UNIT 1

Prestressed concrete- analysis

The idea of prestressed concrete is not new and it has been used in various ways since ancient times. To explain the idea of prestressed concrete some of the very well known examples are given here with.

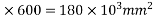

Example number 1

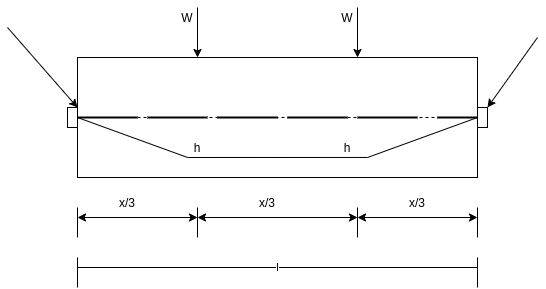

Consider a wooden barrel construction by forcefully fit metal bands around it. Now if this barrel is filled with some liquid which produces internal pressure on the internal surfaces of barrel inducing the hoop tension in wood. However, the forcefully tightened bands which are initially producing the compression in the barrel material will be able to resist the hoop tension produced by liquid inside the barrel.

Example number 2

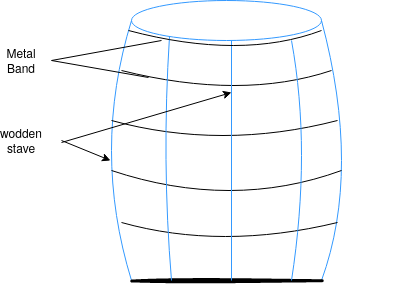

Consider a wooden wheel of bullock cart in which the wooden spokes are subjected to initial tension by shrink fitting (after heating) of metal tyres. Now, when the cart is loaded it produces the compression in the spokes. Some example can be given for the spokes of bicycle or two wheeler in which riders weight producing compression is balanced by the initial tension due to tightening of spokes between the axle and the rim thus the principle depicted in above examples is used in prestressed concrete.

Strength of concrete in weak in tension, hence it is ignored in reinforced concrete design. In RCC design assume compressive force resist in concrete and tensile force resist in steel i.e. reinforced we know stress strain diagram R.C. Beam

In this diagram concrete above neutral axis is useful in resisting applied load while the concrete below neutral axis is not useful in resisting any load. The concrete in tension side only acting as a cover to reinforcement only. This disadvantage of RCC, made the concrete lover to think of improving the use of concrete and it resulted into development of prestressed concrete.

Prestressed concrete is that can create in which the compressive stresses are induced in the concrete section before the member is loaded by external loads.

IS code-1343-2012; concrete in which permanent internal stresses are deliberately introduced usually by tensioned steel, to counteract to the desired degree the stresses caused in the member in service.

Need of prestressing a concrete member

Concrete which is strong in compression but weak in tension; however concrete is very weak in tension and it is very difficult to have concrete of tensile strength greater than 2.5

In RCC use concrete and reinforcement bonded to perfect bond. Due to loading cracks get developed in concrete as the steel yields.

In prestressing concrete member reduces these deflects and use high strength concrete and high tensile steel i.e. tendon.

Table-1:Comparison between prestressed and RCC

R.C.C. | Pre-stressed |

30% to 40% of total cross-sectional area is utilized | Hundred percent cross-sectional area is utilized |

Section is an economical beyond spans of 10m to 12m (load heavy) | Economical up to spans of 25 to 30 m (load small) |

Self weight of section is higher | Self weight of section is lesser |

Cracking and corrosion problems are more | No cracking and corrosion problems |

Reinforcement is straight | Reinforcing tendons can be bent or have parabolic shapes |

Tension is developed below neutral axis | The whole cross section is in compression |

Stresses are developed only after external load is allowed | Stresses are developed before counting due to pre compressive load |

Generally large in size and require additional share reinforcement to resist shear forces | In P.C. Section are smaller in size and due to pre stressed tendon a considerable amount of shear reinforcement is avoided |

It does not require any auxiliary units much for construction | Auxiliary units are required live anchoring devices, equipments for prestressing |

The terms commonly used in prestressed concrete are explain the terms are placed in group as per usage

a) Forms of prestressing steel:-

1) Wires:- prestressing wire is a single unit made of steel.

2) Strands:- 2, 3 or 7 wires are wounds to form a prestressing strands.

3) Tendon:- a group of strands or wires are wounds to form a prestressing tendon.

4) Cable:- a group of tendons forms a prestressing cable.

5) Bars:- tendon can be made up of a single steel bar the diameter of bar is much larger than that of a wire.

b) Nature of concrete steel interface:-

1) Bonded tendon:- when there is adequate bond between the prestressing tendon and concrete, it is called as bonded tendon. Pre-tensioned and grouted post tensioned tendons are bonded tendons.

2) Unbonded tendon:- when there is no bond between the prestressing tendon and concrete, it is called as bonded tendon. When grout is not applied after post-tensioning the tendon is an unbounded tendon.

c) Stages of loading:- the analysis of pre-stressed member can be different for the different stages of loading. The stages of loading are as follows:

1) Initial:- it can be subdivided into two stages

a) During tension of steel

b) At transfer of prestress to concrete

2) Intermediate:- this includes the loads during transformation of the prestressed members.

3) Final:- it can be subdivided into two stages

a) At service, during operation

b) Add ultimate comedy during extreme events

Why high strength concrete used in prestressed concrete

1) High strength concrete is having low shrinkage and creep value, high impermeability, high resistance to abrosion and more ductility.

2) High strength concrete permits hire bond between steel and concrete because stresses transformed from tendons to concrete.

4) It has high modulus of elasticity leading to smaller elastic strain when tendons are cut. This will reduce relaxation loss in steel.

5) Use of high strength concrete is justified in terms of cost also, as in prestressed concrete the entire cross section is in compression and hence full concrete area is utilised in resisting compressive force.

6) To sustain the high stresses at anchorage regions, due to large prestressing force to be applied by tendon.

7) To have higher stiffness for reduced deflection.

8) In factories, with high degree of control it is easier to produce high strength concrete.

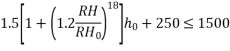

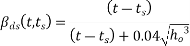

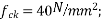

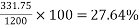

9) For post tensioned prestress concrete, the grade of concrete shall not be less than  However for pre tensioned concrete is shall not be less than

However for pre tensioned concrete is shall not be less than

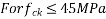

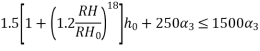

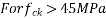

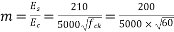

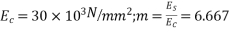

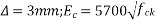

10) High strength concrete will have modulus of elasticity of concrete  [ IS-1343-2012,clause no 6.2.3.1 ,pp-5]

[ IS-1343-2012,clause no 6.2.3.1 ,pp-5]

11) Hence elastic and cracks trains are very low resulting in smaller loss of prestressing force.

12) Just of high strength concrete reduces the size of concrete member thereby resulting in of concrete in reduction of self weight of the member.

Why high strength steel used in prestressed concrete

1) A large prestressing force can be developed on smaller steel area, there force, high tensile strength wires, strands and tendons used in prestressing members.

2) When concrete shortens due to compressive stress, creep and shrinkage, a large amount of prestress is lost. If high tensile bars are used for prestressing, permitting a large initial prestress, the loss of prestress will be small percentage of total initial prestress.

3) For post tensioned structures, anchorage regions have concentrated and very high stresses.

4) High tensile steel give high bond strength to avoid slippage.

Advantages of prestressed concrete

1) This provides a type of construction which is always free from cracks under full working load. Due to this reason, such type of construction is suitable where corrosion is a great danger.

2) Sufficient horizontal compression due to prestress reduces principal tensile stresses and shear resistance is developed without heavy reinforcement of large webs.

3) Less steel is used in the members, it is easier to place good quality of concrete with high compressive strength than in the case of reinforced concrete.

4) This type of construction saves material as well as dead loads and hence considerable savings in supports and foundations is also achieved.

5) Smaller sections are used in this type of construction. For this reason very large spans can be built in prestressed concrete then in reinforcement concrete.

6) For precast prefabricated construction the advantages of a reduction in self weight of the unit are obvious. Also prestressing counteracts handling stress. Hence we can use this method for precast work.

7) The cost of shuttering and centring in large structures is reduced when prestressed precast elements are assembled.

8) The amount of steel required is very low.

9) Deflections of structures are reduced.

10) The time of construction is much less if precast prestressed members are used.

Disadvantages of prestressed concrete

1) It requires high tensile steel and high strength concrete of grades more than  And above. Hence it will become more expensive for small jobs.

And above. Hence it will become more expensive for small jobs.

2) Prestressing is a tedious job. It requires expertise supervision.

3) Cables are required to be anchored by mechanical means. However, full prestressing force cannot be obtained due to losses in prestress to the extent of 25%.

4) Special prestressing techniques are required for both pre tensioned and post tensioned prestressed concrete members.

5) It does not increase ultimate strength of concrete.

6) It requires special equipment such as Jacks, anchorages, high tensile cables, etc.

Limitations of prestressing

Although prestressing is advantageous, some aspects need to be careful address.

1) Prestressing need steel technology hence it is not common as reinforced concrete structures.

2) Reuse of high strength concrete is costly.

3) There is additional cost in auxiliary equipment.

4) There is need of quality control and inspection.

5) Prestressed concrete technology is not effective for small structure.

Prestressing Systems

Introduction:-

The most widely used method for prestressing of structural concrete elements is longitudinal tensioning of steel by different tensioning devices. Prestressing by the application of direct forces between abutments is generally used for arches and pavements, while flat jacks are invariably used to impart the desired forces. For circular structures such as tanks and pipes, it is a common practice to impart pre compression in concrete by circular prestressing with the development of expensive cements, prestress in concrete can be developed by chemical prestressing.

Tensioning Devices:-

The various types of device used for tensioning steel are grouped under four principal categories, namely.

1) Mechanical

2) Hydraulic

3) Electric

4) Chemical

Mechanical devices:- It used include weights with or without level transmission, geared transmission in conjunction with pulley blocks, screw jacks with or without gear drives and wire winding machines. These devices are employed mainly for prestressing structural concrete components produced on a mass scale in factories.

Hydraulic jacks:- The simplest means of producing large prestressing forces are extensively used as tensioning devices. Several commonly used patented jacks are due to freyssient, Magnel, Gifford Udall and baur-Leonhardt for the range of 5-100 tonnes. Large hydraulic jacks for forces in the range of 200-600 tonnes, have also been developed by Baur-Leonhardt. It is important that during the tensioning operation the force applied should be accurately measured. In most of the Jack, calibrated pressure goes directly indicate the magnitude of force developed during the tensioning of the wire.

Electrical devices:- It have been successfully used in erstwhile USSR since 1958 for tensioning of steel wires and deformed bars. The steel wires are electrically heated and anchored before placing concrete in the moulds. This method is often referred to as thermoelectric prestressing.

Chemical devices:-In the chemical method expanding cement are used and the degree of expansion is controlled by varying the curing conditions. Since the expensive action of cement while setting is restrained, it induces tensile forces in tensions and compressive stresses in concrete.

Methods of prestressing

The following two methods are commonly used for prestressing

1) Pre tensioning method

2) Post tensioning method

1)Pre tensioning method:-

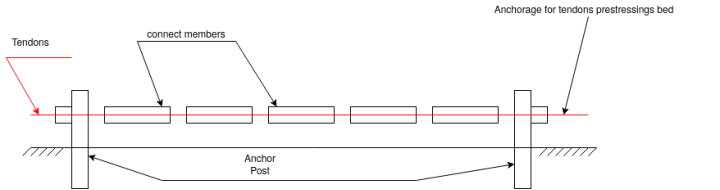

- For prestressing by this method, the reinforcements or tendons are placed on the castling bed in the design position.

- The required tension is applied in them and is anchored with the anchor post provided at each end of the castling bed.

- The formwork is redirected around the tensioned tendons. Concrete is then poured in the prepared formwork, and is compacted and cured. As soon as the concrete has fully hardened and develop the desired strength, the connections between the tendons and the anchor post are cut off.

- Due to bond between steel and concrete, the tensioned tendons, as they try to shorten, transfer the induced forces to the concrete.

- This compresses the hardened concrete member and it is prestressed. Some time special anchorage is provided at the end of the member, when bond between concrete and tendon is not sufficient to retain the applied tension.

