UNIT - 1

INGREDIENTS OF CONCRETE

- India is the second largest cement producer in the world producing 502 million tons of cement per year. There are 210 large cement plants producing 410 million tons of cement annually and 350 small cement plants producing 92 million tons of cement per year. Therefore, the cement industry is deeply involved in the Indian economy.

- There is a great need for cement in India since the Indian government announced their projects and programs related to infrastructure construction, housing associations, road construction, etc. to grow the Indian economy. The real estate sector also proves to be a major driver that needs to account for 65% of India's total consumption.

- To address this demand for future purchases back in 1962, the Cement Manufacturing Association (CMA) was established with the aim of promoting cement sector growth, protecting consumer interest and identifying new cement uses.

Cement Raw Materials

- The Indian mining industry plays a vital role in supplying raw materials used in the cement industry. The most important raw materials used in the cement production process are Limestone found on mountain rock.

- Limestone stones are converted by a powerful metamorphism to turn into marbles. Other types of Limestone are marl, lime shell, algal limestone, coral limestone, pisolite limestone, crinoidal limestone, travertine, onyx, hydraulic limestone, limestone of lithographic, etc. frogs. The limestone mine produces 203,224 million tons of limestone which is widely used in the cement industry.

- Countries like Andhra Pradesh, Karnataka, Madhya Pradesh, Rajasthan, Gujrat, Meghalaya, Telangana have a large lake of limestone.

- Another important element of cement used is coal as a source of energy in the cement production process.

- For this purpose, raw charcoal is also crushed and stored in longitudinal warehouses and extracted by recycling by refineries before grinding fine charcoal.

- Jharkhand has the largest coal mines in India followed by Orissa, Madhya Pradesh, Chhattisgarh, West Bengal and Andhra Pradesh.

- Coal is used to heat raw materials at 1450 degrees centigrade to turn them into smaller ones. The quality of coal supplied to the cement industry depends on the degree of limestone used in the cement production process. If the limestone used in the cement production process is high quality, low coal is used and vice versa.

The Cement Manufacturing Process

- The process of cement production begins with the extraction of limestone mined in open mines. The limestone is then crushed to 80 mm in size and loaded into longitudinal cylinders. Limestone is extracted diagonally from these grinding reserves into green hop. As mentioned earlier, coal is used as fuel for burning raw materials in the cement production process.

- After obtaining cement raw materials from the Indian mining industry, limestone is transferred to an undercooked mill to be ground into a fine powder. This fine limestone powder is then heated to a maximum temperature of 1450 degrees centigrade for clinkerisation. Heat, this fine powder in those high-temperature countries is used in the clinkerisation phase. This raw material is mixed and placed in an electrostatic precipitator hole to keep it in concrete form. This is called fire food. Kiln feeds are pre-packaged for pyro processing.

- The pyro processing of granular food produces chunks of cement. Hot clinkers are then cooled down and placed in a bucket to be stored in clinker barns. After this phase, the clinker and gypsum are mixed together and sent to a mill for further grinding to form a fine powder. This fine gray cement powder is then packaged and sent to the market for sale.

Key take ways

India is the second largest cement producer in the world producing 502 million tons of cement per year. There are 210 large cement plants producing 410 million tons of cement annually and 350 small cement plants producing 92 million tons of cement per year. Therefore, the cement industry is deeply involved in the Indian economy.

There is a great need for cement in India since the Indian government announced their projects and programs related to infrastructure construction, housing associations, road construction, etc. to grow the Indian economy. The real estate sector also proves to be a major driver that needs to account for 65% of India's total consumption.

Introduction

Portland cement derives its power from chemical reactions between cement and water. This process is known as hydration. This is a complex process that is better understood by first understanding the chemical structure of cement.

Manufacturing of cement

Portland cement is made by grinding, grinding and measuring the following materials:

- Lime or calcium oxide, CaO: from limestone, chalk, shells, shale or calcareous rock

- Silica, SiO2: from sand, old bottles, clay or argillaceous rock

- Alumina, Al2O3: from bauxite, recycled aluminum, clay

- Iron, Fe2O3: from clay, iron ore, scrap iron and fly ash

- Gypsum, CaSO4.2H20: obtained with limestone

The building materials, with the exception of gypsum, are subdivided to produce the mixture and chemical composition you need and then grind and combine one of two processes - dry process or wet process. The building materials are then fired at 2,600º F to produce black-and-white-colored tablets known as clinker. Alumina and steel act as flexors that reduce the melting point of the silk from 3,000 to 2600º F. After this phase, clinker is cooled, sprayed and gypsum added to control the setting time. It is then properly buried to produce cement.

Chemical shorthand

Due to the complex chemical nature, a shorter form is used to represent chemical compounds. The basic chemical shorthand is:

Compound | Formula | Shorthand form |

Tri calcium aluminate | Ca O | C |

Silicone dioxide | SiO2 | S |

Aluminium oxide | Al2O3 | A |

Iron oxide | Fe2O3 | F |

Water | H2O | H |

Sulphate | SO3 | S |

Properties of cement compound

These compounds contribute to cement structures in a variety of ways

Tri calcium aluminate, C3A: -

- It releases a lot of heat during the initial hydration, but has a small energy impact. Gypsum reduces the hydration speed of C3A. Low cement in C3A resistance to sulfate.

Tri calcium silicate, C3S: -

- This mixture is watering and firming quickly. It is primarily responsible for the initial setup of port land cement and initial acquisition.

Di calcium silicate, C2S:

- The C2S pulls and tightens slightly. Mainly responsible for energy gain after one week.

Ferrite, C4AF:

- This is a flexible agent that reduces the melting temperature of the material used in the furnace (from 3,000o F to 2,600o F). It breathes quickly, but does not contribute much to the adhesive power of the cement.

- By mixing these chemicals properly, manufacturers can produce different types of cement to suit a number of construction sites.

Key take ways

The building materials, with the exception of gypsum, are subdivided to produce the mixture and chemical composition you need and then grind and combine one of two processes - dry process or wet process. The building materials are then fired at 2,600º F to produce black-and-white-colored tablets known as clinker. Alumina and steel act as flexors that reduce the melting point of the silk from 3,000 to 2600º F. After this phase, clinker is cooled, sprayed and gypsum added to control the setting time. It is then properly buried to produce cement.

- There are different grades of cement, the range of cement is nothing but the strength of the cement (The strength of a person who should lift the weight, is the same as how much energy is produced by cement.)

- We all know that cement is the first ingredient in concrete which means that the strength of cement is exactly the same as the strength of concrete. Therefore, one should have sufficient knowledge about the degree of cement and how it affects the construction.

- Distance is a matrix for measuring the strength of cement. There are different grades of cement. The strength of the cement increases as the quality of the cement increases. The end of the cement increases with increasing distance. The range of cement is selected according to the individual requirement and type of work.

Different Cement grades

No matter what cement you say. There are three different grades of Ordinary Portland cement available on the market.

33 Grade

43 Grade

53 Grade

33 Grade of cement

- By Indian standards, IS 269 - 2015, 33 The cement range means the Pressure after 28 days is 33N / mm2. This cement grade has expired and no one is using it in recent times. The 33 degree cement is not suitable for concrete over M20.

- Where can you use grade 33 cement

- This type of concrete is often used to build composite walls, horn walls, etc.

- The compression strength of 33 Grade Cement is 33N / mm2

43 Grade of cement

- As you already know the 43 cement grade means that the density strength of the cement when tested under CTM is 43N / mm2 according to Indian Standards, IS 8112 - 2013. Concrete grades up to M30 grade can be made using grade 43 cement.

