Unit 5

Measurement and Control of Vibration

Vibration measuring instruments are the devices or instruments that are used to measure the vibration.

Vibration can be measured by measuring the displacement, velocity, acceleration or frequency of the vibration.

The vibration measuring instruments are

Vibration measuring instruments are classified as below:

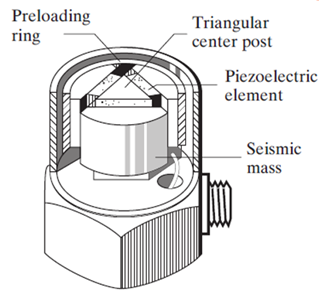

I. Contact type: These types of vibration measuring instruments are in direct contact with the vibration machines. These instruments are compact in size. e.g. Accelerometer

II. Non-contact type: These types of vibration measuring instruments are used when it is very difficult to use the contact type vibration measuring instruments. These types of instruments also small in size.

2. CLASSIFICATION BASED ON DISPLAY METHOD

I. Indicating type: In these instruments, the measured data are displayed on the display unit of the instruments.

II. Recording type: These instruments are used to display and also to record the data for future analysis. e.g. FFT analyzer

3. CLASSIFICATION BASED ON TIME BASE MEASUREMENT

I. Indicating type: In these instruments, the measured data are displayed on the display unit of the instruments.

II. Recording type: These instruments are used to display and also to record the data for future analysis. e.g. FFT analyzer

4. CLASSIFICATION BASED ON POWER SOURCE

I. Active system: In these instruments, source of power is required to operate the instruments for vibration measurement. e.g. FFT analyzer

II. Passive system: These instruments do not require any outside source of power to operate the instruments. They are compact, handy and battery operated. e.g. Frahm’s tachometer

1. Stylus Recording Instrument

2. Seismic Instrument or Seismometer or Vibration Pickup

3. Optical Recording Instrument

4. Simple Potentiometer

5. Capacitance Pickup

6. Mutual Inductance Pickup

A seismic instrument can also be used as a accelerometer if it has high natural frequency and generate output signal which is proportional to the acceleration of the vibrating body.

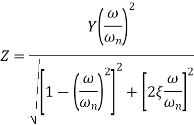

For a seismic instrument, steady state relative amplitude is given by,

Where,

Relative amplitude (Z)  Acceleration of vibrating body

Acceleration of vibrating body

ADVANTAGES OF ACCELEROMETER

Advantages

Disadvantages:

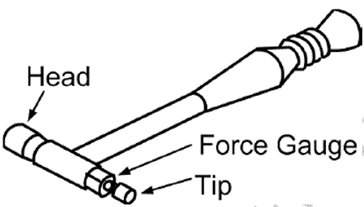

A vibration exciter is a machine which produces mechanical vibratory motion to test object. It is designed to produce a given range of harmonic or time dependent excitation force and displacement through a given range of frequencies.

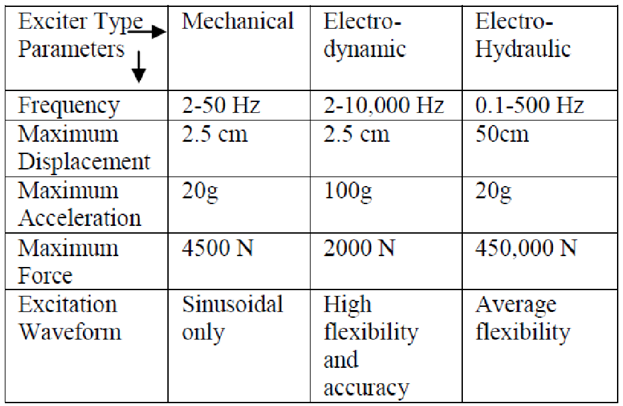

The three major types of vibration exciters are commonly used in several applications as:

1.Mechanical exciters

2.Electro-dynamic exciter

3.Electro-hydraulic exciter

MECHANICAL EXCITER

Mechanical exciters which vibrate the structure or machine by mechanical system.

Types of Mechanical Exciters:

According to applied force mechanical exciters are three types.

