Unit - 6

Steam condensers

Steam condensers

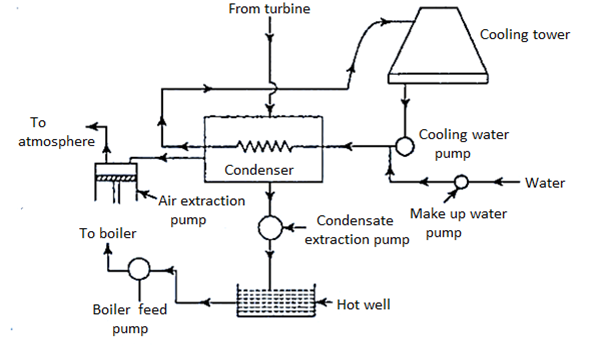

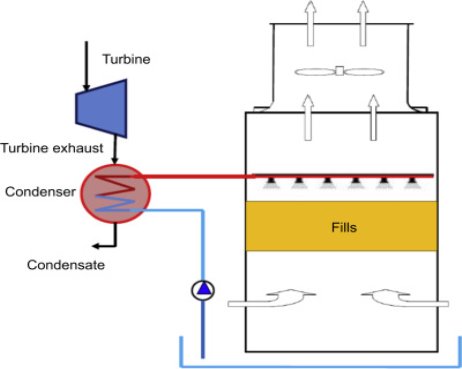

A steam condenser is a closed vessel-kind warmth exchanger implemented to transform low-stress exhaust steam from the turbine to water.

A steam condenser is a mechanical tool hired to condense exhaust steam of the turbine into the water. It conducts this procedure with the assist of cooling water that circulates interior it from the cooling tower. The stress inside a steam condenser is held under the atmospheric stress to decorate efficiency. It is generally used to decrease the backpressure of the exhaust on the turbine quit.

Functions of the Steam Condenser

The reason of the usage of a steam condenser is: supporting maintain the stress low (under atmospheric stress) on the steam turbine quit to get most feasible strength and decrease the unique steam intake of an electricity plant.

Offering natural feed water to and from the new nicely.

The water is once more pumped to the boiler the usage of a boiler feed pump.

Steam Condenser Parts

The additives required to perform a steam condenser are as follows.

Condenser

The steam with low stress offers its warmth to the coolant (right here water from the cooling tower), and it converts into the water thru the condensation procedure.

Condensate Extraction Pump

A Condensate Extraction Pump (CEP) is a pump mounted among the condenser and the new nicely to switch the condensate from the condenser to the new nicely. Hot Well It is a pit among the condenser and the boiler. It takes the condensate with the aid of using condensate pump from the condenser. The feed water is carried from the new nicely to the boiler.

Boiler Feed Pump

It is a pump positioned among the new nicely and boiler to supply the feed water from the new nicely to the boiler. This is achieved with the aid of using growing the condensate stress above boiler stress.

Air Extraction Pump

It is a pump applied to extract or take away the air from the steam condenser. Cooling Tower It is a tower containing bloodless water, and this water is furnished to flow into within the condenser to chill the steam. Cooling Water Pump It is a pump mounted among the condenser and the cooling tower. It circulates the coolant inside the condenser.

Steam Condenser Working Principle

In this section, we are able to supply a simple description of the way a steam condenser works. A glide of cooling water is constantly circulating from the condenser interior a steam condenser to the cooling tower and the cooling tower to the condenser.

When low-stress exhaust steam leaves the turbine and passes thru the condenser, it loses the warmth and condenses into water. The circulating cooling water plays the extraction of the warmth from the steam.

Two forms of gadgets are mounted at the condenser: the condensate extraction pump and the air extraction pump.

Therefore, whilst the steam condenses into water, it re-circulates once more to the steam generator with the assist of a condensate extraction pump. Using the air extraction pump, a vacuum (the stress under the atmospheric stress) is created within the condenser in order that cooling water can flow into effortlessly and additionally the condensate glide may be stabilized.

Due to the low stress within the condenser, the air enters the gadget in order that the condenser is packed with a combination of water, air, and steam.

Types & Classification of condensers

Three Main and Different Types of Condensers.

- Air-cooled condenser

- Natural Convection

- Forced Convection

- Water-cooled condenser

- Double Tube Shell and Coil Condenser

- Shell and Tube Condenser

Evaporative Condenser

Condensers primarily based totally at the condensing medium used to eliminate the warmth from the system, consist of 3 one-of-a-kind kinds. None of those 3 one-of-a-kind styles of condensers has mainly no blessings over the alternative. Depending at the situation, everyone have to be used appropriately. We are going to tricky at the features of those 3 condenser kinds with inside the following.