Where can you use Grade 43 cement

- This type of cement is used to make Plain Cement Concrete (PCC) as well as for roofing walls, mud bricks, Pre cast materials such as tiles, Cement pipes.

- The Pressure Capacity of 43 Grade Cement is 43N / mm2.

53 rade of concrete

- This is the highest level of cement where anyone can easily buy in the market. The strength of the cement strength of 53N / mm2 is called 53 grade cement. The time to set the cement is faster compared to grades 33 and 43 of the cement. Any distance above M25 is easily accessible using grade 53 of cement.

Where can you use grade 53 cement

- This type of cement is used on Pre cast walls, Concrete Roads, Bridges, Dams, RCC for building works.

- The Pressure Capacity of 53 Grade Cement is 53N / mm2

Key take ways

No matter what cement you say. There are three different grades of Ordinary Portland cement available on the market.

33 Grade

43 Grade

53 Grade

- Through the process of hydration (Port reaction) the Portland cement mixed with sand, gravel and water produces a synthetic rock which we call concrete. Concrete is just as important a part of the modern world as it is with electricity or computers.

- Some pages on this website describe how PC is made and where it is located. Here, we will discuss what happens when water is mixed.

- Clinker is anhydrous (without water) from a hot fire. Cement powder is also waterproof if we ignore the small amount of water in any gypsum added to the clinker digestion phase.

- Water reaction is called "hydration". This involves many different reactions, which often occur simultaneously. As the reaction progresses, the products of the hydration process gradually combine with sand and gravel particles, and other concrete materials, to form a solid mass.

Hydration process: reaction

- In a waterless environment, four main types of minerals are commonly present: alite, belite, aluminate (C3A) and ferrite class (C4AF). For more information on clinker construction, see the clinker pages. Also available are small amounts of clinker sulfate (sodium sulphate, potassium and calcium) and gypsum, which were added while clinker was used to produce normal gray powder.

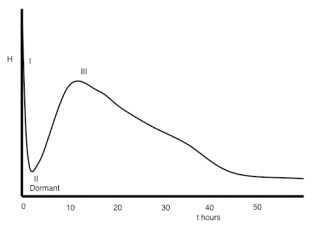

- When water is not heard, the reaction that takes place is mainly worse, that is, the reaction produces heat. We can find an indication of the rate at which minerals react by monitoring the rate at which temperatures change using a process called conduction calorimetry. An illustrative example of the emerging temperature curve shown is shown below.

|

Fig no 1

Graph

- A graph showing the emergence of a typical built-in temperature ranging from mixing to 60 hours

- Three main actions occurred: At about the same time in water, some clinker sulphates and gypsum are dissolved to produce an alkaline, sulfate solution.

- Immediately after mixing, phase (C3A) (which is active in four high-grade minerals) reacts with water to form a gel rich in aluminate (Phase I in the thermal transformation process above).

- The gel reacts with sulfate as a solution for the formation of small crystals such as ettringite. (C3A) water reaction is very stressful but does not last long, usually only a few minutes, and is followed by a few hours of low temperature exposure. This is called bedtime, or admission time (Phase II).

- The first half of the bedtime, up to maybe half a decade, depends on when the concrete can be laid. As bedtime progresses, the attachment becomes too hard to be used.

- At the end of the sleep period, alite and belite in the cement began to react, with the formation of calcium silicate hydrate and calcium hydroxide. This is similar to the main hydration period (Phase III), when the strength of the concrete increases. Each letter responds from the inside inside, and the non-anhydr particles are smaller. (C3A) hydration also continues, as new crystals reach the water.

- The time of high temperature change usually occurs between 10 and 20 hours after mixing and the tail moves slowly. In a compound that only contains PCs, most of the energy gain takes place within a month. When the PC is partially replaced by other materials, such as fly ash, power growth may occur slowly and last for several months or a year.

- Ferrite reaction also begins as soon as water is not added, but then subsides, probably because a layer of iron hydroxide gel form, covers ferrite and acts as a barrier, preventing further reactions.

Hydration Products

The reaction products between cement and water are called "hydration products." In concrete (or mud or other cement materials) there are four main types:

- Calcium silicate hydrate: this is the main reaction product and is the main source of concrete strength. It is often abbreviated, using cement chemical labeling, in "C-S-H," dashes indicating that no solid ratio of SiO2 and CaO is imported. The Si / Ca ratio varies but is usually approximately 0.45-0.50 in the Portland hydrated cement but up to about 0.6 in the presence of slag or ash fly or micro silica, depending on the values.

- Calcium hydroxide: (or Portlandite) - Ca (OH) 2, often abbreviated as 'CH.' CH is formed mainly from alite hydration. Alite has a Ca: Si ratio of 3: 1 and CSH has a Ca / Si ratio of about 2: 1, so excess lime is available to produce CH.

- A Fm and A Ft categories: these are the two groups of minerals found in cement, and elsewhere. One of the most common categories of A Fm in hydrated concrete is mono sulfate and the most common category of A Ft is ettringite. The common definitions of these phases are specific, but for example, ettringite is an A Ft class because it contains three molecules (t-tri) of anhydrite when labeled as C3A.3CaSO4.32H2O and mono sulfate AFM class because it contains one (m-mono) anhydrite molecule when labeled as C3A.CaSO4.12H2O.

The most common categories of A Ft and A Fm in hydrated concrete are:

- Ettringite: ettringite exists as crystals like rods in the early stages of the reaction or sometimes as a large growth that fills holes or cracks in mature concrete or mud. The chemical formula for ettringite is [Ca3Al (OH) 6.12H2O] 2.2H2O] or, mixing notifications, C3A.3CaSO4.32H2O.

- Mono sulfate: mono sulfate usually occurs in the latest stages of hydration, a day or two after mixing. The chemical formula of mono sulfate is C3A.CaSO4.12H2O. Note that ettringite and mono sulfate are compounds of C3A, CaSO4 (anhydrite) and water, in varying degrees.

- Mono carbonate: the presence of fine-grained stone, whether medium to cement or exposed as limestone aggregate, is likely to produce mono carbonate (C3A.CaCO3.11H2O) as other limestone rocks react with pore fluid cement.

Other possible A Fm categories are hemi carbonate, hydroxy-A Fm and Friedel salt.

Some important points to note about the A Fm and A Ft categories are:

- They contain a lot of water, especially A Ft - especially ettringite in the cement content.

- A Fm contains a higher amount of aluminum / calcium compared to AF t.

- Aluminum can be replaced by steel in both A Fm and A Ft categories.

- The sulfate ion in the mono sulfate A Fm phase can be replaced by other anions; one-time replacement if the anion is charged twice (e.g. carbonate, CO22-) or one-for-two if the replacement anion is charged separately (eg hydroxyl, OH- or chloride, Cl-).

- The sulfate in ettringite can be replaced by carbonate or, perhaps, replaced by two hydroxyl ions, although none of these are commonly seen.

- In cement-containing concrete containing only clinker and gypsum, ettringite forms early after mixing with cement and water, but is gradually replaced by mono sulfate. This is because the amount of alumina available with sulfate increases with continuous cement; upon first contact with water, most of the sulfate is readily available to dissolve, but much of the C3A is found within the cement particles without the presence of water first. Continuous hydration releases alumina slowly and the amount of ettringite decreases as this mono sulfate increases.