1.Inertia force mechanical exciters

2.Elastic spring force mechanical exciters

3.Unbalanced force mechanical exciters

ADVANTAGES OF MECHANICAL EXCITERS

DISADVANTAGES OF MECHANICAL EXCITERS

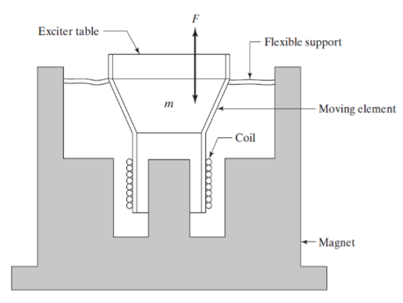

ELECTRO-DYNAMIC EXCITER

Advantages

Disadvantages

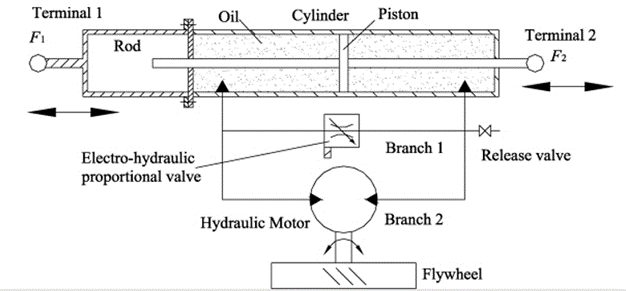

ELECTRO-HYDRAULIC EXCITER

COMPARISON OF EXCITER

Types of FFT Analyzer

- Both measurement and analysis is done in same instrument.

- Data can be collected from actual field for analysis.

2. Computer Based FFT Analyzer

3. Single Channel FFT Analyzer

4. Two Channel FFT Analyzer

Simultaneously 2 input can be taken or connected i.e. accelerometer and microphone can be connected at the same time or same type of data can be measure for different points.

5. Multi-Channel FFT Analyzer

Applications of FFT Analyzer

Condition monitoring of machine implies the determination of condition of a machine and its change with respect to time.

The condition of machines may be determined by measuring the physical parameters like: vibration, noise, temperature, wear debris, oil contamination, etc. The changes in these parameters are called as signatures. The signature indicate the change in condition or health of a machine.

Vibration Monitoring is used for machine condition monitoring.

Vibration monitoring Techniques:

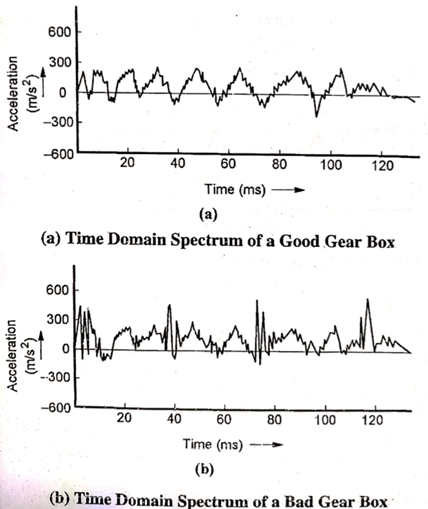

The time domain analysis uses acceleration-time plot of the signal.

The damages such as broken teeth in gears can be identified easily from the acceleration-time plot of the casing of the gear box.

2. Frequency Domain Analysis

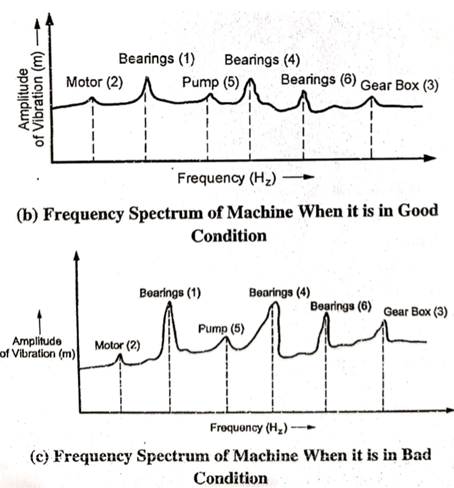

The frequency domain analysis or frequency spectrum is the plot of amplitude of vibration versus frequency. It is converted from time domain signal by using FFT spectrum analyzer.

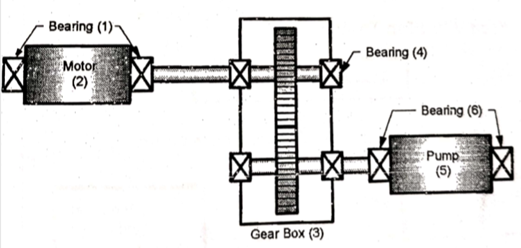

Consider a machine element or Component shown in fig below.