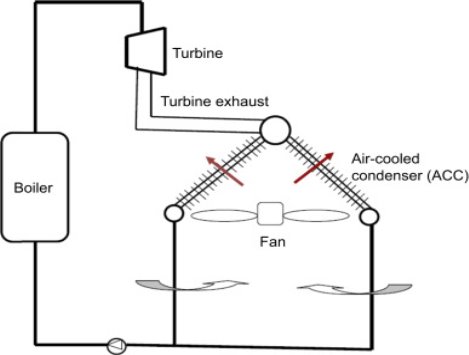

Air-cooled Condenser

Condensers of this kind use air because the outside fluid to reject the warmth from the system. Air-cooled condensers typically have copper coils in which refrigerant flows in. But this isn't always the complete story; this kind is subcategorized into subsets: herbal convection and compelled convection.

Natural Convection

In this kind of condenser, air involves touch with heat coils, soaking up the warmth of refrigerant in the coils, therefore the temperature of air increases. As the nice and cozy air is lighter, it is going up and the bloodless air replaces and once more the bloodless air comes to the touch heat coils to reject the warmth. This herbal cycle maintains till the refrigerant loses its warmth. Since the glide charge of air is small and the radiation warmth switch is likewise now no longer very high, the blended warmth switch coefficient in those condensers is small.

As a result, an especially massive condensing floor is needed to reject a given quantity of warmth. Hence those styles of condensers are used for small capability refrigeration structures like family fridges and freezers.

Forced Convection

One of the alternative styles of condensers is compelled-convection. A fan or a blower does play the maximum essential position in casting off warmth from the refrigerant in the coils. A critical tip needs to be referred to right here and its miles that the fins of compelled convection condenser are positioned tightly subsequent to every other; so, if the dirt and dust fill the mild area among the fins, the air flowing and warmth rejection faces huge trouble.

Forced convection kind condensers are usually utilized in window air conditioners, water coolers, and packaged air con plants.

Water-cooled condenser

As it is able to be guessed, this kind of condenser makes use of water as fluid to eliminate warmth from the refrigerant. It is apparent that water-cooled condensers are used in which we've got an ok deliver of water. This kind, itself has 3 one-of-a-kind kinds: See All Water-Cooled Condenser for Sale

Double Tube

Double tube condensers have a tube of water inner a massive refrigerant tube. The water absorbs maximum of the refrigerant warmth, however because the refrigerant tube is in touch with the herbal move of air, a part of the cooling system is on herbal convection. Although double-tube condensers usually had been used with inside the past, the massive wide variety of gaskets and flanges utilized in those warmth exchangers ends in protection problems.

Shell and Coil Condensers

In a shell-and-coil condenser, a welded shell consists of a coil of finned water tubing. In this kind of water-cooled condenser, the new refrigerant flows with inside the shell even as the cooling water circulates in the coils and condenses the refrigerant. It is normally maximum compact and occasional in fee.

Shell and Tube Condensers

One of the styles of condensers plays the system of rejecting warmth with the aid of using having a cylindrical shell including water tubes.

Installations of fins in pipes permits higher warmth switch. The shell-and-tube condensers are normally low in fee and smooth to maintain. The maximum not unusual place kind of shell and tube condensers is the horizontal shell kind. However, vertical shell and tube condensers are typically used with ammonia in massive capability structures in order that cleansing of the tubes is viable from the pinnacle even as the plant is running.

Evaporative Condensers

And finally, the closing one of the styles of condensers is the evaporative one. Its miles truly the combination true of an air-cooled and water-cooled condenser. Evaporative condensers use air and water because the condensing medium.

The sprayed water over coils evaporates and the desired warmth for the vaporizing water is taken from the warmth of refrigerant. Some quantity of water might be circulated with the aid of using losing into the sump however to make up the quantity evaporated, a further quantity of water is delivered to the water delivery of the sump.

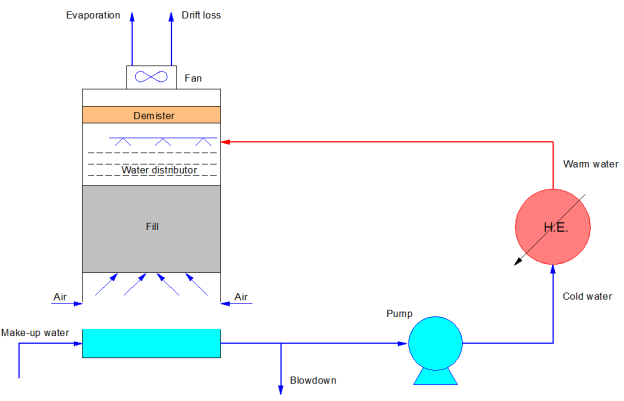

Quality and quantity of cooling water required

Cooling towers are a crucial thing of refrigeration systems. They are not unusual place in industries together with oil & gas, chemical processing, electricity plants, datacenters.

Water is the maximum not unusual place cooling medium utilized in cooling processes, because of its availability and excessive warmness capacity. These makes use of require massive quantities of water and frequently gift ability for water saving.