- If in the end there is more alumina than the available sulfate, all the sulfate will be like mono sulfate, more alumina is present as the A Fm phase is replaced by hydroxyl (hydroxy-A Fm). If there is too little sulfate, the cement paste will contain a mixture of mono sulfate and ettringite. With available sulfate, there will be more ettringite and less mono sulfate, and at higher levels of sulfate there will be ettringite and gypsum.

- In the presence of fine limestone, carbonate ions are available as other lime stones react. Carbonate dissolves sulfate or hydroxyl in A Fm; the amount of mono sulfate or hydroxy-A Fm therefore decreases as the amount of mono carbonate increases. Transferred sulfate usually mixes with the remaining mono sulfate to form ettringite, but in the presence of hydroxy-A Fm, the sulfate will remove hydroxyl ions to form more mono sulfate. The key here is the balance between alumina available on the one hand, and carbonate and sulfate on the other.

- Hydrogarnet: hydrogarnet forms mainly as a result of ferrite or C3A hydration. Hydrogarnets have a variety of formulations, C3AH6 which is the most common component from the normal hydration of cement and then only in small quantities. A wide range of hydrogarnet compositions can be found in autoclaved cement products.

Key take ways

Water reaction is called "hydration". This involves many different reactions, which often occur simultaneously. As the reaction progresses, the products of the hydration process gradually combine with sand and gravel particles, and other concrete materials, to form a solid mass.

When water is not heard, the reaction that takes place is mainly worse, that is, the reaction produces heat. We can find an indication of the rate at which minerals react by monitoring the rate at which temperatures change using a process called conduction calorimetry

Hydrogarnet: hydrogarnet forms mainly as a result of ferrite or C3A hydration.

Ordinary Portland cement

- It is the most common cement used in the construction industry. It has low resistance to chemical attack and has a moderate level of durability. The chemical composition of typical Portland cement is lime, silica, alumina, iron oxide, magnesia, Sulpher, trioxide, soda and potash. For a complete cement product the standard port land cement is about 80 to 90%. The color of typical Portland cement is gray or greenish-gray. It has a rate of energy development and the rate of hydration temperature is moderate. It has a resistance to cracking. Types of cement

Rapid hardening cement

- This cement is similar to ordinary Portland cement. It develops energy very quickly and is therefore called cement for high initial strength. It grows when it is three days old, the same strength as what is expected of a typical Portland cement in seven days.

- The rapid rate of energy growth is due to the high thickness of the cement particles giving a large area or action of water as well as high C3S and low C3S content. The high quality of the cement particles provides a large area for water formation and high C2S effects on fast hydration.

Uses

It is used for the construction of important buildings and underwater works. This cement contains a high percentage of cement. The light weight of the fast-acting cement and the short cooling of the water make its use more economical than conventional set cement. Types of cement

Purpose

- Road payment

- Precast concrete casting

Quick Setting cement (Types of Cement)

The cement starts very early in the morning. This material is extracted from reducing gypsum content during clinker digestion. This cement needed to be mixed, laid, and glued ahead of time.

Uses

- It is widely used in water construction.

- They are also not useful for grouting purposes.

- It is also used in cold and rainy weather.

Sulphate Resistant Cement

- This is the type of application where the concrete comes in direct contact with the soil. Portland cement cannot withstand the onslaught of suphates. Sulphate reacts with calcium hydroxide calcium aluminate. The result of this attack will lead to an increase and disruption of liquid cement paste. This attack is known as a Sulphate attack. Sulphate attacks will be more rapid in a different water environment and set as in a marine structure.

- To fix suphate attacks, cement use with low C3A content is found to be effective. Such cement with low C3A and low C4AF content is known as sulphate-resistant cement. This cement contains a high percentage of silicate. Cement-resistant sulphate is applied to the base and bottom where the soil is infected with suphates. It is also useful in the case of medical and marine facilities.

Uses

When the cement comes in direct contact with the soil

Purpose

- Pile foundation

- Sewage and water Soil treatment.

Low Heat Cement (types of cement)

- Cement hydration is a painful action that produces high temperatures during hydration. This heat of hydration causes cracks in a large concrete body. Technologists therefore produce cement, which produces a small amount of heat at a low rate during the hydration process. This type of cement varies by reducing the content of C3S and C3A which are elements that combine high hydration temperatures and increase C2S.

- The degree of heat exposure will be minimal, so heat exposure will extend for a long time. Therefore, the feature of low-temperature cement is the rapid rate of energy gain.

- But the final strength of low-temperature cement is the same as that of ordinary Portland cement.

Uses

This is the cement used for the construction of large concrete. Such as dam, storage operations, etc.

Portland cement Pozzolana

- It acquires high pressure strength over the years, in contrast to the fast hard cement. This cement is useful for marine and underwater construction. Pozzolans name gives the volcanic ash which is very rare. Pozzolans cement prepared by mixing and grinding clinkers and pozzolana together.

- Pozzolana, introduced with cement, reacts with free lime released during the cement hydration and prevents cracking of the concrete. The pozzolana region shall not be less than one percent and not more than one percent by the weight of the Portland pozzolana cement. Portland pozzolana low heat hydration and provides greater resistance to water attacks than ordinary Portland cement.

Uses

- Water tightness

- It is widely used in building construction

High Strength Cement

- For certain uses in the construction industry such as precast concrete, precast concrete requires high strength concrete. The construction industry therefore requires a special type of typical Portland cement with a very high compressive strength than the compressive strength specified for standard Portland cement.

- Cement that is much stronger than ordinary Portland cement is known as high strength ordinary Portland cement.

High Alumina Cement

It is made by melting a mixture of bauxite and lime and lime and grinding it into a fine powder. This cement contains 32% alumina.

- This cement is very expensive.

- There is no extension in the placement of this cement. It converts a lot of heat into laying so it should not be used in the construction of large concrete.

- It has the ability to withstand the action of acids and high temperatures. The use of high quality alumina cement is limited to oven operations and chemical plants.

Colored cement

Colored cement is used where cooling cement is needed for any relief purpose. Its product by mixing 5-10% pigment minerals with ordinary cement they make extensive use of floor decoration activities.

Uses

- Used for artificial marbles.

- Finishing down.

Air-conditioning cement

- Productive ventilation cement by adding indigenous ones are internal components such as resins, glues, sodium salt of sulphates, etc. During grinding clinker. Types of cement

- Cement goes a long way in improving the water efficiency of a small amount of water in cement and improving frost resistance.

Uses

- It uses concrete frost resistance

Expansive Cement

Increasing cement expands slightly over time and does not shrink during and after hardening. Types of cement

Uses

- This cement is mainly used to fasten anchor bolts and pre-pressurized concrete duets.

- Use in hydraulic structure.

Hydrographic cement

Hydrographic cement prepares by mixing water-soluble chemicals and has high efficiency and strength. It has a water repellent and is not affected during rain or shine. Hydrophobic cement mainly uses the construction of water structures such as dams, water tanks, spill channels, water storage structures, etc.