Each element in machine has identifiable frequency, therefore the change in the spectrum at given frequency can be attributed directly to that corresponding machine component.

The peaks in the frequency spectrum are related to various components as shown in fig (b)

By comparing the frequency spectrum of machine when it is in good condition, fig (b), and the frequency spectrum of machine when it is in bad condition, fig (c), the analysis is done and faults are found from the machine component.

The analytical equations are available to find the fault frequencies of standard components like: bearings, gear, boxes, motors, pumps, fans, etc.

Standard are intended:

Some of the standards are:

Humankind has always had the desire to build, create, and explore. Each of these activities has involved exposure to vibration, whether the source comes from primitive axes, handsaws or riding in carts, from using power tools, industrial machines, or riding in planes, trains, and automobiles. As modern man has harnessed power sources in more efficient ways, the apparatus used to build, create, and explore have used more energy and, as a result, increased quantities of energy have been dissipated in the form of vibration, some of which has been transmitted to people.

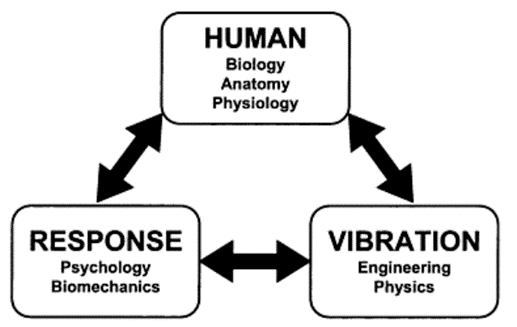

One of the most rewarding aspects of studying human response to vibration is its truly multidisciplinary nature

Whole-body vibration occurs when a human is supported by a surface that is shaking and the vibration affects body parts remote from the site of exposure. For example, when a forklift truck drives over a bumpy surface, vibration is transmitted through the vehicle to the seat and footrest, which are the surfaces that support the driver. The vibration is then transmitted through the body of the driver to the head, which will move. This transmission path includes the seat; the surface of the driver in contact with the vehicle including the driver’s nervous system; the skeleton, including the spine where an injury might occur; and ultimately the skull, which might have its own dynamic responses to the transmitted vibration.

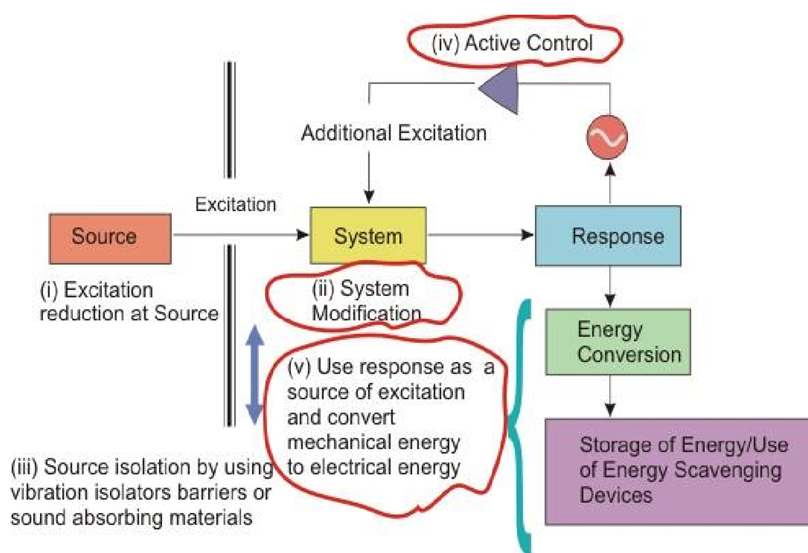

Whenever the natural frequency of a machine or a structure coincides with the frequency of the external excitation, the resonance occurs which leads to the excessive deflection and failure of system. By vibration control the unwanted harmful vibrations can be reduced to an acceptable limit.

The various methods of vibration control aim at modifying the source or the system.

The various methods of vibration control are:

2. Source Isolation

Source provides the energy to maintain vibration. sources of vibration could be of several types

In source Isolation, the transmission path of vibration between source and the system is modified to protect the system.

