Unit 2

CMOS IC Fabrication and Layout

CMOS technology is a prevailing technology for manufacturing integrated circuits. CMOS stands for “Complementary Metal Oxide Semiconductor”. Microprocessors, batteries, and digital sensors among other electronic components make use of this technology due to several key advantages. This technology uses both NMOS and PMOS to realize various logic functions. Both N and P MOSFET channels are designed for matching characteristics.

Key Takeaways:

CMOS, which is short for Complimentary Metal-Oxide Semiconductor, is a predominant technology for manufacturing integrated circuits. This dominance of CMOS Technology in the fabrication of Integrated Circuits or ICs will continue for decades to come.

2.1.1 Self aligned CMOS process

The gate mask worksas a mask for n+/p+ diffusion mask, and there’s no need for separate gate mask and diffusion masks, the diffusion masks are only used to differentiate between n+ diffusion and p+ diffusion areasor we can use a single mask for n+ diffusion and complement it to define p+ diffusion.

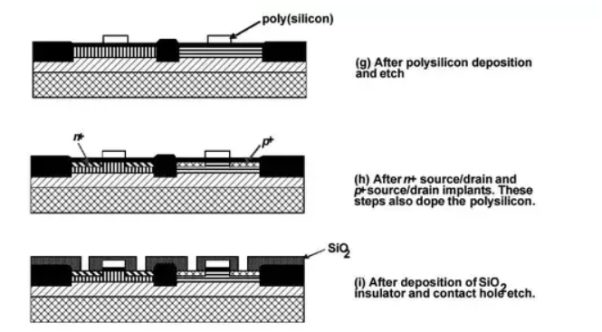

In step (g) we have defined the gate area by growing polysilicon at their respective locations defined by the gate mask. The polysilicon gate now enables us to diffuse the n+ and p+ regions without the need for growing SiO2 and applying a new mask to define source and drain regions of the MOS (n+ diffuse regions).

In step (h) the wafer will be diffused with n+ using polysilicon gate as an alignment mask. That is the polysilicon aligns the source and the drain to be exactly under the gate.

This approach solves the problem of random misalignment errors, which caused the speed of the device to be dramatically influenced by it.

Figure 1. Self aligned CMOS process

Key takeaways

A nickel-monosilicide (NiSi) technology suitable for a deep sub-micron CMOS process has been developed.

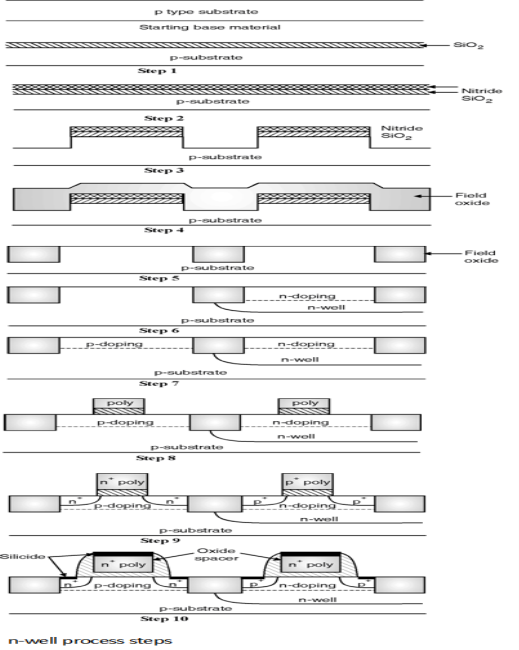

2.1.2 N well

The process starts with a p-substrate.

Step 1 : A thin layer of SiO2 is deposited which will serve as a the pad oxide.

Step 2 : Deposition of a thicker sacrificial silicon nitride layer by chemical vapour deposition (CVD).

Step 3 : A plasma etching process using the complementary of the active area mask to create trenches used for insulating the devices.

Step 4 : The trenches are filled with SiO2 which is called as the field oxide.

Step 5 : To provide flat surface chemical mechanical planerization is performed and also sacrificial nitride is removed.

Step 6 : The n-well mask is used to expose only the n-well areas, after this implant and annealing sequence is applied to adjust the well doping. This is followed by second implant step to adjust the threshold voltage of the PMOS transistor.

Step 7 : Implant step is performed to adjust the threshold voltage of NMOS transistor.

Step 8 : A thin layer of gate oxide and polysilicon is chemically deposited and patterned with the help of polysilicon mask.

