Unit 2

Single Degree of Freedom Systems – Forced Vibrations

Forced Vibration

If the system vibrates under the influence of external periodic force, the vibrations are known as forced vibration.

Longitudinal Forced Vibration

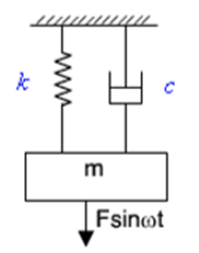

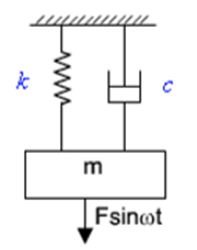

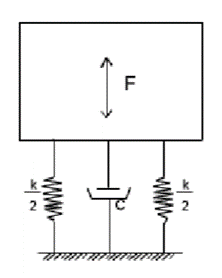

Consider a spring-mass-damper system as shown in figure.

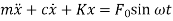

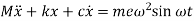

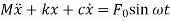

The equation of motion of this system subjected to a harmonic force can be given by

can be given by

where, m , k and c are the mass, spring stiffness and damping coefficient of the system, F is the amplitude of the force, w is the excitation frequency or driving frequency.

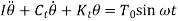

Torsional Forced Vibration

Consider a disc having mass moment of inertia ‘I’ suspended on a shaft with negligible mass subjected to a harmonic torque

The equation of motion for this system is given by

Where,

= angular displacement of disc from mean position in rad

= angular displacement of disc from mean position in rad

= mass moment of inertia of disc =

= mass moment of inertia of disc =  kg m2

kg m2

= torsional stiffness of shaft in Nm/rad

= torsional stiffness of shaft in Nm/rad

= torsional damping coefficient

= torsional damping coefficient

Consider a spring-mass-damper system as shown in figure.

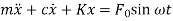

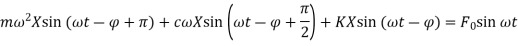

The equation of motion of this system subjected to a harmonic force can be given by

can be given by

where, m, k and c are the mass, spring stiffness and damping coefficient of the system, F is the amplitude of the force, w is the excitation frequency or driving frequency.

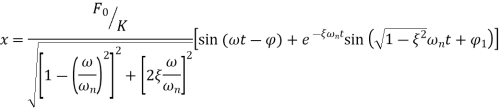

Solution for differential equation

The complete solution of linear second order differential equation consists of two parts

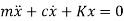

It is obtained by considering no force condition,

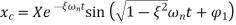

The equation is same as that of damped free vibration. So the solution is

2. Particular Integral  :

:

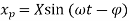

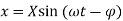

Particular Integral is in the form of

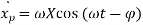

Differentiating above equation w. r. t time ‘t’, we get velocity  ,

,

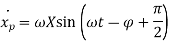

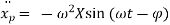

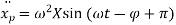

Again differentiating above equation w. r. t time ‘t’, we get acceleration

Substituting  ,

,  ,

,  in differential equation we get,

in differential equation we get,

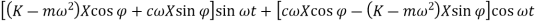

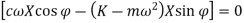

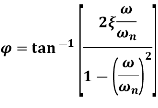

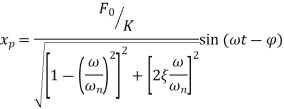

After solving trigonometrically, we get

Comparing coefficients of  and

and  we get

we get

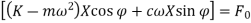

From the above equation, we get,

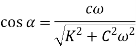

Phase angle  as

as

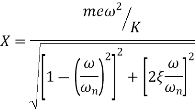

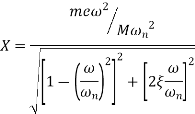

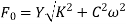

Amplitude X is

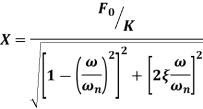

Particular integral becomes

General solution becomes,

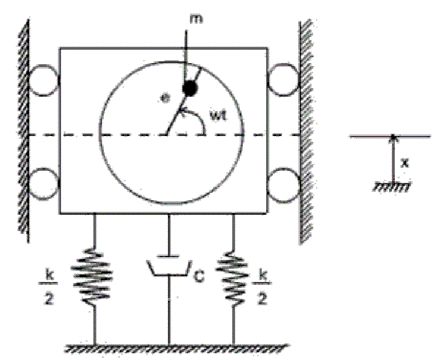

One may find many rotating systems in industrial applications. The unbalanced force in such a system can be represented by a mass m with eccentricity e, which is rotating with angular velocity as shown in Figure

