UNIT - 2

FRESH CONCRETE

WHAT IS THE WORKABILITY OF CONCRETE

- Concrete performance is a broad and automated term that describes how freshly mixed concrete can be easily mixed, laid, assembled and finished with minimal loss of homosexuality.

- Performance is an asset that directly affects the power, quality, appearance, and even personnel costs of placement and completion.

- But ideas are not very important when testing and documenting concrete structures, so how are these quality factors explained in terms of measurement values.

- This will include everything you need to know about concrete operations, contact materials, descriptive tests, and downhill test kits to test you.

- The use of the word indicates the ease or difficulty with which concrete is handled, delivered and laid.

- The amount of water available in concrete should be at the right level. Generally, a high amount of cement water is required for it to work properly.

- In the real work of water is to lubricate the concrete. Easy concrete to manage and install active concrete.

Types of workability

1. Low workable concrete

2. Medium workable concrete

3. High Workable concrete

1. Low workable concrete

- Poor concrete can also mean rough concrete. Low-water concrete is known as underutilized concrete. It is difficult to mix the concrete by hand. Its water content of cement is less than 0.4, and the compaction factor of this concrete is about 0.85.

- The low working concrete has a complete concrete separation due to the lack of cement adhesive tile to adhere to the aggregates. Maintaining such a concrete surface is difficult and requires a great deal of effort.

2. Medium workable concrete

- Medium working concrete is useful for almost all construction work. This type of concrete allows ease of mixing, transport, placement, and assembly without losing homogeneity.

- This concrete does not show much variation. The density factor of such concrete is about 0.92, and the water content of cement is 0.4 to 0.55. This type of concrete is ideal for strong reinforcement construction work

3. High Workable concrete

- This type of concrete provides great ease of mixing, transporting, laying, and assembling. This concrete is useful for that construction project when adequate integration is not possible.

- This type of concrete flows smoothly and settles down without much effort, but there is a strong possibility of separation and the loss of homosexuality in this situation. The water level of the cement in this concrete is more than 0.55.

- Due to the high amount of water cement, the green mixture usually settles to the ground, and then a concrete slab appears. This concrete is suitable when the density of the concrete is high, and vibration of the concrete is not possible. Joint concrete (SSC) is an example of high quality concrete.

- Good Workability Means Different Things to Different People

- There are different expectations and agendas for all construction / construction team groups when it comes to good concrete construction.

- A building engineer wants high strength and good bond with reinforcing steel. The architect is concerned with the attraction of cosmetics.

- The carrying capacity is attractive to the owner because it allows for smaller parts of the material and therefore more user-friendly space.

- The worker needs a blend that can be delivered, packaged, and blended well, and the finish maker is looking for something that takes a solid, high-quality finish quickly and easily.

- The combination of concrete and good performance brings many qualities together in balance and leads to a quality product with a long working life.

The dimensions and features of the building materials and structures of admixtures all contribute to the functionality and other characteristics of all concrete composite drawings, functional impacts including:

Water / cement ratio:

- The higher the amount of cement or cement reinforcement material usually means the greater the strength, and with the right amount of water, the more glue you put in layers for easier mixing and better finishing.

- Not enough water for proper hydration means an increase in negative energy and non-compliant combinations that resist easy installation and elimination. Adding more water may increase performance because it makes it easier to set and mix.

- However, the negative impact on segregation, termination of performance, and retention potential can be so detrimental that you have to approach with extreme caution. Water to a cementitious material ratio (w / cm) of 0.45 to 0.6 is a good place for the production of active concrete.

Combined Size and Shape:

- As the composite surface area increases, more cement paste is required to cover the entire joint area. So mixing with smaller aggregates is less effective compared to larger-size combinations.

- Combined, angular, and hollow joints are difficult to assemble and place and have a large cover area, reducing performance.

- The circular collection has a low surface area, but does not have the angularity of improving the bond strength sufficient for cement adhesion.