This financial savings bring about decrease water and sewer payments and reduced remedy costs. In the commercial marketplace there may be discovered 3 kinds of cooling towers: open circuit, closed circuit and as soon as thru machine.

Cooling towers may be air-cooled or water-cooled. Water-cooled cooling towers are extra not unusual place, because the cooling electricity of water is more potent than air.

Hybrid cooling towers have become increasingly more appealing for Datacenter cooling in critical Europe.

During low temperature months, air is used for cooling, whilst in excessive temperature months, water is used. The water intake is composed at the manager of the makeup water, the blow down water and the evaporated water quantities. These 3 waters decide the cycles of awareness that may be reached with inside the cooling tower.

Make – up = Blowdown + Evaporation loss

The mass stability of a cooling tower machine may be written because the following:

This equation doesn’t take account of the method leaks, the wind age and flow that are simply kinds of out of control blow down. Moreover, the cycles of awareness is a ratio of the awareness in suspended solids among the blow down water and the makeup water.

Cycles =

Water cooling is a technique of warmth elimination from additives and commercial equipment. Evaporative cooling the use of water is regularly extra green than air cooling. Water is less expensive and non-toxic; however, it may include impurities and reason corrosion.

Water cooling is typically used for cooling vehicle inner combustion engines and strength stations.

Water coolers utilizing convective warmness switch are used internal excessive-quit non-public computer systems to decrease the temperature of CPUs.

Other makes use of consist of the cooling of lubricant oil in pumps; for cooling functions in warmness exchangers; for cooling homes in HVAC and in chillers.

Water is less expensive, non-toxic, and to be had over maximum of the earth's surface. Liquid cooling gives better thermal conductivity than air cooling.

Water has surprisingly excessive particular warmness capability amongst typically to be had drinks at room temperature and atmospheric stress permitting green warmness switch over distance with low fees of mass switch.

- Cooling water can be recycled thru a recirculating machine or utilized in an unmarried by skip once-thru cooling (OTC) machine.

- Water's excessive enthalpy of vaporization lets in the choice of green evaporative cooling to get rid of waste warmness in cooling towers or cooling ponds.

- Recirculating structures can be open in the event that they depend upon evaporative cooling or closed if warmness elimination is performed in warmness exchangers with negligible evaporative loss.

- A warmness exchanger or condenser can also additionally separate non-touch cooling water from a fluid being cooled, or touch cooling water can also additionally without delay impinge on gadgets like noticed blades in which segment distinction lets in clean separation.

- Environmental guidelines emphasize the decreased concentrations of waste merchandise in non-touch cooling water

Calculations for surface condenser

In a floor condenser vapor is added into touch with a strong floor that's cooled to a temperature beneath the saturation temperature of the vapor at its triumphing partial pressure.

The floor is generally with inside the shape of a "nest" or "bundle" of metallic tubes, the coolant flowing with inside the tubes and the vapor condensing at the outer or "shell-side. The Overall Heat Transfer Coefficient, U (primarily based totally at the condensing floor area), can be expressed in phrases of nearby coefficients, a, thru the sum of thermal resistances:

From through vapor condensate tube wall fouling coolant

1/U = 1/αU + 1/αf +  + F +

+ F +

Where D0, Di are the tube outer and inner diameters and λw is the thermal conductivity of the tube material.

Heat alternate in unmarried section flows is commonly impeded with the aid of using the presence of insulating boundary layers.

On condensation, however, the huge discount in quantity because the vapor turns to condensate consequences in an influx of vapor toward the floor; the warmth switch is impeded handiest with the aid of using a skinny movie of condensate at the floor.

The thermal resistance, F, of fouling at the coolant aspect is consequently a vital consideration. Condensing warmth switch prices are normally orders of importance better than the prices for a fuel line at the shell aspect, so condensers do now no longer typically require prolonged floor tubing. In a few packages spirally grooved tubing has been used to useful resource drainage of the condensate movie and to growth inner warmth switch with the aid of using tabulating the coolant flow.

If no wetting may be maintained (e.g., with the aid of using surfactants), drop wise condensation occurs, lowering the regions of condensate movie and ensuing in a warmth switch coefficient a few 4 instances that of film wise condensation.

More importantly frictional strain losses because the vapor passes among the intently pitched tubes lowers the partial strain—and subsequently saturation temperature—lowering the warmth alternate using temperature difference.

The important goal in floor condenser layout is to offer identical get right of entry to of vapor to all of the floor.

Modern exercise is to version the proposed nest on pc to calculate thermal overall performance and to make sure that any non-condensable gases gift are extracted on the factor of lowest strain, e.g.,

Poorly designed nests can also additionally go through immoderate frictional strain losses and comprise areas in which the tubes are protected with the aid of using no condensable gases.

Key Takeaways:

- The sprayed water over coils evaporates and the desired warmth for the vaporizing water is taken from the warmth of refrigerant

- Hybrid cooling towers have become increasingly more appealing for Datacenter cooling in critical Europe.