Rotating Unbalance

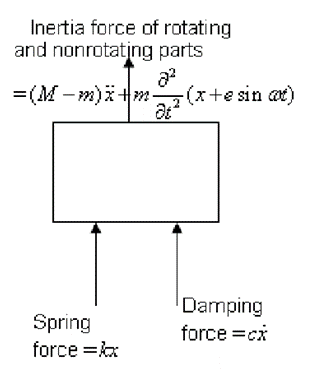

FBD of system

Let x be the displacement of the nonrotating mass (M) from the static equilibrium position, then the displacement of the rotating mass m is

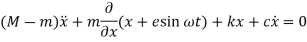

From the free-body diagram of the system shown in figure, the equation of motion is

Or

Comparing this equation with equation of forced harmonic vibration

we get

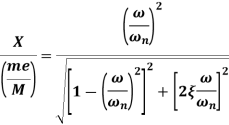

Therefore,

Since,

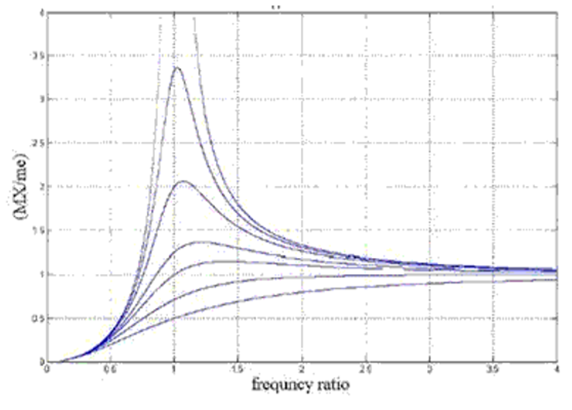

And Phase angle is

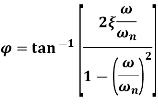

Frequency Response

– Frequency ratio plot

– Frequency ratio plot

Phase angle – frequency ratio plot

From figure following observations may be made for a rotating unbalanced system

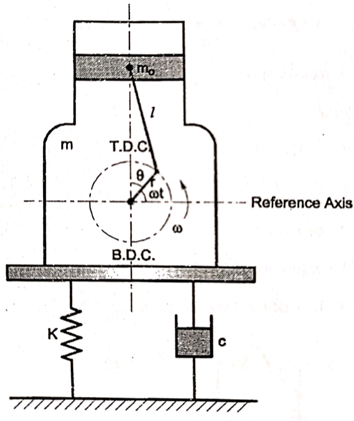

Excitation due to reciprocating unbalance

Consider a reciprocating machine as shown in figure, with M as total mass of system, m as reciprocating mass

Let,

= length of connecting rod

= length of connecting rod

= length of crank

= length of crank

= obliquity ratio

= obliquity ratio

The inertia force due to mass of reciprocating parts acts as the excitation force in reciprocating machines. The inertia force due to mass of reciprocating parts are given by,

As n is large,  is very small and can be neglected

is very small and can be neglected

From the above equation it is seen that, the exciting force due to reciprocating unbalance is same as due to rotating unbalance.

Hence, analysis of the reciprocating unbalance is same as that of rotating unbalance.

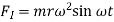

In many cases, the excitation of the system is through the support or base instead of being applied to the mass as shown in figure.

In such condition, the support is considered to be excited by a sinusoidal motion y(t) = y = Y

The analysis of forced vibration due to excitation of support can be done by considering absolute amplitude and relative amplitude of mass w. r. t. support of base.

x(t) = x = X  is absolute displacement of mass

is absolute displacement of mass

Deflection of spring = x – y

And,

Velocity between two ends of damper =

Where,

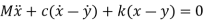

The differential equation is

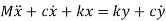

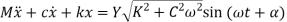

The above equation finally becomes

Where,

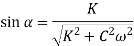

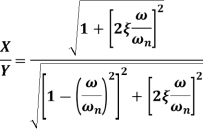

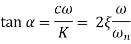

By comparing above equation with equation of forced harmonic vibration

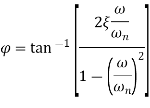

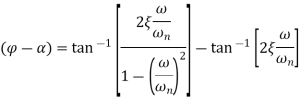

Phase angle = ( )

