UNIT 6

Introduction to Transportation Environmental and Irrigation Engineering

Flexible pavement

A typical flexible pavement consists of a bituminous surface course over base course and sub-base course. The surface course may consist of one or more bituminous or Hot Mix Asphalt (HMA) layers. These pavements have negligible flexure strength and hence undergo deformation under the action of loads. The structural capacity of flexible pavements is attained by the combined action of the different layers of the pavement. The load from trucks is directly applied on the wearing course, and it gets dispersed (in the form of a truncated cone) with depth in the base, sub base, and sub grade courses, and then ultimately to the ground. Since the stress induced by traffic loading is highest at the top, the surface layer has maximum stiffness (measured by resilient modulus) and contributes the most to pavement strength. The layers below have lesser stiffness but are equally important in the pavement composition. The sub grade layer is responsible for transferring the load from the above layers to the ground. Flexible pavements are designed in such a way that the load that reaches the sub grade does not exceed the bearing capacity of the sub grade soil. Consequently, the thicknesses of the layers above the sub grade vary depending upon strength of soil affecting the cost of a pavement to be constructed.

Rigid pavements

Rigid pavements are named so because of the high flexural rigidity of the concrete slab and hence the pavement structure deflects very little under loading due to the high modulus of elasticity of their surface course. The concrete slab is capable of distributing the traffic load into a large area with small depth which minimizes the need for a number of layers to help reduce the stress. The most common type of rigid pavement consists of dowel bars and tie bars. Dowel bars are short steel bars that provide a mechanical connection between slabs without restricting horizontal joint movement. Tie bars on the other hand, are either deformed steel bars or connectors used to hold the faces of abutting slabs in contact. Although they may provide some minimal amount of load transfer, they are not designed to act as load transfer devices and are simply used to ‘tie’ the two concrete slabs together.

Gauge – Inner to inner distance between two rails.

Types of Gauges

- Broad Gauge (BG) – 1.676m

- Meter Gauge (MG) – 1m

- Narrow Gauge – 0.762m

- Feether Track Gauge – 0.61m

Broad gauge is also called wide gauge or large line. The distance between the two tracks in these railway gauges is 1676 mm (5 ft 6 in). It would not be wrong to say that any gauge, wider than standard gauge or 1,435 mm (4 ft 8½ inches), is called broad gauge. Broad gauge railway is also used on ports for crane etc. This gives better stability and they are even better than thinner gauges.

Ballast forms the Bed upon which railway sleepers or railroad ties are laid. It is packed between and around the Sleepers. It is used to bear the load from the Sleepers, to facilitate drainage of water, and also to keep down vegetation that might interfere with the track structure. This also serves to hold the track in place as the trains roll by. It is typically made of crushed stone, although ballast has sometimes consisted of other, less suitable materials.

Formation consists of a certain number of rock strata that have a comparable or similar properties.

Sleeper is a rectangular support for the rail tracks. It is laid perpendicular to the rails, sleepers transfer loads to the track ballast and sub grade. Sleepers hold the rails upright, and keep them spaced to the correct gauge

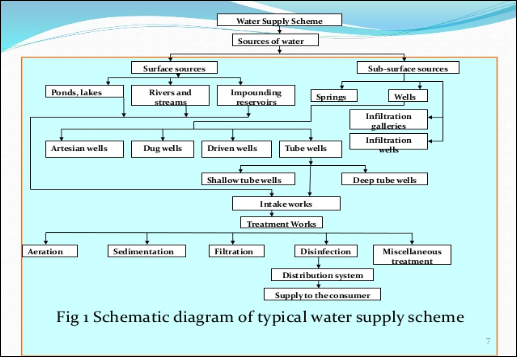

The major components of a water supply system include source, intake arrangements, pumping system, conveying main, treatment plant, storage and finally distribution system.

For the growth of plant/crops: adequate quantity and quality of water required in the root zone of the plant. However, in actual condition during the whole period of plant growth /partly there exists inadequacy of water to full fill the crop water requirements. Thus, the following factors govern the necessity of irrigation:

a) Insufficient rainfall: when the seasonal rainfall is less than the minimum requirement for the satisfactory growth of crops, the irrigation system is essential

b) Uneven distribution of rainfall: when the rainfall is not evenly distributed during the crop period or throughout the cultivable area, the irrigation is extremely necessary.

c) Improvement of perennial crops yield: some crops such as sugarcane etc require water throughout the major parts of the year but the rainfall fulfills the demand during the rainy season only. Therefore, for remaining part of the year irrigation is necessary.

d) Development of agriculture in the desert areas: in the desert, area where the rainfall is very scanty, irrigation is required for the development of agriculture.

e) Insurance of drought: irrigation may not required during the normal rainfall condition and can be necessary during drought.

Earthen Dam

An earthen dam is made of earth (or soil). It resists the forces exerted upon it mainly due to shear strength of soil. Although the weight of dam also helps in resisting the forces, the structural behaviour of earthen dam is entirely different from that of gravity dam.

An Earthen dam can be constructed on all types of foundations, provided suitable measures of foundation treatment and seepage control are taken.

Earthen dams are not suitable for narrow gorges with steep slopes. They are more earthquake resistance than gravity dams.

The maintenance cost of an earthen dam is quite high, requires constant supervision and sluices cannot be provided in a high earth dam to remove silt.

Gravity Dam

The gravity dams are massive constructions, built out of concrete or masonry, which counteract the force of water pressure with only action of self mass. First dam of this type was built around 1220 in Spain, and the building method remained the same until today, the only difference being the building technique and the materials used.

Gravity dams are well adopted for use as an overflow spillway section. Earthen dam cannot be used as an overflow spillway section. Even in earthen dams, the overflow section is usually gravity dam.

The gravity dam does not fail suddenly. There is enough warning of the imminent failure and the valuable property and human life can be saved to some extent.

The gravity dams are generally more expensive than earthen dams but are more durable.