Unit 4

Hydraulic Circuits and Contamination Control

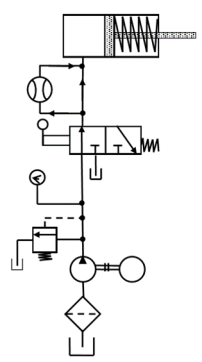

The figure shows that the control of a single-acting, spring return cylinder using a three-way two-position manually actuated, spring offset direction-control valve (DCV).

Fig. Control of Single Acting Cylinder

Fig. Simple Reciprocating Cylinder Circuit

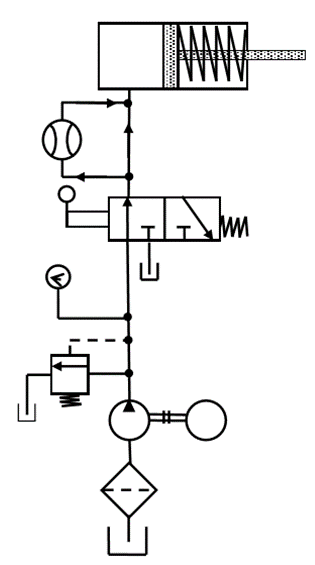

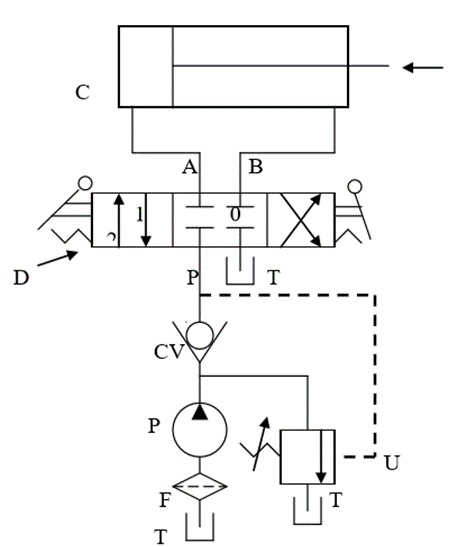

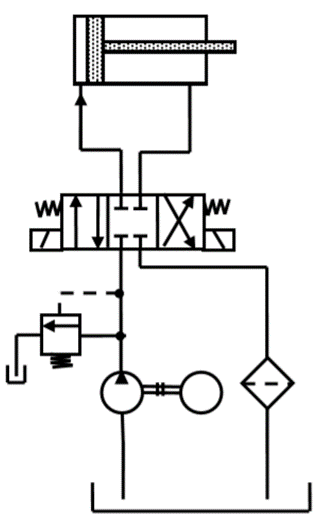

The circuit diagram shows the reciprocating of a double-acting cylinder.

The control of a double-acting hydraulic cylinder is described as follows:

At the end of the stroke, there is no system demand for oil. Thus, the pump flow goes through the relief valve at its pressure level setting unless the four-way valve is deactivated.