)

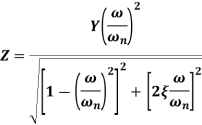

Steady state relative amplitude (Z)

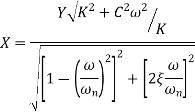

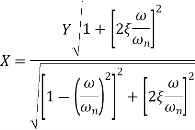

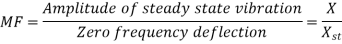

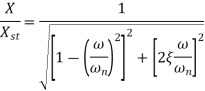

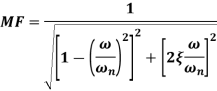

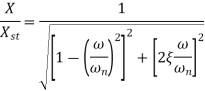

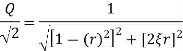

2.5 Magnification Factor

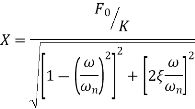

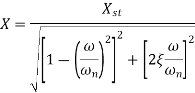

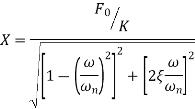

Magnification factor is defined as the ratio of amplitude of steady state vibrations ‘X’ to the zero-frequency deflection ‘Xst’

Where,

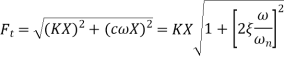

The amplitude X of the steady state forced harmonic vibration is given as

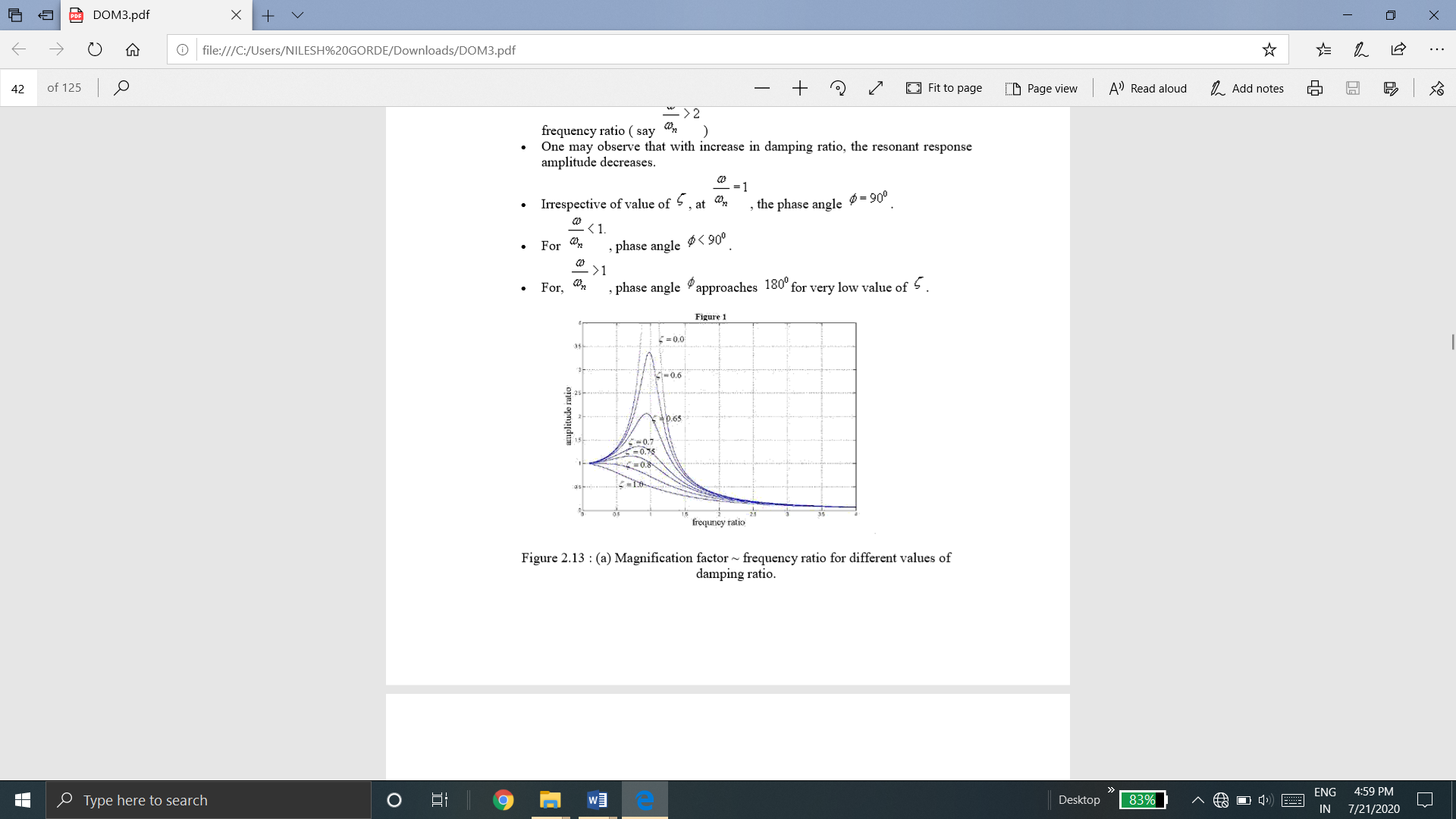

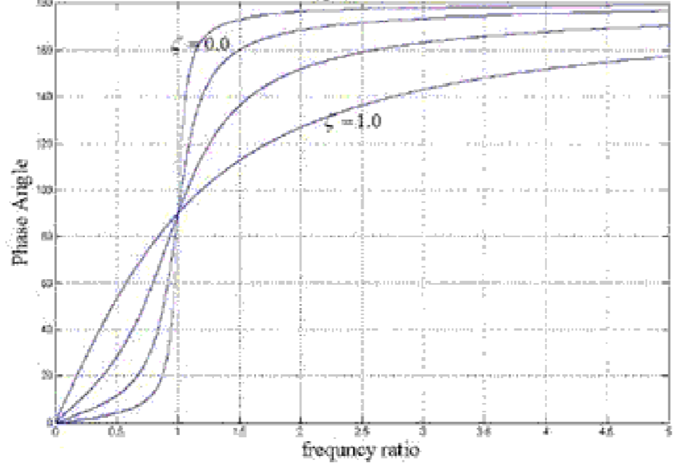

Figure below shows the magnification factor – frequency ratio plot and phase angle – frequency ratio plot.

(a) magnification factor – frequency ratio plot

(b) phase angle – frequency ratio plot

Following observation can be made from these plots.

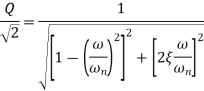

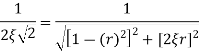

Quality factor

The magnification factor or amplitude ratio of a system at resonance is called as Quality Factor or Q factor of the system

At resonance means,

At,

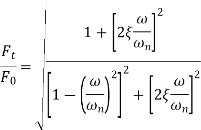

Transmissibility

Force Transmissibility

Force Transmissibility is defined as the ratio of the force transmitted to the supporting structure of foundation Ft to that of force imposed upon the system F0. Force transmissibility measures the effectiveness of the vibration isolating material.

Motion Transmissibility

Motion Transmissibility is defined as the ratio of absolute amplitude X of the mass to the amplitude of the base excitation Y.

In many industrial applications, one may find the vibrating machine transmit forces to ground which in turn vibrate the neighboring machines. So, in that contest it is necessary to calculate how much force is transmitted to ground from the machine or from the ground to the machine.

Vibrating system

Figure. shows a system subjected to a force  and vibrating with

and vibrating with

This force will be transmitted to the ground only by the spring and damper.

Force transmitted to the ground

It is known that for a disturbing force  , the amplitude of resulting oscillation

, the amplitude of resulting oscillation

Substituting these equations and defining the transmissibility TR as the ratio of the force transmitted Force to the disturbing force one obtains

