Unit - 6

Transmission system in Hybrid Electric Vehicle

Transmission system in Hybrid Electric Vehicle

Hybrid electric powered vehicle (HEV) generation is one of the maximum promising solutions. This examine investigated the full performance of a HEV powertrain. To enhance the full performance, the engine ought to be regulated to paintings at its maximum performance and force the wheels immediately as lots as possible.

To accomplish this, we evolved an electricity control method primarily based totally at the direct force area (DDA) of the engine’s performance map. Several traditional HEV fashions have been constructed to evaluate the gas intake the usage of DDA and rule-primarily based totally strategies. Furthermore, the characteristic of the HEV transmission gadget with DDA become considered.

The transmission in a HEV ought to adjust the engine to paintings at its maximum performance as lots as possible, that is instead special than the law in an inner combustion engine vehicle. The useful alternate may also cause transmission structures with fewer gears however most fulfilling equipment ratios. If this fashion is realized, the producing value of HEVs can be in large part reduce

Introduction:

The best energy of hybrid electric powered cars (HEV) are that their electric powered automobiles offer gasoline performance some distance exceeding combustion-engine cars. The using motor in large part helps what the engine does, saving numerous gasoline use. That energy is maximized with the aid of using the whole HEV's layout centered on gasoline financial system.

- Aerodynamic layout is one such layout consideration. Conventional hybrid transmission structures needed to compromise for transmission and using pleasure Hybrid fashions generally tend to are searching for gasoline-performance over powertrain performance.

- Conventional automated transmissions us a torque converter (transmits engine torque through fluid) to mitigate shift surprise. Torque converters assist mitigate surprise and are fantastically speedy in transmitting energy.

- Torque converters aren't without their disadvantages. Torque converters carry energy via a fluid in the converter, so there may be electricity loss.

- Furthermore, torque converters are heavy additives and disadvantageous to gasoline financial system. This manner that torque converters are counterproductive to gasoline-performance in search of HEVs.

- That is why maximum HEVs now not have torque converters now, reducing energy loss and heft. However, this isn't always an excellent solution, due to the fact shift surprise can harm the transmission. One strategy to mitigate shift surprise and permit easy transmission moving is artificially prolonged transmission time.

- It lets in for smoother moving, however the downsides encompass slow or inconsistent transmission. Conventional combustion-engine cars have the engine, automated transmission, and wheels in series, wherein the energy from the engine is transmitted immediately to the wheels.

- The position of the automated transmission if so is to govern engine energy to the wheels relying on tour pace, automobile weight, and avenue conditions. It is simple to understand in case you consider automated transmissions deciding on decrease gears for beginning from a standstill and better gears for much less energy-annoying conditions which include high-pace steady pace operation.

In the case of HEVs, a hybrid force motor is located among the engine and the automated transmission, undertaking energy transmission.

In different words, the energy of the engine and the energy of the using motor generate blended energy, transmitted to the wheels via the transmission. As the electrical motor the engine's energy, gasoline financial system is boosted and definitely affects acceleration.

Types of Hybrid Electric Vehicles: Basic Classification, Basic mode of operation, other derivatives

HEVs commonly encompass an electrical garage device, consisting of a battery, flywheel, or an ultra-capacitor. They additionally integrate this strength garage supply with a mechanical device, like an internal-combustion engine (ICE), fuelling turbine, or a gasoline cell. This aggregate reduces each gasoline intake and tailpipe emissions. In general, hybrids seize strength misplaced at some stage in braking and go back it to the on-board battery. This system is called regenerative braking.

The nature of HEV configuration permits numerous vital benefits over natural electric powered cars (EVs). Because the HEV engine stocks the workload with the electrical motor, it may be built smaller. This discount in length engenders weight reductions, main to extra gasoline financial system. Also, HEV engines may be optimized to function inside a particular velocity variety characterized through higher gasoline financial system and decreased emissions. This permits HEVs to do away with the better emissions and bad gasoline financial system related to traditional ICE cars. While all hybrid-electric powered cars require a hybrid energy unit (HPU), there are some of alternatives open to car manufacturers.

Types of HEV:

Battery Electric Vehicles (BEVs)

Powered solely by an electric battery, with no gas engine parts. Most BEVs are capable of fast charging and L2 charging. Zero emissions.

Battery Electric Vehicles, additionally known as BEVs and greater often known as EVs, are absolutely electric powered automobiles with rechargeable batteries and no gas engine. All strength to run the automobile comes from the battery % that is recharged from the grid. BEVs are 0 emissions automobiles, as they do now no longer generate

Plug-in Hybrid Electric Vehicles (PHEVs)

Similar to a Hybrid, but with a larger battery and electric motor. Has a gas tank and a charging port. Can charge by using L2 chargers.

Plug-in Hybrid Electric Vehicles, or PHEVs, have each an engine and electric powered motor to pressure the car. Like everyday hybrids, they could recharge their battery thru regenerative braking. They fluctuate from everyday hybrids via way of means of having a far large battery, and being capable of plug into the grid to recharge. While everyday hybrids can (at low speed) journey 1-2 miles earlier than the gas engine turns on, PHEVs can move everywhere from 10-forty miles earlier than their fuel line engines offer assistance.

Hybrid Electric Vehicles (HEVs)

Low-emission vehicles that use an electric motor to assist gas-powered engines. All energy comes from gasoline. Cannot charge with Ego.