White cement

It prepares from unripe free iron oxide and is a typical white port land cement in color. It is expensive and used for construction purposes such as precast curtain wall and facing panels, terracazzo areas, etc. Also for interior and exterior decorating work such as exterior design of buildings, building faces, flooring, decorative concrete products, garden paths, swimming pools, etc. Types of cement

Key take ways

There are different type of cements

- Ordinary Portland cement

- Rapid hardening cement

- Quick settings cement

- Sulphate Resistant Cement

- Low heat Cement

- Portland cement Pozzolana

- High strength Cement

- High alumina Cement

- Color Cement

- Air-conditioning cement

- Hydrographic Cement

- White Cement

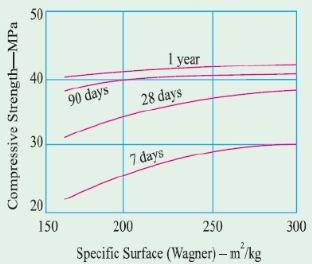

FINENESS

Objective

- The purity of the cement alone has a significant impact on the hydration rate and therefore on the energy gain rate and the degree of heat dissipation.

- Finer cement provides a large area of hydration Specific Surface versus Compressive Strength of Cement and as a result accelerates energy.

- The beauty of digestion has increased over the years. But now it is almost settled. Different cement is subject to different finishes.

- A particle size of less than 3 microns has been found to have a significant effect on energy in one day while a fraction of 3-25 micron has a significant effect on energy for 28 days.

- An increase in the thin layer is also found to increase the thickness of the concrete.

|

Fig no 2

Specific Surface versus Compressive Strength of Cement

Procedure

- Stir the sample of cement to be tested by stirring for 2 minutes in a preheated pot to distribute the agglomerates. Wait 2 min. Mix the resulting flour gently using a clean dry stick to spread the fine mixture all over the cement.

- Place the tray under a strainer, weigh about 10 g of cement in the nearest 0.01 g and place it in a strainer, being careful to avoid loss. Disperse any agglomerates. Place the lid on top of the filter.

- Cover the sieve with a circular motion, planetary motion and movement until it no longer exceeds the fine material in it. Remove and measure the rest. Specify its magnitude as a percentage, R1, of the pre-set filter per 0.1 percent nearby. Gently move all the fine material from the filter into the tray.

- Repeat the whole process using a new sample of 10 g to get R2. Then calculate the remnants of cement R as the value of R1, and R2, as a percentage, expressed in the percentage close to 0.1.

- When the results vary by more than 1 percent altogether, make a third reduction and calculate the meaning of the three values.

- Check the sieve after 100 filters per section 4.4.2 of IS: 4031 (Part 1)

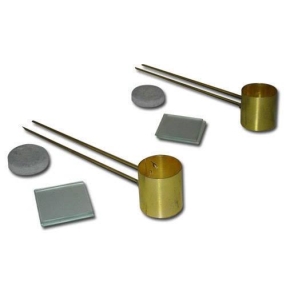

Apparatus used

Fig no 3 Cement

Fig no 4 Balance

Fig no 5 Seive

Fig no 6 Nylon Bristol Brush |

Key take ways

The purity of the cement alone has a significant impact on the hydration rate and therefore on the energy gain rate and the degree of heat dissipation.

Finer cement provides a large area of hydration Specific Surface versus Compressive Strength of Cement and as a result accelerates energy.

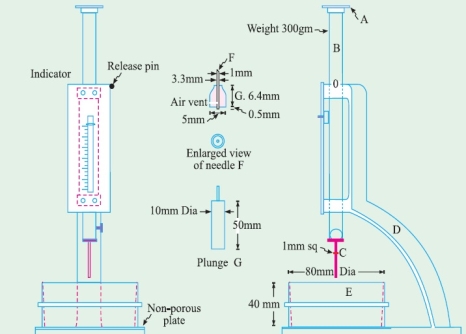

To determine the quantity of water required to produce a cement paste of standard consistency as per IS: 4031 (Part 4) – 1988

Apparatus

1) Vicat apparatus conforming to IS: 5513 – 1976

2) Balance, whose permissible variation at a load of 1000g should be +1.0g

3) Gauging trowel conforming to IS: 10086 – 1982

|

Fig no 7

Vicat apparatus

Procedure

- Measure about 400g cement and mix it with the required amount of water. Estimation time should be between 3 to 5 minutes.

- Fill the Vicat mold with glue and measure it with a trowel.

- Gently lower the plunger until it touches the cement.

- Release the plunger to allow it to sink into the paste.

- Note the reading in the scale.

- Repeat the above process and take new samples of cement with different water sizes until the gauge is 5 to 7mm.

Objective

- For simplicity, the initial set time is considered to have elapsed between the time when water can be added to the cement, at which point the paste begins to lose plastic.

- The last time is the last time the water is put in the cement, and the time when the glue is completely lost to the plastic and gained enough strength to withstand a certain direct pressure.

- The room temperature, dry material and water should be kept at 27 ± 2 ° C. The relative humidity associated with the laboratory will be 65 ± 5 percent.

Procedure

Preparation of test block

- Prepare a clean paste by measuring 0.85 times the water needed to give the glue a normal consistency. Portable or refined water will be used to prepare the paste. Attachments will be measured in accordance with the conditions set out in IS: 4031 (Part 4) -888.

- Start a stopwatch at a time when water can be added to the cement. Fill the Vicat mold with cement paint as limited as above, the mold stays on an empty plate. Fill the mold completely and spread the surface of the paste to make it to the top of the mold. The cement block is thus suspended from the test mold.

- Immediately after molding, place a barrier in a damp cupboard or damp room and allow it to remain there unless a set time is set.

Determination of initial setting time

- Place the test block enclosed in the mold and rest on a waterless plate, under a needle-carrying rod (C); gently lower the needle until it meets the surface of the test block and release it immediately, allowing it to enter the test area. Initially, the needle will completely pierce the test block.

|

Fig no 8

Needles used in Vicat's Apparatus

- Repeat this process until the needle, when attached to the test block and removed as described above, fails to pierce the block more than 5.0 ± 0.5 mm measured from the bottom of the mold. The time elapsed between the time the water is added to the cement and the time when the needle fails to pierce the block reaches a point of 5.0 ± 0.5 mm measured from the bottom of the mold will be the first set time.

Determination of final setting time

- Insert needle (C) of Vicat resources into the needle with a secret attachment (F).

- The cement will be considered to be set at the end where, when the needle is gently inserted into the surface of the test block, the needle makes a picture of it, while the attachment fails to do so.

- The time elapsed between the time the water is added to the cement and the time when the needle makes its appearance on the surface of the block while the attachment fails to do so will be the last set time.

- In the case of a scarf that forms over the test block, use the bottom of the block to cut.

Key take ways

For simplicity, the initial set time is considered to have elapsed between the time when water can be added to the cement, at which point the paste begins to lose plastic.

The last time is the last time the water is put in the cement, and the time when the glue is completely lost to the plastic and gained enough strength to withstand a certain direct pressure.

- Sensitivity refers to the ability of a glue that has been hardened to retain its volume after setting without the delay of harmful expansion.

- Thus, hearing is a very important test. The audio attachment will not make a pleasant volume change after it has hardened and as a result will not be in danger of forming cracks. Sound adhesive is the basis of sound mud or concrete mixing.

- Aircraft ash is the result of coal-fired power generation. During a fire, mineral pollutants in hot coals are released from the combustion chamber in the form of particles composed by flue gases.

- As these particles coo, they harden into round glass particles. The fly fly shows concrete structures and is used in concrete as replacement or replacement of concrete. Insufficiency can occur in the presence of very free magnesia or free lime burned in cement.

- The taste of cement can be determined in a variety of ways. In the Le Chatelier bath, a sample of cement / ash adhesive frosting is placed on the mold and boiled for a specified period of time (approximately 3hr) so that any tendency to stretch can be quickly and detected.

- After the boiling process is complete, the distance between the points of the two control indicators is measured by the nearest 0.5mm and compared to the first measured length before testing.

