Unit - 1

Compass and Levelling

Importance of Surveying:

Key Takeaways:

Surveying is the art of determining the relative positions of different objects on the surface of the earth.

There are two aspects:

1. Location of a point by measurement from two points of reference

2. Work from whole to part:

Key Takeaways:

There are two aspects:

1. Location of a point by measurement from two points of reference

2. Work from whole to part:

Surveying:

Object of Surveying:

There are two types of surveying:

Plane Surveying:

Geodetic surveying:

Key Takeaways:

There are two types of surveying:

The ratio by which actual length of the object is reduced or increased is known as scale.

Types of scale:

1. Full size scale:

2. Reducing scale:

3. Increasing or Enlarging scale:

Key Takeaways:

There are three types of scale:

Key Takeaways:

The process of establishing intermediate points on a straight line between two end points is known as ranging

Metric chain:

Steel Band:

Engineer's chain:

Gunter's chain:

Revenue chain:

Key Takeaways:

There are five types of chain:

1.8 Offsetting:

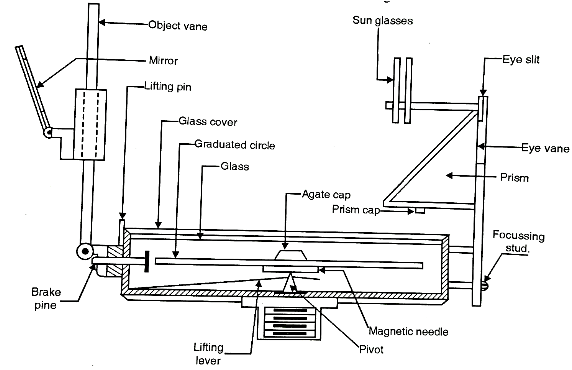

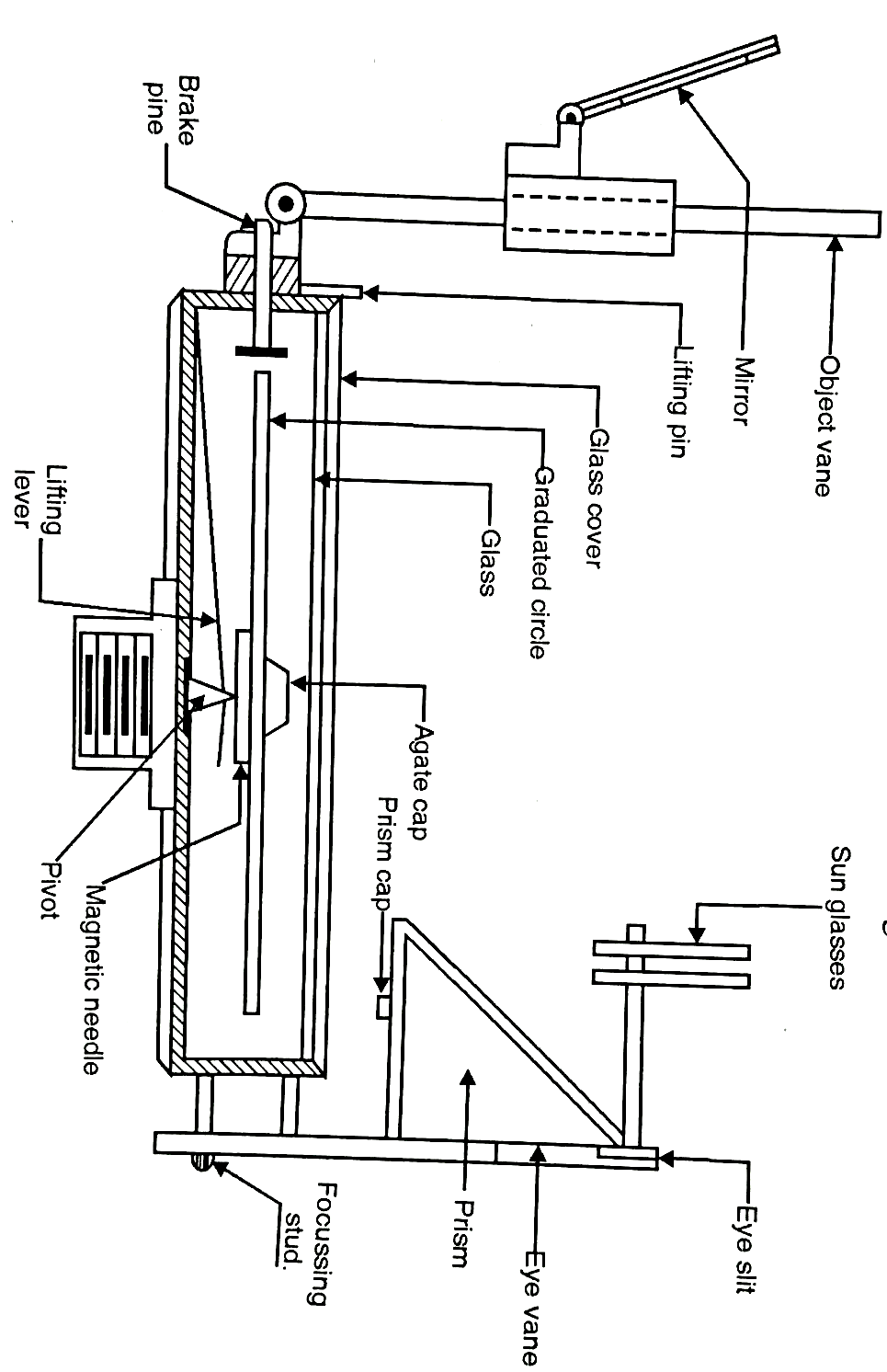

Fig.1.1: Prismatic Compass

1. Pivot:

2. Lifting lever:

3. Brake pin:

4. Reflecting mirror:

5. Sun glasses:

6. Glass prism:

7. Aluminium ring:

Procedure for using the Prismatic Compass:

Fixing the compass in tripod:

Centering:

Levelling:

Observing the bearing of a line:

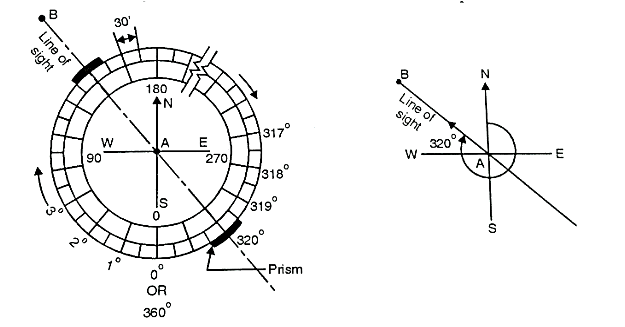

Bearing of a line:

Fig.1.2: Graduations in Prismatic Compass

Key Takeaways:

Prismatic compass is used for angular measurements of angles between two or more relative points in horizontal plane. The prismatic compass is a portable form of magnetic compass which is installed on a tripod stand by which angles are measured in horizontal plane.

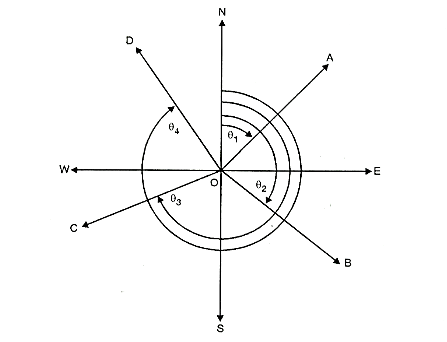

Types of bearings:

1. Whole circle bearing (W.C.B.) system:

Fig.1.3: Whole Circle bearing

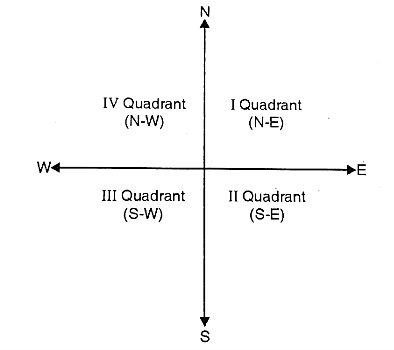

2. Reduced bearing (Quadrantal system):

Fig.1.4: Quadrantal bearing

Key Takeaways:

Generally, the bearings of survey lines are designated in the following two types:

Types of meridians:

a) True Meridian: The line or length passing through the geometrical north pole, geographical south pole and any point on the earth surface is known as true meridian.

b) Magnetic Meridian: It is the direction indicated by freely suspended and balanced magnetic needle unaffected by local attractive forces. The location of magnetic pole is continuously changes hence, the direction of magnetic also changes.

c) Arbitrary Meridian: It is any convenient direction usually from survey station to some well-defined permanent object. This is used for small area survey or to determine the relative direction of small traverse.

Key Takeaways:

There are three types of meridian:

Detection of Local Attraction:

Note: If F.B.-B.B. = 180°; free from local attraction / same local attraction.

If F.B.-B.B. 180°; affected by local attraction.

Effect on included angle:

Adjustment of Local Attraction or Eliminating the Effect of Local Attraction:

There are two methods by which the effect of local attraction can be eliminated or can be adjusted.

Method I:

Method II:

Key Takeaways:

The deviation of the magnetic needle from its normal position (North direction) under the influence of external forces is called as local attraction.

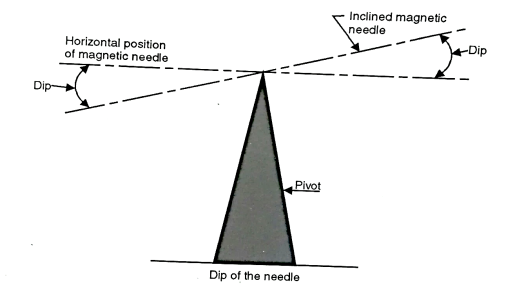

Fig.1.5: Dip of the needle

Key Takeaways:

The angle which the deflected needled makes with horizontal is known as dip of the magnetic needle.

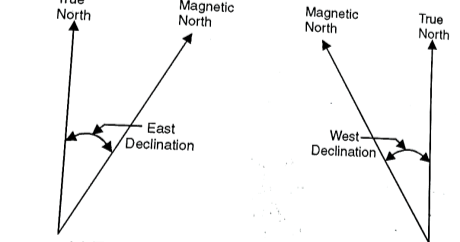

Fig.1.6: East and West declination respectively

Determination of Declination:

The methods commonly adopted for determining magnetic declination are:

1. By observation to sun:

2. By isogenic charts:

Key Takeaways:

The horizontal angle between the true meridian and magnetic meridian at a place is known as 'magnetic declination".

Q. A line was drawn to magnetic bearing of 238° 20' on an old map when mag. 5°40’ E. To What bearing it should be set now if present magnetic declination is 3° 10' W

True bearing of line = magnetic bearing  Declination = 288°20'+ 5°40’=244 °

Declination = 288°20'+ 5°40’=244 °

Now, declination is 3°10' W

Bearing = 244°--3°10’=240°50’

Q. The magnetic bearing of sun at noon is 356° 30' Find the declination.

True bearing = mag. bearing ± Declination

360° =356° 30’ Dectination.

Dectination.