- As a result, the condensation warmth switch coefficient is commonly better than that at the liquid coolant aspect, the latter turning into the controlling process.

Dalton’s law of partial pressure

Dalton’s regulation of partial pressures is a fuel line regulation which states that the entire strain exerted through a combination of gases is identical to the sum of the partial pressures exerted through every man or woman fuel line with inside the combination. For example, the entire strain exerted through a combination of gases A and B is identical to the sum of the man or woman partial pressures exerted through fuel line A and fuel line B (as illustrated below).

Dalton’s Law Formula

Dalton’s law of partial pressures can be mathematically expressed as follows:

Ptotal = ∑ni=1pi∑i=1npi (or) Ptotal = P1 + P2 + P3 + …. + Pn

Where,

- Ptotal is the total pressure exerted by the mixture of gases

- P1, P2,…, Pn are the partial pressures of the gases 1, 2,…, ‘n’ in the mixture of ‘n’ gases

Expressing Partial Pressures in Terms of Mole Fraction

Ratio of the partial stress of that fuelling to the general stress exerted with the resource of the use of the gaseous combination.

This mole fraction additionally may be used to calculate the general extensive type of moles of a constituent fuelling even as the general extensive type of moles with inside the combination is known.

Furthermore, the quantity excited about the resource of the use of a particular fuelling in a combination additionally may be calculated with this mole fraction with the help of the equation supplied below.

Xi=Pi /Ptotal = Vi / Vtotal = n1 / ntotal

Where Xi is the mole fraction of a gas ‘i’ in a mixture of ‘n’ gases, ‘n’ denotes the number of moles, ‘P’ denotes pressure, and ‘V’ denotes volume.

Example 1

A mixture of hydrogen gas and oxygen gas exerts a total pressure of 1.5 atm on the walls of its container. If the partial pressure of hydrogen is 1 atm, find the mole fraction of oxygen in the mixture.

Given, Phydrogen = 1 atm, Ptotal = 1.5 atm

Applying Dalton’s law formula, Ptotal = Phydrogen + Poxygen

Therefore, Poxygen = 0.5 atm

Now, the mole fraction of oxygen, Xoxygen = (Poxygen/Ptotal) = 0.5/1.5 = 0.33

Therefore, the mole fraction of oxygen in the mixture is 0.33

Example 2

At a temperature of 300K, 30 liters of gas A kept under pressure of 1 atm and 15 liters of gas B kept under pressure of 2 atm is transferred into an empty 10L container. Calculate the total pressure inside the container and the partial pressures of gas A and gas B (Assume that A and B are ideal gases).

From the ideal gas equation, PV = nRT

Number of moles of gas A = (30L*1atm)/ (0.08206 atm.L.mol-1.K-1 * 300K) = 1.22 mol

Number of moles of gas B = (15*2atm)/ (0.08206 atm.L.mol-1.K-1 * 300K) = 1.22 mol

Total number of moles in the gaseous mixture = 2.44 mol

Total pressure inside the 10L container = Ptot = nRT/V

Ptot = (2.44mol*0.08206 atm.L.mol-1.K-1*300K)/10L = 6.006 atm

Therefore, the total pressure inside the 10 litre container is 6.006 atm

Mole fraction of gas A = mole fraction of gas B = (1.22 mol/2.44 mol) = 0.5

Therefore, partial pressure of gas A = Therefore, partial pressure of gas B = 0.5*6.006 = 3.003 atm

Thus, the partial pressures of gases A and B in the 10L container are both equal to 3.003 atm.

To learn more about Dalton’s law of partial pressures and other important gas laws such as Avogadro’s law, register with BYJU’S and download the mobile application on your smartphone.

Sources of air leakages and air removal

SOURCES OF AIR LEAKAGE IN CONDENSER:

Following are the way through which air is observed in a condenser,

(i) Leakage through packing glands and certainly small holes with within the shell.

(ii) Leakage through joints and vents from atmospheric comfort valves and distinct accessories.

EFFECT OF LEAKAGE AIR ON CONDENSER PERFORMANCE:

The presence of air with within the condenser has the following effects on condenser operation Back strain (or exhaust strain) with within the steam engine or turbine will boom and consequently paintings performed reduces.

Thermal overall performance of the electricity plant reduces. For the same absolute strain (partial pre. Of steam + partial pre. Of air), the partial strain of steam decreases with air infiltration.

Saturation temperature decreases; latent heat (enthalpy of evaporation) will boom. So, condenser requires massive quantity of cooling water.

Air being a terrible conductor of heat, its presence with within the condenser affects price of heat transfer.

Thus to fulfil the requirement, ground place of tubes is to be increased. The Size of condenser will boom.

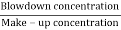

AIR PUMP:

Fig shows the running of Edward's reciprocating wet type air pump (or air extractor). It has no suction valve as it is there with within the ordinary pumps. It is established to the condenser.