- This test requires Le Chatelier water bath, Le Chatelier mold, caliper, measuring cylinder, balance and length comparison. Active standards include EN 196-3, EN 459-2 and EN-450.

|

Fig no 9

Le chatelier apparatus

- Alternatively, the stability of the concrete can be determined by autoclave. These tests include an autoclave expansion of Portland cement using a test in a good cement sculpture.

- Specimens are made of oil-coated mold with reference points attached to a reference length of 250mm. Specimens extracted from the mold and measured after 24hr are placed in an autoclave at room temperature.

- After the autoclave is turned off, the specimens are exposed to a full-pressure current at a specified time. After the heating is complete, the template is rated and compared with the original length measurements.

- Equipment needed for this method includes autoclave, test bar mold, mixer equipment, balance and length gauge. Functional standards include ASTM C151 and AASHTO T107.

- The expansion of the cement can also be determined by comparing the length. The length gauge is a device used to measure changes in the length of attachment of cement, mortar and concrete according to ASTM and AASHTO data.

- The unit consists of a complex dial or digital display embedded in a solid, dual post frame structure. Moving and vertical anvils are designed to detect reference pins thrown at the edges of sample test bars.

- ELE offers a variety of devices for this method, including drying materials, shrinkage and humidity movements, as well as a ASTM-length ratio. Active standards include ASTM C151, C157, C227, C490, C531, AASHTO T-107 and T-160.

Key take ways

Sensitivity refers to the ability of a glue that has been hardened to retain its volume after setting without the delay of harmful expansion.

Thus, hearing is a very important test. The audio attachment will not make a pleasant volume change after it has hardened and as a result will not be in danger of forming cracks. Sound adhesive is the basis of sound mud or concrete mixing.

CLASSIFICATION OF AGGREGATE

The classification is based on: Grain Size

When you divide a combination by size, there are two categories listed above:

- Fine

- Coarse

Fine aggregate

- The size of a good combination is defined as 4.75mm or smaller. That is, a combination that can be passed through a filter number 4, with a mesh size of 4.75mm. Fine aggregates include materials such as sand, mud and clay. Crushed stone and crushed stone can also fall under this category.

- Typically, fine aggregates are used to improve the performance of a concrete mix.

Coarse aggregate

- Coarse collection size above 4.75mm limit. This may be a natural stone or gravel that has not been crushed or processed. These compounds will reduce the amount of water needed in the concrete mix, which can also reduce performance but improve its internal strength.

Classification is based on: Density

There are three variations based on the combination:

- Light weight

- Standard

- High density

- Different aggregates will have very different applications. Lightweight and lightweight figures are much stronger than some of their heavier ones, so they can be used extensively in the construction of a green roof, for example. They are also used in the mix of concrete blocks and corridors, as well as for installation and fire protection.

- High aggregates are used to build heavy concrete. Used when high strength, strong concrete structures are required - building foundations or pipework ballasting, for example.

Classification is based on: Geographic origin

Another way to differentiate aggregates by their origin you can do this in two groups:

- Nature - Aggregates taken from natural resources, such as rivers, quarries and mines. Sand, gravel, rock, and rock are the most common, and these can be either good or bad.

- Processed - Also called 'artificial composites', or 'product combinations', it is usually taken from industrial or engineering waste, and handled for the construction of high quality concrete joints. Common aggregates used include industrial slag, as well as burnt clay. Used aggregates are used for lightweight and high-strength concrete mixtures.

The classification is based on: Shape

Shape is one of the most effective ways of combining. The shape of your chosen joint will have a significant impact on the performance of your concrete. Aggregates purchased in batches from a reputable supplier may be in shape, if required, but you can also include aggregated shapes if you need them.

The different shapes of aggregate are:

- Rounded - Environmental conservation is smooth through climate change, soil erosion and attraction. Rocks, rocks, sand and stones found in rivers are your most common compounds. The circular collection is the main factor that makes it work.

- Unusual - These are also attractively designed, but they do not fit perfectly. These contain small stones and beads, and provide reduced performance for round joints.

- Angular - Used for high strength concrete, angular joints come in the form of crushed rock and stone. Performance is low, but this can be removed by filling the voids with round or small aggregates.

- Flaky - Described as smaller compounds in comparison to length and width. Increases surface area with concrete mixing.

- Combined - It also includes more surface area - which means that more cement paste is required. Combined compositions are larger than larger or wider.

- Flaky and extended - A combination of the previous two - and the most effective form of integration in terms of performance.

Key take ways

The classification is based on: Grain Size

Classification is based on: Density

Classification is based on: Geographic origin

The classification is based on: Shape

- Aggregates should be strong, strong, dense, strong, clear and free of veins and adhesive bonds.

- Aggregates should not contain harmful amounts of split pieces, alkalis, vegetable matter and other contaminants.

- Shiny and compacted pieces should not be present in a composite quantity.

- The total amount of crushed concrete should not exceed 45 percent of the composite applied concrete without erosion, and 30 percent of the erosion concrete area, such as airports, roads and parks.

- The value of the combined impact should not exceed 45 percent by weight in aggregates used for concrete without surface wear and 30 percent by weight for concrete wear in areas, such as airports, roads and parks.

- The amount of aggregated Abrasion when tested using a Los Angeles machine, should not exceed 30 percent by weight so that aggregates are applied to the coating surface and 50 percent by weight of aggregates used in other concrete.

- For concrete to be bound by exposure to the action of ice, coarse and fine aggregates will pass a rapid test of sodium or magnesium sulphate. Normally a normal weight loss, after 5 cycles of rapid testing of sodium or magnesium, should not exceed the following.

Key take ways

Aggregates should be strong, strong, dense, strong, clear and free of veins and adhesive bonds.

Aggregates should not contain harmful amounts of split pieces, alkalis, vegetable matter and other contaminants.

SPECIFIC GRAVITY

Gravity and the combined force of water are essential elements in the formation of concrete and bitumen mixtures. The thickness of a solid mass is a measure of its size to an equal volume of distilled water at a specified temperature. Because the compound can contain a void that is allowed to enter the water, two combined gravity measures are used:

- Apparent specific gravity and

- Bulk specific gravity

Apparent specific gravity, G app, is calculated on the basis of the volume of the number of compounds i.e. the volume without voids entering the water. Therefore

G app = [(MD / VN)] / W

Where,

- MD is a dry aggregate weight,

- VN integrated network volume without volume object focus,

- W the size of the water.

Bulk Specific Gravity, G bulk, is calculated on the basis of the total number of aggregates including the inlet. Therefore

G bulk = [(MD / VB)] / W

Where,

VB total volume of aggregates including volume of water absorbed.

GRADING OF AGGREGATE

- Collection placement determines the average grain size of the composite before it is used in construction.

- This is the use of a complex and clear combination. The combined sample is filtered through a set of sieves and weights stored in each filter by percentage words summarized.

- By dividing this amount by 100, The Fineness Modulus of that total is determined. This assists in the decision-making process about the number of well-known modular composites that must be combined to obtain the concrete of the desired quantity.

- The basis of a green and clear composite mix for a particular soft module is the presence of spaces or open spaces where the composite is packed together.

- For bad clean aggregates packing can leave 30-40 percent, which can only be removed by filling the fine particles.

- Similarly, in fine aggregates too, there are voids left to be filled with better particles (cement).

- This is important to get a mix of composite and blank letters.

