UNIT 4

Magnetic materials

Magnetic materials are utilized mainly for magnetic characteristics. A materials magnetic response is hugely determined through the magnetic dipole moment which is associated with the intrinsic angular momentum or span of its electron. Response of the materials to an applied magnetic field can be characterized as paramagnetic, antiferromagnetic, diamagnetic or ferromagnetic. Materials are get attracted towards a magnet are magnetic, for example nickel or cobalt and iron. Materials that are not attracted towards the magnet are called the non-magnetic materials. For examples coins, rubber, feather and leather.

4.2.1 Magnetic permeability

In the electromagnetism, permeability is the measurement of the resistance of the material against formation of the magnetic field, also known as distributed inductance in the transmission line. Magnetic permeability is crucially represented by Greek letter μ. Magnetic permeability is relatively increase or decrease, in resultant magnetic field inside a substance compared with magnetizing field in that provided materials is placed, or the material property which is equal to magnetic flux density B developed within material through magnetizing field partitioned through magnetic field strength H of magnetic field. Magnetic permeability μ is the defined as the μ=B/H. Flux density B is measured by the actual magnetic field within the materials which is considered magnetic field lines concentration or the flux is per unit cross sectional area. H is the magnetic field strength is measure of magnetizing field which is developed through the electric current flow in the wire coil.

4.2.2 Magnetic susceptibility

In magnetic field, the magnetic susceptibility is the measurement of material will become magnetized in applied magnetic field. This is the dimensionless proportionality constant which indicates magnetization degree of the material in the response to applied magnetic field. It is due to interactions of the electrons and nuclei with externally applied magnetic field. We can define magnetic susceptibility mathematically is ratio of the magnetizing to applied magnetizing field intensity. X=M/H

Where X= magnetic susceptibility

M=magnetization

H=field intensity

4.2.3 Magnetization

The process of magnetization of the given sample material M can be described as net magnetic moment for which material per unit volume.

Magnetic materials can be categorized basically three types. Based on the behavioral of magnetic materials. These are diamagnetic, ferromagnetic and paramagnetic materials that are described below.

4.3.1 Diamagnetism materials

In diamagnetism materials are the orbital motion electrons are around nucleus develops a magnetic field perpendicular to plane orbit. So, different electron orbit has the finite orbital magnetic dipole moment. Orbital planes are oriented in the random way, the sum of the vector magnetic moments are zero and so there is no resultant of the magnetic moment for the each atoms. This process is named diamagnetic action and these materials are called as the diamagnetic materials. Materials are bismuth, water and copper etc. properties of the diamagnetism materials are-

- Negative magnetic susceptibility

- Relative permeability is less than unity.

- Magnetic field line is expelled through diamagnetic materials while take placed in the magnetic field.

- Susceptibility is temperature independent.

4.3.2 Paramegnatic materials

Some of the magnetic materails are, every moleculas or atom contains net magnetic dipople moment that is the vector sum of the orbital and the spin magnetic momnets of the electrons. Besides of the random orinetaion of the magnetism moments, the complete magnetic momnet of materails is zero. Exmaple of the paramegntaic materials are alumium, chromium and platinum etc. propeties of the paramegnatic materails are –

- Susceptibilty of the magntic is positive and small.

- Relative permebaility is greater than the unity

- Magnetic field line is attretcd into paramagnatic materials while take place in the magnatic field.

- Susceptibilty, invresly proportional to the tempertaure.

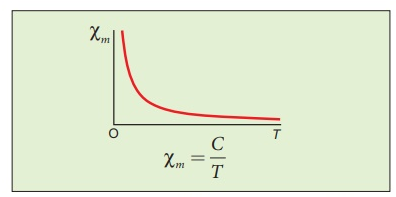

Curies law

Due to the increment of the temperature thermal vibration will be upset alignment of the magnetic dipole moments. So, the magnetic susceptibility is decreases with the increase in the temperature. In the many other cases materials susceptibility is

This relation named curies law.