- Crushed composites in the right proportions provide better bonding with the cement matrix and adequate performance.

Admixtures:

- Many types of admixtures change the performance of a new concrete, either by construction or as a side effect.

- Surfactants such as super plasticizers reduce the attraction between cement and composite particles, allowing compounds that can flow without negative energy and the effects of excess water separation.

- The insertion of internal admixtures of durability / dissolving solids produces internal bubbles of a controlled size that can make it easier to eliminate, although overuse produces an adhesive mix with a different effect.

Grading of concrete

- If the combination is well organized, that means less content will be empty and higher content will work, so as far as possible, the combination should be well organized.

- Surface texture of aggregate

- If the surface of the aggregates is smooth or glassy, it will produce less surface and will provide better performance.

- The contrasting resistance between the smooth particle is reduced and will produce higher performance. So this is an important factor in performance.

Amount of cement

- The concrete content greatly affects the performance of the concrete. If we increase the size of the cement, much will be the cement paste to cover the surface of the composite and the useless filling.

- It helps to reduce the friction between the composites that have led to the smooth movement of aggregates in the transport, placement, and bonding of the concrete.

- At a fixed amount of cement water, an increase in the amount of cement will increase the amount of water per concrete per unit, which is why it increases the efficiency of the concrete.

Key take ways

Factors affecting Workability

Water cement ratio

Combined size and shape

Admixture

Grading of concrete

Amount of cement

1. Slum cone test

Objective

- The word ―workable or concrete used has a broader and deeper meaning than the word alternative that is commonly used freely to make it work. Consistency is a general term that indicates the level of fluid or flow rate.

- Factors that help concrete to have the most effective effect of reducing internal friction that facilitates easy mixing are:

(a) Water content

(b) Mixing Dimensions

(c) Collection Size

(d) Structure Shapes

(e) Spatial Design Design

(f) Placement layout

(g) Use of Admixtures.

- Slump test is the most widely used method of measuring the consistency of concrete that can be used in a laboratory or in the workplace.

- It is not suitable for very wet or very dry concrete. It does not measure all factors that affect performance, nor does it always represent concrete placement.

- Indicates the concrete feature above the drop value. When the concrete slips evenly it is called a true slump. When one part of the lump slips, it is called a shear slump.

- In the event of a shear bend, the slump value is measured as the height difference between the height of the mold and the average amount of shrinkage.

|

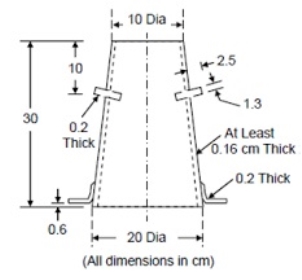

Fig no 1

Slum cone

Procedure

- If this test is performed in the field, a mixed concrete sample will be obtained. In the case of concrete containing a diameter of more than 38 mm, the concrete will be diluted with water by one and a half inches of screen to remove compacted particles larger than 38 mm.

- The inner surface of the mold will be thoroughly cleaned and freed from unwanted moisture and pre-set concrete before testing. The mold will be placed on a smooth, horizontal, strong, and non-abrasive surface, such as a carefully weighed metal table, the mold will be kept firmly in place while filling.

- The mold will be filled in four layers, each about a quarter of the height of the mold. Each layer will be smoothed with twenty-five lashes on the round edge of the lubricating rod. The lashes will be distributed evenly over the section at the cross section of the mold and the second and subsequent layers will fit into the lower layer.

- The bottom layer will be smoothed in the depth of it all. After the upper layer has been coated, the concrete will be flattened and trimmed with a trowel, so that the mold will fill directly.

- After the top layer has been glued, remove the concrete surface by moving and moving the lubricating rod.

- Any mud that may have leaked between the mold and the base plate should be cleaned. The mold will be removed from the concrete immediately by lifting it gently and carefully in a vertical direction. This allows the concrete to drop and the fall will be measured immediately by determining the difference between the height of the mold and that of the highest of the test template.