All power for the battery is won via regenerative braking, which recoups in any other case misplaced power in braking to help the fuel engine at some stage in acceleration. In a conventional inner combustion engine vehicle, this braking power is commonly misplaced as warmth with inside the brake pads and rotors. Regular hybrids can't plug into the grid to recharge and can't price with EVgo.

Basic Classification:

1. Based on Architecture:

1) Series Configuration:

A collection is one wherein handiest one electricity converter can offer propulsion energy. IC engine acts as a top mover. It drives an electric powered generator that can provide energy to the battery or electricity garage link and the propulsion motor. A downsized IC engine drives a generator, which dietary supplements the batteries and may fee them once they fall underneath a certain SOC.

Electric motor energy necessities are precisely the equal as an electric powered car.

2) Parallel Configuration:

A parallel hybrid is one wherein greater than one conversion tool can supply propulsion energy to the wheels. The IC engine and electric powered motor are configured in parallel with a mechanical coupling that blends the torque coming from sources. In parallel HEV, the energy necessities of the electric powered motor are decrease than electric powered car or collection hybrid; on the grounds that IC engine enhances to total energy call for of the car.

3) Series-Parallel Hybrid (Split Type):

In S-P hybrids, the IC engine is likewise used to rate the battery. The structure is greater complicated, related to extra mechanical hyperlinks and controls in comparison to collection hybrid and an extra generator in comparison to parallel hybrid. S-P HEV is essentially collection HEV however with a small collection detail brought to the structure. It guarantees that the battery rate is continued in extended wait durations in visitor’s jams. The energy break up device allotted energy from IC engine to the front wheels thru driveshaft and electric powered generator depending on using condition. For quick bursts of acceleration, energy may be introduced to the driveshaft from each IC engine and electric powered motor. A critical manage unit regulates energy float for the gadget the use of a couple of remarks indicators from diverse sensors.

2. Nature of power source

1) Electric-IC engine hybrid

Electric-IC engine hybrid may be created in many ways. Form of designs differentiate upon how electric powered motor and combustion engine strength train are connected (Series, parallel, series-parallel), what percentage of strength is produced through electric powered motor and IC engine, the time at which both quantities operate

2) Fuel Cells

First a hit gasoline cells have been designed through Francis publisher 1st baron ferula in 1932 (designed alkaline gasoline mobileular system with porous electrodes). Main supply of electricity is hydrogen. They want ultra-capacitor to increase strength density required to begin the vehicle. They have excessive electricity efficiency. Use of hydrogen effects in low use of crude oil as vehicular gasoline and low carbon emissions as well

Basic modes of operation & other derivatives:

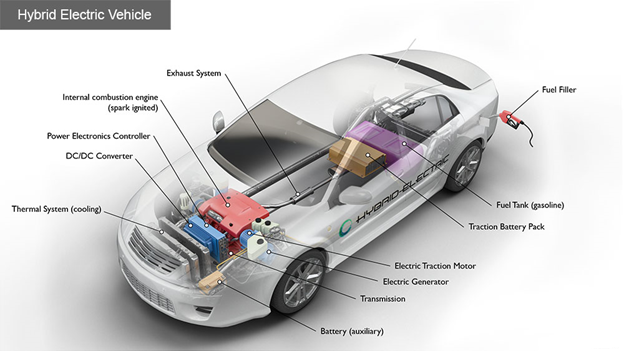

Attery (auxiliary):

In an electric powered pressure car, the low-voltage auxiliary battery offers strength to begin the auto earlier than the traction battery is engaged; it additionally powers car add-ons.

DC/DC converter:

This tool converts higher-voltage DC strength from the traction battery percent to the lower-voltage DC strength had to run car add-ons and recharge the auxiliary battery.

Electric generator:

Generates strength from the rotating wheels at the same time as braking, shifting that strength again to the traction battery percent. Some motors use motor mills that carry out each the pressure and regeneration functions.

Electric traction motor:

Using strength from the traction battery percent, this motor drives the car's wheels.

Exhaust gadget:

The exhaust gadget channels the exhaust gases from the engine out via the tailpipe. A three-manner catalyst is designed to lessen engine-out emissions inside the exhaust gadget.

Fuel filler:

A nozzle from a gasoline dispenser attaches to the receptacle at the car to fill the tank.

Fuel tank (fuel):

This tank shops fuel on board the car till it is wanted with the aid of using the engine.

Internal combustion engine (spark-ignited):

In this configuration, gasoline is injected into both the consumption manifold and the combustion chamber, in which it's far mixed with air, and the air/gasoline aggregate is ignited with the aid of using the spark from a spark plug.

Power electronics controller:

This unit manages the glide of electrical strength introduced with the aid of using the traction battery, controlling the rate of the electrical traction motor and the torque it produces.

Thermal gadget (cooling):

This gadget keeps a right running temperature variety of the engine, electric powered motor, strength electronics, and different components.

Traction battery percent:

Stores strength to be used with the aid of using the electrical traction motor.

Transmission:

The transmission transfers mechanical strength from the engine and/or electric powered traction motor to pressure the wheels.

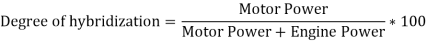

Degree of hybridization:

Parallel and mixed hybrids may be categorized in step with diploma of hybridization. Degree of hybridization relies upon the electricity provided via way of means of IC engine and electric powered motor. In a few vehicles, IC engine is dominant; electric powered motor activates handiest whilst enhance is needed. In many vehicles, each IC engine and electric powered motor percentage identical loads. Others can run handiest with electric powered motor machine operating. The ratio of electricity evolved via way of means of an electric powered motor in a hybrid automobile to the whole electricity ate up via way of means of the automobile is referred to as diploma of hybridization.