4.3.3 Ferromagnetism materials

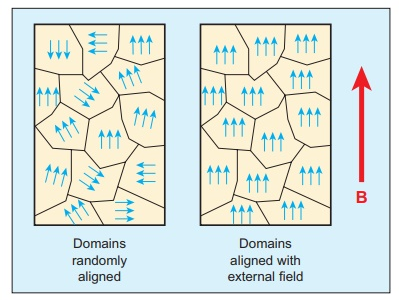

Molecule or an atom in the ferromagnetic material procedures net magnetic dipole moment as in the paramagnetic materials. A ferromagnetic material is developed from the smaller regions, named ferromagnetic domain in the figure. Within each domain, magnetic moments are spontaneously aligned the directions. This alignment is reasoned through the powerful interactions arising from the electron spin that relies on inter atomic distance. Every domain has net magnetization in the direction. But direction of the magnatraction differ from the domain to domain and so net magnetization of the specimen is zero.

Two processes are take place in the presence of the external magnetic field.

Domains containing magnetic moments are parallel to field grow in the size.

Other domains which are not parallel to field are rotated therefore which they are aligned with field.

4.3.4 Ferri-magnetism

Ferri-magnetism materials are type of the permanent magnetism which happens in the solids in that magnetic fields related with the individual atoms impulsively align themselves, some of the parallel or in the similar direction and another normally antiparallel or paired off in the different direction, like in the ant ferromagnetism. Single crystals magnetic behavior of the ferromagnetic materials may be assigned to parallel alignment, atoms diluting effect in antiparallel arrangements contains magnetic strength of these materials normally less than which of purely ferromagnetic solids like iron motel. Ferrimagnetism take place mainly in the magnetic oxides which are known as the ferrites. The original magnetism exhibited through the lodestones and recorded as early in the 6th century BC, is which of the ferrite mineral magnetite, this compound has negative oxygen ions O2 and +ve iron ions in the two states, iron(II) ions, Fe2+, and iron (III) ions, Fe3+. Oxygen ions are not magnetic and but both iron ions are.

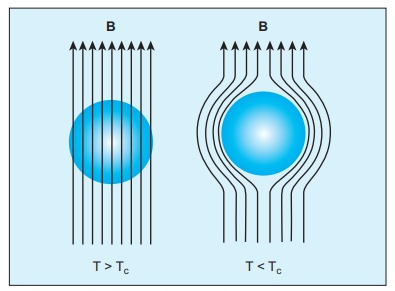

4.3.5 Ferro-magnetic behavior below critical temperature

Materials are when ferromagnetic below critical temperatures. In the absence of the applied magnetic field materials are called ferromagnetic. In the absence of the magnetic field material has been spontaneous magnetization that is a outcome of ordered magnetic moments. Which is for the ferromagnetism, atoms are aligned and symmetrical in the similar direction of creating a permanent magnetic field. Through exchange interactions magnetic interactions are held together, or thermal disorder would overcome weak magnetic interactions moments. Exchange interaction has been 0 parallel probability electrons engaging similar point in time, indirect a preferred a parallel alignment in material. The Boltzmann factor gives heavily as this prefers interacting particle to be aligned in similar direction. This reasons ferromagnets to have been strong magnetic field and high critical temperature of around 1000K (730 degree C). Below the critical temperature atoms are parallel and aligned, this is cause of spontaneous magnetism and the material is ferromagnetic. Above the critical temperature material is paramagnetic, in this atom are lose their order magnetic moments while materials undergoes in a phase transition.

4.3.6 Spontaneous magnetization

At the zero applied magnetic field in the ferromagnetic material spontaneous magnetization is appearance of the ordered spin state which is called magnetization below the critical temperature or TC. Each atom magnetic moment is itself thermal average, as competition between temperature and exchange makes it to fluctuate between various orientation. At 0K, spontaneous magnetization is equals to the saturation magnetization. Ms (T=0)=M0=Nμ0. Here μ0 is complete atomic moment as free atom.

4.3.7 Anti- ferromagnetism

This is the type of magnetism in which solids like manganese oxide (MnO) in that adjacent ions which behave as the tiny magnets for this manganese ions Mn2+ are spontaneously align themselves at the relatively at the low temperature into the opposite, or the antiparallel, arrangements are throughout the materials so which it exhibits almost no gross external magnetism. In the antiferromagnetic materials, include the certain alloys and metals in the addition to the sum of ionic solids, from the magnetic atoms magnetism oriented in the one direction is interrupted out by the magnetic atoms set which are aligned in reverse direction.