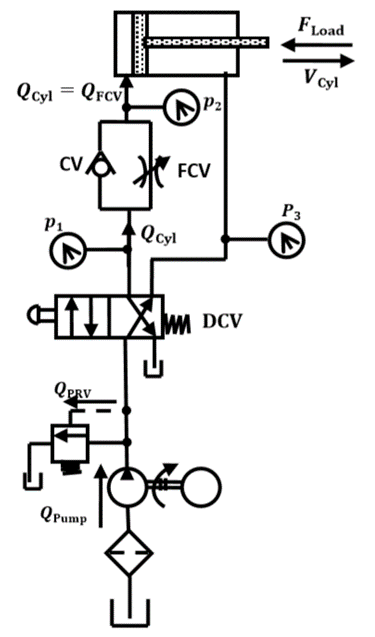

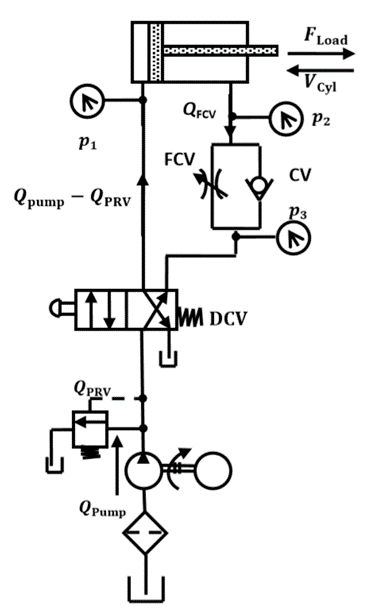

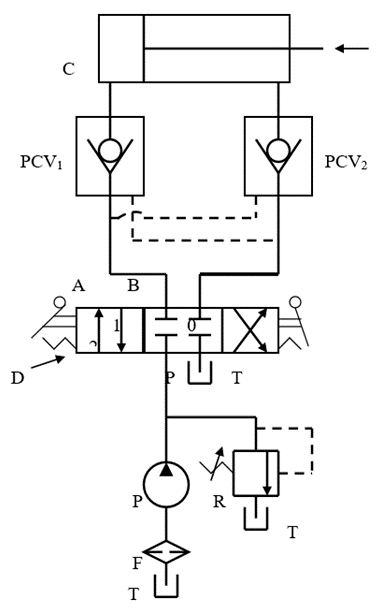

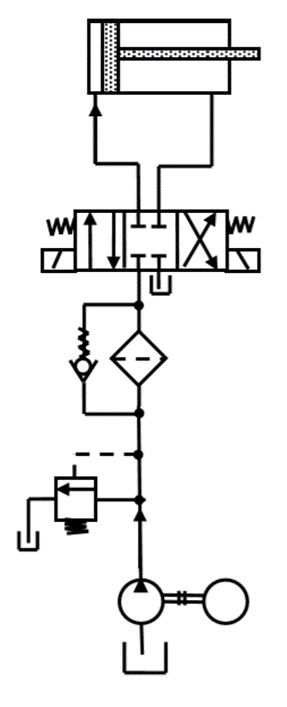

The figure shows a regenerative circuit that is used to speed up the extending speed of a double-acting cylinder.

Fig. Regenerative Circuit

The main function of this circuit is to increase the speed of extending stroke.

In hydraulic operations, it is necessary to control the speed of the actuator to control the force, power, timing, and other factors of the operation. Actuator speed control is achieved by controlling the rate of flow into or out of the cylinder.

There are two methods of controlling the speed of a hydraulic circuit is either by controlling the flow going into the cylinder or by controlling the flow out of the cylinder. To achieve this, Flow control valves are used.

The commonly used methods of speed control are:

4.4.1 Meter-in Circuit

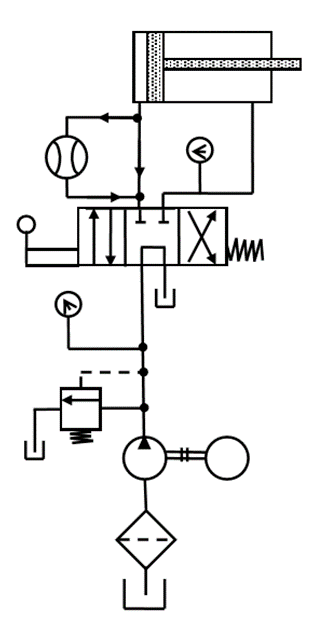

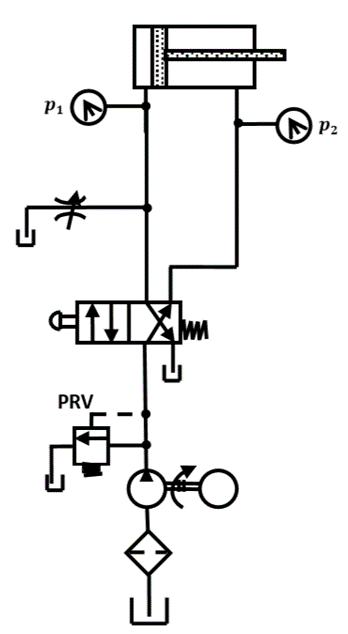

The figure shows a meter-in circuit with control of extending stroke.