- This method is commonly adopted for prestressing simply supported slabs, beams, fence posts , railway sleeper, electric poles, small and medium size beam, floor and wall panles.

Advantages and disadvantages of pre tensioning

1) Pretensioning requires very heavy abutments for anchoring steel wires. Hence it is un economical for small work. Pretensioning is best suited for mass production of precast members.

2) A single pair of abutment can be used for a line of members several meter long.

3) Large size members are difficult to transport and handle and therefore the size of precast members in limited

Post tensioning method:-

- In prestressing by this method, the prestressing force is applied to the tendons after the concrete has completely set and has attained the desired strength. The tendons are not bonded to concrete before tensioning

- The reinforcing steel is in the form of single tendon or cables made up with separate wires.

- The tendons are stretched through ducts or holes left for them in the precast concrete member. The stretching of the cables or tendons is done with the help of Jacks acting against the end of precast member.

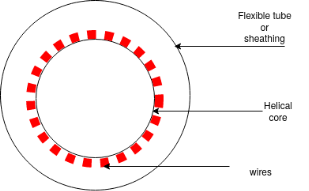

- The tendon or cable is placed in a flexible metal tube, known as sheathing and anchor

Fittings are attached to the ends of the cable.

- The complete assembly is placed in the already prepared from formwork of the member to be concreted and kept in position by means of special spacers.

- Concrete is poured and allowed to harden. Till it attains the required strength.

- The tendon or cable can freely move inside the hardened concrete because it is not in direct contact with the set concrete (since it is placed in the flexible metal tube).

- The prestressing force is created by tensioning in the tendon or cable by means of hydraulic jacks.

- The anchorage at the ends of the tendons are adjusted to keep the stretched tendons firmly in position

- Now, the cement grout in forced under pressure to fill the space around the tendons completely.

- Finally, the anchorages are covered with a protective coat of grout. It is not always essential to place the tendons in the sheath before concreting.

- There are various other methods, which can be used to suit the particular condition.

Advantages and disadvantages of post tensioning:-

1) Stage prestressing can be done in post tensioning members which is suitable for bridge construction.

2) From the consideration of transportation handling it is better to cost the large size members at or near the site , which are generally post-tensioned.

3) In post tensioned members, the cables are anchored by mechanical means which bear against the ends of the member.

4) This result in large concentration of stresses at the ends which is difficult to analysis and requires special attention in the design.

Table-2:

SR.No. | Pre-Tensioning | Post-Tensioning |

1. | Tendons are tensional before costing the concrete. | Tendons are tensioned after the concrete has fully hardened |

2. | One end of tensioned is secured an abutment and another is pulled by using jack then concrete is poured. After hardening the concrete the ends of tendon are released prestress is transmitted to the concrete by action of bond between the reinforcement and surrounding concrete. | The concrete member is casted leaving duct for placing the tendons. One end of the tendon is anchored to the member . After the tendons reaches the desired stress by pulling with it Jack through the duct provided. The other end is also properly anchored to the concrete and the duct is completely filled with cement slurry by grouting. Prestress is his transmitted to concrete. |

3. | Loss of prestress is more. | Loss of prestress is less. |

4. | The cost of pre tensioning system is less. | The cost of post tensioning system is more. |

5. | Pre tensioning is mostly used for small member. | Post tensioning is used for span member. |

6. | Grade of concrete shall not be less than 45  | Grade of concrete shall not be less than 35  |

7. | For ex:- Hoyer system | For ex:-Preyssinet system. |

Linear and circular prestressing:-

Linear prestressing is done in straight members such as beams , piles and slabs whereas circular prestressing is applied to circular structures such as tanks, pipes, soils and pressure vessels in which the wires are put in curve going around the structure.

SYSTEMS OF PRESTRESSING:-

The various systems of fabricating a post tensioned member are described below. In all the systems the cables and the hydraulic jacks employed for stretching the cables are specially designed to perform the job of prestressing

1.Freyssient system

2. Magnet-Blaton system

3. Lee- mccall system

FREYSSINET SYSTEM:-

- The freyssinet cable consists of a number of parallel wires.

- The wires of each cable form a ring in cross- section and are place in a position of helical spring .

- The cable is put into a flexible metal tube or sheathing before playing it in the formwork of the member to be concreted.

- Proper stretching grip, the cable projects about 60 to 75cm beyond the ends of the metallic tube.

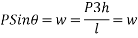

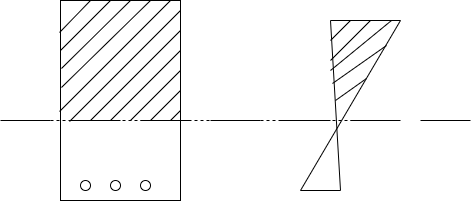

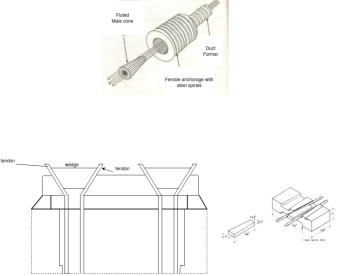

-  The entire assembly of the cable is placed in the prepared formwork of the member and tied in position. The anchorage fittings used in the system consists of two components i.e. i.)the female cone ii.)the male cone figure

The entire assembly of the cable is placed in the prepared formwork of the member and tied in position. The anchorage fittings used in the system consists of two components i.e. i.)the female cone ii.)the male cone figure

- The female cones are threated over the cables at each end and fixed to the inside face of the end shuttering of the member.

- As concrete is poured in the formwork, the female cone is embedded in the concrete.

- Due to the corrugations on outer surface, they develop good bond with the concrete. The member is called. When the concrete has set and attend required strength, the tendons are tensioned by using free Freyssinet Jacking Unit.

- The jacking unit is kept at the tensioning end of the member and the cable wires are passed through the grooves and gripped by the wedges on the main piston.

- The pump of the jacking unit is operated to move the pistons and the wires are stretched.

- After stretching the wires of the desired limit, the male cone is put inside the female cone by operating the inner piston.

- This keeps the tensioned cable firmly in position. The jacking unit is removed for used in stretching the outer cables.

- Cement grout is then forced through the narrow pipe sleeve in the male cone to fill the annular space between the metallic tube and the cable completely.

- Finally the project in wire cut off and then anchorage is grouted to protect the steel from corrosion due to atmospheric actions.

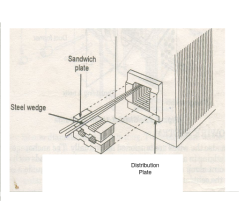

Magnet-blaton system:-

- Cable ducts are formed in the body of the concrete member by extractable rubber cores. The prefabricated cables are then passed through the ducts.

- Metallic special blocks are used to held the cables in the desired position. Cost steel distribution plates are cemented at each end off the precise member.

- The anchorage is done with steel plates known as sandwich plates with two trapezoidal grooves in the upper surface and two in the lower surface. Two wires can be placed in each groove.

- The wires are held in position by steel wedge which fits in the slot. In the sandwich plate which is illustrated in figure c, eight wires can be anchored and a cable may have several such plates.

- One pair of wire is tensioned at a time with the help of tensioning equipment. When the wires attention at the desired limit, the steel wedge is driven inside the groove which keep the two wires firmly in position.

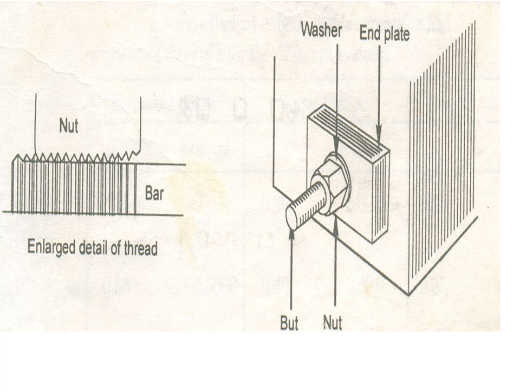

Lee-Mccall System:-

- A rod of high tensile alloy steel is used to act as a single tendon. The diameter of the bar varies between 12 mm to 28mm and it is threaded at both the ends.

- It is a common practice to insert the bar into the flexible rubber tube and suitably place and tie in position in the formwork of the member to be concreted.

- Concrete is poured into the formwork and after it has attained required strength, of the rubber tube is withdrawn.

- Perforated operated bearing plates with one hold for each rod, are provided at each end. At each end of the bar, one nut with washer is screwed.

- Jacking is done at only one end when the length of the members is small and hence the prestressing force required is also small.

- For long members requiring greater magnitude of prestressing force, one Jack is employed at each end of the bar. When the rod is stretch to the required length, the nuts are tightened.

Analysis of pre-stress:-

The analysis of prestress members i.e. rectangular and T-sections members can be different for the different staging of loading. The stages of loading are as follows:-

Stage of loading:-

a) Initial

b) Intermediate

c)Final

The precast members, has to be designed for three stages, the initial stage during prestressing, intermediate stage during handling and transportation and the final stage under external loading whereas for cost-in-sites structure prestressed concrete members are designed for at least two stages, initial stage during prestressing and the final stage under the external loadings.

a)Initial:-i) during tensioning of steel

Ii) at transfer of pre-stress to concrete

b) Intermediate:-This includes the loads during transportation of the prestressed

c) Final:-i) at service, during operation

Ii) at ultimate, during extreme events

ASSUMPTIONS IN THE DESIGN OF PRESTRESSED CONCRETE MEMBERS:-

i) A transverse plane section of the member will remain a plan after bending also.

Ii) With the limits of the deformations taxing place, Hooke’s law is applicable to concrete and steel components.

Iii) The stress in the reinforcement does not change along the length of the reinforcement breast changes take place for the concrete component only. Variation of stress in the reinforcement due to changes in the external loading is ignorable.

Iv) In case of bonded tendons, the bond between concrete and tendons is perfect and they act monolithically.

v) In prestressing stress in steel due to flexure caused by external loads is negligible compared to applied stress for prestressing.

Vi) The sectional properties are taken as that of gross sections of concrete, sends the cross sectional area of steel is very small as compared to that of concrete.

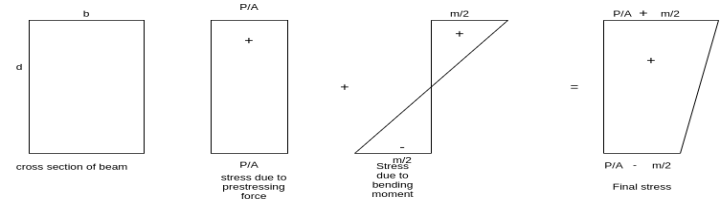

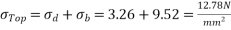

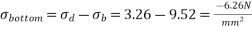

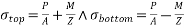

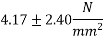

Analysis of prestress are analysed by stress concept

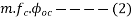

The stress due to prestressing alone are generally combined stresses due to the action of direct load and bending resulting from an eccentrically applied load.

The stresses in concrete are evaluated by using the well-known relationship for combined stresses used in the case of columns.

The analysis of prestressed by two method depends upon positions of tendon.

1) Concentric tendon

2) Eccentric Tendon

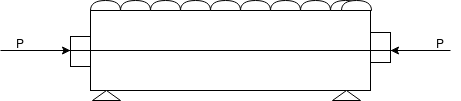

Analysis of pre-stress by concentric Tendon

A simply supported prestressed concentric beam of rectangular section prestressed by a tendon provided through its centroid longitudinal axis.

Let the beam be subjected to an external load system.

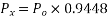

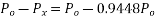

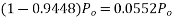

Let P be the prestressing forces supplied by the tendon. Due to this prestressing force, the compressive stress induced in concrete  where A is the sectional area of the member.

where A is the sectional area of the member.

If due to the dead load and external loads, the bending moment at the section is m, then extreme stresses at the section due to bending moment alone.

Where, z is the section modulus of the beam section.

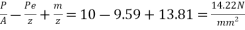

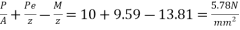

Hence, the final extreme stresses on the beam section are given by

Stress at the extreme top edge=

And stress at the extreme bottom edge=

And stress at the extreme bottom edge=

If the moment due to self weight is mg and that due to live loads  both being sagging, total stress in concrete is

both being sagging, total stress in concrete is

i.e. stresses at bottom most and top most fibres of the section are

Remember, y is positive when it is above the neutral axis and it is negative when it is below the neutral axis.