1) Micro Hybrid:

• It depends on function of automatic start or off.

• it cannot provide extra torque to the motor.

• Electric Motor supplies power 2.5kW at 12 volts.

• Energy saving 5 to 10%.

• Example: BMW 1 series, For two Mercedes, etc.

2) Mild Hybrid:

• Electric motor is integrated and provides power up to 10% more.

• These hybrids improve drawbacks of fossil fuel vehicles. Here motor or generator is in parallel with IC engine

• Electric Motor supplies power 10 to 20 kW at 100-200 volts

• Energy saving 20 to 30%

• Examples: Chevrolet Malibu, Chevrolet Silverado is a full-size pickup truck, Honda Escape, etc.

3) Full Hybrid:

• Electric motor provides at least 40% of engine power as additional torque.

• Bigger motor and motor reduces size of vehicle.

• It has improved fuel consumptions and reduced emissions.

• Circa Electric Motor supplies power 50 kW at 200-300 volts.

• Energy saving 30 to 50%

• Example: -Toyota Prius, Camry Hybrid, Ford Escape Hybrid, Ford Fusion Hybrid/Lincoln MKZ Hybrid, Ford C-Max Hybrid, Kia Optima Hybrid, as well as the General Motors hybrid trucks with 2 –mode.

Key Takeaways:

- In general, hybrids seize strength misplaced at some stage in braking and go back it to the on-board battery.

- While all hybrid-electric powered cars require a hybrid energy unit (HPU), there are some of alternatives open to car manufacturers.

- BEVs are 0 emissions automobiles, as they do now no longer generate

- Low-emission vehicles that use an electric motor to assist gas-powered engines. All energy comes from gasoline. Cannot charge with Ego.

- Electric motor energy necessities are precisely the equal as an electric powered car.

- A parallel hybrid is one wherein greater than one conversion tool can supply propulsion energy to the wheels.

- Use of hydrogen effects in low use of crude oil as vehicular gasoline and low carbon emissions as well

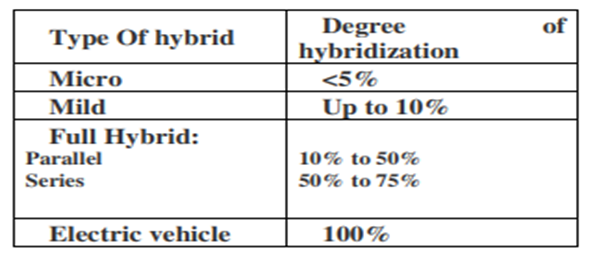

Power Split Devices (PSD): Simple and EM compound PSD:

It is an exceptionally exciting and cleverly designed gearbox that integrates the inner combustion engine and the electrical motor power together. But maximum essential of all it permits each the engine and the electrical motor to power the wheels while necessary.

Fig: Power Split Devices

Functionality:

- So the strength-splitter can perform the subsequent functions: Allow the automobile to act like a chain hybrid.

- In this situation the strength-splitter permits the engine to run and price the batteries at the same time as the electrical motor power presents riding strength to the wheels.

- It permits the inner combustion engine to take over strength shipping to the wheels while extra strength is wanted to boost up the automobile.

- Overtaking different automobiles wishes appreciably extra strength which the engine can provide)

- It removes the want of a guide or automated gearbox. This is due to the fact the strength-splitter tool itself behaves like a Continuous Variable Transmission (CVT).

- It removes the want of a starter motor to begin the automobile. This is due to the fact the strength-splitter permits the generator to begin the automobile.

- The electric powered motor can be completely fed through strength from the battery or thru the generator became through the ICE, or both.

- Such an automobile conceptually resembles a diesel–electric powered locomotive with the addition of a battery which can electricity the automobile without strolling the ICE and performing as an strength buffer this is used to boost up and obtain more speed; the generator might also additionally concurrently price the battery and electricity the electrical motor that movements the automobile.

- When the automobile is stopped the ICE is switched off without idling, even as the battery affords something electricity is wanted at rest. Vehicles at site visitor’s lights, or in sluggish transferring stop-begin site visitors want now no longer burn gasoline whilst desk bound or transferring slowly, lowering emissions.

- Series-hybrids may be geared up with a super capacitor or a flywheel to shop regenerative braking strength, that may enhance performance through improving strength in any other case misplaced as warmness via the braking system. Because a collection-hybrid has no mechanical hyperlink among the ICE and the wheels, the engine can run at a steady and green price no matter automobile speed, attaining better performance (37%, in preference to the ICE common of 20%[16]) and at low or blended speeds this may end result in ~50% growth in ordinary performance (19% vs 29%).

- Lotus supplied an engine/generator set layout that runs at speeds, giving 15 kW of electrical electricity at 1,500 rpm and 35 kW at 3,500 rpm thru the included electric generator, used with inside the Nissan idea Infiniti Emerge-e.

HEV Component Characteristics:

- Generally, an EV/HEV powertrain consists of awesome additives along with electricity unit(s), an inner combustion engine and/or electric powered motor(s), a transmission machine, and batteries.

- Performance evaluation of an EV/HEV powertrain machine calls for the modeling of every incorporated thing. Depending at the powertrain topology, thing fashions ought to be mixed to shape the general powertrain model.

- Components of a powertrain machine may be mathematically modeled through the use of the legal guidelines of physics to reach at a fixed of differential equations representing powertrain dynamics.