3. System Modification

A large number of methods exist in system modification including detuning, decoupling, using additive damping treatments ( constrained and unconstrained ), stiffeners and massive blocks (as foundation).

While designing a system, care should be taken that, its natural frequencies lie outside the excitation frequency range.

4. Active Feedback Control

In this method, a signal generated by the response is suitably processes to produce a desired amplification of the phase change in the signal. This processed signal drives an actuator which in turn provides an additional excitation.

This excitation is then fed back to the vibratory system which shifts the excitation frequency away from its natural frequencies.

The process of isolating the machine from the foundation is known as vibration isolation.

The effectiveness of isolation may be measured in terms of force or motion transmitted to that existence. Accordingly, it’s known as force isolation or motion isolation. The lesser the force or motion transmitted the grater is the isolation.

Objective

There are three methods of vibration isolation:

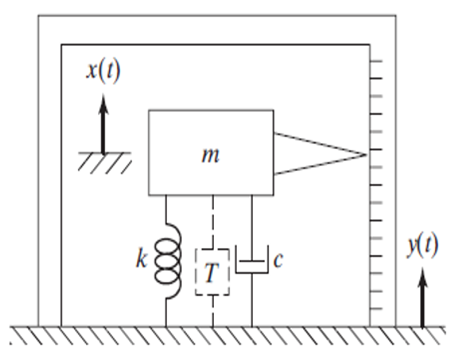

Active Vibration Isolation system requires external power source to perform its function.

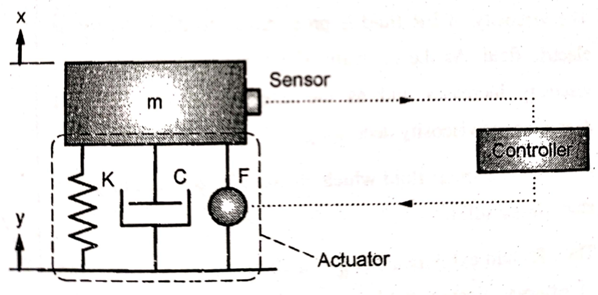

A typical active vibration isolation system is shown in fig.

The sensor is used to detect the vibrations to be controlled, the controller is used to interrupt the vibrations detected by the sensor and to execute commands on the actuators, where as the actuators are used to reposition the mass.

Advantages of Active Vibration Isolation

Fluid which changes its viscosity by application of electric fluid are called as Electro-Rheological Fluids. Dampers which uses electro-rheological fluids are called as electro-rheological dampers.

Fluid which changes its viscosity by application of magnetic fluid are called as Magneto-Rheological Fluids. Dampers which uses magneto-rheological fluids are called as magneto-rheological dampers.

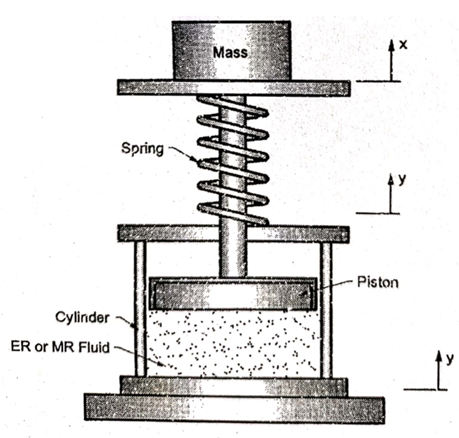

A typical use of ER/MR fluid for vibration isolation is shown in fig.

The vibration isolator consists of a parallel combination of a helical spring and a piston cylinder with ER or MR fluid. It has been observed that with suitable combination of particle concentration, carrier fluid and the strength of electric or magnetic field using high voltage amplifier, the damping characteristics of the dashpot can be varied over a wide range.

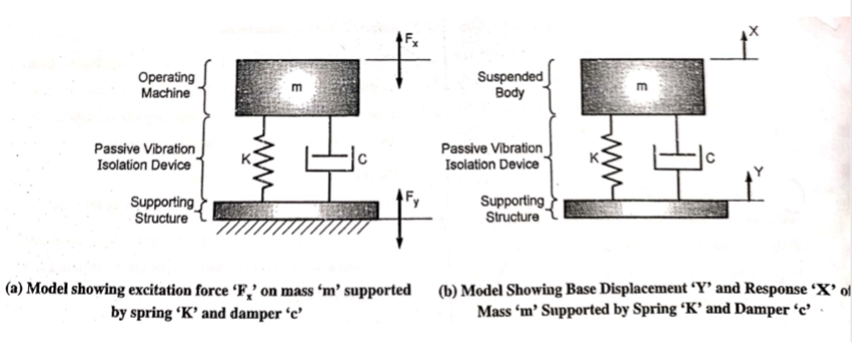

Passive vibration isolation does not require external power to perform its functions.

