two gadgets with inside the case of, separate warmth and energy has decreased to ten gadgets in cogeneration mode.

- Along with the saving of fossil fuels, cogeneration additionally lets in to lessen the emission of greenhouse gases (mainly CO2 emission).

- The manufacturing of energy being on-site, the weight at the software community is decreased and the transmission line losses eliminated.

- Cogeneration makes feel from each macro and micro perspectives.

- At the macro level, it lets in part of the monetary burden of the countrywide energy software to be shared with the aid of using the non-public sector; in addition, indigenous strength reasserts are conserved.

- At the micro level, the general strength invoice of the customers may be decreased, mainly whilst there's a simultaneous want for each energy and warmth on the site, and a rational strength tariff is practiced with inside the country.

Working principle and applications

Cogeneration is a manner of producing each thermal electricity and strength. In convectional thermal electricity stations outlet steam wishes to be cooled earlier than pumping it to the boiler again.

Cogeneration permits for the usage of the waste warmth and for that reason improving the general device performance.

Looking at separate technology, on the basis that strength is generated with performance of 35% there are 60 gadgets of number one electricity had to create 21 gadgets of strength.

To generate 33 gadgets of warmth there are 37 gadgets of number one electricity required, for that reason the whole quantity of number one electricity utilized in that device is ninety seven and the general performance totals 55%.

Cogeneration perceptibly improves typical performance and offers the equal quantity of electricity while simplest 60 gadgets of number one electricity is used. Production of warmth is essential at some stage in bloodless seasons while warmth call for is excessive however there are months in a 12 months while its miles alternatively inefficient.

Graph. 1 indicates a theoretical graph of warmth and coolness call for inside one year period.

As it is able to be seen, from April to September that the cooling call for is better than warmth call for and it might be very effective to generate cool electricity in place of warm one at some stage in the ones seasons. The era which permits for technology strength and using the waste warmth for heating and cooling is trigeneration.

First one is called Back-Pressure Turbine and its miles characterized with easy configuration.

The outlet steam exits the turbine with better stress than in Extraction-Condensing Turbine and flows without delay to the masses in which it releases warmth and condenses.

Except the simplicity it has extra advantages, it's miles efficient, it makes use of a bit or none cooling water and it's miles relativity inexpensive.

The largest drawback of that device is its inflexibility, the strength technology is associated with the manufacturing of warmth and its miles not possible to alter it with independence of thermal technology. The different kind is Extraction-Condensing Turbine. Here the excessive stress steam enters the turbine and while it has suitable stress and temperature it feeds the heating method at the same time as the relaxation of the steam maintains on increasing and is eventually condensed.

This sort of flora in contrast to the Back-Pressure flora generate extra strength and are extra flexible. However they want auxiliary equipment’s along with cooling towers and condenser.

They also are extra pricey and much less efficient. Another sort of CHP is fuel line turbine cogeneration device (GTCS).

Those structures have skilled fast improvement with inside the latest years and grow to be an opportunity for steam turbine cogeneration structures.

Consequently fumes depart the combustor and input the turbine generating mechanical electricity to propel a generator and a compressor. Fumes leaving the turbine are warm sufficient to feed the thermal masses.

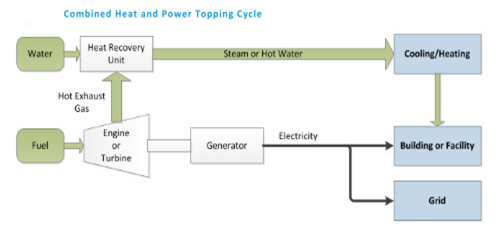

Topping cycle

Non-fossil gas primarily based totally Co-producing Stations –

The mission shall qualify to be termed as a non-fossil gas primarily based totally co-era mission, if it's far the use of new plant and equipment and is according with the definition and additionally meets the qualifying requirement mentioned below:

Topping cycle mode of co-era –

Any facility that makes use of non-fossil gas enter for the electricity era and additionally makes use of the thermal strength generated for beneficial warmth packages in different business sports

Topping cycle CHP is the method of the use of gas to generate mechanical strength that is used to create power the use of a generator. The ensuing waste warmth is captured from this method to warmth water to be used as warm water or steam at some point of the facility.