When the piston is at the top of the barrel, the condensate and air from the condenser are collected with within the conical a part of the barrel.

On the downward stroke of the piston, partial vacuum is created above the piston due to the fact that shipping valve is stored closed.

When the piston uncovers the ports in the course of its further downward movement, the air and water vapor entrapped with within the conical portion, rush into the barrel location above the piston via the ones ports.

During pass returned journey (upward movement) of the piston, the above combination is compressed and strain rises. When strain exceeds the atmospheric strain, the shipping valve opens.

The aggregate of air and water vapor escapes out to the modern day well, over a weir. The weir continues enough head of water above the transport valve to save you air leakage into the pump barrel. The water sealed comfort valve operates whilst the stress with in the barrel exceeds atmospheric stress.

CONDENSER VACUUM:

The vacuum available within the condenser is based upon on tightness of valve joints, quantity of air infiltration and temperature of steam after condensation. Vacuum will now not be uniform throughout.

It is least on the air pump section, excessive in. The frame of the condenser and despite the fact that better at exhaust valve. The diploma of vacuum measured thru way of method of the vacuum gauge mounted on condenser may be expressed with in the following ways.

(i) By greater of atmospheric stress over the positioned vacuum: For instance 650 mm vacuum way, atmospheric stress is 650 mm of Hg above the condenser stress.

(ii) By the share vacuum: It is the ratio of positioned vacuum to atmospheric stress. For instance, if the gauge reads 650 mm Hg, with the barometer studying of 750 mm Hg, the share vacuum 650/750 x 100 = 86.67%.

(iii) By clearly the stress: It is the distinction among barometric studying and vacuum gauge studying.

The characteristic of condensers in steam electricity flora is to hold a low temperature. This is important to attain the most thermal performance from a given plant.

The lowest temperature attained relies upon the temperature of the circulating water which condenses the steam. When the steam expands to a stress under the atmospheric stress, it can't be exhausted into ecosystem and consequently it exhausts in a vessel that is at a decrease stress than that of the exhaust steam.

The exhaust steam is condensed with inside the vessel that is called condenser. The temperature of condensed steam, normally called condensate, leaving the condenser is better than that of the circulating water at inlet and the condensate is eliminated from the condenser with the aid of an extraction pump which discharges the condensate to the hot-properly from in which the boiler feed pump feeds it to the

Thus floor condensers offer each a low exhaust stress and restoration of the condensate, while jet condensers offer handiest the low exhaust stress; there can be greater intimate warmth trade among cooling water and the steam with a realistic drawback because of blending of the cooling water the condensate, which drawback is obviated in floor condensers.

With jet condensers, exhaust steam mixes with cooling water, so this cooling water ought to be sparkling and loose from dangerous impurities if the condensate is to be re-used for feeding into boiler.

Salt water may be used; accordingly all marine steam installations are geared up with floor condensers.

In big steam turbine installations jet condensers are impractical due to the fact there may be lack of condensate, the excessive electricity intake of jet condenser pumps and the primary price of needful air pumps.

Therefore, for contemporary-day steam electricity plant floor condensers are used. However, with reciprocating steam engines and slight length turbine units, the jet condensers are used particularly in which a considerable deliver of desirable water is available.

Air ejectors

A vacuum ejector, or actually ejector is a kind of vacuum pump, which produces vacuum via the Venturi effect.

The outer tube then narrows right into a blending phase wherein the excessive pace running fluid mixes with the fluid this is drawn in with the aid of using the vacuum, supplying sufficient pace for it to be ejected, the tube then usually expands with the intention to lower the speed of the ejected stream, permitting the strain to easily boom to the outside strain.

The electricity of the vacuum produced relies upon on the speed and form of the fluid jet and the form of the constriction and combining sections, however if a liquid is used because the running fluid the electricity of the vacuum produced is constrained with the aid of using the vapor strain of the liquid (for water, 3.2 kPa or forty six psi or 32 mbar at 25 °C or 77 °F).

If now no longer thinking about the supply of the running fluid, vacuum ejectors may be considerably greater compact than a self-powered vacuum pump of the equal capacity.

The reasonably-priced and easy water aspirator is typically utilized in chemistry and biology laboratories and includes a tee becoming connected to a faucet and has a hose barb at one side.

The waft of water passes via the instantly part of the tee, which has restrict on the intersection, wherein the hose barb is connected. The vacuum hose ought to be linked to this barb.

However, they're water-intensive, and relying on what the vacuum is getting used for (e.g. Solvent removal), they are able to violate environmental safety legal guidelines together with the RCRA with the aid of using blending doubtlessly dangerous chemical compounds into the water stream, then flushing them down a drain that frequently leads immediately to the municipal sewer.

Their use has reduced extremely as small electric powered vacuum pumps are a ways greater effective, environmentally safe, and feature emerge as greater affordable, however the unrivaled simplicity and reliability of this tool have induced it to stay famous for small labs or as a backup.