Comparing equations for support motion, it can be noted that

i.e. Mathematically, Force Transmissibility = Motion Transmissibility

When damping is negligible,

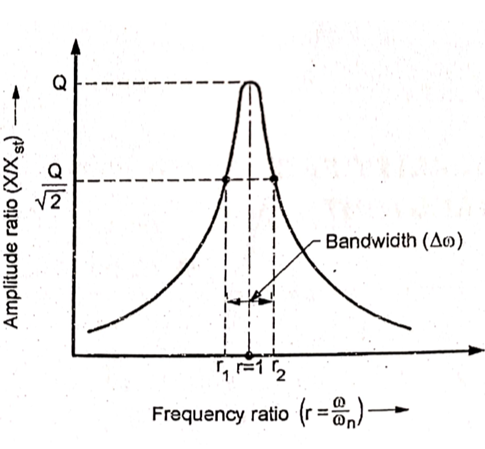

Bandwidth

Fig below shows a response curve of amplitude ratio  versus frequency ratio

versus frequency ratio  for values of

for values of  less than 0.1

less than 0.1

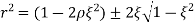

Let r1 and r2 be the frequency ratio where, the amplitude ratio falls to  and are called as half power points.

and are called as half power points.

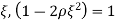

The difference between the frequencies associated with the half power points is called as bandwidth of the system.

We have,

Substituting,

Now,

Squaring both sides and solving, we get

For small values of  and

and  ,

,

higher power terms of

higher power terms of

Neglecting higher power terms

Bandwidth

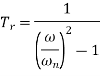

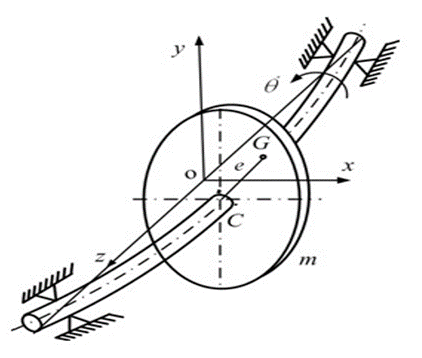

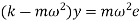

Critical speed of shaft

When rotor is mounted on a shaft its center of gravity usually not coincide with the rotation of the shaft. This C.G. is displaced from axis of rotation although amount of displacement may very slow.

As a result, shaft is subjected to a centrifugal force when it begins rotate. The CF acting radially outward, which make the shaft to bend in the direction of eccentricity of the C.G. This unbalance CF, a shaft start vibrating violently in the direction perpendicular to the axis of the shaft. This phenomenon is known as whirling of shaft.

The speed at which the shaft starts to vibrate violently in the direction perpendicular to the axis of the shaft is known as critical speed.

Consider a vertical shaft having negligible inertia and carrying a single rotor is shown in fig

When the shaft is in rotating condition, two forces acts on the shaft

In equilibrium condition, CF = RF

Where,

= eccentricity of the rotor. i.e. distance between CG and geometric centre.

= eccentricity of the rotor. i.e. distance between CG and geometric centre.

= deflection of geometric center from the axis passing from O.

= deflection of geometric center from the axis passing from O.

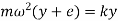

Critical speed is given by

Where,

= Critical speed of shaft in r.p.s

= Critical speed of shaft in r.p.s

= Static deflection of shaft

= Static deflection of shaft

Ranges of speed

When the speed of shaft is less than the critical speed, then the deflection of shaft is positive.

Deflection of shaft increases with shaft speed. Fig (a)

2.

When the speed of shaft is equal to the critical speed, then the deflection of shaft is tending to infinity. This may lead to failure of shaft

3.

When the speed of shaft is greater than the critical speed, then the deflection of shaft is negative. Fig (b)

References

1. Weaver, Vibration Problems in Engineering, 5th Edition Wiley India Pvt. Ltd, New Delhi.

2. Bell, L. H. and Bell, D. H., Industrial Noise Control – Fundamentals and Applications, Marcel Dekker Inc.

3. Alok Sinha, Vibration of Mechanical System, Cambridge university Press , India

4. Debabrata Nag, Mechanical Vibrations, Wiley India Pvt. Ltd, New Delhi.

5. Kelly S. G., Mechanical Vibrations, Schaums outlines, Tata McGraw Hill Publishing Co.Ltd., New Delhi.

6. Meirovitch, L., Elements of Mechanical Vibrations‖, McGraw Hill.

7. Ver, Noise and Vibration Control Engineering, Wiley India Pvt. Ltd, New Delhi.

8. Bies, D. and Hansen, C., Engineering Noise Control - Theory and Practice, Taylor and Francis.

9. Shrikant Bhave, Mechanical Vibrations Theory and Practice, Pearson, New Delhi