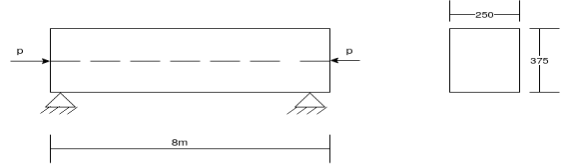

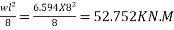

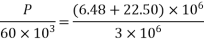

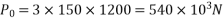

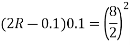

Problem 01:- A pre-stress concrete beam 250mm wide and 375mm deep is prestress by concentrically placed tendon. The span of beam is 8m and beam has two sports and imposed load of 4.25 KN/M. Find the prestressing force necessary so that tension is just avoided at the soffit of the mid span

Solution:- given data

Width of beam b=250mm; depth of beam d=375mm, span=l=8m ; imposed load=w=4.25KN/M

To find:- prestressing force P=?

To find:- prestressing force P=?

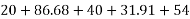

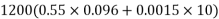

1) Self weight of beam=25×0.375×0.250

=2.344KN/M

Total load=2.344+4.25=6.594 KN/M

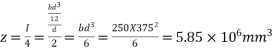

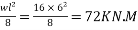

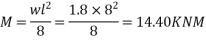

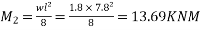

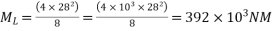

2) Maximum bending moment= M=

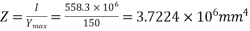

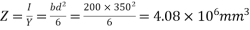

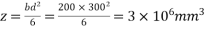

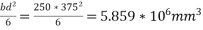

3) Section modulus=

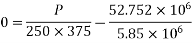

4) Prestressing force at the soffit of mid span

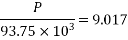

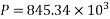

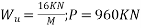

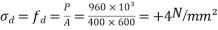

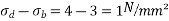

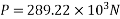

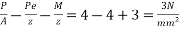

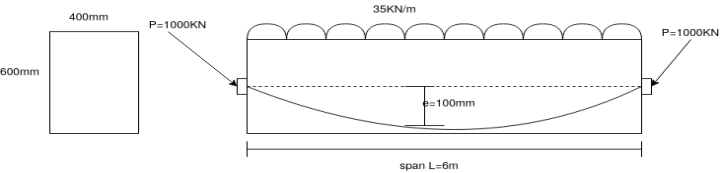

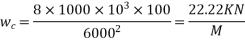

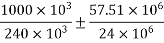

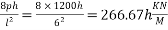

Problem 02:-A prestressed concrete beam 400×600mm in section has a span of 6m and is subjected to uniformly distributed load of 16KN/M including the self weight of the beam. The prestressing tendons which are located along the longitudinal centroidal axis provided an effective prestressing force of 960KN. Determine the extreme fibres stresses in concrete at the mid span section.

Given data:- b=400mm ; d=600mm ; L=6m ;

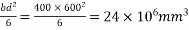

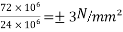

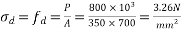

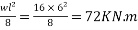

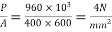

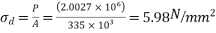

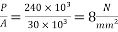

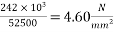

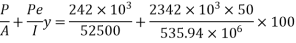

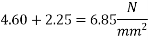

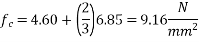

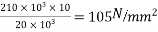

1) Direct stress due to prestressing force

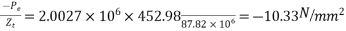

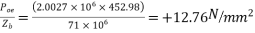

2) Extreme stress due to bending moment

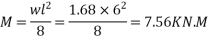

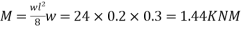

M=maximum bending moment M=

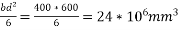

Z=section modulus=

=M/Z =±

=M/Z =±

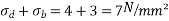

3) Finals faces in the extreme fibre will be as

Final stress in the extreme top fibres =

Final stress in the extreme bottom fibres =

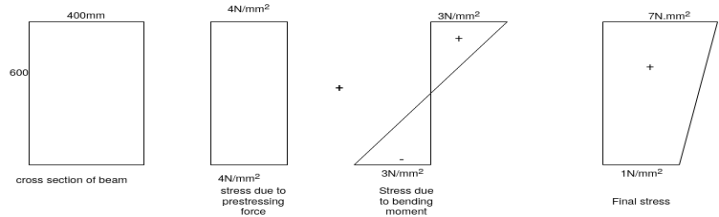

Problem 03:- A simply supported pre-stressed concrete beam of span 6m is of symmetrical I-section. The beam is 300mm deep each flange is 300mm ×60mm while the web is 60 mm thick. The overall depth of the beam is 300mm. It is provided with 60 wires of 2.50mm diameter equally distributed in the top and the bottom flanges. The beam has to support a superimposed load (in addition to its own weight) of 2 A moving paint load causes an additional bending moment of 5.60 KN.M

A moving paint load causes an additional bending moment of 5.60 KN.M

The beam has to support its own weight during the prestressing stage. Determine the stress distribution for the mid span section during transfer of prestress and after the action of other loads. Allow 15% loss at transfer and a further loss subsequently. The initial prestress in the wire is 1075

Solution:-

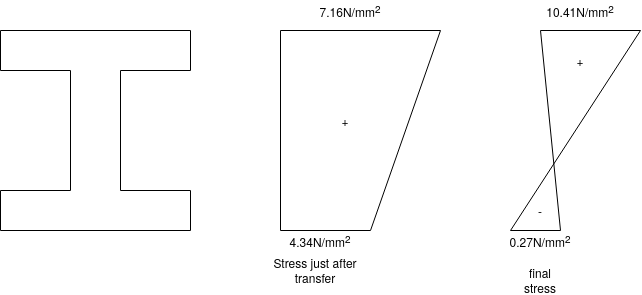

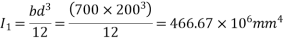

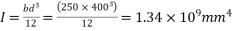

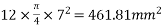

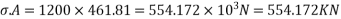

1) Area of the beam section A

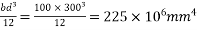

A=(2×300×60)+(180×60) = 46800

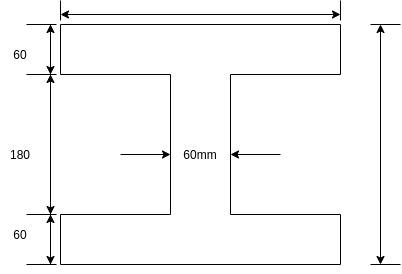

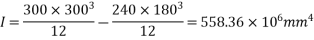

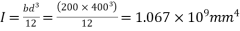

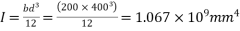

2) MI of the beam section

3) Section modulus

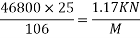

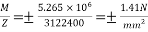

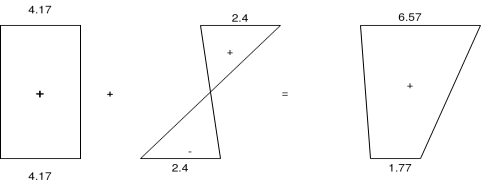

4) Dead load of The beam=A×γ=

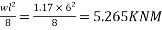

5) B.M. Due to dead load of The beam=

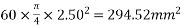

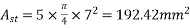

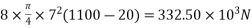

6) Area of 60 wires of 2.50mm diameter=

7) Initial prestress in the wires=1075

8) Allow 15% loss at transfer stress=0.85×1075=1075=913.75

Just after transfer

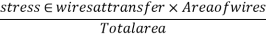

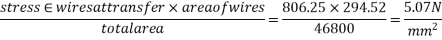

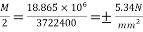

1) Compressive stress in concrete due to prestressing force

2) Extreme stress due to dead load of beam=

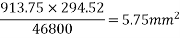

Hence, just after transfer

Stress at top=5.75+1.41=7.16

Stress at bottom=5.75-1.41=4.34

3) BM due to moving point load=5.60KNM

4) BM due to additional superimposed load=

5) Total BM=9+5.60+5.265=19.865KNM

6) Stress in the wires=0.75×1075=806.25

7) Compressive stress in concrete due to prestressing force

8) Extreme stress due to dead load of beam=±

9) Final stresses at top=5.07+5.34=10.41

10) Stresses at bottom=5.07-5.34=-0.27

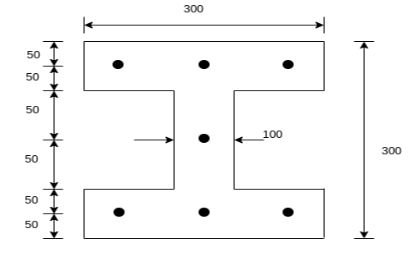

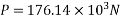

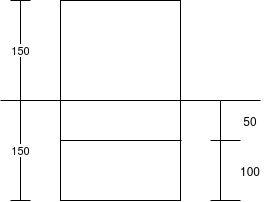

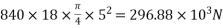

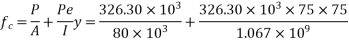

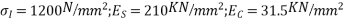

Problem 04:- An I section in concrete has the following dimensions flanges=(300×100)mm ; web=100mm×100mm. It is pre tensioned by 7 high tension steel wires of 8mm diameter. They are located as shown in figure. The wires are subjected to an initial stress of 1000 Find the stresses in concrete and steel immediately on cutting the wires, when the members is still supported in the prestressing bed. Assuming a loss of prestress of 200 N/

Find the stresses in concrete and steel immediately on cutting the wires, when the members is still supported in the prestressing bed. Assuming a loss of prestress of 200 N/ including the loss of stress due to elastic shortening of concrete, calculate maximum moment so that tensile stress is avoided and the compressive stress does not exceed 12

including the loss of stress due to elastic shortening of concrete, calculate maximum moment so that tensile stress is avoided and the compressive stress does not exceed 12 in concrete. Take m=6

in concrete. Take m=6

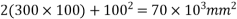

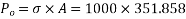

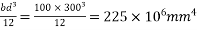

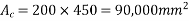

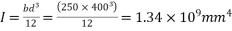

Solution:- area of the section A=

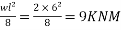

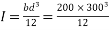

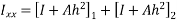

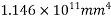

Moment of inertia I=

Section modulus

Section modulus

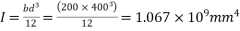

Area of steel wire

Now, initial stress  =1000

=1000

Initial prestressing force

Stresses immediately after cutting the wires

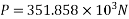

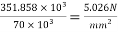

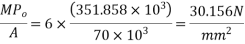

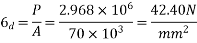

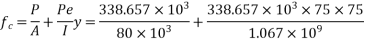

Stress in concrete  =

=

Loss of stress in steel due to elastic shorting of concrete

Stress in steel immediately after cutting the wires =1000-30.156

=

Subsequently the total loss of stress in the wires = 200

Final stress in steel. =1000-200 = 800

Final prestressing force P = final stress in steel×area of steel wire

= 800×351.858

= 281.486

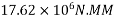

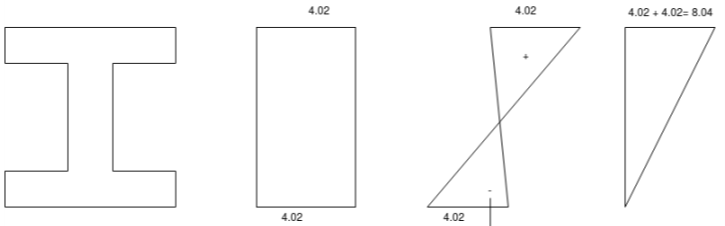

Direct stress=

To avoid the tensile stress, bending stress in the extreme fibres = ± 4.02

Let m = maximum permissible bending moment

=

=17.62KNM

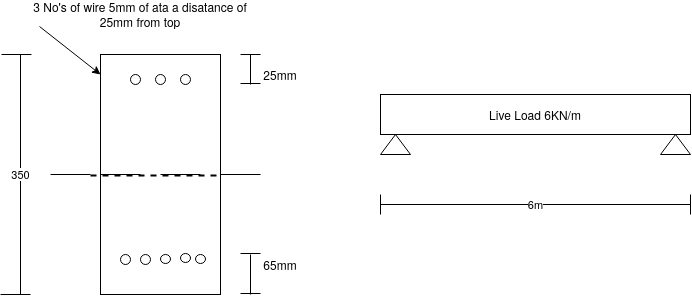

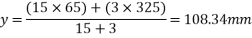

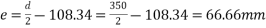

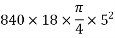

Problem 05:- A Rectangular concrete beam of cross section 350 mm and 200 mm wide is pre-stressed by means of 15 wires of 5 mm diameter located at 6.5cm, 3 No.’s from the 5mm from the 2.5cm from the top. Assuming the prestress in the steel as 840  calculate the stresses at the extreme fibre of mid span section. When the beam is supporting its own weight over a span of 6m. If uniformly distributed live load of 6KN/M is imposed, evaluate the maximum working stress in concrete. The density of concrete is 24 KN/

calculate the stresses at the extreme fibre of mid span section. When the beam is supporting its own weight over a span of 6m. If uniformly distributed live load of 6KN/M is imposed, evaluate the maximum working stress in concrete. The density of concrete is 24 KN/

Given data:- b=200mm d=350mm

15 No.’s of wire 5mm  at a distance of 65 mm bottom a distance

at a distance of 65 mm bottom a distance

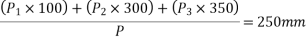

1) Calculate distance of the centroid of prestressing force from base

Eccentricity

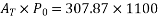

2) Prestressing force P=prestressing× number of wire× area of one wire

3) Area of cross section A= bd = 200×350 =

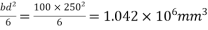

4) Section modulus

5) Moment calculation M =?