Another, a good deal large model of this tool is utilized in maritime operations as a tool to dewater (drain) regions in a deliver which have been flooded in emergency conditions.

Typically called an educator in those packages, that is desired over electric pumps because of their simplicity, compact length, and substantially mitigated threat of explosion with inside the occasion that flammable drinks and/or vapors are gift.

Additionally, in contrast to many mechanical pumps, they also can by skip particles because the educator has no transferring elements that may be fouled.

This makes an educator specifically beneficial in conditions wherein becoming a particles strainer to the suction port will gift greater problems than it resolves.

Sizes, waft ratings, and packages vary, along with educators which might be completely installed (usually utilized in very big areas, together with a deliver's major engine room), or transportable fashions that may be reduced into areas with the aid of using a rope and provided and tired via firefighting hoses.

Most are provided via a deliver's firefighting major, and transportable fashions also can be provided with the aid of using an emergency pump, supplied it may deliver enough waft to perform the educator.

Let’s discover how an Ejector works. Firstly, it's far really well worth noting that Ejectors also are called Educators, Surface Jet Pumps, and Velocity Spools.

Working of air ejectors:

- Based upon Bernoulli’s Principle, as the speed of a fluid increases, its strain decreases, and vice versa.

- This is regularly known as the suction chamber of the Ejector.

- Where the strain on this area is decrease than the strain of the suction fluid linked to the Ejector side-inlet or ‘suction branch’, it will likely be entrained/sucked into the frame of the Ejector.

- The fluid streams then tour via the diffuser phase of the Ejector, in which pace is reduced due to the diverging geometry and strain is regained.

- Importantly, the low strain suction circulation stories a strain increase/compression, even as the cause circulation sees a lower in strain, as a number of its power has been used to ‘do work’ at the suction circulation.

- The resultant discharge strain is consequently someplace among the cause and suction pressures.

- Ejectors are pipeline established gadgets and may be synthetic in nearly any fabric to match the manner conditions.

- They have three connections; Motive, Suction and Discharge.

Key Takeaways:

- Saturation temperature decreases; latent heat (enthalpy of evaporation) will boom. So, condenser requires massive quantity of cooling water.

- It is least on the air pump section, excessive in.

- The fact that better at exhaust valve. The diploma of vacuum measured thru way of method

- Salt water may be used; accordingly all marine steam installations are geared up with floor condensers.

Cooling towers

Cooling towers may also both use the evaporation of water to take away method warmness and funky the operating fluid to close to the wet-bulb air temperature or, with inside the case of closed circuit cooling towers or dry cooling towers, depend entirely on air to chill the operating fluid to close to the dry-bulb air temperature the use of Common programs encompass cooling the circulating water utilized in oil refineries, petrochemical and different chemical flowers, thermal electricity stations, nuclear electricity stations and HVAC structures for cooling homes.

The category is primarily based totally at the form of air induction into the tower: the primary styles of cooling towers are herbal draft and triggered draft cooling towers.

Cooling towers range in length from small roof-pinnacle gadgets to very huge hyperboloid systems (as with inside the adjoining image) that may be as much as 2 hundred meters (660 ft) tall and one hundred meters (330 ft) in diameter, or square systems that may be over forty meters (a hundred thirty ft) tall and eighty meters (260 ft) long.

Hyperboloid cooling towers are regularly related to nuclear electricity flowers, even though they're extensively utilized in a few coal-fired flowers and to a point in a few huge chemical and different business flowers.

Although those huge towers are very prominent, the good sized majority of cooling towers are a good deal smaller, inclusive of many gadgets established on or close to homes to discharge warmness from air conditioning.

This reduces the returned pressure, which in flip reduces the steam consumption, and as a consequence the gasoline consumption, at the same time as on the identical time growing electricity and recycling boiler-water.

While water utilization isn't always a trouble with marine engines, it paperwork a substantial difficulty for plenty land-primarily based totally structures.

By the flip of the twentieth century, numerous evaporative strategies of recycling cooling water have been in use in regions missing a longtime water deliver, in addition to in city places in which municipal water mains might not be of enough deliver; dependable in instances of demand; or in any other case ok to fulfill cooling needs. In regions with to be had land, the structures took the shape of cooling ponds; in regions with confined land, including in cities, they took the shape of cooling towers.

These early towers have been placed both at the rooftops of homes or as free-status systems, provided with air with the aid of using fanatics or counting on herbal airflow.

At the pinnacle is a fixed of dispensing troughs, to which the water from the condenser have to be pumped; from those it trickles down over "mats" fabricated from wood slats or woven cord screens, which fill the gap with inside the tower.

Wet cooling towers

Wet Cooling Towers are those houses wherein the water that have become heated via commercial enterprise or power technology approaches is cooled, again.

The warmth is given off to the environment. Wet cooling towers are a critical part of the thermodynamic circle. The water to be cooled is sprayed and disbursed over the splash fills.