Fig. Meter-in Circuit

4.4.2 Meter-out Circuit

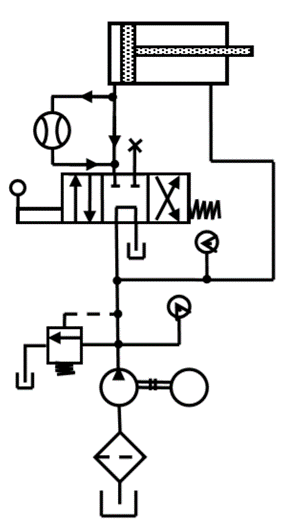

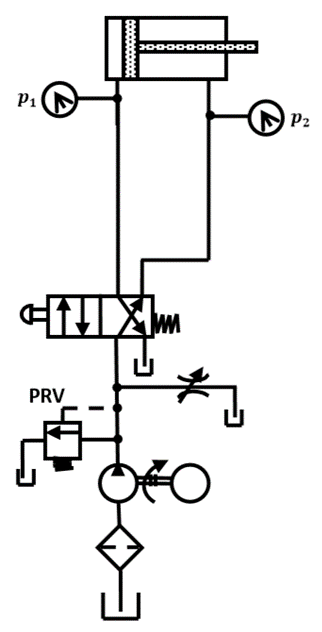

The figure shows a meter-out circuit for flow control during the extend stroke.

Fig. Meter-out Circuit

Both the meter-in and meter-out circuits mentioned above perform the same operation (control the speed of the extending stroke of the piston), even though the processes are exactly opposite to one another.

4.4.3 Bleed-off Circuit

Compared to meter-in and meter-out circuits, a bleed-off circuit is less commonly used. The figure shows a bleed-off circuit with extend stroke control.

Fig. Bleed-off Circuit for the inlet to the cylinder

The cylinder can also be bleed-offed in both direction as shown below

Fig. Bleed-off Circuit for both directions

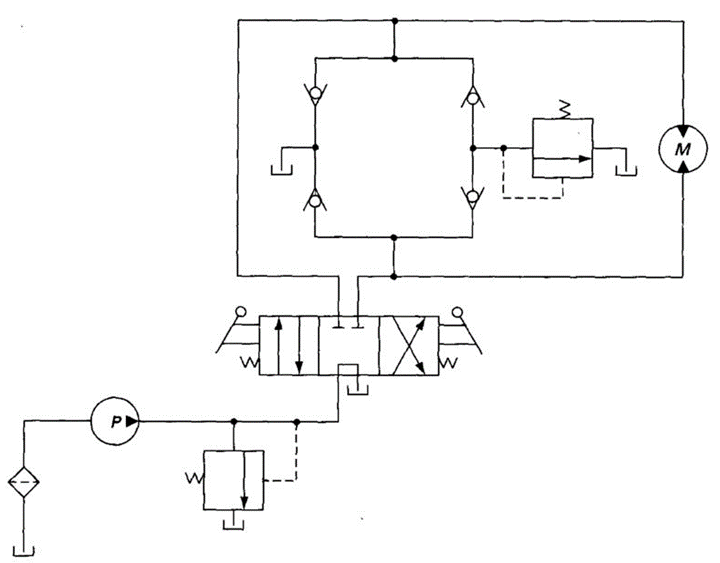

4.4.4 Speed Control of Hydraulic Motor

The figure shows the speed control circuit of a hydraulic motor using a pressure-compensated FCV.

Fig. Speed Control of Hydraulic Motor

The operation is as follows:

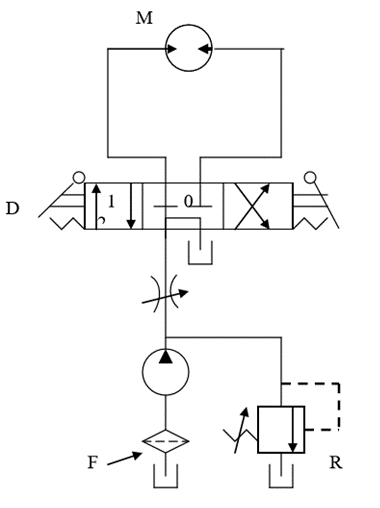

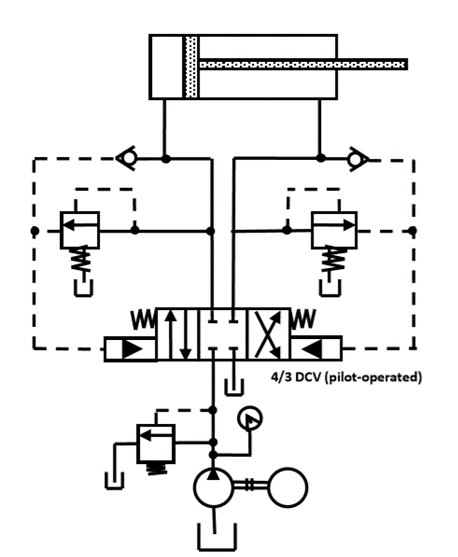

Hydraulic cylinders can be operated sequentially using a sequence valve. The figure shows that two sequence valves are used to sequence the operation of two double-acting cylinders.