Step 9 : Ion implantation to dope the source and drain regions of the PMOS (p+) and NMOS (n+) transistors, this will also form n + polysilicon gate and p+ polysilicon gate for NMOS and PMOS transistors respectively. Hence this process is called as self aligned process.

Step 10 : Then the oxide or nitride spacers are formed by chemical vapour deposition.

Step 11 : In this step contact or via holes are etched, metal is deposited and patterned. After the deposition of last metal layer final passivation or overglass is deposited for protection.

Figure 2. N well process

Key takeaways:

The N-well / P-well technology, where n-type diffusion is done over a p-type substrate or p-type diffusion is done over n-type substrate respectively.

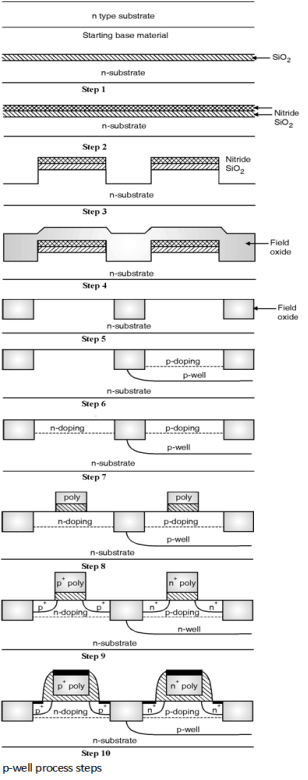

2.1.3 P well

The fabrication steps of p well process are same as that of an n-well process except that instead of n-well a p-well is implanted . The process steps involved in p-well process are shown in Figure below. The process starts with the n type substrate.

Step 1 : A thin layer of SiO2 is deposited which will serve as the pad oxide.

Step 2 : A thicker sacrificial silicon nitride layer is deposited by chemical vapour deposition (CVD).

Step 3 : A plasma etching process is used to create trenches used for insulating the devices.

Step 4 : The trenches are filled with SiO2 which is called as the field oxide.

Step 5 : To provide flat surface chemical mechanical planerization is performed and also sacrificial nitride and pad oxide is removed.

Step 6 : The p-well mask is used to expose only the p-well areas, after this implant and annealing sequence is applied to adjust the well doping. This is followed by a second implant step to adjust the threshold voltage of the NMOS transistor.

Step 7 : Implant step is performed to adjust the threshold voltage of PMOS transistor.

Step 8 : A thin layer of gate oxide and polysilicon is chemically deposited and patterned with the help of polysilicon mask.

Step 9 : Ion implantation to dope the source and drain regions of the PMOS (p+) and NMOS (n+) transistors, this will also form n + polysilicon gate and p+ polysilicon gate for NMOS and PMOS transistors respectively. Hence this process is called as self aligned process.

Step 10 : Then the oxide and nitride spacers are formed by chemical vapour deposition.

Step 11 : In this step contact or via holes are etched, metal is deposited and patterned. After the deposition of last metal layer final passivation or overglass is deposited for protection.

Figure 3. P well process steps

Key takeaways:

The fabrication steps of p well process are same as that of an n-well process except that instead of n-well a p-well is implanted

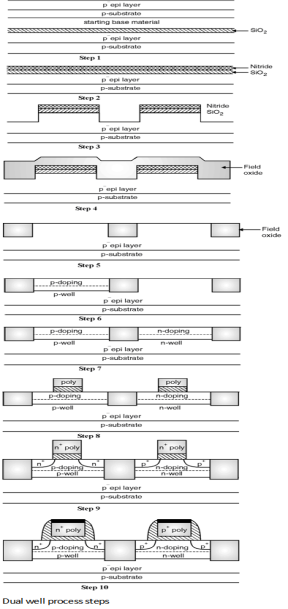

2.1.4 Twin tub

In Dual-well process both p-well and n-well for NMOS and PMOS transistors respectively are formed on the same substrate. The starting material for this process is p+ substrate with epitaxially grown p-layer which is also called as epilayer.

The process starts with a p-substrate surfaced with a lightly doped p-epitaxial layer.

Step 1 : A thin layer of SiO2 is deposited which will serve as the pad oxide.

Step 2 : A thicker sacrificial silicon nitride layer is deposited by chemical vapour deposition.

Step 3 : A plasma etching process is used to create trenches used for insulating the devices.

Step 4 : The trenches are filled with SiO2 which is called as the field oxide.

Step 5 : To provide flat surface chemical mechanical planarization is performed and also sacrificial nitride and pad oxide is removed.

Step 6 : The p-well mask is used to expose only the p-well areas, after this implant and annealing sequence is applied to adjust the well doping. This is followed by second implant step to adjust the threshold NMOS transistor.

Step 7 : The n-well mask is used to expose only the n-well areas, after this implant and annealing sequence is applied to adjust the well doping. This is followed by a second implant step to adjust the threshold voltage of PMOS transistor.

Step 8 : A thin layer of gate oxide and polysilicon is chemically deposited and patterned with the help of polysilicon mask.

Step 9 : Ion implantation to dope the source and drain regions of the PMOS (p +) and NMOS (n+) transistors is used this will also form n+ polysilicon gate and p+ polysilicon gate for NMOS and PMOS transistors respectively.

Step 10 : Then the oxide or nitride spacers are formed by chemical vapour deposition (CVD).

Step 11 : In this step contact or holes are etched, metal is deposited and patterned. After the deposition of last metal layer final passivation or overglass is deposited for protection.

Figure 4. Twin tub process

Key takeaways:

In Dual-well process both p-well and n-well for NMOS and PMOS transistors respectively are formed on the same substrate

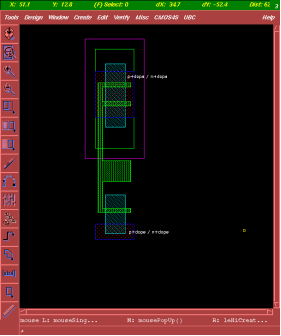

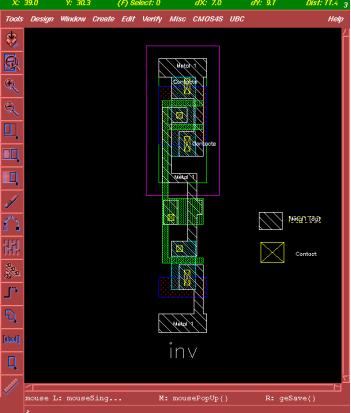

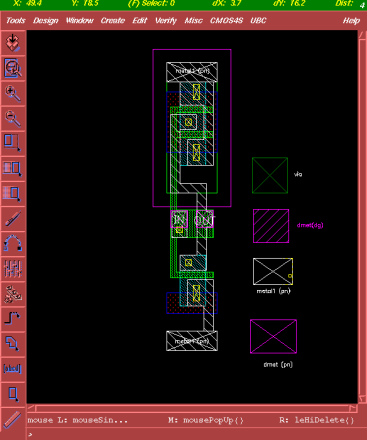

2.1.5 Layout of CMOS Inverter

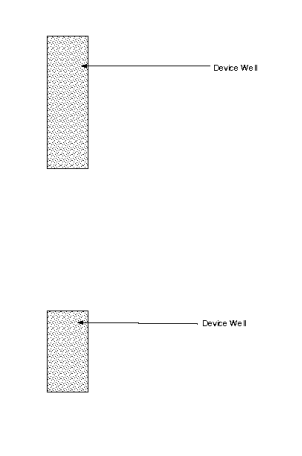

Figure 5. Device well

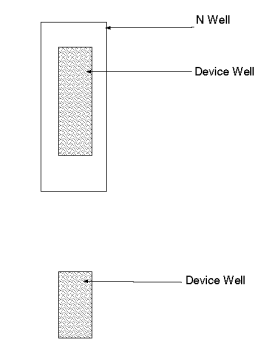

Figure 6. Nwell

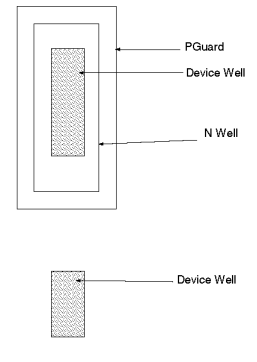

Figure 7. P Guard

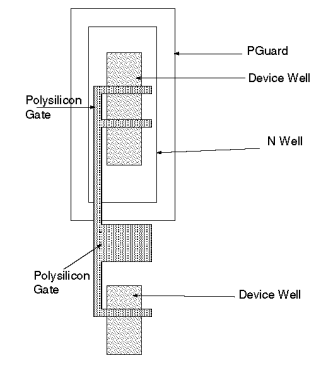

Figure 8. Polysilicon gate

Figure 9.Masks

Figure 10. Metal contacts

Figure 11. Complete circuit

Key takeaways:

Various Steps For Laying out an Inverter A CMOS inverter consists of both P-type and N-type MOS devices on the same common substrate.