- Physics-primarily based totally fashions are very effective equipment for the layout and optimization of powertrain systems. However, they may be complex and from time to time do now no longer fit the experimental consequences exactly.

- Alternatively, output electricity and torque, in addition to the electricity intake and performance of a powertrain machine may be calculated thru function curves in place of complex physics-primarily based totally fashions.

- Characteristic curves illustrate the consequences of trendy experiments with enough accuracy. Driving cycles are also an essential device with inside the layout and offline assessment of powertrain systems. There are special using cycles representing city and motorway using situations for special geographical regions.

1. High Power density and high voltage circuit:

Most of the extent of inverters for HEVs and EVs with widespread 450 Vdc-magnificence batteries comes from the high-voltage foremost circuit, so enhancing foremost circuit issue components is the important thing to decreasing inverter length.

Hitachi Automotive Systems has finished a chief discount in inverter length through growing double-sided cooling energy module era that makes use of cooling water without thermal grease to allow direct cooling of the high-voltage energy module, which generates maximum of the inverter warmness. The contemporary output of this double-sided cooling energy module also can be scaled to comply to one of a kind car weight lessons through converting the hooked up chips and a number of the packaging components.

2. High performance control circuit:

These inverters additionally want to guide features inclusive of excessive-capacity, excessive-pace communication, anomaly detection, torque security, failure diagnosis, and purposeful protection through the use of Controller Area Network (CAN) or Flex Ray.

To meet those demands, Hitachi has evolved excessive-overall performance motor manage circuit era with a integrated excessive-overall performance relevant processing unit (CPU) and compact characteristic circuits.

They want to perform at speeds and currents excessive sufficient to preserve up with the modern-day overall performance evolution in energy devices, whilst making sure defensive operation. To meet those demands, Hitachi has evolved a compact gate manage circuit pushed through an excessive-overall performance included circuit (IC).

3. Compact, highly reliable structure:

The technology defined above had been utilized in a compact, noticeably dependable package deal shape that Hitachi has advanced and carried out to products. It achieves excessive reliability and sturdiness even as assembly the desires of onboard mounting.

The instance product proven in Figure 2 achieves a 40% discount in length with better output relative to preceding Hitachi Automotive Systems products. And, a excessive-performance DC/DC converter with a most performance of 94% has additionally been simultaneously advanced for this product.

Ongoing evolution in strength modules and force structures at the side of the usage of next-technology low-loss SiC strength factors have to lessen inverter length and boom EV riding variety and the quantity of to be had electric powered car versions with inside the years ahead.

4. High Efficiency Motor Technologies:

The idea in the back of the usual motor is to lessen the improvement workload and to standardize components, manufacturing equipment, and production practices via way of means of designing trendy motor specs with a view to fit a number of unique styles of electric powered vehicles, which includes HEVs, EVs, and plug-in HEVs (PHEVs), in addition to unique length training of vehicles, at the same time as nevertheless presenting capabilities which includes small length, mild weight, excessive output, excessive efficiency, quiet operation, and coffee vibrations. The improvement technique became to expand a low-fee motor at the same time as additionally enhancing improvement efficiency.

Meeting those necessities would require bodily dimensions with a view to permit car layouts to be designed in a standardized manner over unique training of vehicles, output traits that fulfill a huge variety of output necessities, time scores that fit the traits of various styles of electric powered vehicles, and a number of version versions to fit unique give up uses.

5. Stator winding method for standard motor:

To gain small length and excessive torque density, wave winding the use of rectangular cord turned into selected for the stator windings on the same old motor.

Compared with the allotted windings with spherical cord used with inside the past, people with rectangular cord offer an about 20 development in area factor (conductor cross-section/slot cross-section) and an about 15 development with inside the motor's output torque density (= Output torque / (Stator middle diameter) 2 × Stator middle period).

Wave winding section coils may be flexibly tailored to stator stack period versions with the aid of using converting the period of the coil's instantly portion.

Key Takeaways:

- Overtaking different automobiles wishes appreciably extra strength which the engine can provide)

- The electric powered motor can be completely fed through strength from the battery or thru the generator became through the ICE, or both.

- Lotus supplied an engine/generator set layout that runs at speeds, giving 15 kW of electrical electricity at 1,500 rpm and 35 kW at 3,500 rpm thru the included electric generator, used with inside the Nissan idea Infiniti Emerge-e.

- . There are special using cycles representing city and motorway using situations for special geographical regions.

- To meet those demands, Hitachi has evolved a compact gate manage circuit pushed through an excessive-overall performance included circuit (IC).

- To gain small length and excessive torque density, wave winding the use of rectangular cord turned into selected for the stator windings on the same old motor.

IC Engines:

It is pretty apparent from the call that during inner combustion engines, gasoline is burned within the engine. Unlike outside combustion engines wherein gasoline is burned out of doors the engine.

Most famous form of inner combustion engine which we see these days is the engine which we use in our automobile and motorcycle.

We can without problems observe that we positioned gasoline in those engines and that gasoline receives burned within the cylinder. Engine converts power of gasoline into electricity and releases exhaust gases of combustion process.

Advantages of IC engines

Size of engine could be very much less as in comparison to outside combustion engines

Power to weight ratio is excessive Very appropriate for small electricity requirement packages

Starting time could be very much less

High performance than outside combustion engine

No probabilities of leakage of operating fluids

Requires much less maintenance

Lubricant intake is much less compared to outside combustion engines

In case of reciprocating inner combustion average operating temperature is low due to the fact top temperature is reached for simplest small duration of time (simplest at detonation of fuel).