Fig. Sequencing Circuit

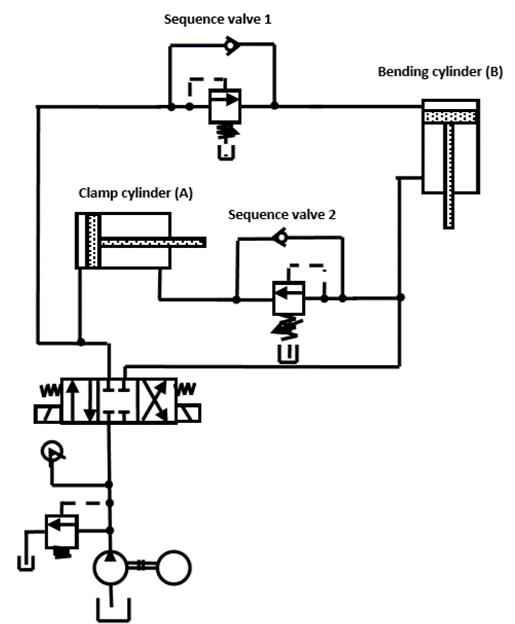

In industry, there are instances when a large mass must be moved, and it is not feasible to move it with just one cylinder. In such cases, we use two or more cylinders to prevent a moment or moments that might distort and damage the load.

For example, in the press used for molding and shearing parts, the platen used is very heavy. If the platen is several meters wide, it has to be of very heavy construction to prevent the damage when it is pressed down by a single cylinder in the middle. It can be designed with less material if it is pressed down with two or more cylinders. These cylinders must be synchronized.

There are two ways that can be used to synchronize cylinders:

Parallel and series.

4.6.1 Synchronization of cylinders in parallel

4.6.2 Synchronization of cylinders in series

Fig. Synchronization Circuit

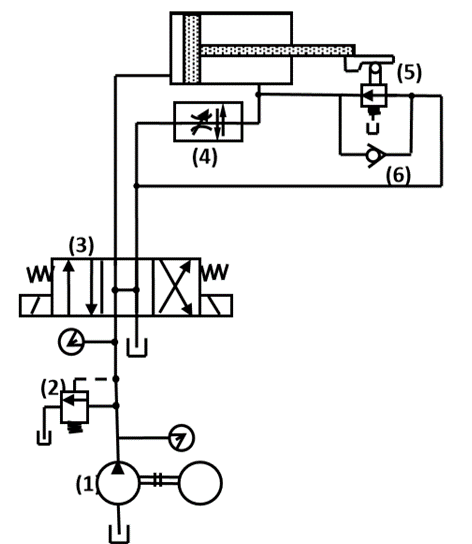

Fig. Traverse and feed circuit

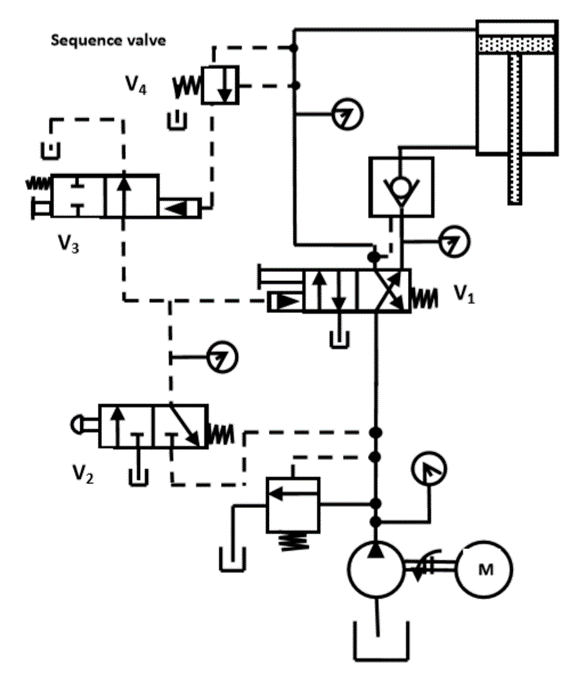

The sequence valve can also be used to reciprocate the cylinder automatically.