- The above operation will be performed in a non-vibrating or panic-free environment, and within two minutes after sampling.

|

Fig no 2

Dimensions of slum cone

2. COMPACTION FACTOR TEST

Objective

The compacting factor test is mainly designed for use in the laboratory but can also be used in the field. It is more accurate and sensitive than fall testing and is especially useful for very low-performance concrete mixes and is often used when the concrete will be squeezed by vibration. This method works on bare and ventilated concrete, made of lightweight, standard weight or heavy aggregates with a maximum weight of 38 mm or less but not on open concrete or non-reinforced concrete.

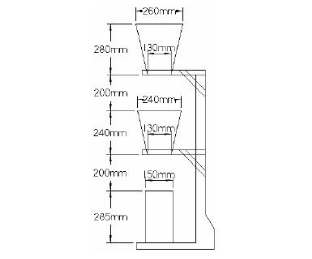

|

Fig no 3

Compaction factor apparatus

Procedure

- A sample of the test concrete will be gently placed on the upper hopper, using a hand scoop. The hopper will be evenly filled with its edge and the trap door will be opened so that the concrete falls to the ground.

- Some mixes tend to stick to one or both hoppers. When this happens, the concrete can be helped by pushing the rod gently into the concrete from the top. During this process, the cylinder will be covered with tiles.

- As soon as the concrete is out, the cylinder will be exposed, the door to the bottom trap will be opened, and the concrete will be allowed to fall into the cylinder. The remaining concrete over the top of the cylinder will be removed by holding a trowel in each hand, the plane of the belts horizontally, and then moving them simultaneously to each side above the cylinder, at the same time keeping them pressed against the upper edge of the cylinder.

- The outside of the cylinder when it is wiped will be clean. The above work will be done in a place that will not tremble or shake. The weight of the concrete in the container will be determined by the nearest 10 g.

- The remaining concrete over the top of the cylinder will be removed by holding a trowel in each hand, the plane of the belts horizontally, and then moving them simultaneously to each side above the cylinder, at the same time keeping them pressed against the upper edge of the cylinder. The outside of the cylinder when it is wiped will be clean. The whole process will be done in a place where there is no vibration or shock.

- This weight will be known as the weight of the partially bonded concrete. The cylinder will be filled with concrete from the same sample with layers about 5 cm deep, the layers folded tightly

- or shaken to achieve complete integration.

- The surface of the fully covered concrete will be carefully beaten and weighed above the cylinder. The outside of the cylinder when it is wiped will be clean.

|

Fig no 4

Dimensions of compaction factor apparatus

3. Flow test

Flow tests were performed to measure the performance of the concrete. As the name suggests, in this experiment concrete performance is measured by examining the flow of concrete material. Flow test Easy laboratory test. This test applies to the principal for the general weight loss of concrete and is measured by the flow of concrete. The flow of concrete indicates the performance of the new concrete.

Why flow test of concrete required

Flow tests are used to measure the performance of high or very active concrete, which ultimately indicates a fall. It gives an idea about the quality of concrete in terms of consistency and consistency. This performance test is easy to perform and is best suited for concrete with a high overall size of the joint less than 38 mm.

Flow Test Apparatus

Metal Cone or Mould: Mould is in the form of a frustum of a cone with a base diameter of 250 mm, upper surface diameter of 170 mm and 120 mm height. The mould comes with handles for support.

Flow Table

Trowels

Hand scoop

Scale

Tamping Rod

|

Fig no 5

Flow test apparatus

Procedure

- Clean anything toxic or dusty from the flow table and inside the mold.

- Place the lump on the marked area or in the middle of the flow table.

- Now pour the freshly mixed concrete into the mold in two layers, each layer should be moistened 25 times with a soft stick. If the concrete overflows after stamping and measure with the help of a torch, and the excess concrete should be removed from the table.

- After that, lift the mold upwards and allow the concrete to stand on its own without support.

- After that the table is raised and lowered from 12.5 mm high, 15 times in about 15 seconds.