- When other pieces of equal size are put together, voids or open spaces are always left. Percentage of voids can be as high as 45 percent of the total volume of aggregates.

- It turned out that this effect (presence of voids) was independent of the size of the aggregates used in the packaging, whether worse, medium or good.

- Only, while composite packaging should be of the same size, that is the same distance.

- Either all should be rough, or they should all be medium or good. This means that even if the sand alone is full, voids at a rate of 40-45 percent are left as well.

- This principle of spacing is the governing principle for the preparation of concrete under this method.

- When coarse aggregates are full to make concrete, the voids built into the weight should be filled with some good material. Sand is used for this purpose.

- However, there will be voids between the grains of sand as well. These are filled with cement particles.

- In this way, the weight of the resulting concrete is either empty or dense. Cement binding material is used to give this dense cone a stone-like character.

- Concrete, artificial stone, in a broad sense.

- Collection classification is intended to determine the particle size of a given group of composites.

- This is usually found by the Method of Fineness Modulus. This method can be used to determine the best modulus for coarse combinations, fine aggregates, and all composites, i.e., composite composites.

- In this way, the ideal weight of the sample is taken and filtered through a series of sieves respectively. The number of sieve is five in coarse aggregates and ten in all aggregates.

Sieve Size of Collection.

- Coarse Aggregates: 80 mm, 40 mm, 20 mm, 10 mm, IS No..480

- Fine Aggregates: Numbers 480, 240, 120, 60, 30 and 15.

- Total included: 80 mm, 40 mm, 20 mm, 10 mm, Nos: 480, 240, 120, 60, 30 and 15.

FLAKINESS INDEX

Object

For determination of flakiness index of coarse aggregate, where the size of the coarse aggregate are larger than 6.3mm .

Apparatus

- Thickness gauge

- Sieves [63, 50, 40, 31.5, 25, 20, 16, 12.5, 10 & 6.3mm]

- Balance [0-10 kg]

- Thickness Gauge

Procedure

- The sample was removed with the IS filter defined in the Table shown below.

- Thickness size and long length

- Thickness size and long length

- A minimum of 200 pieces for each fraction is taken and measured.

- In order to separate the faulty material, each component is individually measured by the thickness of the size gauge.

- The total amount of blurring objects that transmit the size gauge is measured with an accuracy of 0.1% of the sample weight.

ELONGATION INDEX

Objective

For determination of elongation index of coarse aggregate, where the size of the coarse aggregate are larger than 6.3 mm

Apparatus

- Length gauge

- Sieves (63mm,50mm,40mm,31.5mm,25mm,20mm,16mm,12.5mm,10mm)

- Balance (0-10kg)

- Oven (3000c)

Procedure

- The sample was removed with the IS filter defined in the Table shown below.

- A minimum of 200 pieces for each fraction is taken and measured.

- To separate the extended objects, each fraction is measured individually in length in the length gauge.

- Combined pieces from each tested segment that could not exceed the specified gauge length and its long cut sides are collected separately to obtain the total composite weight stored at the gauge length from each segment.

- The total amount of extended material retained by the length gauge is measured with an accuracy of 0.1% of the sample weight.

IMPACT VALUE

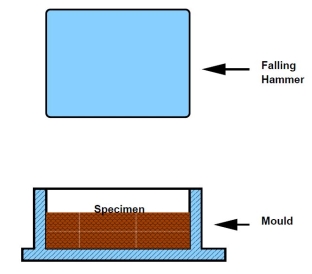

|

Fig no 10

Impact test apparatus

- Combined impact tests were performed to test for resistance to compound effects.

- The aggregates pass through a filter of 12.5 mm and are kept at 10 mm per filter are filled with a diameter of a diameter of 10.2 mm internal diameter and a depth of 5 cm attached to the metal base of the impact test machine.

- The content is completed in 3 layers where each layer is marked with 25 strokes.

- A steel hammer weighing 13.5 to 14 Kg is scheduled to be dropped with a free fall of 38.0 cm in v

- ertical directions and a test sample is placed at 15 hits.

- The crushed joint is allowed to pass through a filter of 2.36 mm IS. And the impact value is measured as the percentage of aggregates that pass through the filter (W2) to the total sample weight (W1).

Combined value = (W1 / W2) * 100

- Aggregates will be used to wear the course, the impact value should not exceed 30 percent. For bituminous macadams the maximum permissible value is 35 percent.

- In the basic studies of Water bound macadam the maximum allowable rate specified by the IRC is 40 percent.

ABRASION VALUE

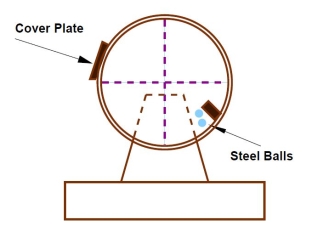

|

Fig no 11

Abrasion value setup

- Abrasion testing is performed to test the hardness of the material and to determine whether it is suitable for various stone construction activities.

- The abrasion test in Los Angeles is very popular to achieve hard materials and is standardized in India (IS: 2386 part-IV).

- The goal of the Los Angeles abrasion test is to find a percentage wear due to the rubbing action associated between the balls attached to the metal used as a serious offense.

- The Los Angeles machine consists of a 700 mm diameter inner diameter and 520 mm long attached to a horizontal axis that makes it possible to rotate (see Fig-2). A circular charge with round metal balls 48 mm wide and weighing 340-445 g is inserted into the cylinder and compound.

- The number of alrasive panorama varies depending on the sample size. The amount of compounds to be used depends on the catch and usually ranges from 5-10 kg.

- The cylinder is then locked and rotated at a speed of 30-33 rpm at a rate of 500 -1000 changes depending on the assembly rate.

- After the specified changes, the material is filtered through a filter of 1.7 mm and a fraction is transferred as a percentage of the sample weight. This figure is called the Los Angeles abrasion rate.

- A maximum of 40 per cent is allowed in the WBM study in the Indian state. In bituminous concrete, a maximum of 35 percent is specified.

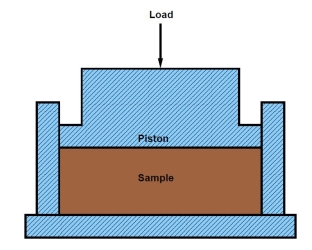

CRUSHING VALUE

|

Fig no 12

Crushing test setup

- One of the models where the material is paved where it fails to press down under joint pressure.

- The test was rated with IS: 2386 part-IV and used to determine the combined crushing power.

- The combined value of the crush provides an approximate level of crushing resistance under the gradual crushing load.

- The test consists of placing a composite sample in a standard mold in a pressure test under normal load conditions.

- Dry aggregates pass through 12.5 mm sieve and 10 mm sieve are stored with a cylindrical dimension of 11.5 mm in diameter and 18 cm in height in three layers. Each layer is applied 25 times with a standard lubricant.

- The test sample is weighed and placed in a test cylinder in three layers each layer is also softened. The specimen is under a pressure load of 40 tons used slowly at an average of 4 tons per minute.

- The aggregates are then compressed and reduced by a filter of 2.36 mm and the weight of the passing object (W2) is expressed as a percentage of the total sample weight (W1) which is the total crushing value.

Total crushing value = (W1 / W2) * 100

- A value less than 10 means a particularly strong combination while the above 35 can often be considered a weak combination.