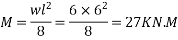

a) Due to self weight W = 24×0.2×0.35 =1.68KN/M

B) Due to live load w = 6KN/M

6) Stress calculation

a) Direct stress due to prestressing

b) Bending stress due to prestressing

c) Stress due to self weight

d) Stress due to live load

7) Resultant stress

a) At top

b) At bottom

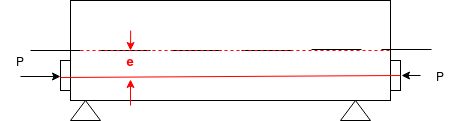

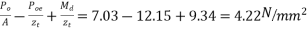

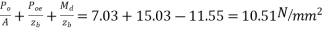

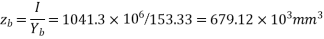

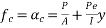

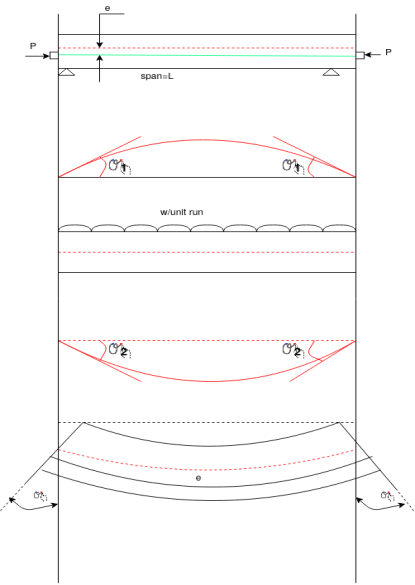

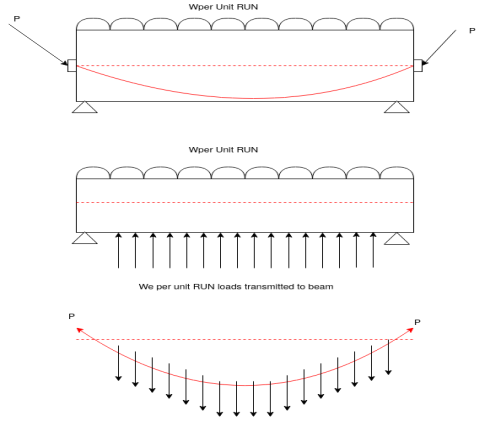

Analysis of prestress by eccentric tendon

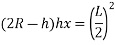

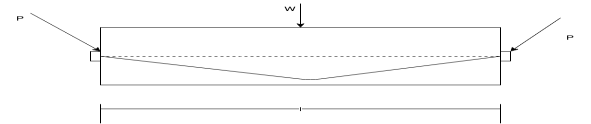

It will be advantageous to place the tendon at an eccentricity. Following figure shows a beam of rectangular section pre-stressed bi a tendon placed longitudinally, at an eccentricity 'e' from the centroidal longitudinal axis. Let The beam be subjected to an external load system. Let P be the prestressing force supplied by the tendon. Letter due to the dead load and external loads the bending moment at a section be m.

The stresses on the section consists of the following

1) Direct stress due to prestressing force = +P/A

2) Extreme stresses due to eccentricity of the prestressing force = ±

3) Extreme stresses due to bending moment = ±

Final stresses

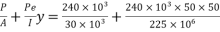

a) Stress at the extreme top edge =

b) Stress at the extreme bottom edge=

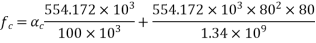

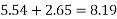

Problem No. 01:- A prestressed concrete beam 300 mm wide and 600 M deep is prestressed using 5 high tension bars of 12mm. Provide at 220 mm from the soffit of the beam. The effective stress in the steel is 800 Find the bending that must be applied to the section to just avoid tension at the soffit of the beam.

Find the bending that must be applied to the section to just avoid tension at the soffit of the beam.

Given data:-

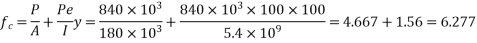

1) Area of beam A = 300×600 =180000

2) Area of steel =

3) Prestress force by wires = 800×565.48 = 452.38

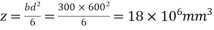

4) Section modulus

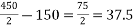

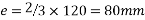

5) Eccentricity e = 300-220 = 80mm

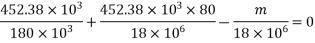

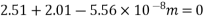

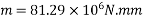

Let m be the bending moment required so that the tension at the soffit in just avoided.

For this condition

Problem No. 02:-A pre-stress concrete beam 350 mm wide and 700mm deep has a span of 11 m. The beam is subjected to UDL of 18 KN/M including self weight over entire span. A prestressing force of 800KN is applied along the centroidal axis determine the extreme fibres stress in the section.

Given data:- b=350mm; d=700mm; L=11m; UDL=w=18KN/M prestressing force P=800KN

To find:- final stress at top and bottom

Solution:-

1) Direct stress

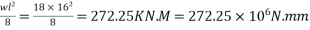

2) Extreme stress due to BM =

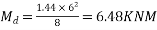

M = moment =

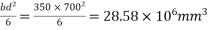

Z=section modulus

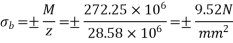

3) Final stress

a) Top =

b) Bottom =

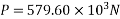

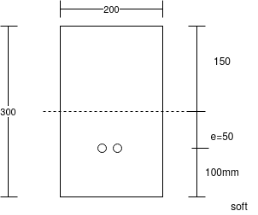

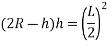

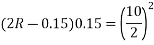

Problem No. 03:- Rectangular concrete beam of cross section 200mm×300mm having a length of 6m uniformly distributed load of 5KN/m acting on whole span. The density of concrete is is 24

1) Concrete prestressing force necessary for zero fibre stress at the soffit when the beam is fully loaded.

2) Eccentric prestressing force located 100 mm from the bottom of the beam which would nullity the bottom fibre stresses due to loading.

Given data:- b=200mm; d=300mm ; L=6m ;

Solution:-

1) Section modulus

2) Direct stress due to prestressing force

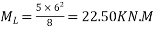

3) Bending moment

Due to dead load

Due to live load

Case-I when applied prestressing force is concentric

P = 580KN

Case-II When applied prestressing forces having an eccentricity 100mm from soffit i.e. (e=50mm)

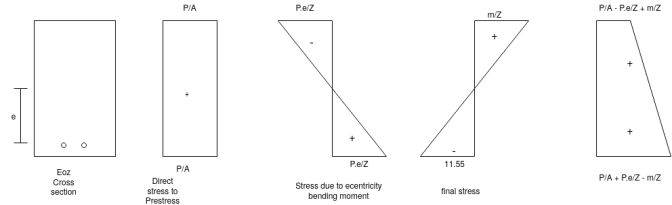

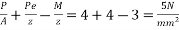

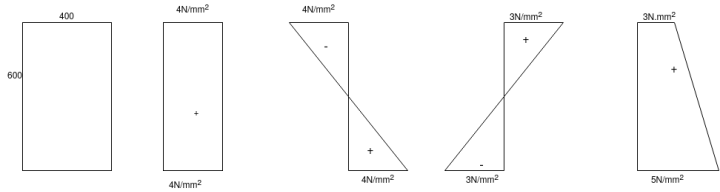

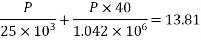

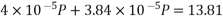

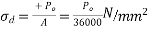

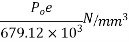

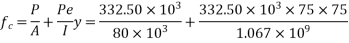

Problem No. 04:- A prestressed concrete beam 400×600 mm in section has a span of 6m and is subjected to a uniformly distributed load of 16KN/m including the self weight of the beam. The prestressing tendons are located at the lower third point and provide an effective prestressing force of 960 KN. Determine the Extreme fibre stresses in concrete at the mid span section.

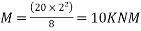

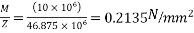

i) Section modulus z=

Ii) Maximum bending moment due to external loading M

Iii) Direct stress due to prestressing force =

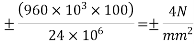

Iv) Extreme stress due to eccentricity of the prestressing force =

v) Extreme stress due to external bending moment =

Vi) Final stresses for the extreme fibres will be as follows

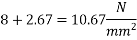

At the top edge =

At bottom edge

Problem No. 05:-A prestressed concrete beam 250 mm wide 375 mm deep is prestressed by concentrically placed tendon. The span of the beam is 8m and the beam has to support an imposed load of 42.5 KN/M. Find the prestressing force necessary so that the tension is just avoided at the soffit of the mid-section.

If, however, the tendon is provided at an eccentricity of 65 mm find the prestressing force necessary so that tension is just avoided at the soffit of the mid-section. Concrete weights 24

Given data:-

1) Area of beam A = b×d = 250×375 = 93750

2) Section modulus z =

3) Load calculation

Dead load of beam = 0.25×0.375×24 = 2.25KN/M

Superimposed load on beam = 4.25KN/M

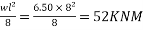

Total load = 6.50KN/M

4) Bending moment m

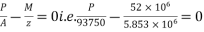

Let P be the prestressing force so that the tensile stress at the soffit of the mid section is just avoided.

Case 1 when the tendon is concentrically provided

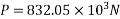

For this case

P=832KN

Case 2 when the tendon is provided at an eccentricity of 65mm

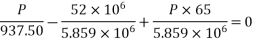

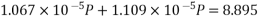

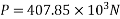

For this case

Problem No. 06 :-A rectangular concrete beam 100mm wide by 250 mm deep spanning over 8m is prestressed by a straight cable carrying and effective prestressing force of 250KN located at an eccentricity of 40mm. The beam support a live load of 1.2KN/m

1) Calculate the resultant stress distribution for the centre of span cross-section of the beam assuming the density of concrete as 24

2) Find the magnitude of prestressing force with an eccentricity of 40mm which can balance the stresses due to dead and live load at the soffit of the centre span section.

Given data:- b=100mm; d=250mm; A = BD =100×250=25× span=L=8m ;

span=L=8m ;

Prestressing force P = 250KN = ; eccentricity e =40mm

; eccentricity e =40mm

Live load on beam =

Solution:-

1) Section modulus z =

2) Maximum bending moment due to external loading =

Total load = (24×0.1×0.25)+1.2=0.6+1.2

=1.8KN/M

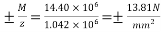

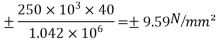

3) Extreme stress due to external bending moment =

4) Extreme stress due to eccentricity of the prestressing force =

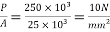

5) Direct stress due to prestressing force =

Case 1

6) Resultant stresses for the extreme fibres will be as

At top edge =

At bottom edge =

Case-II if p=prestressing force required to balance the stresses at soffit, then

i.e.