- Next, measure the width of the concrete spread by about 6 points and write down the scale.

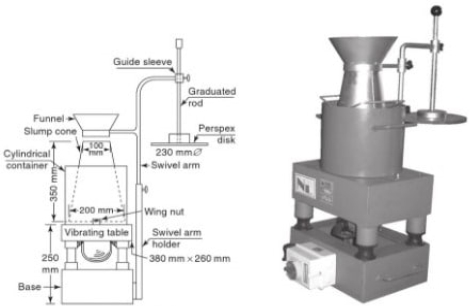

4. VEE- BEE CONSISTOMETER TESTS

Objective

- The performance of the new concrete is a composite material, which incorporates various requirements for stability, mobility, durability, placement and finishing. There are various ways to measure performance.

- Each of them measures only a specific aspect of it and there is no unique test, which measures the performance of concrete completely. This test provides an indication of the flow rate of the newly mixed concrete mix.

- The test measures the concurrent effort required to change a pile of concrete from one concrete to another (e.g., from a circle to a cylindrical) using vibration.

- The amount of effort (called retrieval attempt) is taken as the time in seconds, which is required to complete the change. The results of this experiment are useful when you study the flow of concrete piles made of different amounts of water, cement and different types of composite placement.

- The time required for a full recovery in seconds is taken as a performance measure and is expressed as the Vee-Bee number of seconds.

- This method is suitable for dry concrete. With concrete drop of more than 50mm, reconstruction is so fast that time cannot be measured.

|

Fig no 6

Vee bee Consistometer Test

Procedure

- Slump test as described in "IS 1199: 1959 Details of Concrete Testing Equipment (Fourth Review). Confirmed- Dis 2013". is made, inserting a collapsible lump inside a round metal pot of consist meter.

- The glass disk attached to the rotating arm will be moved to the top of the cone in the pot and before the cone is raised, the location of the concrete cone will be identified by fixing the glass disc attached to the arm wrist. The cone will then be lifted and the fall will be marked on the graduating rod by lowering the glass disc over the concrete cone. The electric heater will then light up and the concrete will be allowed to lay in the pot.

- The vibration continues until the point where the concrete shape disappears and the concrete takes on a circular shape. This can be judged by looking at the glass disc from the top disappearing visually.

- As soon as the concrete completely begins to form a circle, the stand clock is turned off. The time required for concrete formation to change from the formation of a collapsing lump into a circle in seconds is known as the Vee Bee Degree.

- This method is best suited for dry concrete with an unmeasured fall value with a Slump Test, but vibration is much stronger than concrete with a fall of more than 50 mm.

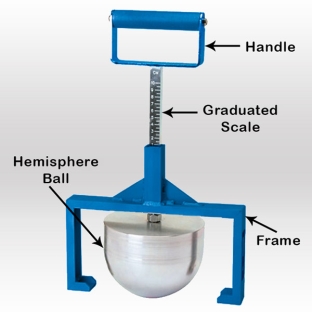

5. KELLY BALL TESTS

- Kelly's ball test is a test that measures the performance of new concrete in a building. Kelly's ball test method has been developed as one of the fastest and most effective fall tests. This type of test can be done quickly and the end result may not be related to the slump.

- The performance of the concrete in Kelly's ball test, is determined by the depth of penetration of the metal hemisphere (ball) that will fall under its weight on the new concrete. Metal hemisphere or ball has a diameter of 152 mm and weighs 13.6 kg. UJ. W. Kelly (Professor, University of California) had developed a device for testing Kelly's football equipment. Therefore, it was later renamed as a football entry test.

Advantages of Kelly Ball Test

- The ball entry test does not require filling, rolling the container or basically no need to use any setting as it is much faster than the fall test.

- For a more direct and immediate result, Kelly's ball test can be performed on new concrete on-field or in form, cart, wheelbarrow, or hopper.

- We can get more accurate and accurate results from a ball entry test than a fall test.