Disadvantages of IC engines

Variety of fuels that may be used is confined to very satisfactory first-rate gaseous and liquid fuel used could be very high priced like gas or diesel

Engine emissions are normally excessive as in comparison to outside combustion engine

Not appropriate of huge scale electricity generation In case of reciprocating inner combustion noise is generated because of detonation of fuel

Applications:

They are used for Automotive, Marine, Aircraft purposes.

Gas Engines: They are used for Industrial Power purposes

Diesel Engines: They are used for Automotive, Railways, Power, Marine purposes.

Gas Turbines: They are used for Power, Aircraft, Industrial, Marine purposes.

Electric Machines and Battery:

An electric powered motor is a tool that converts electric strength into mechanical strength. In today’s life, electric powered automobiles have severa programs which include in homes, business buildings, and production industries. An electric powered motor works at the precept of Ampere’s regulation which states whilst a cord is sporting an electric powered current, it generates magnetic area round itself. In different words, an electric powered motor is capable of generate movement with the aid of using use of magnets and consequently its entire operation is ready magnets & magnetism.

HEV performance analysis:

Effect of Hybrid Sales in Auto enterprise

While it would not appear to be as imminent, the gaining recognition of the hybrid vehicle ought to unearth those troubles yet again for those industries.

However, now there are even greater problems clouding the development of hybrid vehicle technology.

While the hybrid vehicle enterprise is growing, the leaders on this marketplace are overseas, with Japanese producers Honda and Toyota main the pack. If there may be a referred to client shift to hybrids, this will price our home production enterprise in addition to harm the task marketplace

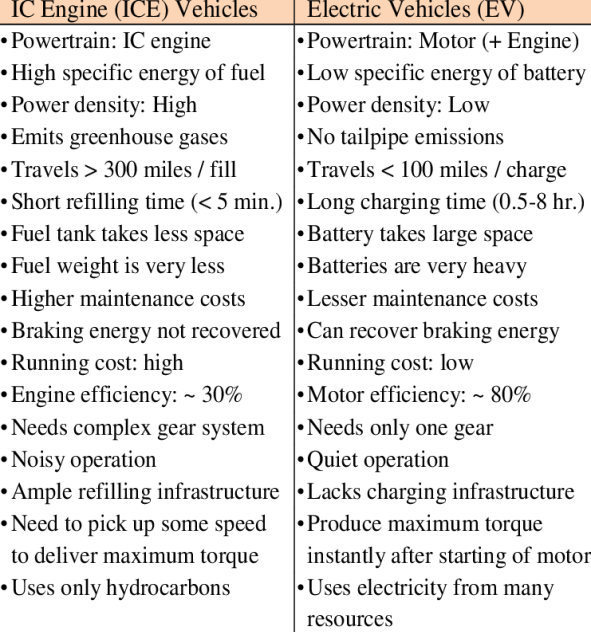

Comparative Analysis

- Looking on the person parameters that have an effect on HEV, we've laid out the basis for discussing how the Hybrid-Electric Vehicle stacks up in opposition to the different to be had technologies.

- We took an initial examine the performance of the hybrid opposite numbers to standard cars in phrases of gasoline quantity and price financial savings.

- There were combined perspectives on whether or not the preliminary top class paid became justified with the aid of using those financial savings and different life-time period benefits.

- It is obvious that there are numerous assumed inputs, together with a stagnant gasoline price for a short-time period outlook, that make this a completely subjective evaluation of prescribing the best generation for a sustainable future.

- In order to do an extra thorough evaluation, we can technique in phrases of price-performance and energy-performance relative to different opportunity gasoline technologies.

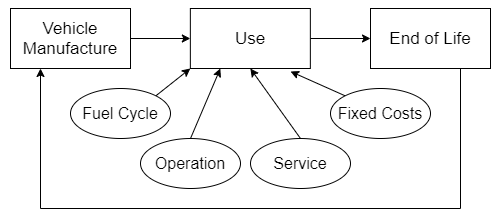

Life Cycle Analysis (LCA) & Life Cycle Cost Analysis (LCCA)

Life Cycle Analysis and Life Cycle Cost Analysis examines and elements in the economic or electricity fees related to every level of the life-cycle version of a motor vehicle. Most LCA and LCCA analyses have analogous fees for price and electricity due to the fact electricity costing procedures society are generally penalized with a better price, such as extracting uncooked mat, refining, processing, or smooth up.

Life cycle price evaluation commonly consists of gasoline price, capital price, and aspect wear price. The capital price in opportunity technology in particular refers back to the price of the strength unit, whether or not it's far an ICE or a gasoline cell.

In the examine of comparative opportunity powertrain systems, the hybrid system's overall performance turned into evaluated factoring in:

- How the car is being implemented, i.e. the surroundings it's far being driven, in

- How do fluctuations of destiny fossil gasoline fees have an effect on the special opportunity technology?

Hybrid-Electric Vehicles emerged as a promising candidate to standard car, because it makes use of multiple "strength units" to supply efficiency.

While each efficient, gasoline cells and batteries have their drawbacks: gasoline cells are costly and batteries have a low power density. The parameters that had been numerous had been car kind and time setting.

Three car identities that had been considered: the auto with blended town and toll road driving; the town bus with common stops in a city area; and the intercity bus at the toll road strolling at regular speeds for lengthy durations of time.