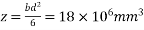

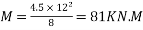

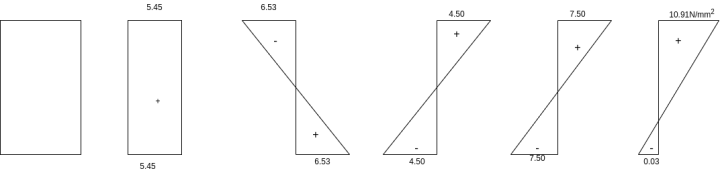

Problem No. 07:- A prestressed concrete beam of rectangular section 300 mm wide and 600 M deep has a span of 12m. The effective prestressing force is 980 KN add an eccentricity of 120mm. The dead load of the beam is 4.5KN/M and The beam has to carry a live load of 7.5KN/M. Determine the extreme stresses.

1) At the end section

2) At the mid section without the action of live load

3) At the mid section with the action of live load

Given data

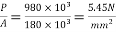

1) Area of beam section A = 300×600=180

2) Section modulus of the section

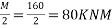

3) Bending moment

Due to DL

Due to LL

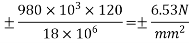

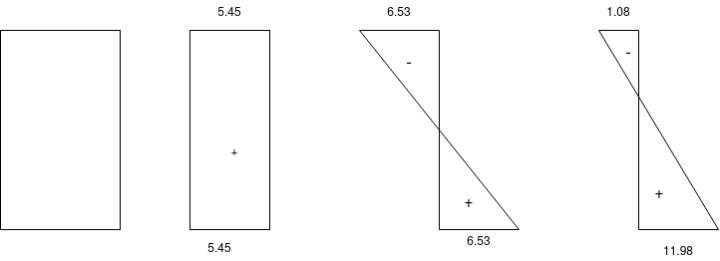

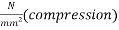

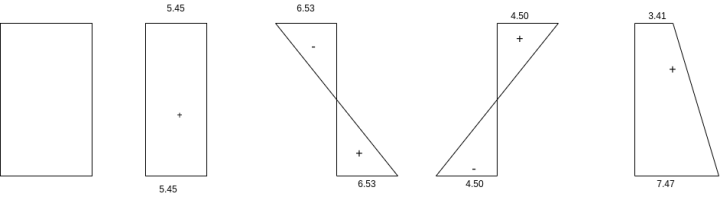

1) At the end section

Direct stress due to prestressing force =

Extreme stress due to eccentricity of the prestressing force =

Resultant stress at top edge = 5.45-6.53 = -1.08

At bottom edge = 5.45+6.53 = 11.98 (compressive)

(compressive)

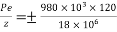

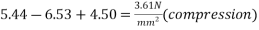

2) Analysis of the midsection subjected to prestressing force and dead load

1) Direct stress due to prestressing force =

2) Extreme stress due to eccentricity of the prestressing force = ±

3) Extreme stress due to dead load moment =

4) Resultant stress at top edge =

At bottom edge = 5.44+6.53-4.50 = 7.47

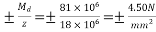

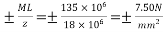

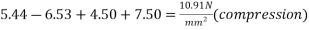

3) Analysis of the mid section subjected to prestressing force, dead load and live load

1) Direct stress = +5.44

2) Extreme stress due to eccentricity of the prestressing force = ±6.53

3) Extreme stress due to dead load moment =

4) Extreme stress due to live load moment

5) Resultant stress at top edge =

Resultant stress at bottom = 5.44+6.53-4.50-7.50= -0.03 (tensile)

(tensile)

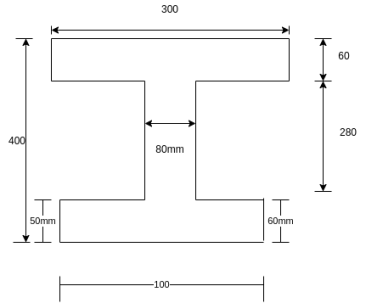

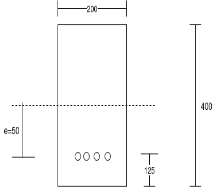

Problem No. 08:- An unsymmetrical I section to support and imposed load of 1.8KN/M over a span of 7.8m top flange is 300mm wide and 60 mm thick bottom flange 100mm wide and 60 mm thick, web thickness is 80 mm with overall depth as 400mm. And effective prestressing force is 150 KN is there at 50 mm from soffit of beam at midspan what are the stress at the centre of span for

Pre-stress+self weight

Pre-stress+self weight

1) Prestress + self weight + imposed load

[Amarvati-S-2014,2015,W-2014]

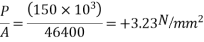

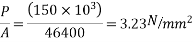

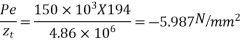

Given data:- imposed load=1.8KN/M

Span. L=7.8m, prestressing force=P=150KN

Area of total I-section A=

A= (300×60)+(100×60)+(80×280)

= 46400

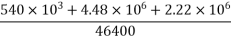

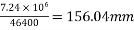

Solution:-

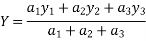

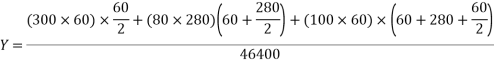

1) Calculate C.G.

Y=distance of centroid from top

=

2) Calculate eccentricity of prestressing force N.A.

Eccentricity (e) =(400-50)-y=350-156.04=193.96≈194mm

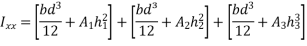

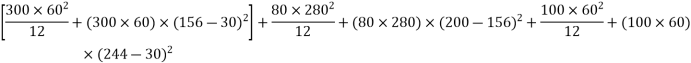

3) Calculate moment of inertia of section

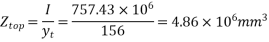

4) Calculate section modulus (z)

mm

mm

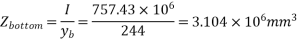

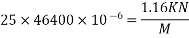

5) Calculate self weight of beam

6) Calculate moments

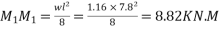

- Self weight of beam (

- Imposed load

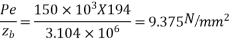

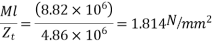

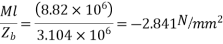

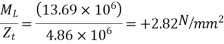

7) Calculate stresses

Stress Type | Top Fibres | Bottom Fibres |

Direct stress |  |  |

Stress due to moment |  |  |

Stress due to self weight of beam |  |  |

Stress due to imposed load |  |  |

Prestress +self weight

At top=3.23-5.987+1.814 =- 0.943

At bottom=3.23+9.375-2.841=9.764

Pre-stress+self weight+imposed load

At top =3.23-5.987+1.814+2.82 = 1.877

At bottom=3.23+9.375-2.841-4.410= 5.354

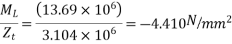

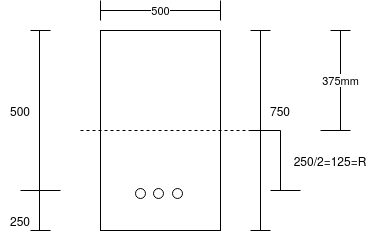

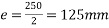

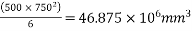

Problem No. 09:- A pre-stressed beam 500mm*750mm has a simple span of 8m and is loaded with a uniformly distributed load of 20KN/M including at 250mm from bottom face. The applied effective pre-stressing force is 2700 KN. Calculate the extreme fiber stresses in the concrete at the quarter span and mid-span section of beam. [AMIE-W-2017]

Given Data:-b=500mm;d=750mm: span L=8m UDL=W=20KN/M

Prestressing force P=2700KN

Eccentricity

Eccentricity

To find:-final stress at top and bottom

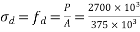

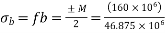

Solution:-Area=b.d=500*750 =

Section modulus  =

=

Maximum bending moment m= 160KN.M

160KN.M

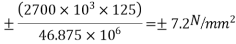

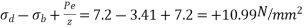

a) Direct stress due to prestressing force  = 7.2N/m

= 7.2N/m

b) Extreme stress due to bending moment  =

=  3.41N/m

3.41N/m

c) Extreme stress due to eccentricity of the Prestressing force =

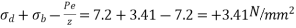

d) Final stress for the extreme fibers will be as follows

i) Top stress =

Ii) Bottom stress=

b) Extreme stress due to bending moment of quarter

L= = 2m

= 2m

At the quarter of span=

At the center of span = But M=

But M=

Problem No. 10:-A prestressed concrete I-beam span 28m and carries a live load of 4 KN/M. Prestressing steel consists of 120 wires of 5mm diameter. Initial prestress is 1000  . Loss of prestress is 16%. Calculate the extreme fibre. Stress at mid span at transfer of prestress and at working load. [AMIE-S-2016]

. Loss of prestress is 16%. Calculate the extreme fibre. Stress at mid span at transfer of prestress and at working load. [AMIE-S-2016]

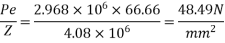

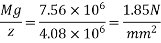

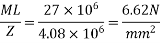

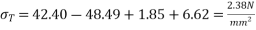

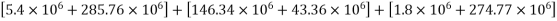

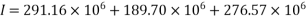

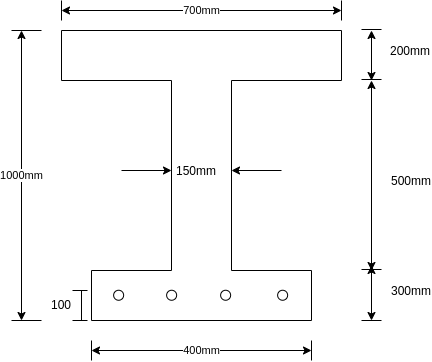

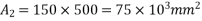

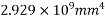

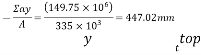

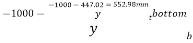

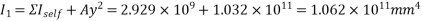

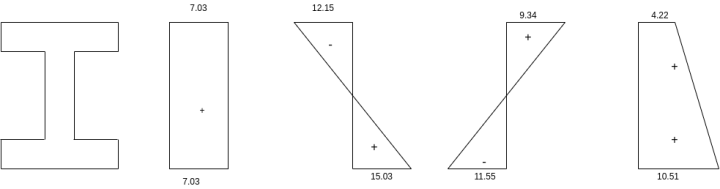

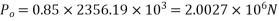

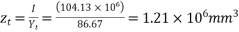

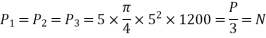

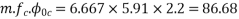

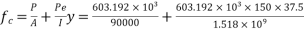

Solution:- The geometrical properties of the various components are given in the table below:

Component | Area (  | C.G. From top | a.y |  | I |

Top flange |  |  |  |  |  |

Web |  |  |  |  |  |

Bottom flange |  |  |  |  |  |

Total |  |

|  |  |  |

Moment of inertia about the axis

Dead load of the beam = Area*Density = 0.335*25=8.375KN/m

Eccentricity

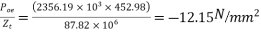

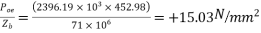

The extreme fibre stresses are calculated for the following cases.

Case-1 Beam subjected to initial prestressing force and dead load.

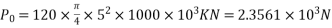

Initial prestressing force

Dead load moment

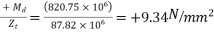

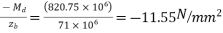

Direct stress

a) Extreme stress due to eccentricity of the prestressing force

1) At top

2) At bottom

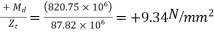

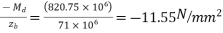

b) Extreme stress due to D.L. Moment

- At top

- At bottom

c) Final stress

- At top

- At bottom

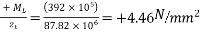

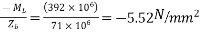

Case-2 Beam subjected to final prestressing force, Dead/Live loads

Final prestressing force P=0.85

Live load moment

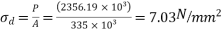

Direct stress

Extreme stress due to eccentricity of the prestressing force

3) At top

4) At bottom

Extreme stress due to D.L. Moment

3. At top

4. At bottom

Extreme stress due to LL moment

1) At top

2) At bottom

Final stress

3. At top =

4. At bottom=

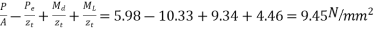

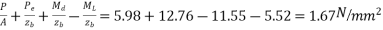

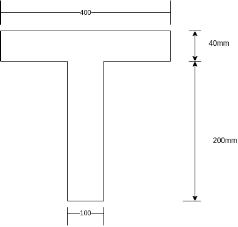

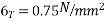

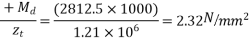

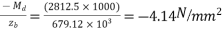

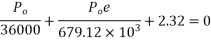

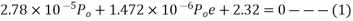

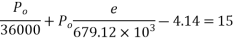

Problem No. 11:- A prestressed concrete T-beam is to be designed to support an imposed load of 4.4KN/M over the span of 5m. The T-beam is made up of flange of size 400mm*40mm. The rib is 100mm wide and 200mm deep. If the allowable stress is limited to 15MPa and 0.75MPa in compression and tension, respectively determine the required prestressing force and its eccentricity at mid-span section.