- To find concrete performance or to install or understand test results, this performance test does not require a long calculation.

Component of Kelly Ball Test

- Metal hemisphere (Ball): This is the most important constituent of Kelly ball test apparatus and it has 152 mm Diameter and 13.6 kg weight

- Graduated Scale: The reading of penetration of hemisphere (ball) is shown by the graduated scale .

- Handle

- Frame

|

Fig no 7

Kelly Ball Test

Procedure

01. Concrete intended for testing should be poured into a container-like container or in a form that should be up to a depth of 200mm (20cm). Then when the concrete is poured the surface should be measured.

02. On the concrete surface should be placed Kelly's ball bearings. The handles of the hemisphere (ball) should be placed in such a way that the frame touches the concrete surface. Only contain containers the minimum lateral size of the frame should be approximately 230 mm (23 cm).

03. When finished, the handle should be slightly removed and the ball should be allowed to enter the concrete by its own weight.

04. Once the ball (hemisphere) has been released, the stability of the ball will be shown on the scale.

05. Then the calculation of the graduation rate should be in writing. (Where entry is indicated).

06. The same process should be repeated in different parts at least three times in the container and the values between these readings should be reduced.

Points to be take care of

- In the center of the container should be placed Kelly's ball equipment. Concrete should be poured to a depth of 200mm (20 cm) and the lateral diameter should be at least 460 mm (46 cm) when the concrete is poured into a container to avoid boundary effects.

- The concrete should be properly placed on top.

Key take ways

There are 5 Different tests for measurement of workability

1. Slum cone test

2. Compaction factor test

3. Flow test

4. Vee bee Consistometer

5. Kelly Ball Test

- Bleeding is a process of separation when some of the water in the concrete tends to rise above the newly installed object. This is due to the failure of the solid concrete elements to retain all the water in the mixer when it settles down (water is the lightest of all mixtures). Bleeding continues until the cement is sticky enough to complete the process.

- Types of cement can affect bleeding, several increases, for example, a mixture of cement containing slag blast furnace slag (g g b s) of the soil, leading to an increase in bleeding time persists due to prolonged setting. The presence of an adequate amount of excellent aggregate (less than 150µm) reduces bleeding. Similarly polypropylene micro-fibers are known to reduce bleeding.

- If the bleeding is mixed during the removal of the upper face, there will be a more weak effect. To avoid this, the finishing operations can be delayed until the water supply evaporates. On the other hand, if water vapor evaporates faster than the rate of bleeding, plastic cracks are less likely to occur. BS 8500-1: 2015 Table A.9 c) states that Cement or a compound containing more than a fraction of 55% ggbs may not be suitable for wear of stone concrete areas due to the measuring potential of the earth at a few millimeters high.

- In the most severe cases, the separation of aggregates is also possible, with the heavy particles straight at the bottom of the concrete, leaving a layer of cement sand at the top.

- Excessive use of bleeding-prone concrete can increase bleeding and promote coexistence.

- Completing an unoccupied area can be mistaken for bleeding

Key take ways

Bleeding is a process of separation when some of the water in the concrete tends to rise above the newly installed object. This is due to the failure of the solid concrete elements to retain all the water in the mixer when it settles down (water is the lightest of all mixtures). Bleeding continues until the cement is sticky enough to complete the process.

- Good quality concrete is actually a compact mixture of cement, composite and good mixing with water that mixes into a hard mass due to the chemical action between cement and water.

- Each of the four regions has a specific function. The coarser collection serves as a filler. A good collection fills the gaps between the attachment and the green combination. Cement by contact with water acts as a bond.

- The flow of the mixture is aided by the adhesion of cement, fines to this day, increasingly using mixtures.

- Most of the reinforced concrete materials depend on the care used in all stages of concrete production. The logical separation of concrete ingredients is the core of the mixing design.

- However, it may not guarantee the achievement of the goal of quality workmanship. The purpose of quality control is to ensure the production of concrete of the same power from batch to batch.