- For every scenario, with an aggregate of those conditions, a most efficient powertrain configuration turned into observed.

- The evaluation confirmed that during cutting-edge times, a hybrid powertrain should be powerful however most effective for positive applications, consisting of forestall and move movement of the town bus.

- The version proved hard for a price powerful hybrid vehicle to be evolved with today's technology. The evaluation observed that even the maximum price powerful hybrid vehicle has comparable lifestyles cycle fees to a traditional car due to the fact the financial savings in gasoline intake is not sufficient to compensate the preliminary price of the strength unit with inside the 2005 scenario.

- However, the excessive fuelling charges and aggressive fee-slicing for electric element charges in destiny situations proved HEVs to be greater price powerful. Electric motors powered via way of means of Limon batteries display the least power intake at a low fee in 2020.

- This is because of a low gasoline price (i.e. electricity) however that is closely reliant on the idea that their power density will increase six-fold. Moreover, Limon batteries might in no way have the ability to strength a bus, which calls for an excessive strength supply with an extended lifetime.

Key Takeaways:

- Most famous form of inner combustion engine which we see these days is the engine which we use in our automobile and motorcycle.

- Power to weight ratio is excessive Very appropriate for small electricity requirement packages

- Lubricant intake is much less compared to outside combustion engines

- In different words, an electric powered motor is capable of generate movement with the aid of using use of magnets and consequently its entire operation is ready magnets & magnetism.

- However, now there are even greater problems clouding the development of hybrid vehicle technology.

- Life Cycle Analysis and Life Cycle Cost Analysis examines and elements in the economic or electricity fees related to every level of the life-cycle version of a motor vehicle.

- Hybrid-Electric Vehicles emerged as a promising candidate to standard car, because it makes use of multiple "strength units" to supply efficiency.

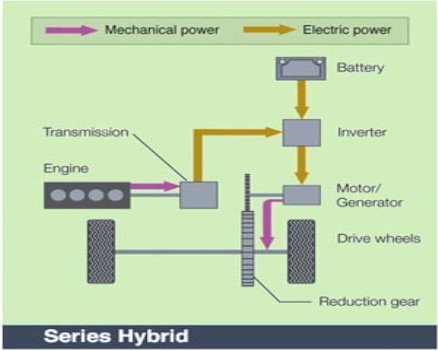

Series HEV:

Series (Extended-Range) Hybrid A collection hybrid is sort of a battery electric powered vehicle (BEV) in design.

The generator each costs a battery and powers an electric powered motor that movements the vehicle. When massive quantities of energy are required, the motor attracts energy from each the battery and the generator. Series hybrids will also be called prolonged-variety electric powered vehicles (EREVs) or variety-prolonged electric powered vehicles (REEVs) because the fueloline engine handiest generates energy to be utilized by the electrical motor and in no way immediately drives the wheels. Modern examples encompass the Cadillac ELR, Chevrolet Volt, and Fisker Karma.

Fig: Series HEV

- Advances in strength conversion generation, in addition to battery layout and efficiency, have enabled the enlargement of the generation into client markets with hybrid motors now to be had at a rate factor similar to traditional motors.

- Popular hybrid generation A famous shape of hybrid generation combines an Internal Combustion Engine (ICE) with an electric powered motor or motor.

- The ICE is commonly powered via way of means of fuel or diesel gas and the electrical cars are normally an induction kind or a Permanent Magnet AC (PMAC) layout. Hybrid motors may be maximum surely described as the ones which use multiple supply of strength.

- Hybrid structures may be in addition described via way of means of architecture: parallel or series, which suggests how the cars deliver strength to the vehicle’s wheels.

Series hybrid car advantages

- When as compared to the parallel hybrid design, collection hybrid structures acquire higher gas performance and emission reductions.

- Parallel hybrid motors have a tendency to be automatically complex, requiring a bigger combustion engine, a transmission, and a mechanism to couple each vehicles to the pressure wheels.

- Series hybrid motors haven't any connection among the ICE and the car pressure train, counting on saved electricity to offer for acceleration demands.

- This permits the ICE to run at optimum speeds ensuing in smaller, greater green engines.

- Since electric powered vehicles pressure the wheels, strength saving is likewise carried out via regenerative braking structures that use the car’s momentum to permit the traction motor to behave as a generator, offering braking torque to the wheels and returned to the batteries.

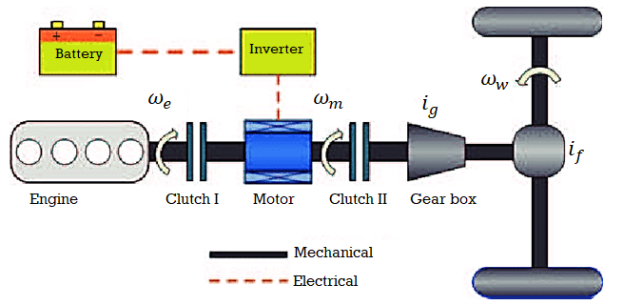

Parallel HEV:

In a parallel hybrid configuration, ICE and electric powered motor are linked in parallel to supply strength to the wheel as proven in Fig. 31.9. The powers from electric powered motor and ICE are pooled collectively with the assist of mechanical coupling.

However, the mechanical coupling provides to the complexity on top of things set of rules for the automobile. The automobile may be pushed with the ICE, the electrical motor, or each simultaneously, and therefore, it's miles feasible to feed the preferred quantity of strength at any given length of time [5–10]. In parallel HEV, besides modes VII, VIII, and IX, all different modes (I–VI) may be used for higher usage of strength reasserts and dependable operation.