Key take ways

There are different tests for coarse aggregate which are

1. Specific gravity

2. Grading of aggregate

3. Flakiness index

4. Elongation index

5. Impact value

6. Abrasion value

7. Crushing value

SPECIFIC GRAVITY

- The gravitational force of fine aggregate (sand) is defined as the mass of a given volume of aggregates in equal amounts of water. The gravitational force of fine aggregate (sand) is considered to be around 2.65 to 2.67.

- Quartz sand particles have a specific strength of between 2.65 to 2.67. While the odd clay starts from 2.70 to 2.80. Soils that contain a lot of organic matter or furry particles (such as diatomaceous earth) have a gravitational force of less than 2.60 (Some are as low as 2.00).

What is specific gravity of Aggregates?

The gravitational force of aggregate is considered to be the measure of the strength or quality of an object. The specified gravitational force is defined as the ratio of the weight of a given volume to a combination of the equivalent volume of water. Lower gravity scales are usually weaker than those with high gravity compounds. This property assists in the general identification of mergers.

|

Fig no 13

Pycnometer bottle

Determination of Specific Gravity of Fine Aggregate as per IS: 2386 Part 3: (1963)

Hello friends, welcome to the world of Civil Allied Gyan. Read here the description, the list of apparatus, the IS code, the testing process, the formula and the web report about the determination of the gravitational force of a good collection.

Resources Required for Specific Integrated Voting Power Testing: -

- Pycnometer bottle of capacity 1000ml

- Touch stick

- Trench

- Balance scale

Is the Gravity Specific of Fine Aggregate test code: -

IS: 2386 (Part 3): 1963, Methods for testing concrete scales (Determining Specific Gravity of aggregates)

Procedure

- Take a clean and dry pycnometer and determine its empty weight (W₁ g).

- Take a pure sample of fine aggregate (about 1kg) to determine the gravitational force and transfer that to the pycnometer and weight (W₂ g). Aggregates better than 6.3mm taken.

- Pour the refined water into a pycnometer with a mixed sample at a temperature of 27 ºC, to water the sample only.

- Immediately after immersion, remove trapped air from the sample by moving or alternating the pycnometer, placing a finger in the hole at the top of the closed pycnometer.

- Clear the outer area of the pycnometer. Now the pycnometer is completely filled with water until the top hole, and after making sure that there is no more air trapped in the pycnometer, its weight (W₃ g).

- Transfer the value of the pycnometer to the care test being performed to ensure that all the components are transmitted. Clean the pycnometer.

- Re-fill the pycnometer with the added water to the top of the pycnometer, without any trapped air. It should be completely dry on the outside and take off weight (W₄ g).

- To fill the mineral, a special magnetic field bottle is used and the equipment is filled up to three times the volume of the bottle. The whole process of determining gravity is similar to that described above.

SEIVE ANALYSIS

Objectives:

The whole process of sieve analysis determines the distribution of particle size of fine aggregates and determines whether it is suitable for use in concrete mixing.

Testing Resources

A series of IS filters

4.75 mm

2.36 mm

1.18 mm

600 mic

300 mic

150 mic

75 mic

Procedure

- The sample was weighed exactly 1000g.

- First, we must clean all the sieve using a wire brush to make it clear that aggregates are trapped in some gaps.

- After that we have to prepare the sieve in the moving machine from top to bottom, in size from the largest (4.75mm) to the smallest (0.075mm).

- The sample was diluted using a collection of IS Sieves 10 minutes.

- After sieving is done, the merging with each filter is measured individually.

- The aggregate weight that passes through each filter is calculated as a percentage of the total sample weight.

- The same procedure is followed by two other samples.

|

Fig no 14

Mechanical Sieve Shaker

FINENESS MODULES

The fineness modulus (FM) of aggregates may be a frightening term, but it is just a conceptual measure that describes the average size of particles in a composite sample. This feature provides the basis for selecting the approximate size of concrete joint design, but its actual impact is not always understood. The Fineness modulus is not a fixed value, as it provides a way to estimate the amount of integration needed to measure the mixing designs.

How to fineness modulus measure

Fineness modulus is determined using the percentage of size fractions from the sieve analysis and calculated for any selected series of sieve sizes. When designing concrete mixes, FM for good mixing is required to properly separate the mixes. Changes in the placement of the coarse aggregate section have little effect on the overall concrete structures. Combined partitions can be made using different cutting and fine-grained joints and blending techniques to control FM with concrete mix.

Origin of the Fineness Modulus Concept

Duff Abrams, an American inventor of the early 20th century, was an influential figure in the study of concrete structures and features. As well as explaining the importance of water / cement ratio and developing a fall test, he described the fineness modulus in 1918 as a way to separate concrete aggregates, simplify a gradation curve, and measure the appropriate size for use in mixing designs. Explaining the principle he said, "The integration of the same good modulus will require the same amount of water to produce the same coherence and provide the same strength concrete."

Includes Fineness Modulus

The simple FM calculation procedure requires a precise particle size analysis as described in ASTM C136, Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. In addition to the required particle size sizes, specific FM statistics must be included. Although manual upgrade of the sieve is permissible in standard, Gilson strongly recommends the use of the appropriate connector to ensure accuracy, durability and efficiency. After the filter has been analyzed and the fractions are measured in the correct proportions or proportions, the percentage of fractions is calculated.

Fineness Modulus of sand

To calculate the simple sand module, the total percentage accumulated stored in the following sieve is divided into 100: 150μm (No. 100), 300μm (No. 50), 600-μm (No. 30), 1.18mm (No. 16) , 2.36mm (No. 8), and 4.75mm (No. 4) of fine aggregates. If FM coarse aggregates are required, filters of 9.5mm (3⁄8in.), 19.0mm (3⁄4in), 37.5mm (11⁄2in) can be installed. There may be even larger sieves that can be added by continuing at a ratio of 2: 1 with the original sieve size. No additional equipment is required to make the determination. The same ASTM E11 test filters are used for integrated particle size analysis tests. In the example below, aggregate percentages from 4.75mm to 150µm are used to calculate the correct modulus for this fine mixing sample.

ALKALI AGGREGATE REACTION

- Alkaline reaction - silica (ASR), more commonly known as "concrete cancer", is a painful inflammatory process that occurs over time in concrete between alkaline cement and active amorphous (eg, non-crystalline) silica found in many common compounds, sufficient moisture is provided.

- The pattern of cracks is associated with an alkaline-silica reaction that affects the concrete step barrier on the US highway. Note the common oily feature of the silicage debris embibing the concrete surface on both sides of the crack.

- This undesirable chemical reaction results in the expansion of the altered composition by the formation of soluble and viscous gel of sodium silicate (Na2SiO3 • nH2O, and marked Na2H2SiO4 • nH2O, or N-S (sodium silicate hydrate), depending on the assembly received).

- This hygroscopic gel swells and increases in volume as it absorbs water: it has a high pressure inside the siliceous compound, which causes cracks and loss of concrete strength, eventually leading to its failure.

- The ASR can lead to severe cracking of the concrete, leading to serious structural problems that could force the demolition of a particular building.

- The extension of the concrete reaction between cement and composite size was first studied by Thomas E. Stanton in California in the 1930s with his publication in 1940.

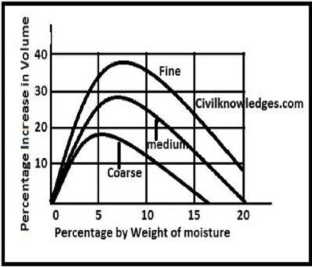

BUCKLING OF SAND

- The increase in volume of a good compound due to the presence of moisture content is known as bulking. This is because the moisture causes a film of water around the sand particles leading to an increase in the volume of the sand, at a moisture content of about 5 to 8%, this increase in volume can be 20 to 40%, depending on the placement of the sand.