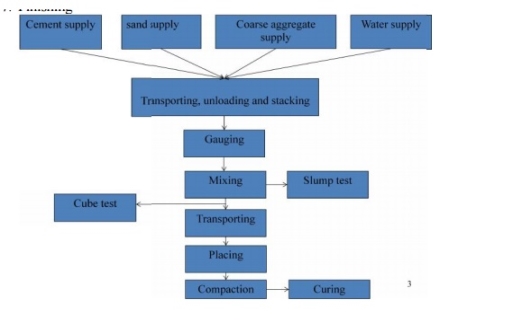

- This requires that certain rules be followed in the various stages of concrete production and discussed below. The stages of concrete production are:

1. Batching and measurement of material

2. Mixing

3. Transport

4. Placement

5. Compacting

6. Curing

7. Finishing

|

Fig no 8

Manufacturing process of concrete

BATCHING OF MATERIAL

- For good quality concrete should be used the correct and accurate amount of all ingredients. Combined, cement and water must be measured with an accuracy of 3 percent of batch quantity and admixtures at 5 percent of the total value. There are two most common forms of baking material, batching volume and heavy batching. Factors affecting the choice of baking method by the size of the work, the required production rate, the required batching performance standards. It is recommended for the most important tasks.

a) Volume batching

b) Weight batching

MIXING

1. Hand Mixing

2. Mixing Machine

a) Tilting mixers

b) Non- tilting mixer

c) Reversing Drum mixer

d) Pan type or stirring mixer

e) Transit mixer

f) Charging Mixer and mixing time

The order for the ingredients in the mixer is as follows:

- About 25 percent of the water needed for mixing is initially placed in the mixing tank to prevent any cement attachment to the rings and bottom of the drum. Then the ingredients are extracted in excess. To skip over the loading sequence should be to insert the first half of the coarse cement and then the composite half to be on top of this complete cement and the aggregate to balance. After adding the ingredients to the drum equal volume was introduced. The mixing time is calculated from the total water added to the mixture.

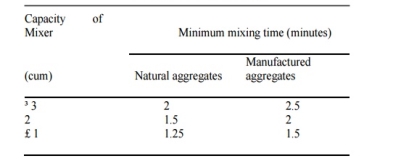

- The speed of the aggregates is usually 15 to 20 per minute. With proper mixing, the number of changes per minute required by the drum is 25 to 30. The mixing time also depends on the mixing capacity

|

Fig no 9

Table of mixing

- Poor quality of concrete is obtained when mixing time is reduced. on the other hand if the mixing time is extended it is not economical. however, it is found that when the mixing time is extended to 2 minutes the compressive strength of the produced concrete is improved and beyond this time the improvement of the compressive strength is not significant. prolonged mixing can cause separation. Also, due to the long mixing times water can get in or out and lead to loss of function and energy.

TRANSPORTING

The concrete should be moved to the storage area immediately without the loss of homosexuality acquired during mixing. a maximum of 2 hours from mixing time is allowed if trucks have an agitator and 1 hour using trucks without stimulants to move the concrete. And it must be ensured that separation does not occur during travel and placement. The methods used to transport concrete depend on the quality and value of the work, the distance to the placement site, and the location. some of the concrete delivery methods are below:

a. Mortar pan

b. wheel barrow

c. Chutes

d. Dumper

e. Bucket and ropeway

f. Belt conveyor

g. skip and hoist

h. Pumping

PLACING

- Achieving quality concrete should be placed very carefully to protect the homosexuality achieved during mixing and to avoid transport segregation. studies have shown that delays in the installation of concrete results in gaining greater compressive strength as long as the concrete is not sufficiently compacted. in dry mixes in hot weather a delay of half an hour is allowed and in wet mixtures when it is cold it can be a few hours. the various conditions in which concrete is applied are discussed below.