AMIE-W-2015

Given Data:- Live load

Given Data:- Live load  : Span=L=5m Allowable stress

: Span=L=5m Allowable stress  &

&

To find:-

1) Prestressing force

2) Eccentricity

Solution:-

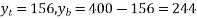

1) Area of section = (400*40)+(100*200)

=3600

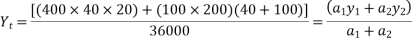

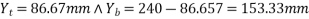

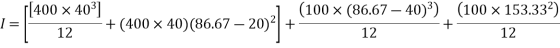

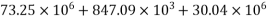

2) Depth of the centroidal axis from the top edge

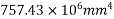

3) Moment of inertia about the centroidal axis

4) Section modulus

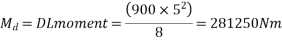

5) Dead load of the beam=0.036*25000=900N/M

6) Live load of the beam=4.4KN/M =4400N/M

Assume P=Initial prestressing force(N)

E=Eccentricity (mm)

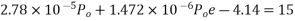

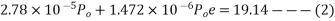

Case-I :- When the beam is subjected to the initial prestressing force and dead load

Direct stress =

Extreme stress at top due to eccentricity of the prestressing force

Extreme stress at top due to DL moment

Extreme stress at bottom due to DL moment

=

For the condition of zero stress at top

The condition that the stress in the bottom to read, 15

Solve equation 1 & 2 we get,

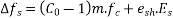

- It has been observed that the prestressing force induced in a member does not remain constant but it decreases with the passage of time on account by various reasons.

- The total loss may be as high as 15 to 20% of the initial press tracing force.

- The designer must take into account all such losses. The important causes of loss in prestressing force are the following.

1) Due to elastic shortening of concrete

2) Due to creep in concrete

3) Due to Shrinkage of concrete

4) Frictional loss

5) Due to creep in steel

6) Due to slip at anchorages.

Losses in pre-stress concrete

Cause | Post tensioned member | Pre tensioned member |

Shrinkage of concrete | 6% | 7% |

Creep of concrete | 5% | 6% |

Creep in steel | 3% | 2% |

Elastic shortening and bending of concrete | 1% | 3% |

Total | 15% | 18% |

No. Pre tensioning | No. Post tensioning |

Elastic deformation of concrete | No loss due to elastic deformation if all the wires are simultaneously tensioned. If the wires are successively tensioned, there will be loss of prestress due to elastic deformation of concrete |

Relaxation of stress in steel | Relaxation of stress in steel |

Shrinkage of concrete | Shrinkage of concrete |

Creep of concrete | Creep of concrete |

| Friction |

| Anchorage slip |

- 1)Loss due to elastic shortening of concrete

a) For pre tensioned members: - Due to the prestress transferred to the concrete, the concrete will shorten. This results in a corresponding shortening of the steel. The prestress in the steel is automatically reduced as it is allowed to shorten slightly.

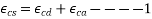

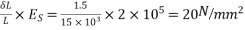

Let the intensity of the compressive stress in concrete be

Let the Young's modulus for concrete be

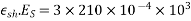

Strain in concrete  but.

but.

If  is the area of concrete and P beat the prestressing force

is the area of concrete and P beat the prestressing force

We have  =>

=>

Since the steel will also shorten as the concrete shortens,

The loss of strain in steel=strain in concrete =

Loss of prestress  = Young's modulus for steel

= Young's modulus for steel

where

where  modular ratio=

modular ratio=

In the above expression P the prestress prevailing finally may not be known. But for a sufficiently correct estimation of the loss of prestress it is enough if the initially applied prestress P is adopted.

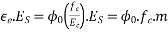

- Strain in concrete at the level of steel =

- Stress in steel corresponding to this strain =(

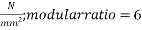

Modular ratio m =

- Loss of stress in steel =

- if the initial stress in steel is known the percentage loss of stress in steel due to the elastic deformation of concrete can be computed.

b) For post tensioned members

- When more than one tendon is provided the various tendons are not simultaneously tensioned. There will be tensioned in succession.

- Consider one tendon is tensioned. Due to this, elastic shortening takes place. When elastic shortening of concrete takes place elastic shortening of second tendon causes loss of prestress in first tendon.

- Similarly after tightening of third tendon, first two tendons suffer loss of prestress. The average loss is half the loss of prestress experience by 1st tendon.

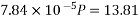

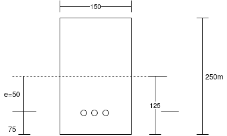

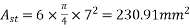

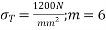

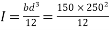

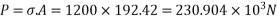

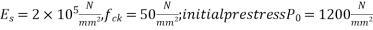

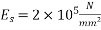

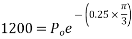

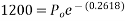

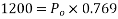

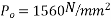

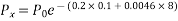

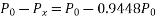

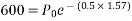

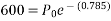

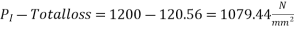

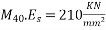

Problem:- Determine the loss of prestress due to elastic shortening in concrete beam of size 150 mm wide and 250 m deep which is prestressed with 6 wires of 7mm diameter, located at 75 mm from soffit, take initial prestress=1200

Given data:- b=150mm; D=250mm ;

Given data:- b=150mm; D=250mm ;

Soffit=75mm; eccentricity=125-75=50mm

Initial prestress

Solution:- to find the loss of prestress due to elastic shortening

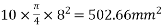

1) Area of beam=A=bd=150×250=

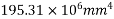

2) Second moment of inertia

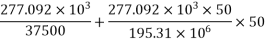

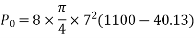

3) Prestressing force applied at tendon=F=A. = 230.91×1200 = 277.092×

= 230.91×1200 = 277.092×

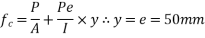

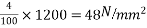

4) Stress in concrete at the level of steel

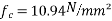

=7.389+3.55

5) Loss of stress due to elastic deformation=  =6×10.94=65.64

=6×10.94=65.64

6) Percentage loss of stress in steel=

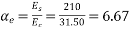

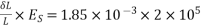

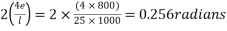

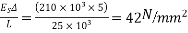

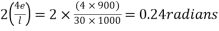

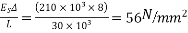

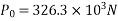

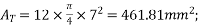

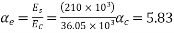

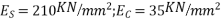

Problem no 02:- A pretensioned concrete beam of rectangular cross section, 150mm wide & 300mm deep, is a prestressed by eight high tensile wires of 7 mm diameter located at 100 mm from the soffit of the beam. If the wires are tension to a stress of 1100  , calculate the percentage loss of stress due to elastic deformation assuming the modulus of elasticity of concrete and steel as 31.5 and 210

, calculate the percentage loss of stress due to elastic deformation assuming the modulus of elasticity of concrete and steel as 31.5 and 210

Solution:- b=150mm ; d=300mm;

Solution:- b=150mm ; d=300mm;

Eccentricity=150-100=50mm

Tension stress

Modulus of elasticity of concrete

Modulus of elasticity of steel

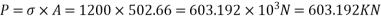

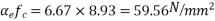

Solution:- 1) prestressing force

=1100×308

=338.8KN

2) area of section A=bd=150×300=

3) Second moment of inertia M

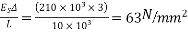

4) Modular ratio m=

5) Stress in concrete at the level of steel

6) Loss of stress due to elastic deformation =

= 6.67×10.03 = 66.90

7) Percentage loss of stress in steel =

=6.08%

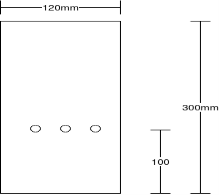

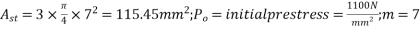

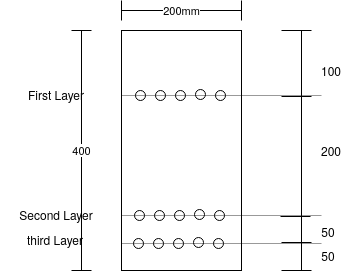

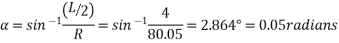

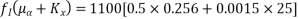

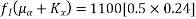

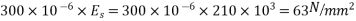

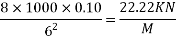

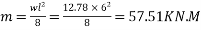

Problem no 03:- The figure shows the cross section of a pretensioned beam of span 6m, simply supported at an ends and carrying uniformly distributed load of 8KN/m over entire span. Determine the loss of prestress due to elastic the formation under the combined effect of prestressing force and external moment. Given No.’s of 7mm prestressing straight wires =3

Initial prestress in steel=1100 ; modular ratio=7

; modular ratio=7

Given data:- b=120mm; D=300mm ;

Given data:- b=120mm; D=300mm ;

To find:- loss of prestress due to elastic deformation

Solution:-

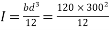

1) Area of beam=A=b.d =120×300 = 36000

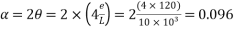

2) Moment of inertia

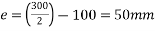

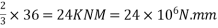

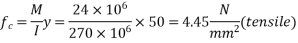

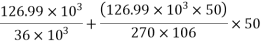

3) Pre-stress force at tendon =115.45×1100 =126.99×

4) Eccentricity

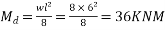

5) Bending moment due to external load

This moment where is parabolically along the length of the beam with zero value add supports and 36KNM at midspan

∴ Average moment=

6) Hence average stress in concrete at the level of steel (y=50mm)

7) Increase in stress in steel wires = m×

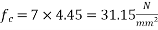

8) Compressive stress in concrete at the level of steel due to prestressing force

=3.53+1.175

=4.705

9) Loss of stress in steel =

10) Due to combined effect of prestressing force and external movement loss of prestress

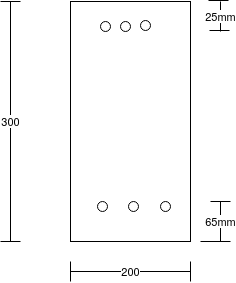

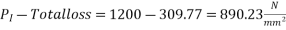

Problem no 04:- A rectangular concrete beam 300 mm deep and 200 mm wide, is a prestressed by means of 15mm diameter wires located 65 mm from the bottom of the beam and 3mm wire, located 25mm from the top of the beam. If the wires are initially tension to a stress of 840  calculate the percentage loss of stress in steel immediately after transfer allowing for the loss of stress due to elastic deformation of concrete only.

calculate the percentage loss of stress in steel immediately after transfer allowing for the loss of stress due to elastic deformation of concrete only.

Given data:- b=200mm ; d=300mm

Assume modulus of elasticity of concrete

Assume modulus of elasticity of concrete

Assume modulus of elasticity of steel

Solution:-

Area of concrete A=300×200=60000

Position of the centroid of the wires from the soffit of the beam

Eccentricity e=150-100=50mm

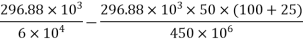

Second moment of area

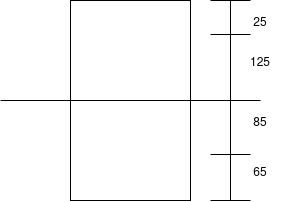

σ=P/A=

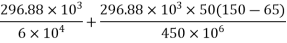

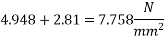

Initial prestressing force P=296.88KN

Stress in concrete

Stress in concrete

a) At the level of top wires =

= 4.948 - 4.12

=0.828

b) At the level of bottom wears =

Modular ratio =

1) Loss of stress in wires at top =

=6.67×0.828

2) Loss of stress in wires at bottom =

=6.67×7.758 =51.75

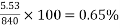

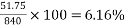

Percentage of loss of stress

1) For wires at top =

2) For wires at bottom =

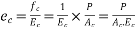

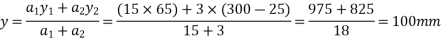

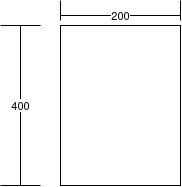

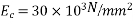

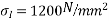

Problem no 05:- The given figure shows the cross section of a pretensioned beam of size 200mm×400mm, which was prestressed with 15 straight wires of 5 mm diameter located in three layers. Determine the average loss of prestressing force due to elastic shortening, if initial stress was 1200  Take modular ratio m=

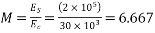

Take modular ratio m=  = 7

= 7

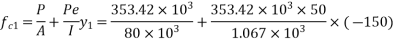

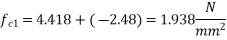

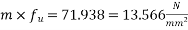

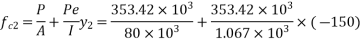

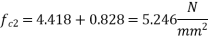

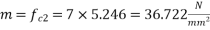

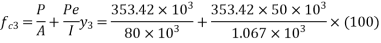

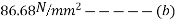

Solution:-

1) Area of beam= A=b.d=200×400=80×

2) Moment of inertia

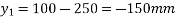

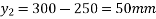

3) Total prestressing force

=353.42KN

4) Prestressing force at each level

5) Centre of gravity of prestressing force from top edge

6) Eccentricity of prestressing force e = 250 -

7) Distances of every layer from N.A.