Declination = 3°30' E

The accessories of plane table are:

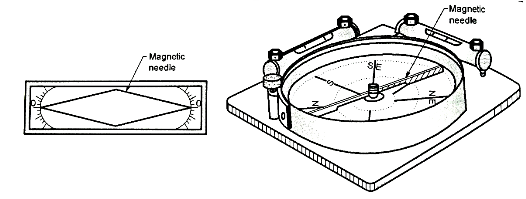

Fig.1.7: Trough and Circular Compass

A trough compass or circular box compass:

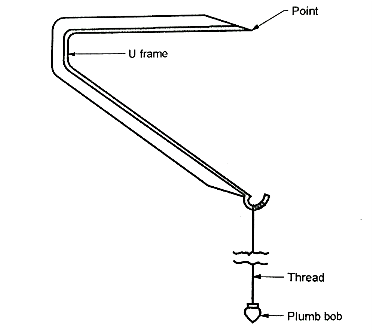

A plumbing fork or U frame:

Fig.1.8: Plumb bob with U frame

A bubble tube or spirit level:

Fig.1.9: Spirit level

A water proof cover:

Drawing sheet:

Other drawing materials:

Key Takeaways:

The accessories of plane table are:

Advantages:

Disadvantages:

1. Instrumental Errors:

2. Error due to Manipulation and Sighting: These includes-

(a) Non-horizontality of board.

(b) Defective sighting.

(c) Defective orientation.

(d) Movement of board between sights.

(e) Defective or inaccurate centering.

(a) Non-horizontality of board:

(b) Defective Orientation:

(c) Defective Orientation:

(d) Movement of board between sights:

(e) Inaccurate Centering:

Key Takeaways:

There are two types of errors:

1.21.1 Radiation:

Fig.1.10: Resection Method

Procedure:

Use:

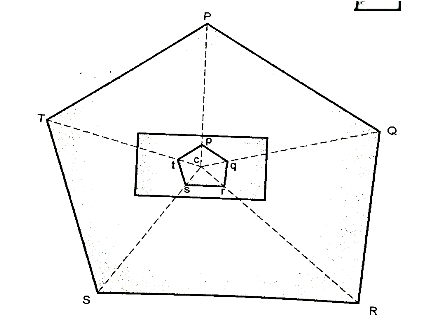

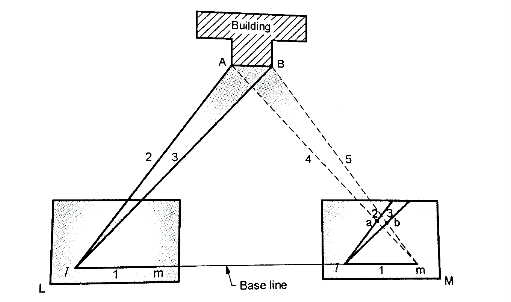

1.21.2 Intersection method:

Fig.1.11: Intersection method

Procedure:

Use:

The intersection method is used for:

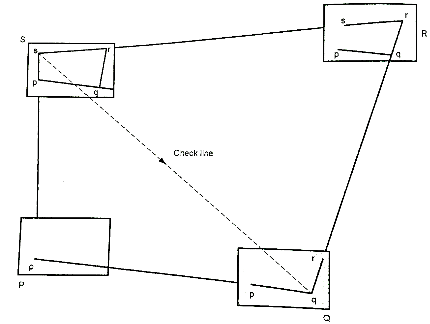

1.21.3 Traversing Method:

Fig.1.12: Traversing Method

Procedure:

Uses:

Traversing method is used:

1.21.4 Resection Method:

Procedure:

Key Takeaways:

Methods of plane table surveying are as follows:

1.22.1 Types of leveling:

Types of leveling are as follows:

1. Simple leveling:

2. Differential leveling:

3. Fly leveling:

4. Profile leveling:

5. Cross-section leveling:

Key Takeaways:

There are five types of leveling:

Types of Benchmark area as follows:

1. G.T.S. bench marks (Great trigonometrical survey bench marks):

2. Permanent bench marks:

3. Arbitrary bench marks:

4. Temporary bench marks:

Key Takeaways:

There are four types of benchmarks:

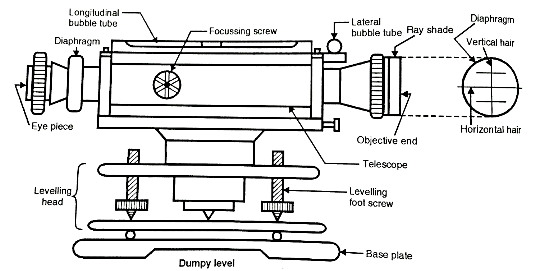

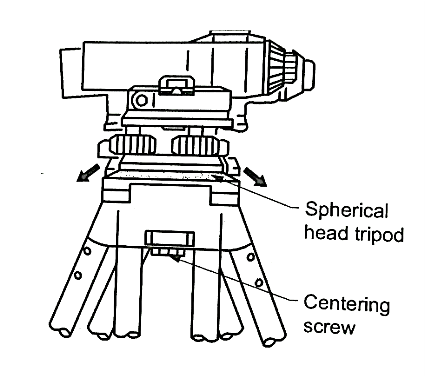

a) A tripod stand

b) Levelling Head

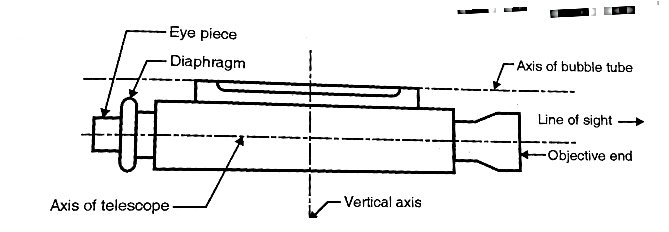

c) Telescope

(a) A tripod stand:

Fig.1.13: A tripod stand

(b) Levelling head:

(c) Telescope:

Fig.1.14: Dumpy level

Key Takeaways:

The dumpy level is commonly used for levelling work being compact and stable type instrument

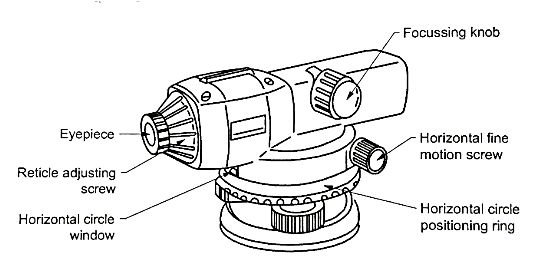

Fig.1.15: Auto level

Setting up the Instrument:

Fig.1.16: Auto level

Focusing and Sighting:

Operation:

Measuring height difference:

Fig.1.17: Set up

Measuring Horizontal Angle:

Key Takeaways:

These instruments require only approximate levelling by reference to a good circular bubble, and they have no sensitive bubble.

Procedure:

Key Takeaways:

It is an automatic level consisting of pendulum compensator. It is capable for normal optical levelling with a rod graduated in meter or feet. Digital level has a provision to take readings automatically by using a bar code

Key Takeaways:

Lazer level is advanced type of instrument used in surveying work. It consists of a revolving laser beam to ensure precise horizontal level detection and dramatically improve the efficiency of levelling jobs on civil engineering and construction sites

Line of collimation:

Axis of telescope:

Fig.1.18: Axes of Dumpy level

Axis of the level tube:

Vertical axis:

Key Takeaways:

There are four types of principle axis:

There are following permenant adjustments:

Fig.1.19; Set up

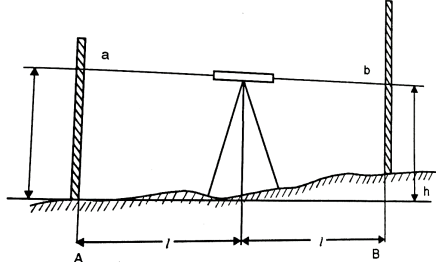

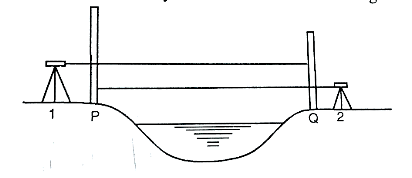

Reciprocal levelling involves:

Curvature:

where,

d is the distance in km from the level to the staff station.