Foundations

- Concrete foundations for walls and columns are provided underground. Before laying concrete on the foundation all open ground, tree roots etc., are removed. If the area is found dry it is made wet so that the soil does not absorb water from the concrete. On the other hand when the foundation bed is wet the water and mud are removed and the cement is sprinkled before laying the concrete.

Beams, columns and slabs

- Before laying the concrete, the forms must be inspected for proper alignment. They should be strong enough to withstand the weight of concrete and construction loads without undue damage. The forms should be light enough to avoid any mud loss that has resulted in concrete mixed with bees. the inside of the forms should be cleaned and oiled before use to avoid any adhesion to the concrete and forms and make it difficult to remove them.

- Concrete should not be discarded but should be placed in a place to protect against discrimination. it should be lowered as high as possible. it should be placed in one place on the formwork and allowed to flow in separate ways to take care of the bee colony.

- The formation of seas should be avoided. Can be tested by preventing concrete thickness by 150-300 mm with r c c function. Laitance, however, if constructed must be removed before laying the next layer of concrete. Several such layers form an elevator, as long as they follow each other fast enough to avoid cold joints. The top of the previous elevator is kept rugged and all the money spent is wiped out before setting the next elevator.

- Firmness should be checked for firmness and clean face. Rust or loose scales if present, are removed with a wire brush. Paint, oil or grease if found should be removed. a small tightening cover should be checked before assembly.

Mass concreting

- Where the concrete will be laid in bulk as a foundation for raft, dam, bridge, pier etc., the concrete is laid in sections of 350-450 mm in diameter. Several such layers arranged in quick succession form an elevator. before applying the concrete to the next lift, the front elevator area is thoroughly cleaned with water jets and scrubbing with a wire brush. in the case of dams, sand explodes.

- Laitance and lax matter are removed and cement mortar is applied. where the concrete is subjected to lateral thrust, binding bars or binding stones are provided to form the key between the various layers.

Concreting Highways and Runways

- Concrete is placed in the areas of highway, open road, or floor slabs. First the soil on which the concrete is to be placed is prepared and all loose material and grass are removed etc. The ground is wet and compacted. The subgrades into which the concrete is to be placed should be well mixed and diamond-plated to avoid any moisture loss in the concrete. The concrete is then placed elsewhere. This allows the concrete to pass through enough and the cracks do not grow after that. Concrete is not placed in a pile in one place and then pulled out, instead it is placed in the same size.

Concreting underwater

- Concrete can be placed under water with the help of dumping buckets. The concrete is soaked in water from a water-tight bucket. When you get to the floor the bucket is made open and the concrete is discarded. In this process a certain amount of cement is washed away resulting in a decrease in the strength of the concrete. Another way to make underwater concrete is to fill a bag of cement with a dry or dry mixture of cement and aggregates and lower it into the storage area. The downside to this approach is that the concrete will fill the gaps filled with the bags with the guns.

- A good way to put concrete under water is to use a termie pipe. Concrete is poured into it by a ditch. The lower edge of the pipe is covered with thick ploythene paper, below the pipe in the installation area. Concrete (150-200 mm fall) is poured into the mortar until the entire pipe is filled with cement. The pipe is slightly raised and given a jerk, the polythene metal cover falls off and the concrete is shown. It must be ensured that the end of the pipe stays inside the concrete so that water does not enter the pipe. The pipe is then filled with concrete along the border and the process is repeated to the concrete level above the water level. No reduction is required for underwater concrete as combined with hydrostatic water pressure. Concrete can also be placed under water with the help of pipes and pumps.

COMPACTION

- After the concrete has been applied to the desired location, the next step in the concrete production process is its assembly. The joint consists of new concrete inside the mold or frames and surrounding embedded parts with reinforcing steel. A lot of air is trapped in the concrete during its production and there may be partial separation. Both of these factors adversely affect the quality of the concrete. Concrete compression is the process of removing trapped air and voids, eliminating the separation and creating a uniform weight. It was found that 5 percent of the void in reinforced concrete reduced energy by more than 30 percent and 10 percent of voids reduced energy by more than 50 percent. Therefore, the density and consequence of the strength and durability of concrete depend largely on the degree of density. For maximum strength dry concrete should be mixed 100 percent.