In this configuration, efforts are made to function the electrical motor by myself at decrease pace and ICE by myself at better speeds.

In case of acceleration or hill climbing, each the strength reasserts are activated to meet the preferred strength demand. When ICE is operating by myself or in case of regenerative braking, the electrical motor can function as a generator to price the battery.

Fig: Parallel HEV

Advantages:

Parallel hybrids have a tendency to apply a smaller battery percent than collection drivetrains, counting on regenerative braking to hold it recharged. When electricity needs are low, parallel hybrids additionally make use of the motor as a generator for supplemental recharging, similar to an alternator in traditional cars.

General Considerations, sizing for performance, optimum sizing, and power management: Control Potential

Power and Mass Computations for Initial Vehicle

Sizing Hybrid electric powered cars (HEVs) are predicted to fulfill overall performance standards in order to compete effectively with traditional cars. The first criterion is the time required to boost up from 0 to 60 mph. The cars ought to additionally be capable of negotiate a minimal grade at a steady speed. Argonne advanced a version to compute electricity necessities related to those standards. Each drivetrain issue is sized to fulfill the electricity necessities and its mass is then computed. The version is defined in this section.

Power Requirements

The manner supplied right here estimates electricity necessities for accelerating on a flat road (no grade) and negotiating a grade represented through a perspective θ at a steady speed. We anticipate that the air continues to be and cars aren't required to boost up from a present to the most accelerate a hill or a ramp.

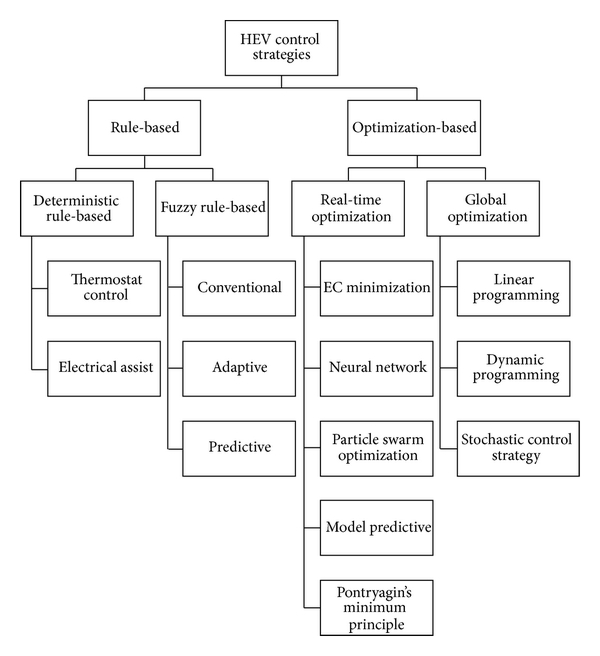

Acceleration Power

A hybrid vehicle that has an inertia mass of Mv and is accelerating on a flat road (i.e., 0° grade) would require a power Pa specified by the following equation.

Where

v = Vehicle speed

= Air density,

A = Vehicle frontal area,

Cd = Coefficient of aerodynamic drag,

g = Gravity, and

Cr = Coefficient of rolling resistance.

After the acceleration energy is determined, the drivetrain additives could be sized to permit for losses at diverse levels.

Since the car is accelerating from a forestall to a most pace vm, the acceleration energy necessities in equation 1 may be restated with the aid of using integrating the primary time period from 0 to vm.

Sizing Performance and Optimal Sizing:

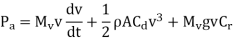

- It may be very essential to decide the specs of additives covered with inside the drive-educate of automobiles on the preliminary layout stage.

- In this study, an aspect sizing procedure and an overall performance evaluation for a plug-in hybrid electric powered transit bus (PHEB) as a chain kind hybrid gadget are mentioned primarily based totally on a sure gadget configuration and overall performance targets.

- Six varieties of riding cycles and numerous regeneration ratios (zero to 100%) are taken into consideration that allows you to estimate the battery ability so one can obtain an electric powered variety of as a minimum 20 km whilst the usable kingdom of charge (SOC) variety of the battery percent is confined from 90% to 20% of the entire battery ability.

- The score output energy of a gen-set (Engine Generator) is analyzed the use of a way that sustains the SOC degree of the battery in a charge-maintaining mode.

- The top energy of the engine and gen-set may be decided via way of means of thinking about the output traits of the battery percent and the riding motor.

- Also, this paper affords a definition of a highest quality gen-set running line to reduce gas intake at a hard and fast degree of electrical output energy. The gas intake effects are in comparison to the ones of a traditional highest quality running line.

Fig: Sizing workflow of HEV

Optimal Sizing:

It may be very essential to decide the specs of additives covered with inside the drive-educate of automobiles on the preliminary layout stage.

In this study, a aspect sizing procedure and an overall performance evaluation for a plug-in hybrid electric powered transit bus (PHEB) as a chain kind hybrid gadget are mentioned primarily based totally on a sure gadget configuration and overall performance targets.

Six varieties of riding cycles and numerous regeneration ratios (zero to 100%) are taken into consideration that allows you to estimate the battery ability so one can obtain an electric powered variety of as a minimum 20 km whilst the usable kingdom of charge (SOC) variety of the battery percent is confined from 90% to 20% of the entire battery ability.