In this system, the isolation is achieved by reducing the amount of transmitted forces or displacements transmitted using the passive vibration isolation devices like rubber, felt, cork, springs, etc.

2. Rubbers or Elastomers

3. Ribbed elastomers

4. Pneumatic isolator

5. Other materials

In most of the cases, the excitation frequency cannot be controlled. In such cases, it is necessary to change the natural frequency of system to avoid the resonance.

The natural frequency of the system depends on the mass and stiffness of the system. Therefore, by changing one of the parameter, the natural frequency can be changed.

In many applications, mass cannot be changed easily, since it is determined by the functional requirement of the system. Therefore, in such cases, stiffness is the parameter that is changed to change the natural frequency.

It can be done by changing material or number and location of support points.

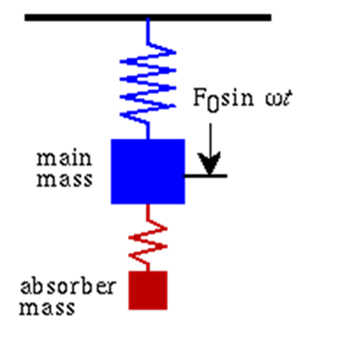

A classical tuned dynamic vibration absorber is shown below:

A sinusoidal force F0sin w t acts on an undamped main mass-spring system (without the absorber mass attached). When the forcing frequency equals the natural frequency of the main mass the response is infinite. This is called resonance, and it can cause severe problems for vibrating systems.

When an absorbing mass-spring system is attached to the main mass and the resonance of the absorber is tuned to match that of the main mass, the motion of the main mass is reduced to zero at its resonance frequency. Thus, the energy of the main mass is apparently "absorbed" by the tuned dynamic absorber. It is interesting to note that the motion of the absorber is finite at this resonance frequency, even though there is NO damping in either oscillator. This is because the system has changed from a 1-DOF system to a 2-DOF system and now has two resonance frequencies, neither of which equals the original resonance frequency of the main mass (and also the absorber).

If no damping is present, the response of the 2-DOF system is infinite at these new frequencies. While this may not be a problem when the machine is running at its natural frequency, an infinite response can cause problems during startup and shutdown. A finite amount of damping for both masses will prevent the motion of either mass from becoming infinite at either of the new resonance frequencies. However if damping is present in either mass-spring element, the response of the main mass will no longer be zero at the target frequency.

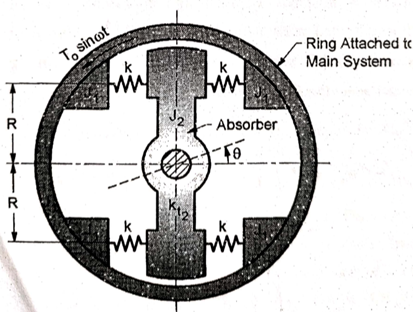

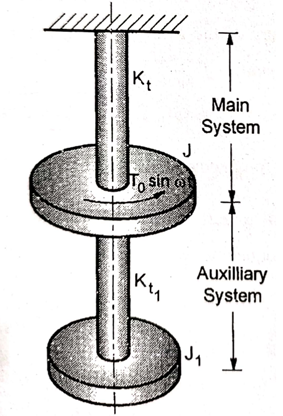

A torsional vibration damper or absorber is used to reduce or complete eliminate torsional oscillation of system.

Consider a torsional vibration system.

The natural frequency of the main system is given by

When the natural frequency of the system coincides with the impressed torque frequency, resonance occurs.

The vibration of the system can be reduced or completely eliminated by using a dynamic vibration absorber, which is simply a disc system or another shaft.

A shaft and disc system act as vibration absorber. If the natural frequency of the shaft and disc system becomes equal to the excitation frequency, then it reduces the amplitude of main system to zero.