- Voids increase the penetration of concrete. Impossible loss results in the easy penetration of moisture, oxygen, chlorides, and other harsh chemicals into the concrete. This causes metal corrosion and cracking (dispersion) of the concrete i.e., loss of strength. The easy penetration of sulphates from nature causes a strong reaction with tri calcium aluminate (C3A) present in the cement. This causes concrete damage and loss of strength. The infiltration of carbon dioxide causes the lightening of the concrete i.e., the loss of alkalinity of the concrete or the loss of protective energy provided by the concrete to the reinforcement or other metal embedded in it. When the depth of the carbon exceeds the size of the concrete cover of the embedded metal, the metal is exposed to moisture. This speed up the corrosion of metal as the protective concrete cover remains naturally alkaline.

- Voids also reduce the connection between the embedded metal and the concrete. This leads to the loss of the strength of the bond of the reinforced concrete joint and thus the member loses strength. Spaces such as honeycombs and blowholes on the exposed surface reveal a visible feature. Concrete surfaces are not good to look at in all such aspects. Concrete smoothly and perfectly, the finishing area not only looks good but is also durable and durable.

- The joints are obtained by providing external work over the concrete to overcome internal tensions between the particles that make up the concrete, between the concrete and the reinforcement and between the concrete and the forms and by reducing the air barrier to a minimum. Concrete congestion can be obtained in the following ways.

1. Hand compaction

2. Compaction by vibration

a. Needle Vibrator:

b. Formwork Vibrator

3. Compaction by spinning

4. Compaction by jolting

5. Compaction by rolling

CURING OF CONCRETE

- Cement gets stronger and harder due to the chemical action between cement and cement. This chemical reaction requires moisture, a good temperature and a period of time called treatment. Differences in compression strength and healing time. The healing of newly installed concrete is very important for its strength and durability. Most of the energy in the first phase is supplied by the clinker compound C3S and half is C2S, and is completed in about three weeks. Recent power

- Provided by C2S is slow and long lasting. Since enough water should be made of concrete to allow it to get full strength. The process of maintaining concrete moisture for this purpose is known as cooling. The purpose is to prevent moisture loss in concrete due to

- Evaporation for any other reason, provide extra moisture or heat and humidity to accelerate energy gain. Treatment should be done for at least three weeks and is not possible in less than ten days.

- About 14 liters of water is needed to irrigate each bag of cement. Immediately after the laying of the concrete, the increase in strength is very rapid (3 to 7 days) and then progresses slowly thereafter indefinitely. Wet concrete cured for 7 days is about 50 percent more than dry air produced all the time. If the concrete is kept wet for one month, the strength is almost twice as high as that of concrete exposed only to dry air.

|

Fig no 10

Development of strength with curing

METHOD OF CURING

- Concrete can be kept moist in many ways. The methods consist of supplying excess moisture to the concrete during the initial solidification by meditation, spraying, spraying, etc. Or by preventing moisture loss in concrete by sealing the concrete with a membrane formed by the applied treatment. The following are some of the earlier treatments.

1. Water curing

2. Steam curing

3. Curing by infra red radiation

4. Electrical curing

5. Chemical curing

Finishing

Concrete is used primarily because of its high compression strength. However, the end of the final product is not a good thing. In the last few decades efforts have been made to complete the construction of the land so that it can be seen better in concrete areas and is as follows.

1. Formwork finishes

2. Surface treatment

3. Applied finishes

Key take ways

Manufacturing process of concrete

- Batching

- Mixing

- Transportation

- Compaction

- Curing

- Curing methods

References

1. A.M Neville J.J.Brooks Concrete technology

2. A.M Neville Concrete technology

3. R.S. Varshney Concrete technology

4. IS 10262 - 2009 , Recommend guidelines for Concrete