The hydraulic circuit shown in Fig produces continuous reciprocation of a double-acting cylinder using two sequence valves.

Fig. Automatic cylinder reciprocating circuit

Fail-safe circuits are those designed to prevent injury to the operator or damage to the equipment. In general, they prevent the system from accidentally falling on an operator and also prevent overloading of the system.

In the following sections we shall discuss two fail-safe circuits:

One is protection from inadvertent cylinder extension and the other is fail-safe overload protection.

4.9.1 Protection from inadvertent cylinder extension:

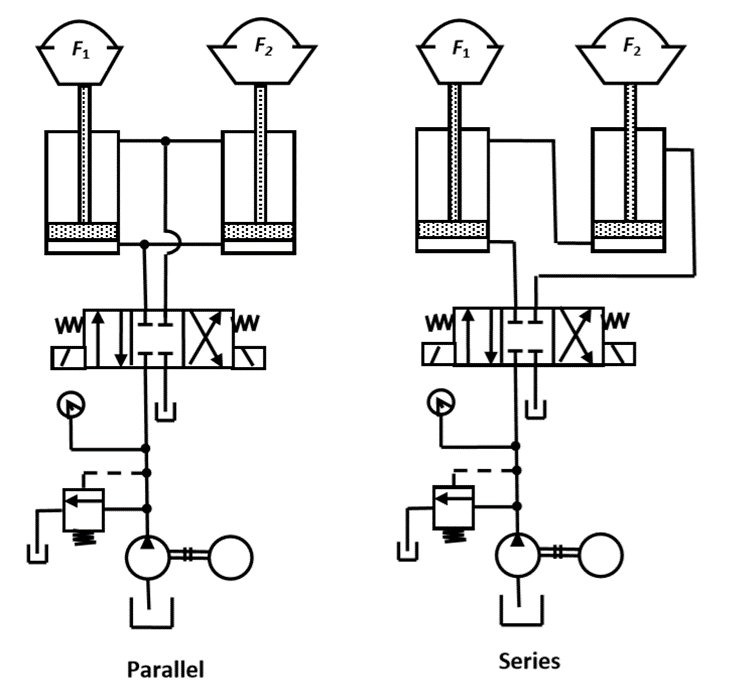

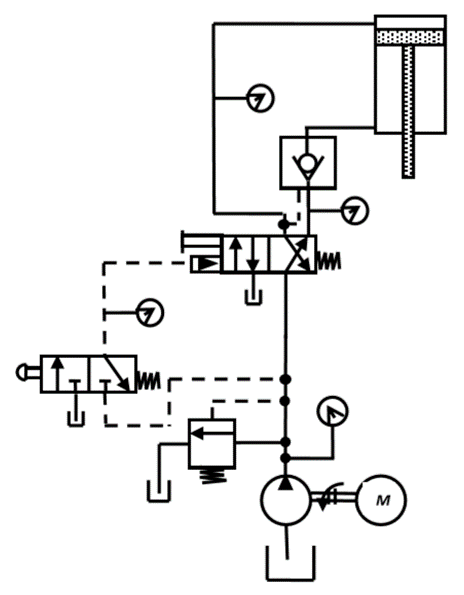

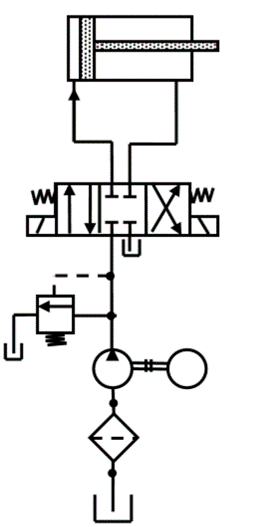

The figure shows a fail-safe circuit that is designed to prevent the cylinder from accidentally falling in the event when a hydraulic line ruptures or a person inadvertently operates the manual override on the pilot-actuated DCV when the pump is not working.

Fig. Fail-safe circuit – inadvertent cylinder extension

4.9.2 Fail-Safe System with Overload Protection:

The figure shows a fail-safe system that provides overload protection for system components.