The score output energy of a gen-set (Engine Generator) is analyzed the use of a way that sustains the SOC degree of the battery in a charge-maintaining mode. The top energy of the engine and gen-set may be decided via way of means of thinking about the output traits of the battery percent and the riding motor.

Also, this paper affords a definition of a highest quality gen-set running line to reduce gas intake at a hard and fast degree of electrical output energy. The gas intake effects are in comparison to the ones of a traditional highest quality running line.

Power Management and Control Potential:

Power control is a computing tool characteristic that lets in customers to govern the quantity of electrical electricity fed on through an underlying tool, with minimum effect on performance. It permits the switching of gadgets in diverse electricity modes, every with exclusive electricity utilization traits associated with tool performance.

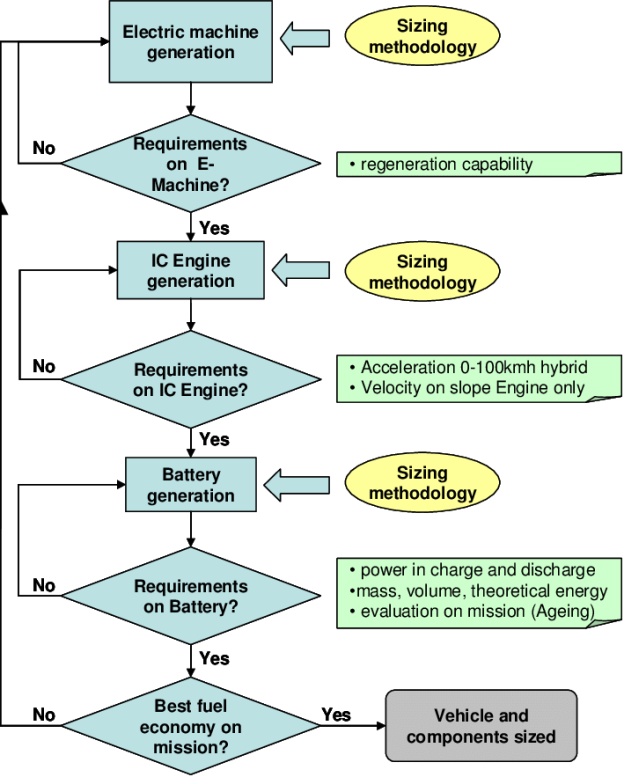

- With the fashion of low emissions and sustainable development, the call for for hybrid electric powered motors (HEVs) has extended rapidly.

- By combining a traditional inner combustion engine with one or extra electric powered cars powered with the aid of using a battery, HEVs have the blessings over conventional motors in higher gas financial system and decrease tailpipe emissions.

- Nevertheless, the energy control techniques (PMSs) for traditional motors which specifically consciousness at the performance of inner combustion engine are not relevant because of the complicated inner shape of HEVs. Hence, a massive quantity of novel techniques suitable for HEVs were surveyed, however maximum of the researches deal with discussing the classifications of PMSs and evaluating their cons and professionals.

- This paper affords a complete assessment of energy control techniques followed in HEVs aiming at unique demanding situations for the primary time. The classes of the prevailing PMSs are offered primarily based totally at the extraordinary algorithms, observed with the aid of using a short examine of every kind inclusive of the evaluation of its professionals and cons.

- Afterwards, the implementation and optimization of energy control techniques aiming at proposed demanding situations are added in element with the outline in their optimization targets and optimized results. Finally, destiny instructions and open troubles of PMSs in HEVs are discussed.

Control Potential:

- Controlled Potential Coulometer may be used as an absolute (standards-less) analytical method to decide many metals or compounds.

- By absolutely electrolyzing the analytic of hobby and noting the whole fee ate up, the amount of the analytic is without difficulty determined.

- Controlled Potential Coulometer also can be used to decide the general quantity of electrons in a faradaic reaction.

- Unlike voltammetry strategies in which the electrode location and diffusion coefficient of the redox species have to be known, Controlled Potential Coulometer can decide the general quantity of electrons with inside the redox procedure without earlier understanding of the electrode location or diffusion coefficient.

- In this method, the capability of the electrode is held steady for an extended time mines to hours and the ensuing incorporated fee is recorded.

Key Takeaways:

- However, the mechanical coupling provides to the complexity on top of things set of rules for the automobile.

- In this configuration, efforts are made to function the electrical motor by myself at decrease pace and ICE by myself at better speeds.

- Parallel hybrids have a tendency to apply a smaller battery percent than collection drivetrains, counting on regenerative braking to hold it recharged.

- The manner supplied right here estimates electricity necessities for accelerating on a flat road (no grade) and negotiating a grade represented through a perspective θ at a steady speed.

- After the acceleration energy is determined, the drivetrain additives could be sized to permit for losses at diverse levels.

- The top energy of the engine and gen-set may be decided via way of means of thinking about the output traits of the battery percent and the riding motor.

References:

1. Design Data - P.S.G. College of Technology, Coimbatore.

2. Vehicle Powertrain Systems by Behrooz Mashadi, David Crolla. A John Wiley & Sons, Ltd

3. Automobiles–Power trains and Automobiles–Dynamics by Crolla, David, A John Wiley &Sons, Ltd

4. Automotive Engineering Powertrain, Chassis System and Vehicle Body by David A Crolla, Elsevier B H New York, London, Oxford.

5. Lack P.H. And O. Eugene Adams, Machine Design, McGraw Hill Book Co. Inc.

6. Willium C. Orthwein, Machine Components Design, West Publishing Co. And Jaico Publications House.