First layer

Second layer

Third layer

8) Compressive stress at the level of first layer

9) Loss of prestress in first layer =

10) Compressive stress at the level of second level

11) Loss of prestress in second layer

12) Compressive stress at the level of third level

13) Loss of prestress in third layer

14) Average loss of prestress due to elastic shortening

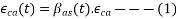

Loss due to creep in concrete

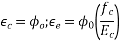

- Creep is deformation of concrete depending upon the time interval to which the member is loaded.

- A concrete member undergoes deformation due to external loading. If now this member is loaded for a long time, It is seen that the deformation increases.

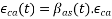

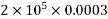

- The additional deformation due to long time interval loading is called creep. If

is the instantaneous strain immediately after loading the

is the instantaneous strain immediately after loading the  is the strain after long time then the ratio

is the strain after long time then the ratio  is called the coefficient of creep.

is called the coefficient of creep.

- Value of coefficient of creep varies considerably up to two years period and then there is no appreciable change.

is then taken as 2.5 to 3. Lower value is for post tensioned members and higher value for pre tensioned members.

is then taken as 2.5 to 3. Lower value is for post tensioned members and higher value for pre tensioned members.

Loss of stress due to creep will be.

Where;  =creep coefficient

=creep coefficient

=original stress in concrete

=original stress in concrete

m=modular ratio

Loss due to shrinkage and creep can be combined as:

Where  shrinkage strain

shrinkage strain

Creep coefficient method

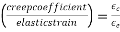

Creep coefficient=c=

Hence, loss of stress =

The Indian and British quotes recommend the values of 70 creep coefficient for varying humidity age at loading and the notional size of the member. The value of the creep coefficient varies from a minimum of 1.0 to maximum of 5.8

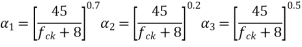

For grades of concrete from M-30 to M-60 generally used in prestressed members, the values of creep coefficient listed in the table below are useful in computing the loss of stress due to creep in concrete.

Where;  =creep coefficient ;

=creep coefficient ;  creep strain

creep strain  elastic strain

elastic strain

m= modular ratio ;  stress in concrete

stress in concrete  modulus of elasticity of steel

modulus of elasticity of steel  =modulus elasticity of concrete.

=modulus elasticity of concrete.

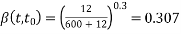

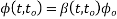

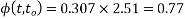

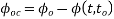

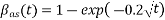

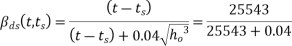

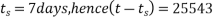

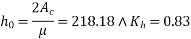

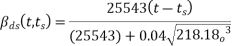

Where

t=age of concrete in days at the moment considered.

age of concrete at loading in days,

age of concrete at loading in days,

duration of loading in days

duration of loading in days

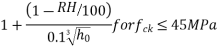

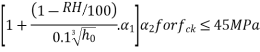

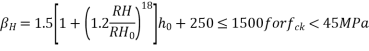

=A coefficient depending on the relative humidity( RH in percent) and the notional member size

=A coefficient depending on the relative humidity( RH in percent) and the notional member size  .

.

RH=relative humidity expressed as percent

100(that is, 100 percent relative humidity)

100(that is, 100 percent relative humidity)

= coefficients to consider the influence of the concrete strength,

= coefficients to consider the influence of the concrete strength,

t=age of the concrete at the moment considered in days,

=age of the concrete at the beginning of drying shrinkage, in days; normally this is at the end of curing; and

=age of the concrete at the beginning of drying shrinkage, in days; normally this is at the end of curing; and

=notional size of the cross section, in mm=

=notional size of the cross section, in mm= where

where  is the concrete cross-sectional area and use the parameter of that part of the cross-section which is exposed to drying.

is the concrete cross-sectional area and use the parameter of that part of the cross-section which is exposed to drying.

6.2.5 Creep

Creep of concrete depends, in addition to the factors listed in 6.2.4 on the stress in the concrete, age at loading and the duration of loading. As long as the stress in concrete does not exceed one third of characteristic compressive strength, creep may be assumed to be proportional to the stress.

6.2.5.1 The creep coefficient.

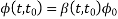

Where

=Creep strain at time

=Creep strain at time

=Initial strain at loading, and

=Initial strain at loading, and

=initial time of loading

=initial time of loading

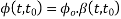

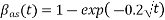

The creep coefficient  is given by:

is given by:

Where

=Notional creep coeffcient to which the creep coefficient reaches asymptotically with time (this can be taken as value reached in 70 years), and

=Notional creep coeffcient to which the creep coefficient reaches asymptotically with time (this can be taken as value reached in 70 years), and

= Coefficient describing development of creep with time ( see 6.2.5.2)

= Coefficient describing development of creep with time ( see 6.2.5.2)

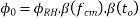

The notional creep coefficient  is given by

is given by

Where

=a factor to allow for the effect of relative humidity on the notional creep coefficient.

=a factor to allow for the effect of relative humidity on the notional creep coefficient.

(RH=relative humidity of the ambient environment in percent,

notional size of the member, in mm=

notional size of the member, in mm=

=cross sectional area, and

=cross sectional area, and

=perimeter of the member in contact with the atmosphere.

=perimeter of the member in contact with the atmosphere.

=A factor to allow for the effect of concrete strength on the notional creep coefficient

=A factor to allow for the effect of concrete strength on the notional creep coefficient

=a factor to allow for the effect of concrete age at loading on the notional creep coefficient

=a factor to allow for the effect of concrete age at loading on the notional creep coefficient

Where end read results are not sensitive precise values calculated as given above, the values given in table below can be considered as final creep coefficient for design for normal weight concrete of grades between M 30 and M 60 subject to condition that the compressive stress does not exceed  at the age of loading, and mean temperature of concrete is between 10°C and 20°C with seasonal variation between -20°C and 40°C. For temperature greater than 40°C the coefficient given may be increased by 10%. In the absence of accurate data.

at the age of loading, and mean temperature of concrete is between 10°C and 20°C with seasonal variation between -20°C and 40°C. For temperature greater than 40°C the coefficient given may be increased by 10%. In the absence of accurate data.

Age at loading Creep coefficient  of an ordinary structural concrete after 70 years of

of an ordinary structural concrete after 70 years of

loading

loading

Under Dry Atmospheric Under humid Atmospheric Conditions (RH 50%) Conditions (Outdoor ) (RH 80%)

Notional Size( Notional Size (

Notional Size (

| 50mm | 150mm | 600mm | 50mm | 150mm | 600mm |

(1) | (2) | (3) | (4) | (5) | (6) | (7) |

1 | 5.8 | 4.8 | 3.9 | 3.8 | 3.4 | 3.0 |

7 | 4.1 | 3.3 | 2.7 | 2.7 | 2.4 | 2.1 |

28 | 3.1 | 2.6 | 2.1 | 2.0 | 1.8 | 1.6 |

90 | 2.5 | 2.1 | 1.7 | 1.6 | 1.5 | 1.3 |

365 | 1.9 | 1.6 | 1.3 | 1.2 | 1.1 | 1.0 |

6.2.5.2 the development of creep with the time may be taken as

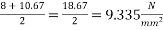

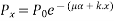

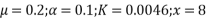

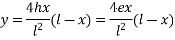

Problem No 01:- A concrete beam having a width of 100 mm and depth 300mm is post tensioned by a parabolic cable with an eccentricity of 50 mm at the centre of span and concentric at the supports. Assuming an ultimate creep coefficient of 3.0 Estimate the loss of stress in the cable due to creep of concrete. [Force in cable P=240KN]

Given data:- b=100mm ,d=300mm ,e=50mm ; creep coefficient  =3.0

=3.0

Solution:-

1) area of concrete A =100×300=

2) Force in cable P=240KN=240×

3) MI=

4) Modular ratio

5) stress in concrete at the level of cable at support and centre of span sections are computed as

a) At support section =

b) At centre of span section =

Average stress at the level of cable  =

=

Loss of stress =  = 3×9.335×5.42 =151.78

= 3×9.335×5.42 =151.78

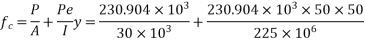

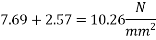

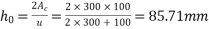

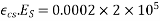

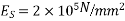

Problem No 02:-A concrete beam of rectangular section 100mm wide and 300 M deep is prestressed by five wires of 7 mm diameter located at an eccentricity of 50mm, the initial stress in the wires being 1200  .estimate the final loss of stress in steel due to creep of concrete according to the IS-1343-2012 (

.estimate the final loss of stress in steel due to creep of concrete according to the IS-1343-2012 ( )

)

Given data:- b=1000mm ; d=300mm  ; eccentricity e=50mm

; eccentricity e=50mm

Solution:-

1) area of concrete =b.d =100×300=30

2) Second moment of area I =

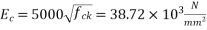

3) Assume modulus of elasticity of concrete

Modulus of elasticity of steel =

4) Modular ratio

5) Initial prestressing force in wire

Assume humidity=50%, age at loading=28 days

6) Stress in concrete at the level of steel is given by

7) Loss of stress =

Assuming that the sides and bottom width of the beam is exposed to the environment:- notional size

Use table, read out the value of creep coefficient corresponding to the values of relative humidity 50%, age at loading as 28 days and notional size 85.71mm

Loss of stress=  =2.8×10.26×5.42=155.70

=2.8×10.26×5.42=155.70

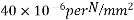

Problem No 03:-A Post tensioned PC beam of rectangular section 150 mm wide and 350 M deep is stressed by a parabolic cable concentric at the supports and an eccentricity 55mm at the centre of span. The area of high tensile steel in cable is 220  and initial stress in the cable is 1100

and initial stress in the cable is 1100 . If the ultimate creep strain is

. If the ultimate creep strain is  of stress and modulus of elasticity of steel is 210

of stress and modulus of elasticity of steel is 210  Compute the average loss of stress in steel due to creep of concrete.

Compute the average loss of stress in steel due to creep of concrete.

Given data:- width of beam=b=150mm ; depth of beam=d=350mm

Eccentricity e=55mm at centre of span and zero at supports.

Cable stress P=(220×1100)=242×

Ultimate creep strain =  =

= modulus of elasticity

modulus of elasticity

Calculate average loss of stress in steel due to creep of concrete

Solution:-

Area of beam A = bd =150×350 = 52500

Moment of inertia I =

Stress at support  =

=

Stress at centre of span section

Average stress at the level of steel

Loss of stress in the cable due to creep of concrete is

=

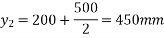

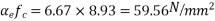

Problem No 04-:- Figure shows the cross section of a pretensioned prestress T-beam, built in a dry atmospheric condition. The beam is a prestressed with 7000KN force the centroid of wires being at 150 mm from the soffit. Determine the loss of pre-stress due to creep, if modular ratio is 6 and age of concrete at loading is 28 days.