2.1.6 CMOS Layout and Design Rules

The layout design rules provide a set of guidelines for constructing the various masks needed in the fabrication of integrated circuits. Design rules consist of the minimum width and minimum spacing requirements between objects on the different layers.

The most important parameter used in design rules is the minimum line width. This parameter indicates the mask dimensions of the semiconductor material layers. Layout design rules are used to translate a circuit concept into an actual geometry in silicon.

The design rules is the media between circuit engineer and the IC fabrication engineer. The circuit designers requires smaller designs with high performance and high circuit density whereas the IC fabrication engineer requires high yield process.

Minimum line width (MLW) is the minimum MASK dimension that can be safely transferred to the semiconductor material. For the minimum dimension design rules differ from company to company and from process to process.

To address this issue scalable design rule approach is used. In this approach rules are defined as a function of single parameter called ''. For an IC process '' is set to a value and the design dimensions are converted in the form of numbers. Typically a minimum line width of a process is set to 2 e.g. for a 0.25 m process technology '' equals 0.125 m.

Layered Representation of Layout :

The layer representation of layout converts the masks used in CMOS into a simple layout levels that are easier to visualise by the designers.

The CMOS design layouts are based on following components :

(1) Substrates or Wells : These wells are p type for NMOS devices and n type for PMOS devices.

(2) Diffusion regions : At these regions the transistors are formed and also called as active layer. These are defined by n+ for NMOS and p+ for PMOS transistors.

(3) Polysilicon layers : These are used to form the gate electrodes of the transistors.

(4) Metal interconnects layers : These are used to form the power supply and ground rails as well as input and output rails.

(5) Contact and Via layers : These are used to form the inter layer connections.

Key Takeaways:

Layout design rules are introduced in order to create reliable and functional circuits on a small area.

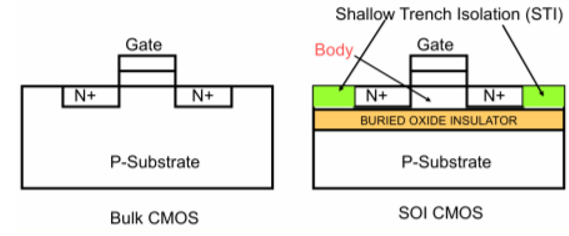

2.1.7 Silicon on Insulator Technology

Scaling of Bulk CMOS technology leads to issues such as sub-threshold leakage Power Parasitic device capacitances affecting the performance SOI technology and used in other devices like IGFETs

Figure 12. SOI CMOS

Unlike thin-film transistor, the top silicon layer of an SOI (silicon-on-insulator) wafer is high-quality single-crystalline material that is suitable for high-performance and high-density integrated. Many forms of SOI structures have been demonstrated with different insulator materials and holding substrates.

These include silicon-on-oxide, silicon-on-sapphire (SOS), silicon-on-zirconia (SOZ), and siliconon-nothing(air gap).

In SOS and SOZ technologies, a single-crystalline silicon film is epitaxially grown on a crystalline insulating substrate. In these cases, the insulators are the

There are many ways to fabricate this structure. Among them SIMOX (separation by implantation of oxygen) where high-dose oxygen is implanted onto a

silicon wafer followed by high-temperature anneal to form the buried SiO2, layer.

Another technique involves bonding of two silicon wafers one of which has an oxidized layer followed by thinning or removal of the majority of the top wafer until a thin silicon layer is left.

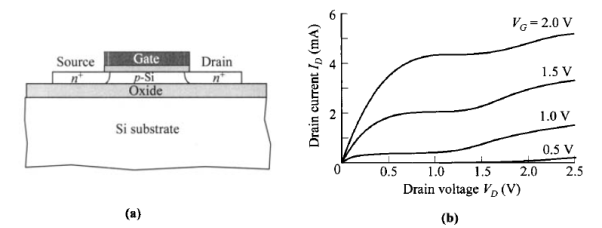

Figure (a) shows a schematic diagram of an n-channel MOSFET made on an SOI substrate, with its typical I-Vcharacteristics shown in Fig. (b).

The kinks associated with floating body without a substrate tie are noticeable.

Figure 13. SOI substrate and V-I characteristics

Key takeaways:

The future of SOI is tentatively explored, by addressing the further scalability of SOI transistors as well as the innovating architectures

References

1. Fundamentals of Modern VLSI Devices Book by Tak H. Ning and Yuan Taur

2. Introduction to VLSI systems Book by Carver Mead

3. VLSI physical design automation Textbook by Sadiq Sait

4. Cmos Digital Integrated Circuits Book by Sung-Mo Kang and Yusuf Leblebici