As a quit end result the water temperature drops at the same time as the evaporation warmth is withdrawn and the air gets mummified.

The required air float for the cooling is produced via ventilators which is probably mounted on an output shaft of the system unit.

To permit the FLENDER Wet Cooling Tower Gear Units to take with inside the giant air float forces the system devices are prepared with an in addition axial bearing. Therefore, most effective application-tailor-made 2-staged bevel helical system devices are used to satisfy the precise requirements of this application.

The motor is mounted outside the door. He is robotically linked to the equipment unit this is located proper within side the center of the diffuser of the cooling tower thru lengthy Composite Couplings. These unique couplings also are determined within side the FLENDER product range. Your blessings at a glance

- Low noise emission because of torsion ally inflexible housings

- Variable dimensions of the output bearings for the distinct ventilator types (consistent with the ventilating rail)

- Highest operational reliability because of one-element housings, bolstered bearings, centrifugal discs at the ventilator shaft

- Additional cooling found out through fan cooler at the enter shaft

- Long carrier existence because of optimized equipment unit choice and use of high-grade materials

- Complete force device from an unmarried source

Applications

- Power producing industries, like:

- Biomass energy plant

- Gas energy plant

- Waste incineration plant

- Oil energy plant

A cooling tower is designed to cast off warmth from a constructing or facility through spraying water down via the tower to trade warmth into the interior of the constructing.

Air is available in from the perimeters of the tower and passes via the falling water.

As the air passes via the water, warmth is exchanged and a number of the water evaporates.

This warmth and evaporated water go with the drift out the pinnacle of the tower within side the shape of an exceptional cloud-like mist.

The cooled water is amassed at the lowest of the tower and pumped again into the plant or constructing for reuse.

Cooling towers offer big scale air-conditioning wherein land and (or) water are expensive, or policies limit the go back of once-via cooling waters

Dry cooling towers

Dry cooling towers are the various cooling towers designed to attain the equal cause as different towers: disposing of the extra warmness as plenty as viable.

The more warmness from machines and business methods may be dangerous to the performance of the machine and can even result in risk and risk our personal protection. So it’s essential to pick out the proper one to your particular utility to now no longer best make certain your protection, however additionally preserve your machine’s performance as excessive as viable and keep time and money in the end as nicely. In this newsletter from Liquid, we can speak the fundamentals of dry cooling towers, in which you could use them, how they function, and so on.

Cooling towers are taken into consideration as gadgets that assist reject the extra warmness to the atmosphere. This method occurs with the assist of a water movement that acts as a medium to switch the warmth.

There are unique forms of cooling tower that could attain one of these cause. Though the fundamentals are the equal for all of them, however every of them is particular for particular packages consisting of massive scale or small scale, etc. Each cooling tower layout belongs to a selected category.

This categorization may be primarily based totally on unique parameters consisting of shape, warmness switch approach, etc. and Dry cooling towers additionally belong to a specific category.

Dry cooling towers are one of the sorts beneath the warmth switch approach category. They are recognized for his or her particular manner of shifting the warmth.

They function through warmness switch thru a floor keeping apart the ambient air from the running fluid. The medium utilized in dry cooling towers is both water and an aggregate of water-glycol.

The precept of warmth switch is used on this machine which takes vicinity through a warmness exchanger with prolonged fins. In dry cooling towers, the air may be brought through herbal draft or mechanical draft to transport the air thru the air-cooled warmness exchangers/ACC.

Unlike different towers, they don’t use evaporation and as a result, the intake of make-up water in those structures is minimal; plus, the fan on this machine makes use of an electric powered motor to run, so it’s every other plus factor for this kind.

This machine features with air cooling generation and the flow of warm water from the condenser thru skinny tubes permits the warmth alternate for the reason that tubes are uncovered to ambient air flowing round them.

The low air temperature absorbs the warmth from the water to chill it right all the way down to the favored degree.

The boom of volumetric waft charge of the air thru the warmth exchangers has an enhancing impact at the overall performance, which relies upon at the air dry-bulb temperature.

But one of the dangers of such gadgets is their decrease performance whilst the ambient air temperature is excessive. In order to offer uniform warmness switch and an easy and easy internal tube floor for water pressure-drop, this tower has been designed with managed growth among the tube and fin.

Plus, to preserve the performance excessive, the cars are designed to face up to rain, moisture, and dust.

And the low velocity of the motor allows boom the performance and minimizes the noise.

There are unique overall performance levels for this machine, and you could pick out the proper one to your particular utility.

It is ranged from about five to 2,000 kW performances.

These structures have unique noise degrees and have to be used for out of doors installation.

Dry cooling towers may be used for the sun industry, plastic industry, information middle cooling, manufacturing unit cooling, electricity plant, and plenty of different packages.

You can use dry coolers in pc room air con structures, in cooling manufacturing gadget structures, in water-cooled chilled water air con structures, in garage refrigeration structures, and additionally in cooling diesel generator sets.