Given data:- prestress force P=7000KN; m=6, age of concrete at loading=28 days

Solution:-

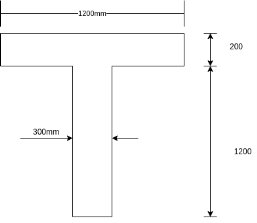

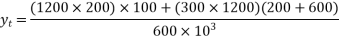

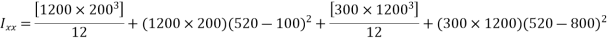

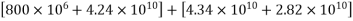

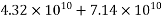

1) Area of section = (1200×200)+(300×1200) = 600

2)  Distance of N.A. From top fibre

Distance of N.A. From top fibre

=520mm

3) Eccentricity e = y =1400 - 200-520 = 680mm

4) Moment of inertia

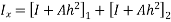

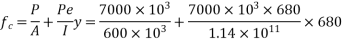

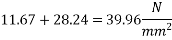

5) Stress in concrete

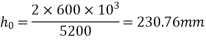

6) Calculate notional size of the member

[IS-1343-2012; Cl. No. 6.2.5.1 PP-6]

[IS-1343-2012; Cl. No. 6.2.5.1 PP-6]

Where

u= perimeter of section = (2×1200)+(200+1200)×2

=2400+2800

=5200

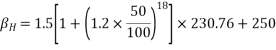

Now, as per IS-1343-2012; Clause No. 6.2.5.1 PP-6 from table calculate  by interpellation for 28 days

by interpellation for 28 days

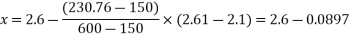

150 | 2.6 |

230.76 | X |

600 | 2.1 |

=2.51

We know,

Loss of stress in steel =

=2.51×39.91×6

=601.04

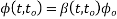

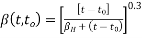

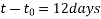

Problem No 04-:- Determine the loss of prestress due to creep, if the beam referred previous example in post tensioned. Given that age of transfer is 12 days after the end of curing for 28 days and

Given data:-

Solution:- we know that,

Loss of prestress due to creep=

As per IS-1343-2012; Clause No. 6.2.5.2 PP-6

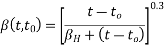

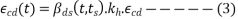

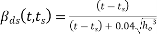

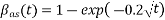

The development of creep with time may be taken as

------------------(1)

------------------(1)

Where ; t=age of concrete in days at the moment considered

age of concrete at loading in a days

age of concrete at loading in a days

Now,  = duration of loading in days

= duration of loading in days

=Coefficient depending on the relative humidity and the notional member size(

=Coefficient depending on the relative humidity and the notional member size( )

)

relative humidity expressed as percent=50(given)

relative humidity expressed as percent=50(given)

100 (that is, 100 percent relative humidity)=100

100 (that is, 100 percent relative humidity)=100

230.76mm (previous problem)

230.76mm (previous problem)

1=>

We know

Where;

[Calculate previous problem]

[Calculate previous problem]

Creep coefficient after post tensioning

=1.74

Loss of prestress due to creep =

Where

M=modular ratio=6

stress in concrete = 39.91

stress in concrete = 39.91  (calculate previous example)

(calculate previous example)

=creep coefficient =1.74

=creep coefficient =1.74

(2) => =6×39.91×1.74

=416.66

Loss of prestress due to shrinkage of concrete [IS 1343-2012, clause no. 6.2.4 PP-5]

- Shrinkage of concrete occurs due to chemical changes and drying. This depends upon the interval of time and moisture conditions, but this is independent of the stresses due to loads.

- Shrinkage is in proportion with water content in concrete. Hence by minimising the water cement ratio this shrinkage can be reduced by using well graded and large size aggregates also this loss can be reduced.

- Shrinkage strain is in between 0.0002 to 0.0004

Loss of stress = shrinkage strain×

Generally moist curing is restored to in order to prevent shrinkage until the time of transfer. Consequently the total residual shrinkage strain will be larger in three tensioned members after transfer to prestress in comparison with post tensioned members, where a portion of shrinkage will have already taken place by the time of transfer of stress.

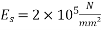

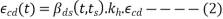

Total shrinkage strain ( comprises of two components, the drying shrinkage strain (

comprises of two components, the drying shrinkage strain ( and the autogenous shrinkage strain (

and the autogenous shrinkage strain (  Expressed as

Expressed as

Loss of stress=

Where  modulus of elasticity of steel

modulus of elasticity of steel

6.2.4 shrinkage

The total shrinkage of concrete depends upon the constituents of concrete, size of the member and environmental conditions. For a given humidity and temperature, the total shrinkage of concrete is most influenced by the total amount of water present in the concrete at the time of mixing and, to a lesser extent, by the cement content.

6.2.4.1 the total shrinkage strain is composed of two components, the autogenous shrinkage strain and the drying shrinkage strain.

The value of the total shrinkage strain, is given by:

Where

=Total shrinkage strain;

=Total shrinkage strain;

=Drying shrinkage strain; and

=Drying shrinkage strain; and

= Autogenous shrinkage strain

= Autogenous shrinkage strain

6.2.4.2 The autogenous shrinkage strain develops during hardening of concrete; the major part develops in the early days after casting. Autogenous shrinkage is a linear function of concrete strength. It should be considered specifically when new concrete is cast against hardened concrete.

In the absence of accurate field/laboratory data, the following values may be considered in design:

Grade of concrete | Autogenous shrinkage  |

M 30 | 35 |

M 35 | 45 |

M 45 | 65 |

M 50 | 75 |

M 60 | 95 |

6.2.4.3 the drying shrinkage strain develops slowly, as-it-is function of migration of the water through the hardened concrete.

The final value of the drying shrinkage strain,  may be taken equal to

may be taken equal to values of

values of  may be taken from the table given below for guidance. These values are expected mean values, with a coefficient of variation of about 30%.

may be taken from the table given below for guidance. These values are expected mean values, with a coefficient of variation of about 30%.

Unrestrained Drying Shrinkage Values

Unrestrained Drying Shrinkage Values  for concrete with Portland

for concrete with Portland

Cement, for Relative Humidity

Cement, for Relative Humidity

| 50 percent | 80 percent |

(1) | (2) | (3) |

25 | 535 | 300 |

50 | 420 | 240 |

75 | 330 | 190 |

Note-The values for the other designated grades may be obtained by interpolation

is 1 or fission depending on the notional size

is 1 or fission depending on the notional size  as given below:

as given below:

Mm |  |

100 | 1.0 |

200 | 0.85 |

300 | 0.75 |

| 0.70 |

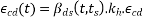

6.2.4.4 The development of autogenous shrinkage with time may be taken as:

Where

where t is in days.

where t is in days.

6.2.4.5 the development of the drying shrinkage strain in time may be taken as

Where

t=age of the concrete at the moment considered, in days;

age of the concrete at the beginning of drying shrinkage, in days; normally this is at the end of curing; and

age of the concrete at the beginning of drying shrinkage, in days; normally this is at the end of curing; and

=notional size of the cross section, in mm =

=notional size of the cross section, in mm = where

where  is the concrete cross-sectional area and use the perimeter of that part of the cross-section which is exposed to drying.

is the concrete cross-sectional area and use the perimeter of that part of the cross-section which is exposed to drying.

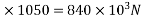

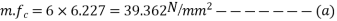

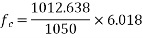

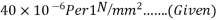

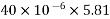

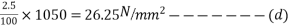

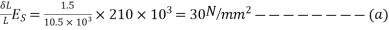

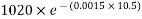

Problem No 01:- calculate the percentage of prestress due to shrinkage when tendon is subjected to initial prestress 1050  and shrinkage strain is 0.0003.[ AMIE-W-2016]

and shrinkage strain is 0.0003.[ AMIE-W-2016]

Given data:-

Shrinkage strain

Initial prestress  =1050

=1050

Solution:-

We know

=

=

=60

Percentage of prestress due to shrinkage =

= 5.71%

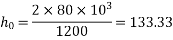

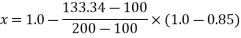

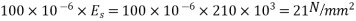

Problem No 02:- calculate the percentage loss of prestress in the cables of a pretensioned beam of size 200mm×400mm due to shrinkage of concrete. Take the relative humidity of the region as 50 percent,  relative humidity=50% ;

relative humidity=50% ;  initial prestress

initial prestress

To find:- percentage loss of pre-stress in the cables.

Solution:- As per IS-1343-2012; clause number 6.2.4 PP-5

Total shrinkage strain

Where,

=Total shrinkage strain

=Total shrinkage strain

=Drying shrinkage strain

=Drying shrinkage strain

= Autogenous shrinkage strain

= Autogenous shrinkage strain

= Autogenous shrinkage depends upon grade of concrete

= Autogenous shrinkage depends upon grade of concrete

M-50 =>

= During shrinkage strain =

= During shrinkage strain =

=

= …..[IS-1343-2012- Clause No. 6.2.43 PP-05]

…..[IS-1343-2012- Clause No. 6.2.43 PP-05]

Now,

Now,

is a coefficient depending on the notional size

is a coefficient depending on the notional size

Now,

Where,  =area of concrete = 200×400 =

=area of concrete = 200×400 =

= The perimeter of that part of c/s which is exposed to drying

=(2×200)+(2×400)=1200mm

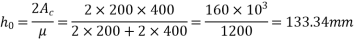

|  |

100 | 1.0 |

133.33 | x |

200 | 0.85 |

Total shrinkage strain

We know, loss of prestress in The beam =

Percentage loss of prestress due to shrinkage of concrete

Problem No 03:- Determine the percentage loss of pre-stress due to shrinkage in the beam if the beam size 200 mm ×400mm is a post tensioned beam. Take the relative humidity of the region as 50 percent,  grade of concrete M-50, initial prestress =

grade of concrete M-50, initial prestress = age of transfer in 12 days after the end of curing for 28 days.

age of transfer in 12 days after the end of curing for 28 days.

Given data:- size of beam b=200mm ; d=400mm post tensioned beam; relative humidity=50% ;  ;age of transfer is 12 days after the end of curing for 28 days.

;age of transfer is 12 days after the end of curing for 28 days.

Solution:- we know; loss of prestress in the beam= –---------------(I)

–---------------(I)

Where

=Drying shrinkage after post tensioning

=Drying shrinkage after post tensioning

= Final drying shrinkage - drying shrinkage at the time of post tensioning –------(II)

Final drying shrinkage =

is the coefficient depending on the notional size

is the coefficient depending on the notional size

|  |

100 | 1.0 |

133.34 | x |

200 | 0.85 |

And  =drying shrinkage strain

=drying shrinkage strain

= [IS-1343-2012; Clause No. 6.2.4.3 PP-5]

[IS-1343-2012; Clause No. 6.2.4.3 PP-5]

Final drying shrinkage=

Drying shrinkage at the time of post tensioning

Where,

Where,

(3) =>

(2)=>

=

(1) => Loss of prestress in the beam =

Percentage loss =

=

Problem No 04:-A concrete beam is the prestressed by a cable with an initial stress of 1000  in the wires. The grade of concrete in the beam is M-50 . The beam is located in an area having a relative humidity of 50%. The beam is exposed to the environment on three sides having a depth of 400mm and a width of 300mm. The beam was cured for 7 days before it was prestressed using the IS code method, estimate the loss of stress in steel due to shrinkage of concrete at the age of a) 28 days b) 70 years

in the wires. The grade of concrete in the beam is M-50 . The beam is located in an area having a relative humidity of 50%. The beam is exposed to the environment on three sides having a depth of 400mm and a width of 300mm. The beam was cured for 7 days before it was prestressed using the IS code method, estimate the loss of stress in steel due to shrinkage of concrete at the age of a) 28 days b) 70 years

Assume modulus of elasticity of steel as 210

Given data:- Initial stress in wires

relative humidity= 50% : d=400mm ; b=300 mm

relative humidity= 50% : d=400mm ; b=300 mm

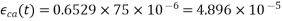

Case-I loss of stress due to shrinkage at 28 days

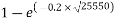

1) At 28 days, the autogenous shrinkage strain [ 6.2.4.4 PP-5]

Where,

where t is in days

where t is in days

=

=0.6529

From Clause no. 6.2.4.2 PP-5 use table, corresponding to M-50 grade concrete, read the value of

(1) =>

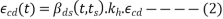

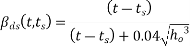

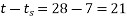

Ii) The drying shrinkage strain at 28 days is computed as using 6.2.4.5 PP-5

Where,

In this expression, t=28 days & hence (

hence (

The value of  corresponding to a value of

corresponding to a value of

So,

For M-50 grade concrete at a relative humidity of 50% read the value of unrestrained drying shrinkage from table 6.2.4.3 pp-5

(2) =>

2) Total shrinkage strain is computed as =