Fig. Fail-safe circuit – overload protection

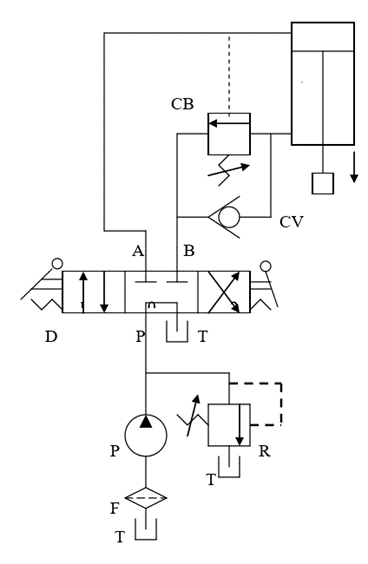

A counterbalance valve is applied to create back pressure or cushioning pressure on the underside of a vertically moving piston to prevent the suspended load from free-falling because of gravity while it is still being lowered.

Valve operation:

The pressure setting on the counterbalance valve is set slightly higher than the pressure required to prevent the load from free falling. Due to this backpressure in line A, the actuator piston must force down when the load is being lowered. This causes the pressure in line A to increase, which raises the spring opposed spool, thus providing a flow path to discharge the exhaust flow from line A to the DCV and then to the tank. The spring-controlled discharge orifice maintains back pressure in line A during the entire downward piston stroke.

2. Lifting:

As the valve is normally closed, flow in the reverse direction (from port B to port A) cannot occur without a reverse free-flow check valve. When the load is raised again, the internal check valve opens to permit flow for the retraction of the actuator.

3. Suspension:

When the valve is held in suspension, the valve remains closed. Therefore, its pressure setting must be slightly higher than the pressure caused by the load. Spool valves tend to leak internally under pressure. This makes it advisable to use a pilot-operated check valve in addition to the counterbalance valve if a load must be held in suspension for a prolonged time.

Fig. Counterbalance circuit

Fig. Actuator (Cylinder) locking Circuit

The figure shows a hydraulic circuit to unload a pump using an unloading valve.

Fig. Pump unloading circuit

Fig. Hydraulic Motor Braking Circuit

- Types of contaminants

Particle sizes are generally measured in micrometers or microns. Some examples of microns: Grain of salt 100 microns, human hair 70 microns, lower limit of visibility 40 microns, milled flour 25 microns, average bacteria 2 microns. Note that most damage-causing particles in hydraulic or lubrication systems are smaller than 14µm micrometers, so they cannot be seen.

2. Water

The most common chemical contaminant in hydraulic systems is water. The presence of water in hydraulic oil can have wide-ranging effects on system components because of its effect on the physical and chemical properties of hydraulic oil. Rust in tanks, reduced lubrication characteristics resulting in accelerated metal surface wear are some of the most obvious physical results of excessive water, however, the effects could be as diverse as the jamming of components due to ice crystals at low temperatures.

3. Air

The air in a hydraulic system can exist in either a dissolved or entrained (undissolved, or free) state. Dissolved air may not pose a problem, providing it stays in solution. When a liquid contains undissolved air, problems can occur as it passes through system components. There can be pressure changes that compress the air and produce a large amount of heat in small air bubbles. This compressibility of air means that control of the system is lost. Air bubbles and frothing in the oil reservoir can cause major damage to pumps or it can also cause the oil to “boil” out of the tank.

4. Heat

Excessive heat in hydraulic systems can also result in additive depletion or chemical changes to the oil.

4.14.2 Sources of contamination in hydraulic systems

In general, there are four main sources of contamination in hydraulic oil.

For proper operation and long service life of a hydraulic system, oil cleanliness is of prime importance. Hydraulic components are very sensitive to contamination. The cause of the majority of hydraulic system failures can be traced back to contamination. Hence, the filtration of oil leads to proper operation and long service life of a hydraulic system. Strainers and filters are designed to remove foreign particles from the hydraulic fluid.

The process of removal of contaminants from the oil by use of filters and strainers is called as filtration.

They can be differentiated by the following definitions:

4.16.1 Types of Filters

1. According to the filtering methods:

2. According to the size of pores in the material:

3. According to the location of filters:

4.16.2 Suction Strainers

Fig. Suction Filter

Advantages of suction filters:

(a) A suction filter protects the pump from dirt in the reservoir. Because the suction filter is outside the reservoir, an indicator telling when the filter element is dirty can be used.