This tower kind works top notch for locations in which water sources are limited.

They can without problems assist to cast off the extra warmness without negative the out of doors surroundings and make certain your protection and your gadgets’ protection all yr. Long.

Keep in thoughts which you want to set an appointment for everyday protection to make certain your dry cooling tower works nicely and permits you to get the maximum from your machine.

The everyday protection allows keep away from compressor failure too.

Plus, whilst the machine is efficient, the fees of strength intake and protection will lower through the years even as preserving excessive performance.

On the opposite hand, their simplistic layout in addition to different factors that we referred to above, are the motives that this kind is famous for each residential and business makes use of.

Now which you’ve examine this newsletter, you could without problems communicate approximately dry cooling towers, how they function, and in which they’re used.

You can without problems comprehend what the distinction among this one and the opposite numbers is and whether or not it fits your wishes or now no longer.

Cooling ponds

A cooling pond is a synthetic frame of water more often than not fashioned for the reason of cooling heated water and/or to keep and deliver cooling water to a close-by strength plant or business facility along with a petrol refinery, pulp and paper mill, chemical plant, metallic mill or a herbal or synthetic open reservoir used to chill the new circulating water

The water is cooled within side the pond mainly via evaporation and convective warmness switch (water to air).

The temperature of the cooled water relies upon on meteorological situations—the temperature and humidity of the atmospheric air, the overall cloud cover, and the wind speed—and at the temperature of the incoming warm water.

Cooling ponds are noticeably easy to operate, and at some point of the extra a part of the year, particularly within side the winter, they are able to offer a decrease water temperature than different coolers.

With a cooling pond there may be no want to boost the water to a full-size height, as, for example, with cooling towers; accordingly much less electric strength is expended in riding the circulating pumps.

A drawback is the noticeably low precise warmness switch from the pond’s floor, a reality that necessitates the advent of a good sized floor vicinity for the pond.

River floodplains that may be spanned via way of means of dams are used within side the production of cooling ponds, as are lakes and dike-enclosed regions outdoor of watercourses.

Cooling ponds are commonly huge our bodies of water that could seem extra like a lake or massive pond. They historically are used to method and funky the nice and cozy water created via way of means of an business method along with: Power plant operations [nuclear plants, coal-fired plant] Refineries Mills [paper, steel etc.] & Chemical flora Food processing plants The cooling method is finished thru warm/warm water from the method being pumped into the pond, which then might be allowed to glide certainly to permit cooling thru radiation, evaporation, and conduction earlier than being recirculated again into the cooling device thru the device pumps.

For an example, seek advice from Lake Anna, wherein Dominion Energy operates the North Anna Nuclear Generating Station, imparting strength for 450,000 homes. Due to the warmth switch inefficiencies via way of means of the usage of this method, a massive water floor is required.

Advantages of Cooling Ponds

- Construction prices are pretty low, wherein land and soil situations permit

- They can function a settling pond for any suspended solids produced via way of means of the water being cooled

- Limited cooling water makeup required, may be replenished via way of means of rain

Disadvantages of Cooling Ponds

They additionally be aware the subsequent disadvantages:

- Large vicinity of land needed

- Low soil permeability

- Issues if there may be ice

- Can purpose fog

In case the desired quantity of water isn't to be had at steam energy plant site, both the cooling ponds and cooling towers are constructed.

The technique of cooling the recent water via way of means of cooling ponds as compared to cooling towers is easy and cheaper however it's miles much less efficient.

The schematic diagram of a cooling pond is proven in Figure.

The floor location required for cooling pond may be very large, its miles approximately 30 to 50 instances the dimensions of a cooling tower.

The incoming condensate from condenser is sprayed within side the cooling pond thru nozzles.

These nozzles are stored at a distance to every different in order that there's no interference among Sprays.

The spray nozzles are stored at a peak of one to two m above the floor degree for powerful cooling.

The quantity of water misplaced via way of means of evaporation and via way of means of the wind blowing throughout the cooling pond.

Key Takeaways:

- Cooling towers offer big scale air-conditioning wherein land and (or) water are expensive, or policies limit the go back of once-via cooling waters

- In dry cooling towers, the air may be brought through herbal draft or mechanical draft to transport the air thru the air-cooled warmness exchangers/ACC.

- Dry cooling towers may be used for the sun industry, plastic industry, information middle cooling, manufacturing unit cooling, electricity plant, and plenty of different packages.

References:

1. Thermal Engineering, Mathur & Mehtra, Jain Brothers Publications, New Delhi.

2. Heat Engineering, V.P. Vasandani & D.S. Kumar, Metropolian Book Publishers.

3. Power Plant Engineering, A.K. Raja, Shrivastava and Dwivedi, New age International Publishers.

4. Fluidized Bed Combustion, S. Oka and E. Anthony, Marcel Dekker Inc.

5. Power Plant Engineering, M. M. EI- Wakil, McGraw Hill International.