4.3.8 Ferrites

These materials are hard, iron, brittle and normally black and gray and are polycrystalline and made up from the large number of the small crystals. These are composed of one or more other metal and oxide in chemical combination. Like ferrite ferrite magnets with the different metal objects. Structure of the ferrites is , the chemical formula of the ferrite molecule is M2+fe2 3+O4 2-, where the M2+ represents divalent metal ion like Zn2+, Fe2+, Mg2+, Mn2+ Cd2+ etc, ferrites crystallize in form of the cubic structure. The ferrites are materials which are crystals having the small electric conductivity which is compared to the ferromagnetic materials. So they are useful in the high frequency conditions because of absence of the particular eddy current losses. Three are commonly utilized ferrite devices are phase shifters, isolators and circulators.

4.3.9 Applications of ferromagnetic materials

Ferromagnetic materials applications are comprehensive. Hysteresis curve is plays a big role and it has great importance.

It has its applications in the transformers, magnetic tape recording and electromagnetic.

Nano wires, power generation, distribution and shape memory alloys, electronics and carbon nano tubes, for sudden cooling, in nuclear reactors neutron absorber, easy polarization and high magnetic susceptibility, and magnetic tape emulsion.

4.4.1 Transformer core

In transformer core we use variety of materials which can be utilized to made these magnetic cores, most commonly used materials are-

Solid iron- in transformer core solid iron cores are provide excellent pathway to give magnetic flux and retain higher magnetic fields without iron saturation.

Carbonyl iron- this iron has the quality that this is the highly pure iron which ahs the stability over a broad range of the temperature and magnetic flux levels.

Amorphous steel- magnetic core which utilize amorphous steel is made of various layers which are paper thin metallic tapes which help to remove flow of eddy currents. These core ahs fewer losses than other of the magnetic cores, that help them to simply operate at the higher temperature as compared with standard lamination stacks.

Silicon steel- silicon steel has the higher electrical resistivity and this provide high saturation flux density. This also has been high permeability and low losses, that enables silicon steel cores to be utilized in the high-performance applications.

Amorphous metals- amorphous metals are non-crystalline and glassy, so can be utilized to develop high- performance and high-efficiency transformers. These materials have the low conductivity which reduce eddy currents.

Ferrite ceramics- these materials are contain iron oxide and one or many metallic elements, that are made in various specifications to meet with the various electrical needs.

Laminated magnetic cores- these are made from the stacks of thin iron sheets coated with an insulated layer, this is parallel to flux lines.

4.4.2 Core of rotating machines

For reducing the eddy current losses, laminations are needed to be thin as possible and contains large resistivity. Electrical rotating machines, set of materials for designing of magnetic systems from conventional electrical steels SiFe with the oriented and non-oriented grains (GO and NO) to the nickel irons (NiFe), and cobalt irons (CoFe) amorphous, composite and microcrystalline alloys.

4.4.3 Soft magnetic materials

Silicon iron, aluminum iron alloys and unalloyed iron are broadly utilized in the high power machines. But, for some typical applications expensive materials are more suitable. Some of examples superalloy and permalloy different types of the amorphous alloys and nanocrystalline alloys. There are some other soft magnetic materials are pure iron, silicon iron alloys and nickel iron alloys. Soft magnetic materials has the properties are utmost permeability, slight coercive force, small hysteresis loss, small remanent induction and high saturation magnetism.

4.4.4 Hard magnetic materials

Hard magnet called permanent magnet, these are magnetic materials which retain their magnetism after the being magnetized. We can say that materials which have an intrinsic coercivity of greater than 10kAm-1. Hard magnetic materials are steel, alnico, rare earth alloys, hard ferrites, bonded magnets and nano crystalline hard magnet. Applications of the hard magnet materials are automotive, telecommunication, data processing, consumer electronics, electronic and instrumentation, industrial, astro and aerospace and bio surgical.

Reference book

Sandhu, A., & Handa, H. Magnetic nanoparticles for medical diagnostics.

Graham, C. (1974). Magnetism and Magnetic Materials - 1973. New York: AIP.