(b) The filter element can be serviced without dismantling the suction line or reservoir (easy to maintain).

Disadvantages of suction filters:

(a) A suction filter may starve the pump if not sized properly.

4.16.3 High-pressure Filter

These are placed immediately after the pump to protect valves and actuators and can be a finer and smaller mesh (Fig). They should be able to withstand the full system pressure. Most filters are pressure line filters.

Fig. Pressure line filters

Advantages of a pressure line filter:

(a) A pressure filter can filter very fine contaminants because the system pressure is available to push the fluid through the element. (b) A pressure filter can protect a specific component from the harm of deteriorating particles generated from an upstream component.

Disadvantages of a pressure line filter:

(a) The housing of a pressure filter must be designed for high-pressure because it operates at full system pressure. This makes the filter expensive. (b) If pressure differential and fluid velocity are high enough, dirt can be pushed through the element or the element may tear or collapse.

4.16.4 Low-pressure Filters

These filters filter the oil returning from the pressure relief valve or the system, that is, the actuator to the tank (Fig). They are generally placed just before the tank. They may have a relatively high-pressure drop and hence can be a fine mesh. These filters have to withstand low-pressure only and also protect the tank and pump from contamination.

Fig. Return line filter

Advantages of a return line filter:

(a)A return line filter catches the dirt in the system before it enters the reservoir.

(b)The filter housing does not operate under full system pressure and is, therefore, less expensive than a pressure filter.

Disadvantages of a return line filter:

(a) There is no direct protection for circuit components.

(b) In return line full-flow filters, flow surges from discharging cylinders, actuators, and accumulators must be considered when sizing.

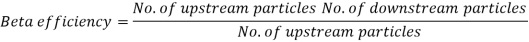

The filtration industry uses the ISO 16889 “Multipass Test Procedure” to evaluate filter element performance. During the Multipass Test, fluid is circulated through the circuit under precisely controlled and monitored conditions. The differential pressure across the test element is continuously recorded, as a constant amount of contaminant is injected upstream of the element. Online laser particle sensors determine the contaminant levels upstream and downstream of the test element. This performance attribute (The Beta Ratio) is determined for several particle sizes. Three important element performance characteristics are a result of the Multipass Test:

1. Dirt holding capacity.

2. A pressure differential of the test filter element.

3. Separation or filtration efficiency expressed as a “Beta Ratio”

Fig. Multipass Test

Beta Ratio of Filters

Filters are rated according to the smallest size of particles they can trap. Filter ratings are identified by nominal and absolute values in micrometers. A filter with a nominal rating of 10 μm is supposed to trap up to 95% of the entering particles greater than 10 μm in size. The absolute rating represents the size of the largest pore or opening in the filter and thus indicates the largest size particle that could go through. Hence, the absolute rating of a 10 μm nominal size filter would be greater than 10 μm.

A better parameter for establishing how well a filter traps particle is called the beta ratio or beta rating. The beta ratio is determined during laboratory testing of a filter receiving a steady-state flow containing fine dust of selected particle size. The test begins with a clean filter and ends when the pressure drop across the filter reaches a specified value indicating that the filter has reached the saturation point. This occurs when contaminant capacity has been reached.

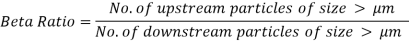

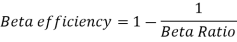

By mathematical definition, “the beta ratio equals the number of upstream particles of size greater than Nμm divided by the number of downstream particles having a size greater than Nμm where N is the selected particle size for the given filter.”

The ratio is represented by the following equation:

A beta ratio of 1 would mean that no particle above specified N is trapped by the filter.

A beta ratio of 50 means that 50 particles are trapped for everyone that gets through. Most filters have a beta ratio greater than 75

Thus,

References :

1. Pipenger J.J, Industrial Hydraulics, McGraw Hill

2. Pinches, Industrial Fluid Power, Prentice Hall

3. Yeaple, Fluid Power Design Handbook

4. Andrew A. Parr, Hydraulics and Pneumatics, Elsevier Science and Technology Books

5. ISO - 1219, Fluid Systems and components, Graphic Symbols

6. Standard Manufacturer’s Catalogues