- The more effective it is, the more volume will be given to the moisture content provided. This practice is known as sand bulking.

- As the moisture content increases by adding more water, sand particles accumulate closer and the bulking value of the sand decreases. Therefore, dry sand and water-soaked sand are about the same size.

- Constipation of sand affects the balance of the sand to a large extent. Most with fine sand and less with coarse sand. If the right grant is not made for sand extraction, the cost of concrete, and vehicles will increase and it will result in less sandy loam and hard to operate and maintain.

Important facts regarding sand formation are as follows

- As the moisture content increases by adding more water, sand particles accumulate closer and the bulking value of the sand decreases.

- One of the reasons for adopting a weight measurement is the constipation of sand as weight loss avoids difficulty due to the abundance of sand.

- Sanding of the sand should be considered when the volumetric value of the value is accepted.

|

Fig no 15

Buckling of fine aggregate

Determining of buckling of fine aggregate

Opera and the process of determining the best percentage output

- Laboratory testing of bulk composites

- Field test for average quantity

Fine Aggregate Collection Laboratory Testing

Apparatus

- 250 ml measuring cylinder

- Weight balance

- Good combination

Procedure

- Take 500 grams of frozen fine aggregate at a temperature of 100 to 110 degrees Celsius for 24 hours. This is a weight measure as W1.

- Cool sand picks up airtight containers. So this weight ratio as W2.

- Sample water content is calculated as

Wc = (W1-W2) X 100 / W1

- In a pan, 250 grams of sand take.

- In this case 2% by weight of water add. This is well integrated.

- The mixture is poured into a 250ml cylinder. This is compounded by shanking.

- The test was repeated with the remaining amount of 2% water sand at each time point. The reading takes as Y2, Y3… etc until the volume reading decreases.

- After their level, 4% of the water is added and the test continues until the sample is completely filled.

- For a standard sample in a measuring cylinder, add about 50 ml of water and stir the sample well.

ARTIFICIAL AND RECYCLED AGGREGATE

Artificial aggregates

- Many synthetic aggregates can be controlled, by industrial process products, such as various slags, or uncontrolled waste from other industrial processes, such as clinkers and ashes.

- Another important source of waste is the mining industry, including the extraction of coal and china clay.

- Some products that come out once or the waste can be made, or need to be recycled, to make things that are suitable for use as concrete mixers or that show special properties. In addition, other natural materials, such as perlite or vermiculite, can also be processed to produce compounds that reflect special properties.

- Demolition debris is reused to produce concrete scales. The RILEM (TC-121) technical committee recommended the separation of those compounds.

Recycled aggregate

- The construction industry produces a large amount of waste that needs to be recycled and used as recycled aggregates (RAs) for partial or complete environmental integration.

- Recycling reduces waste and reduces energy consumption and that is why it has an impact on the sustainable construction industry.

- In this chapter the need to redefine the current situation and situation around the world is highlighted. The structures of the RA are discussed. RAs weigh less than viral substances and higher water absorption.

- The state of the art of RA performance of concrete in a new and difficult world is summarized. The RA concrete exhibits low pressure and flexibility as well as low-strength mode and low cracking due to the porous nature of the RA and the old mud attached to the cement above the composite.

- The strength of the bond and the strength of the abrasion are less affected. Depletion, water infiltration and water infiltration by capillary increase with increased RA content.

- However, low performance can be reduced with a good mixing design using cement additives. Successful applications for RA in the manufacture of adhesive and truck concrete are also being discussed

Key take ways

There are different type of test for fine aggregate which are

1. Specific gravity

2. Seive analysis

3. Fineness modulus

4. Alkali aggregate

5. Buckling of sand

6. Artificial and recycle aggregate

GENERAL REQUIREMENTS

- Water used for mixing and curing shall be clean and free from injurious amounts of Oils, Acids, Alkalis, Salts, Sugar, Organic materials

- Potable water is generally considered satisfactory for mixing concrete

- Mixing and curing with sea water shall not be permitted.

- The pH value shall not be less than 6

The permissible limit for solid in water

Solid | Permessible limit |

Organic | 200 mg/l |

Inorganic | 3000 mg / l |

Sulphate | 500 mg/l |

Chloride | 500 mg/l |

Suspended matter | 2000 mg / l |

Key take ways

Water used for mixing and curing shall be clean and free from injurious amounts of Oils, Acids, Alkalis, Salts, Sugar, Organic materials

Introduction

- Concrete is a chemical compound made of binding materials and water-repellent materials. It is a popular construction material because of its unique durability and sensible strength; more interesting can be modified and designed for different energy needs and set under changing environmental conditions.

- Cement is the most important component of concrete produced at the expense of natural CO2 emissions; production of 1 ton cement is about to emit CO2 900 kg from the environment. So materials like these that use high energy form concrete that can be very sensitive (in terms of strength and durability) with available and cheap but valuable water; precise contamination of water.

- The quality of the water mix is highly dependent on the performance of the concrete in both new and difficult areas.

- Contamination in water mixing can interfere with the adhesion setting time and can have a detrimental effect on the strength and durability of the concrete.

- When contaminants are chemically active, they can contribute to chemical reactions that offer significant changes in the placement, hardening and development of concrete strength. Excess of health risk during handling this water should be considered carefully.

- In this case the previous operation of a particular water source can be used to assess the suitability of the water; if not available, further tests can be avoided to test the water during setup, compression strength and durability.

Water Function in Concrete

Three waters serve the following purpose:

- Moisten the surface of the compounds to improve adhesion because the cement paste adheres faster and satisfies the wet surface of the aggregates than on the dry surface.

- Preparing the plastic mixture of various ingredients and providing concrete performance makes it easy to put in the desired location as well

- Water is also needed for cement mortar to be set and strong during curing.

- The amount of water in the junction plays an important role in the strength of the concrete. Some water has a detrimental effect on hard concrete. Sometimes it may be harmless or beneficial during mixing. A clear distinction should therefore be made between the effect on solid concrete and the quality of the water mix.

Potable water as mixing water

- The general specification regarding the quality of water mixing should be suitable for drinking. Such water should have an unusual strength of less than 1000 ppm. This content results in a solid value of 0.05% of the weight of the cement when the w / c ratio is given to 0.5 resulting in a small impact on energy.

- But some non-potable water can be used to make concrete for any significant effect. Dark color or odor of water can be used if they do not contain harmful substances. Water pH to 9 is allowed if it does not like brak. In coastal areas where local water is salty and free of other sources, suspension of chloride up to 1000 ppm is also permitted for drinking. But these excess amounts of alkali carbonates and bicarbonates, in some natural mineral water, can cause an alkali-silica reaction.

Key take ways

Concrete is a chemical compound made of binding materials and water-repellent materials. It is a popular construction material because of its unique durability and sensible strength; more interesting can be modified and designed for different energy needs and set under changing environmental conditions.

Cement is the most important component of concrete produced at the expense of natural CO2 emissions; production of 1 ton cement is about to emit CO2 900 kg from the environment. So materials like these that use high energy form concrete that can be very sensitive (in terms of strength and durability) with available and cheap but valuable water; precise contamination of water.

References

1. Shetty M.S. Concrete technology S Chand publication

2. GAMBHIR M.L. Concrete technology Tata McGraw Hill

3. A.M Neville J.J.Brooks Concrete technology

4. A.M Neville Concrete technology