The topping cycle fashion CHP structures are the maximum famous because of their versatility.

Cineplex cogeneration structures utilize topping cycle CHP fashion electricity era.

Combined warmness and electricity (CHP) structures are proving to be a powerful manner of lowering waste and riding efficiency. A CHP gadget, additionally called cogeneration, is an easy process.

It makes use of an unmarried gasoline supply to supply energy and warmness. That warmness is then used to both lessen strength prices or to create extra energy.

However, there are major styles of cogeneration structures. Knowing that is quality for a facility will imply a radical knowledge of the differences.

For electricity flowers and production centers that produce substantial quantities of warmness, a bottoming cycle or topping cycle cogeneration plant could be the important thing to maximizing the benefits afforded via way of means of CHP gadget adoption.

This method focuses by and large at the era of electrical or mechanical electricity. The warmness this is in any other case wasted in non-cogeneration optimized settings is as an alternative captured and used to carry out sensible functions.

Most commonly, this technique is used to warmness centers and may result in more cogeneration plant efficiency.

There are a whole lot of secondary functions that this strength may be used for.

For example, extra energy may be bought to the neighborhood electricity distribution grid or used to electricity centers themselves.

Bottoming cycle

Based on its excessive performance, the diesel engine is the main electricity supply for numerous heavy-obligation applications, along with marine installations, strength manufacturing, on-avenue vans and buses, and diverse off-avenue machines. Inherently, the excessive performance approach low carbon dioxide (CO2) emissions.

Still today, one of the international demanding situations over the entire strength subject is to in addition lessen greenhouse fuel line emissions to fight weather change, consisting of the discount of the CO2 emissions.

This may be performed through growing the strength performance and strength savings, and through locating renewable alternatives in place of traditional fossil strength sources. In this respect, the diesel engine presents a very good place to begin with a capacity to reap vast upgrades each in strength performance and emissions discount. (FCEP 2010)

Within the continued big Finnish studies software Future Combustion Engine Power Plant (FCEP), one of the paintings programs concentrates at the strength performance of inner combustion engines.

Technologies associated with the improvement of strength performance are developed. The engine itself, waste warmness recuperation (WHR) structures, or electricity conversion are investigated.

This examine turned into a part of the FCEP studies software and centered specially on the waste warmness recuperation structures with a goal to locate possible answers to increase the strength manufacturing of diesel and fuel line engine pushed electricity vegetation.

At the identical time, strength performance is improved, reducing CO2 emissions. On January 24, 2019, NCSLT filed a grievance alleging that Smith breached the Contract and owed $6,854.75, in addition to gathered and ongoing statutory interest.

Bottoming cycle plant operators are required to document disbursed gasoline combustion emissions among the thermal strength, strength, and synthetic merchandise the use of an in depth performance method.

Bottoming cycle CHP structures can have, in some cases, decrease efficiencies than the CHP machine performance referred to of sixty five to eighty percent.

Bottoming cycle vegetation produce warmness for a commercial system first, after which strength is produced the use of a waste warmness recuperation boiler. Bottoming cycle vegetation might be required to calculate disbursed emissions the use of an in depth performance method. Bottoming cycle vegetation are handiest used whilst the commercial system calls for very excessive temperatures, along with furnaces for glass and metallic production and claiming coke?

Within the content material of the SPCD the contractor will encompass a assertion that they have got examine and recognize the CSPP and the way they'll follow all of the necessities and protection approaches particular inside it. Bottoming cycle vegetation get better steam or warmness from a system movement to supply strength at the lowest or give up of the cycle.

Key Takeaways:

- Cogeneration or blended warmness and energy (CHP) is the usage of a warmness engine or energy station to generate energy and beneficial warmness on the identical time.

- Cogeneration permits for the usage of the waste warmth and for that reason improving the general device performance.

References:

1. Thermal Engineering, Mathur & Mehtra, Jain Brothers Publications, New Delhi.

2. Heat Engineering, V.P. Vasandani & D.S. Kumar, Metropolian Book Publishers.

3. Power Plant Engineering, A.K. Raja, Shrivastava and Dwivedi, New age International Publishers.

4. Fluidized Bed Combustion, S. Oka and E. Anthony, Marcel Dekker Inc.

5. Power Plant Engineering, M. M. EI- Wakil, McGraw Hill International.