True staff reading = observed staff reading -0.0785 d²

Refraction:

where d is taken in km.

Key Takeaways:

In precise levelling work or when the sights are long, the effects of curvature and refraction have to be taken into account. It is evident that a horizontal line departs from a level surface because of the curvature of earth.

d = 3.853 √C km.

C being in meters.

Level page of the field book

Staff Station | B.S | I.S | F.S | H.I (Collimation plane level) | R.L | Remarks |

B.M |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

2 |

|

|

|

|

|

|

3 |

|

|

|

|

|

|

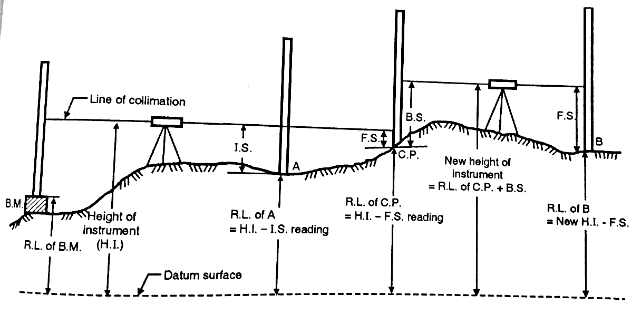

Procedure:

For entering the readings of reduced level of different sights, the following format of level page is commonly used into practice.

Keep the levelling staff on bench mark (B.M.) and take reading and find the reduced level of collimation plane or height of instrument by adding back sight reading to the R.L. of bench mark.

Note that, Height of instrument is equal to R.L. of collimation plane.

Height of instrument (H.I.) = R.L. of bench mark + B.S. reading.

Reduced level of intermediate points can be found out as follows:

R.L. of intermediate points =Height of instrument - Intermediate sight reading

=H.I-.I.S. reading

R.L. of change point =Height of instrument - Fore sight reading

= H.I. - F.S. reading

Note: When levelling work is to be stopped or change point is to be taken, then foresight reading is taken.

The instrument is shifted and set up and levelled at new position so that reading on levelling staff would be clear and distinct. Then take back sight reading on change point (C.P.) and find the R.L. of new collimation plane or new height of instrument. Refer to Fig.

R.L. of new height of instrument =R.L. of change point + B.S.

Fig.1.20: H.I Reading method

Find the reduced levels of the remaining points from new set up of instrument with respect to new height of instrument or new R.L. of collimation plane.

Repeat the above procedure till all the levelling work is over.

After completion of levelling work, arithmetical check is found out. From this check. accuracy of the field work of levelling can be cross-checked. This check can be taken at each level page.

Sum of backsights - sum of foresights =Last R.L. - First R.L.

In short,  . -

. -  .= Last R.L. - First R.L.

.= Last R.L. - First R.L.

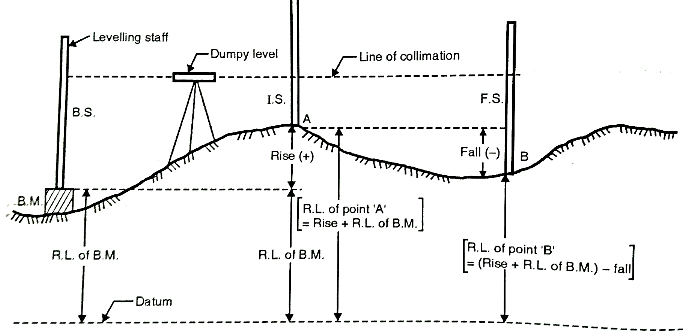

Rise and fall method is stepwise explained as follows:

Level Page of field book

Staff Station | B. S | I.S | F. S | Rise | Fall | R. L | Remark |

B.M |

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

Fig.1.21: Rise and fall method

Sum of backsights - sum of foresights = Sum of all rise- sum of all= Last R.L. - First R.L.

In short, Σ B.S. -  . = Rise-fall=Last R.L – First R.L

. = Rise-fall=Last R.L – First R.L

References: