Unit 4

Quality improvement Strategies and Certifications

Lean thinking is a term used to describe the process of making business decisions in a Lean way. It’s regarded as the foundation of any Lean practice. Of course, there is no single definition of Lean; however, there are a few concepts that guide most Lean practices in the world today. We refer to that collection of concepts as Lean thinking. Lean thinking supports the notion that we must devote as much focus to improvement efforts as we do to project work.

Lean thinking can be broken down into these seven Lean principles that guide Lean thinking in businesses today. These principles are:

- Optimize the whole

- Eliminate waste

- Create knowledge

- Build quality in

- Deliver fast by managing flow

- Defer commitment

- Respect people

Principles of Lean Thinking

Eliminate waste

Waste in manufacturing, where Lean thinking was developed, looks quite different than in knowledge work, and the way we identify waste is different, as well. Much of the value, and the waste, in knowledge work is found inside the heads of the people doing the work, not on the shop floor.

Waste in knowledge work can be:

- Context switching

- Inefficient information systems

- Poor tooling

- Bad communication practices across teams

Anything that the customer would not willingly pay for is defined as waste in Lean thinking.

Create knowledge

The Lean thinking concept of Create Knowledge is simple: To scale, we must build learning and teaching into our organizations, so that more people can add more value in more ways. Of course, to do this, we must create environments that allow space for learning.

We create knowledge, and thereby improve, by taking the time to:

- Have retrospectives

- Hold team meetings to discuss how work in being done

- Cross-train team members

By creating knowledge throughout our organizations, we’re able to deliver faster with more value.

Build quality in

To create a system that is built for growth, we need to error-proof our systems as much as possible. To do this, Lean organizations standardize and automate those things that are tedious, repeatable, or prone to human error, so they can focus the skills and efforts of their employees on innovation, growth, and continuous improvement.

Building quality in looks different depending on your industry, but the general concept is the same: Create a system that is built for growth, by building a solid foundation.

Deliver fast by managing flow

At the core of Lean thinking is the idea that focus produces higher quality work. When our environment isn’t designed to help us focus, we move slower and slower than we would if we all had fewer things on our plates.

Think of it like traffic on a road: If that road is at 90% capacity, it’s basically at a standstill. If it’s at 50% capacity, each car will reach its destination sooner, because there are fewer cars on the road.

How does this apply to knowledge work? It means we must be more intentional about the way we work. Lean thinking encourages teams to visualize, manage, and continuously optimize their flow. If the goal is to deliver value to the customer at a sustainably fast pace, then we must have control over how work gets done; we must manage flow.

Defer commitment

Businesses often feel an artificial pressure to plan, make decisions, and complete work far in advance of when that specific value is needed by the market. This leads to a lack of flexibility that is necessary to continuously deliver value to customers.

The Lean thinking principle of Defer Commitment encourages organizations to make decisions at the last responsible moment, to continuously make decisions based on the most up-to-date, relevant, comprehensive information.

The reasoning behind this ties back to the concept of eliminating waste: If we plan and complete work before it’s needed, then how do we know it will still be relevant to the market when we release it?

If we complete work before we truly understand the needs of the market, we could spend time, money, and energy on work that’s undesirable to the market, which then leaves us with the choice of either releasing something undesirable or accepting that work as waste. Deferring commitment gives us the agility to continuously deliver value.

Respect people

Lean thinking reminds us that most of the value created in organizations is in the heads of employees, and that to retain those employees, we must create environments for employees to do their best work. Retaining quality talent is essential for sustainable value delivery.

The Lean interpretation of “respect” includes, of course, being a kind, courteous, and thoughtful employee, but it goes deeper than that. Lean organizations:

- Respect their employees by giving them what they need to do good work

- Create environments where the best ideas can be heard

- Encourage employees to pursue educational opportunities

- Give employees the autonomy to make decisions based on what is best for the customer

Getting Started with Lean Thinking

Though there is no single definition of Lean thinking, these concepts will help any organization get started with Lean thinking. Lean thinking offers the agility to continuously deliver value in an ever-changing business environment. Implementing Lean thinking will guide your organization toward a stronger, more sustainable future.

What is the Kepner Tregoe Method?

Problems occur in any given organization. Often there is pressure of time to solve the problems and it is debatable what the right way of solving these problems is. The Kepner Tregoe method (KT-method) is a problem analysis model in which the “problem” is disconnected from the “decision”. An English synonym for this problem solving method is Problem Solving and Decision Making (PSDM).

Traditional thinking pattern

The founders Charles Kepner and Benjamin Tregoe developed a rational working method in the 1960s in which they researched and identified the troubleshooting skills of people. Throughout the centuries mankind has learned to deal with complexity and to (directly) anticipate on this. As a consequence, the traditional thinking pattern became a part of human nature.

When solving problems people search for the answer to the following four questions:

- What happened?

- Why did it happen?

- How should we act?

- What will be the (future) result?

Rational processes

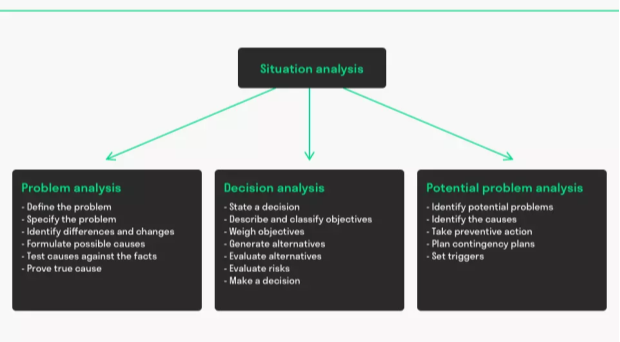

To break through this traditional pattern Charles Kepner and Benjamin Tregoe came up with four rational processes in which four fundamental questions are reflected:

- Situation analysis

This clarifies the problem situation (what happened).

2. Problem analysis

Here the actual cause of the problem and the relationship between cause and result are searched for (why did it happen).

3. Decision analysis

Based on the decision making criteria, choices are made to arrive at potential problem resolutions (how should we act).

4. Potential Problem analysis

Here potential future problems are anticipated and preventative actions are developed (what will the result be).

|

Six Sigma is a highly disciplined process that focuses on delivering near-perfect products and services consistently. Its strength is that it is a continuous improvement process with an unwavering focus on change empowerment, seamless training of resources and continuous top management support. These three are known as the Pillars of Six Sigma. If Six Sigma is implemented methodically, it will give sustained results for any process. Now the question arises as to what is a process. This will be explained in the next screen.

Process of Six Sigma

Six Sigma follows a process named DMAIC (Pronounced as D-MAC) DMAIC stands for Define, Measure, Analyze, Improve, and Control. Click each tab to know more. In the Define phase, define the problem statement and plan the improvement initiative. Consider a typical problem in an Organization. A particular organization’s customers are not satisfied with the current support process of the organization. You can define the problem as the support process of the organization is at 20% satisfaction. In Six Sigma, the projects are always defined objectively. In addition to defining the problem, the Six Sigma project team is also formed in this phase. The Measure phase collects the data from the process and understands the current quality or operational performance levels. Additionally, the measurement criteria such as how to measure, when to measure, and who will measure are established. In the Analyze phase, the business process and the data generated from the measurement phase are studied to understand the root causes of the problem. In the Improvement phase, possible improvement actions are identified and prioritized. These are then tested and the improvement action plan is finalized. In the last phase, which is the Control phase, the Six Sigma team goes for a full-scale implementation of the improvement action plan and sets up controls to monitor the system in order to sustain the gains.

Features of Six Sigma

Six Sigma's aim is to eliminate waste and inefficiency, thereby increasing customer satisfaction by delivering what the customer is expecting.

- Six Sigma follows a structured methodology, and has defined roles for the participants.

- Six Sigma is a data driven methodology, and requires accurate data collection for the processes being analyzed.

- Six Sigma is about putting results on Financial Statements.

Six Sigma is a business-driven, multi-dimensional structured approach for −

- Improving Processes

- Lowering Defects

- Reducing process variability

- Reducing costs

- Increasing customer satisfaction

- Increased profits

The word Sigma is a statistical term that measures how far a given process deviates from perfection.

The central idea behind Six Sigma: If you can measure how many "defects" you have in a process, you can systematically figure out how to eliminate them and get as close to "zero defects" as possible and specifically it means a failure rate of 3.4 parts per million or 99.9997% perfect.

Primary Goals of Six Sigma

Any organization that seeks to implement Six Sigma or any enhancement programme should have a clear understanding of what it expects the action plan to achieve. Instead of abstract thinking, such as ‘we want to get better,’ project leadership needs to set clear and achievable targets that can be expected from the execution of any development strategy, even Six Sigma.

Six Sigma’s key objectives would include these particular results anticipated for the program:

Six Sigma’s target is to achieve a defect rate of six standard deviations from the norm or 3.4 defects per million goods, and it will educate six Sigma practitioners (green belts, black belts) to aim towards this degree.

This will not, however, be possible for all organizations and goods. Motorola invented Six Sigma, and General Electric popularised it, which produces several different interests. Consequently, it has been adopted as a basis for multiple development methods. Yet Six Sigma was questioned in that the six standard deviation law (six sigmas) is not uniformly valid to all sectors and goods. Many companies will refuse to reduce the defect rate to that level, since dealing with more defects is easier. A higher defect rate could attract customers too.

Quality management is one of the important primary goals of Six Sigma implementation. For practically every Six Sigma program, consistency is a natural, primary target. Without resolving quality problems in any phase, any more enhancement attempts will inevitably fall short. The major quality-related focus areas for standard Six Sigma initiatives include the elimination of error/defects (or the proofing of errors) and the reduction of waste involved in manufacturing a good or service.

The project team will use a specified methodology and statistical methods to attempt to recognize and remove the causes of the defects in a given procedure. In doing so, the goal is to optimize the process’s final result with as few mistakes as possible. Secondary purposes related to consistency targets include improved consumer loyalty and enhanced profitability.

Do you understand how many of your items are wrong or are your services short? If you know the consistency level as opposed to your competitors? If you know how to boost the efficiency of your service? Want to be higher than the average?

Implementation of Six Sigma would improve your numbers:

- Where the consistency of the product/service now is.

- Wherever you want to go

- How to get inside

- How to keep at it

If nothing else, only the numbers you’ll know.

In this case, variability refers to the difference between the planned quality and the real performance of a product or service. Variance is sometimes, products or services that are not satisfactory to the end-user / client, and are refused to result in excessive duplication, lower profits, and increased costs.

Variability may be caused by common causes (steady, random fluctuation) or by special causes (once, non-random fluctuation). Six Sigma aims to reduce uncertainty, resulting in stable processes generating consistent output.

Are you trying to keep people focused and deliver career growth targets that make them happy? Giving somebody a Six Sigma green belt or black belt certification training is a perfect way to keep them interested, practicing, and pushing their career forward. With the Six Sigma hierarchy structure in different colored belts representing enterprise structure, professionals can take up popular Quality Management Certification courses to get ahead in their careers.

Rising efficiency is an overall goal for several implementations of Six Sigma. Also, small increases in a process’s productivity will bring significant advantages for the organization. Six Sigma ventures usually focus on reducing cycle time (the amount of time it takes to complete one processing process), such as a bank teller that serves a single customer. The longer the cycle time, the more cycles (clients) within a single shift can be handled.

Other areas of change include eliminating measures that are duplicative or don’t add value in a process. The streamlining of the processes tends to maximize processing time and minimize idle time, thereby enhancing the total process efficiency.

Perhaps a few individuals will become Six Sigma Yellow, Green, or Black Belts but this acts as a precedence for the entire organization which will see the quality emphasis throughout the organization. Implementing Six Sigma is an obvious way to say that “safety matters” to everyone. That’s a value you can’t quickly put a price on.

So these are the primary goals of Six Sigma Implementation in any organization.

DMAIC is a data driven quality strategy used to identify opportunities in the process to make improvements and reduce the errors and defects

D - Define-(Defining the problem, opportunities, business objectives, customer demands)

Here you define what opportunity are you looking for or we can say what problem you are trying to fix or simply what new business objective or customer demand you are trying to complete.

M - Measure performance

This is the crucial step for professional who are seeking out any opportunity to improve the service, process or product. Measurement is critical in the step and it must be accurate because you are trying to build solution on the basis of that measurement. In this process the measurement team has to focus on the process and what customer actually cares about.

A - Analyze opportunities

In this step the team has to analyze what is causing the problem and where there will be the opportunity to improve the process or service quality or cost or product. In this step team spend their time on finding root causes of problem and building the solution depending upon the results.

In this step mostly experienced and Six Sigma Green belt certified person analyze. The teams have to develop hypothesis according to finding and results and then define then work to prove or disprove the hypothesis.

I – Improve Performance

After implementing solution into process the teams have to concentrating on the factors which are crucial for improving the process or service or product. In this step the team have to collects data to check if there is measurable improvement or not if yes then the team will follow these process as a core process than pilot process and then finally improve the baseline ultimately it leads to improve the service quality or product quality which finally meets the customer satisfaction.

C - Control performance

This is the step in which team have to control the process and sustain the changes and improvement they made in the process or service. This is one of the most important activity required by the business because sustaining the improved process is very important to hold the service quality or product quality ultimately to hold the customer.

DMADV is a Six Sigma framework that focuses primarily on the development of a new service, product or process as opposed to improving a previously existing one. This approach – Define, Measure, Analyze, Design, Verify – is especially useful when implementing new strategies and initiatives because of its basis in data, early identification of success and thorough analysis.

The DMADV methodology should be applied:

- when a non-existent product or process needs to be developed at a company and…

- when an existing process or product already exists but still needs to meet a Six Sigma level or customer specification.

Let’s examine the five major phases of DMADV more closely.

Define

The goals of the first phase are to identify the purpose of the project, process or service, to identify and then set realistic and measurable goals as seen from the perspectives of the organization and the stakeholder(s), to create the schedule and guidelines for the review and to identify and assess potential risks. A clear definition of the project is established during this step, and every strategy and goal must be aligned with the expectations of the company and the customers.

Measurement

Next comes measuring the factors that are critical to quality, or CTQs. Steps taken should include: defining requirements and market segments, identifying the critical design parameters, designing scorecards that will evaluate the design components more important to the quality, reassessing risk and assessing the production process capability and product capability. Once the values for these factors are known, then an effective approach can be taken to start the production process. It is important here to determine which metrics are critical to the stakeholder and to translate the customer requirements into clear project goals.

Analysis

Actions taken during this phase will include: developing design alternatives, identifying the optimal combination of requirements to achieve value within constraints, developing conceptual designs, evaluating then selecting the best components, then developing the best possible design. It is during this stage that an estimate of the total life cycle cost of the design is determined. After thoroughly exploring the different design alternatives, what is the best design option available for meeting the goals?

Design

This stage of DMADV includes both a detailed and high level design for the selected alternative. The elements of the design are prioritized and from there a high level design is developed. Once this step is complete, a more detailed model will be prototyped in order to identify where errors may occur and to make necessary modifications.

Verify

In the final phase, the team validates that the design is acceptable to all stakeholders. Will the design be effective in the real world? Several pilot and production runs will be necessary to ensure that the quality is the highest possible. Here, expectations will be confirmed, deployment will be expanded and all lessons learned will be documented. The Verify step also includes a plan to transition the product or service to a routine operation and to ensure that this change is sustainable.

For any DMADV project, there may be more emphasis on certain components of the approach over others, though the goal remains the same: to address an identified issue and produce desired results in a way that can be maintained through normal operations.

Key Takeaways

|

What Is the Taguchi Method of Quality Control?

The Taguchi method of quality control is an approach to engineering that emphasizes the roles of research and development (R&D), product design and development in reducing the occurrence of defects and failures in manufactured goods.

This method, developed by Japanese engineer and statistician Genichi Taguchi, considers design to be more important than the manufacturing process in quality control, aiming to eliminate variances in production before they can occur.

Understanding the Taguchi Method of Quality Control

The Taguchi method gauges quality as a calculation of loss to society associated with a product. In particular, loss in a product is defined by variations and deviations in its function as well as detrimental side effects that result from the product.

Loss from variation in function is a comparison of how much each unit of the product differs in the way it operates. The greater that variance, the more significant the loss in function and quality. This could be represented as a monetary figure denoting how usage has been impacted by defects in the product.

Example of the Taguchi Method of Quality Control

For instance, if the product is a precision drill that must consistently drill holes of an exact size in all materials it is used on, part of its quality is determined by how much the units of the product differ from those standards. With the Taguchi method of quality control, the focus is to use research and design to ensure that every unit of the product will closely match those design specifications and perform exactly as designed.

Special Considerations

Loss from detrimental side effects on society speaks to whether or not the design of the product could inherently lead to an adverse impact. For example, if operating the precision drill could cause injury to the operator because of how it is designed, there is a loss of quality in the product.

Under the Taguchi method, work done during the design stage of creation would aim to minimize the possibility that the drill would be crafted in a way that its use could cause injuries to the operator.

From a higher perspective, the Taguchi method would also strive to reduce the cost to society to use the product, such as designing goods to be more efficient in their operation rather than generate waste. For instance, the drill could be designed to minimize the need for regular maintenance.

History of the Taguchi Method of Quality Control

Genichi Taguchi, a Japanese engineer and statistician, began formulating the Taguchi method while developing a telephone-switching system for Electrical Communication Laboratory, a Japanese company, in the 1950s. Using statistics, he aimed to improve the quality of manufactured goods.

By the 1980s, Taguchi's ideas began gaining prominence in the Western world, leading him to become well-known in the United States, having already enjoyed success in his native Japan. Big-name global companies such as Toyota Motor Corp. (TM), Ford Motor Co. (F), Boeing Co. (BA) and Xerox Holdings Corp. (XRX) have adopted his methods.

For organizations asking how to improve the quality of their products and services and consistently meet their customers’ expectations, ISO has an answer. Addressing various aspects of quality management and containing some of ISO’s best-known standards, there’s the ISO 9000 family.

WHY ISO 9001?

hf It can be used by any organization, large or small, regardless of its field of activity. In fact, there are over one million companies and organizations in over 170 countries certified to ISO 9001.

This standard is based on a number of quality management principles including a strong customer focus, the motivation and implication of top management, the process approach and continual improvement. These principles are explained in more detail in ISO’s quality management principles. Using ISO 9001 helps ensure that customers get consistent, good-quality products and services, which in turn brings many business benefits.

WHAT IS THE ISO 9000 STANDARDS SERIES?

ISO 9000 is defined as a set of international standards on quality management and quality assurance developed to help companies effectively document the quality system elements needed to maintain an efficient quality system. They are not specific to any one industry and can be applied to organizations of any size.

ISO 9000 can help a company satisfy its customers, meet regulatory requirements, and achieve continual improvement. It should be considered to be a first step or the base level of a quality system.

ISO 9000 VS. 9001

ISO 9000 is a series, or family, of quality management standards, while ISO 9001 is a standard within the family. The ISO 9000 family of standards also contains an individual standard named ISO 9000. This standard lays out the fundamentals and vocabulary for quality management systems (QMS).

ISO 9000 series of Standards

The ISO 9000 family contains these standards:

- ISO 9001:2015: Quality Management Systems - Requirements

- ISO 9000:2015: Quality Management Systems - Fundamentals and Vocabulary (definitions)

- ISO 9004:2018: Quality Management - Quality of an Organization - Guidance to Achieve Sustained Success (continuous improvement)

- ISO 19011:2018: Guidelines for Auditing Management Systems

ASQ is the only place where organizations can obtain the American National Standard Institute (ANSI) versions of these standards in the ISO 9000 family.

ISO 9000 history and revisions: ISO 9000:2000, 2008, and 2015

ISO 9000 was first published in 1987 by the International Organization for Standardization (ISO), a specialized international agency for standardization composed of the national standards bodies of more than 160 countries. The standards underwent major revisions in 2000 and 2008. The most recent versions of the standard, ISO 9000:2015 and ISO 9001:2015, were published in September 2015.

ASQ administers the U.S. Technical Advisory Groups and subcommittees that are responsible for developing the ISO 9000 family of standards. In its standards development work, ASQ is accredited by ANSI.

ISO 9000:2000

ISO 9000:2000 refers to the ISO 9000 update released in the year 2000.

The ISO 9000:2000 revision had five goals:

- Meet stakeholder needs

- Be usable by all sizes of organizations

- Be usable by all sectors

- Be simple and clearly understood

- Connect quality management system to business processes

ISO 9000:2000 was again updated in 2008 and 2015. ISO 9000:2015 is the most current version.

ISO 9000:2015 principles of Quality Management

The ISO 9000:2015 and ISO 9001:2015 standards are based on seven quality management principles that senior management can apply to promote organizational improvement.

Customer focus

- Understand the needs of existing and future customers

- Align organizational objectives with customer needs and expectations

- Meet customer requirements

- Measure customer satisfaction

- Manage customer relationships

- Aim to exceed customer expectations

- Learn more about the customer experience and customer satisfaction

Leadership

- Establish a vision and direction for the organization

- Set challenging goals

- Model organizational values

- Establish trust

- Equip and empower employees

- Recognize employee contributions

- Learn more about leadership

Engagement of people

- Ensure that people’s abilities are used and valued

- Make people accountable

- Enable participation in continual improvement

- Evaluate individual performance

- Enable learning and knowledge sharing

- Enable open discussion of problems and constraints

- Learn more about employee involvement

Process approach

- Manage activities as processes

- Measure the capability of activities

- Identify linkages between activities

- Prioritize improvement opportunities

- Deploy resources effectively

- Learn more about a process view of work and see process analysis tools

Improvement

- Improve organizational performance and capabilities

- Align improvement activities

- Empower people to make improvements

- Measure improvement consistently

- Celebrate improvements

- Learn more about approaches to continual improvement

Evidence-based decision making

- Ensure the accessibility of accurate and reliable data

- Use appropriate methods to analyze data

- Make decisions based on analysis

- Balance data analysis with practical experience

- See tools for decision making

Relationship management

- Identify and select suppliers to manage costs, optimize resources, and create value

- Establish relationships considering both the short and long term

- Share expertise, resources, information, and plans with partners

- Collaborate on improvement and development activities

- Recognize supplier successes

- Learn more about supplier quality and see resources related to managing the supply chain

For companies and organizations of any type that require practical tools to manage their environmental responsibilities, there’s the ISO 14000 family.

WHAT DO THE STANDARDS IN THE ISO 14000 FAMILY COVER?

The ISO 14000 family of standards are developed by ISO Technical Committee ISO/TC 207 and its various subcommittees. For a full list of published standards in the series see their standards catalogue.

ISO 14001 provides requirements with guidance for use that relate to environmental systems. Other standards in the family focus on specific approaches such as audits, communications, labelling and life cycle analysis, as well as environmental challenges such as climate change.

ISO 14001:2015 specifies the requirements for an environmental management system that an organization can use to enhance its environmental performance. ISO 14001:2015 is intended for use by an organization seeking to manage its environmental responsibilities in a systematic manner that contributes to the environmental pillar of sustainability.

ISO 14001:2015 helps an organization achieve the intended outcomes of its environmental management system, which provide value for the environment, the organization itself and interested parties. Consistent with the organization's environmental policy, the intended outcomes of an environmental management system include:

· enhancement of environmental performance;

· fulfilment of compliance obligations;

· achievement of environmental objectives.

ISO 14001:2015 is applicable to any organization, regardless of size, type and nature, and applies to the environmental aspects of its activities, products and services that the organization determines it can either control or influence considering a life cycle perspective. ISO 14001:2015 does not state specific environmental performance criteria.

ISO 14001:2015 can be used in whole or in part to systematically improve environmental management. Claims of conformity to ISO 14001:2015, however, are not acceptable unless all its requirements are incorporated into an organization's environmental management system and fulfilled without exclusion.

QS 9000 is a company level certification based on quality system requirements related specifically to the automotive industry. These standards were developed by the larger automotive companies including Ford, General Motors and DaimlerChrysler. This standard is obsolete and has been replaced by either ISO/TS 16949 or ISO 9001.

This certification was for organizations in the automotive supply chain.

Organizations that wanted to become certified to the current version of QS9000 would need to complete an application, undergo a document review and certification audit. Once the certification was received, annual or regularly scheduled audits would be conducted to verify continued compliance to the standard.

QS 9000 was replaced by TS 16949:1999 and became obsolete in December, 2006. Currently, the latest version of this standard is IATF 16949.

QS 9000 was introduced in 1994. QS 9000 was an international quality management system (QMS) standard for the automotive industry originally developed by the ‘Big Three’ of the American auto industry, namely, Daimler Chrysler Corporation, Ford Motor Company, General Motors Corporation and major truck manufacturers, and is now managed by AIAG: Automotive Industry Action Group.

Like IATF 16949, QS-9000 applied to companies who supplied automotive production materials, production and service parts, heat treatment, painting, plating, and other finishing services. All suppliers of the automotive industry were not required to be certified to QS-9000 standards.

The Malcolm Baldrige National Quality Award (MBNQA) is an award established by the U.S. Congress in 1987 to raise awareness of quality management and recognize U.S. companies that have implemented successful quality management systems. The award is the nation's highest presidential honor for performance excellence.

Three MBNQA awards can be given annually in six categories:

- Manufacturing

- Service Company

- Small Business

- Education

- Healthcare

- Non-profit

The education and healthcare categories were added in 1999, while the government and non-profit categories were added in 2007.

The MBNQA award is named after the late Secretary of Commerce Malcolm Baldrige, a proponent of quality management. The U.S. Commerce Department’s National Institute of Standards and Technology manages the award, and ASQ administers it.

THE SEVEN MBNQA CRITERIA CATEGORIES

Organizations that apply for the MBNQA are judged by an independent board of examiners. Recipients are selected based on achievement and improvement in seven areas, known as the Baldrige Criteria for Performance Excellence:

Leadership: How upper management leads the organization, and how the organization leads within the community.

Strategy: How the organization establishes and plans to implement strategic directions.

Customers: How the organization builds and maintains strong, lasting relationships with customers.

Measurement, analysis, and knowledge management: How the organization uses data to support key processes and manage performance.

Workforce: How the organization empowers and involves its workforce.

Operations: How the organization designs, manages, and improves key processes.

Results: How the organization performs in terms of customer satisfaction, finances, human resources, supplier and partner performance, operations, governance and social responsibility, and how the organization compares to its competitors.

The 2021-2022 Baldrige Excellence Framework is available for the business/nonprofit industries. The 2019-2020 Baldrige Excellence Framework is available for the business/nonprofit, healthcare, and education industries. The criteria focuses on managing all components of an organization as a whole, cybersecurity risks, and understanding the role of risk management within a systems perspective of organizational performance management.

MBNQA RESOURCES

You can also search articles, case studies, and publications for Malcolm Baldrige National Quality Award resources.

Books

- Baldrige Users Guide, 2019-2020

- Insights to Performance Excellence 2019-2020

- Baldrige in Plain English, 2019-2020

- Baldrige for Leaders, 2019-2020

- Journey to Excellence: How Baldrige Health Care Leaders Succeed

- Road Map for the Baldrige Journey

What is the Deming Application Prize?

The Deming Application Prize is an annual award presented to a company that has achieved distinctive performance improvements through the application of TQM. Regardless of the types of industries, any organization can apply for the Prize, be it public or private, large or small, or domestic or overseas. Provided that a division of a company manages its business autonomously, the division may apply for the Prize separately from the company.

There is no limit to the number of potential recipients of the Prize each year. All organizations that score the passing points or higher upon examination will be awarded the Deming Application Prize.

Companies Qualified for Receiving the Prize

The Deming Application Prize is given to applicant companies or divisions of companies (applicant companies hereafter) that effectively practice TQM suitable to their management principles, industry, business and scope. More specifically, the following evaluation criteria are used for the examination to determine whether or not the applicant companies should be awarded the Prize:

1) Reflecting their management principles, industry, business, scope and business environment, the applicants have established challenging and customer-oriented business objectives and strategies under their clear management leadership.

2) TQM has been implemented properly to achieve business objectives and strategies as mentioned Item 1) above.

3) As an outcome of Item 2), outstanding results have been obtained for business objectives and strategies as stated in Item 1).

How to apply for the Deming Application Prize—Due date: January 15th

The application form, which is provided at the end of this booklet, must be completed and submitted with necessary documents.

The application deadline is January 15th.

Examination

- The Deming Application Prize Subcommittee examines and selects the candidates for the Prize.

- A document examination will be carried out based on the Description of TQM Practices submitted by the applicant company. If the applicant company passes the document examination, an on-site examination will be conducted. The Subcommittee makes judgment according to the evaluation criteria and reports the results to the Deming Prize Committee.

- The examination process is not open to the public, and all possible measures are taken to ensure the confidentiality of applicant companies.

Determination of the winners—Mid October

According to the report by the Subcommittee, the Deming Prize Committee determines the winners of the Prize and notifies them.

In the event that the applicant has not attained passing points, final judgment is reserved and, unless the applicant requests withdrawal, the status is considered as “continued examination.” Subsequent examinations are limited to twice during the next three years.

Public announcement of the winners—Mid October

After the Prize winners have been determined by the Deming Prize Committee as mentioned above, the winners are announced in the following publications and the reasons for receiving the Prize are stated:

1) The “Nippon Keizai Shimbun” (Japan Economic Journal)

2) The monthly magazine “Quality Management” (published by JUSE)

3) The monthly magazine “JUSE News” (JUSE Newsletter)

4) JUSE Home Page

Award ceremony—Mid November

The winners receive the Deming Medal with an accompanying Certificate of Merit from the Deming Prize Committee. The winners also receive a written report on the examination findings (including recommendations for future improvement of their TQM activities.)

Best practices presentations by prize winners—Mid November

The winners’ best practices presentations follow the award ceremony the next day.

Status Report and On-Site Review Three Years after Receiving the Prize

The prize-winning company is requested to submit a short report on the status of its TQM practices three years after having received the prize. As a rule, an on-site review for about half-day will be conducted based on the report.

In lieu of this review, the winning company may chose the following to further promote and develop its TQM:

1) To receive TQM Diagnosis by the Deming Prize Committee Members.

2) To receive the examination for the Japan Quality Medal.

As for the details, please contact the Secretariat for the Deming Prize Committee.

For more detailed information about the application procedures and the examination criteria, please refer to “The Deming Prize Application Guide”, can be downloaded on Deming Prize main page.

Key Takeaways

|

Reference:

1. Course Notes - National Institute of Technology, Calicut

2. Production and Operation Management - DDCE Utkal University