Unit – 5

Electrical Machines

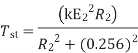

Q1) Draw and explain construction of DC machines.

A1) Whether machine is D.C. generator or motor the construction basically remains the same.

A cross section of typical D.C. machine

1)Yoke

a)Functions

1. It serve the purpose of outermost cover of the D.C. machine. So that the insulating materials get protected from harmful atmospheric elements like moisture.dust and various gases like  , acidic fumes etc.

, acidic fumes etc.

2. It provides mechanical support to the poles.

3. It forms a part of the magnetic circuit.

It provides a path of low reluctance for magnetic flux. The low reluctance path is important to avoid wastage of power to provide same flux large current and hence the power is necessary if the path has high reluctance to produce the same flux.

4.Choice of material:- It is prepared by using cast iron, silicon steel is used which provides high permeability i.e. low reluctance and gives good mechanical strength.

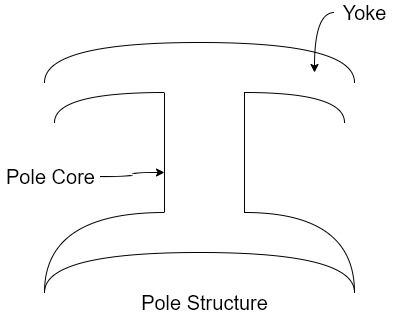

2) Poles

Pole structure

Each Pole is divided into two parts namely

Functions of pole core and pole shoe:-

Choice of material:-

It is made up of magnetic material like cast iron or cast steel.

As it requires a definite shape and size, laminated construction is used. The laminations of required size and shape are stamped together to get a pole which is then bolted to the yoke.

3) Field Winding (

The field winding is wound on the pole core with a definite direction.

a) Functions:-

To carry current due to which pole core on which the field winding is placed behaves as an electromagnet, producing necessary flux.

As it helps in producing the magnetic field i.e. exciting the poles as an electromagnet it is called Field winding or Exciting winding.

b) Choice of material:-

It has to carry current hence obviously made up of some conducting material.

So aluminium or copper is the choice. But field coils are required to take four types of shape and bent about pole core and copper has good pliability i.e. it can be bend easily. So copper is the proper choice .field winding is divided into various coils called field coils. These are connected in series with each other and wound in such direction around pole cores, such that alternate 'N' and 'S' poles are formed.

The total number of poles is denoted as P.

4) Armature

The armature is further divided into two parts namely

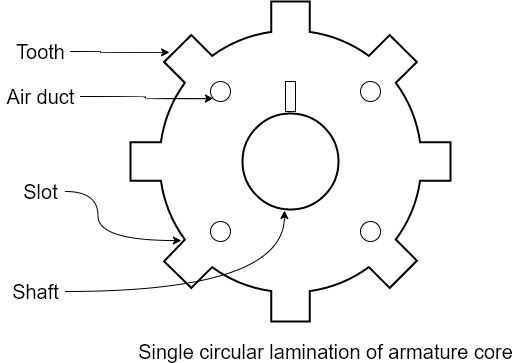

1.Armature core:- Armature core is cylindrical in in shape mounted on the shaft. It consists of slots on its periphery and air ducts to permit the air flow through armature which serves cooling purpose.

a) Functions-

1) Armature core provides house for armature winding i.e. armature conductors.

2)To provide the path of low reluctance to the magnetic flux produced by the field winding.

b) Choice of material:-

As it has to provide a low reluctance path to the flux, it is made up of magnetic material like cast iron or cast steel.

It is made up of laminated construction to keep Eddy current loss as low as possible. A single circular lamination used for the construction of armature core is shown in figure.

3. Armature winding

Armature winding is nothing but the interconnection of the armature conductors placed in the slots provided on the armature core periphery.

When the armature is rotated in case of generator magnetic flux gets cut by armature conductors and e.m.f gets induced in them.

a)Functions

1) curvatures of e.m.f takes place in the armature winding in case of generators.

2) To carry the current supplied in case of D.C. motors.

3) To do the useful work in the external circuit.

b) Choice of Material:-

As armature winding carries entire current which depends on external load, it has to be made up of conducting material which is copper.

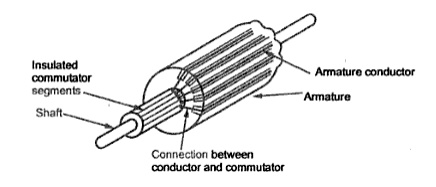

5.Commutator

The basic nature of e.m.f in the armature conductors is alternating. This needs verification in case of D.C. generator, which is possible by a device called commutator.

a)Functions:

1)To facilitate the collection of current from the armature conductors.

2) To convert internally developed alternating e.m.f to unidirectional (D.C.) e.m.f.

3) To produce unidirectional torque in case of motors

b) Choice of Material:-

As it collects current from armature, it is also made up of copper segments.

It is cylindrical in shape and is made up of wedge-shaped segments of hand drawn high conductivity copper .the segments are insulated from each other by thin layer of Mica.

Each commutator segment is connected to the armature conductor by means of copper lug or strip. This construction is shown in figure above.

6. Brushes and Brush Gear

Brushes are stationary and resting on the surface of the commutator.

a)Function-

to collect current from computer and make it available to stationary external circuit.

b) Choice of Material:-

Brushes are normally made up of soft material like carbon.

To avoid wear and tear of commutator the brushes are made up of soft material like carbon.

7) Bearings

Ball bearings are usually used as they are more reliable. For heavy duty machines roller bearing are preferred.

Q2) Find Voltage equation of DC motor.

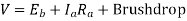

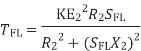

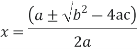

A2) From the equivalent circuit the voltage equation for a DC motor can be obtained as

The brush drop is practically neglected.

Hence the armature current  is expressed as

is expressed as

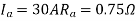

Q3) A 220 volt DC motor has an armature resistance of 0.75 ohm. It is drawing and armature current of 30 A, driving a certain load. Calculate the induced EMF in the motor under this condition.

A3) V=200V

Are the given values

For a motor ,

V=

220= +30*0.75

+30*0.75

=197.5 V

=197.5 V

This is the induced EMF called a back EMF in a motor

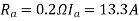

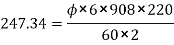

Q4) Find the useful flux per pole on no load of a 250V 6 pole shunt motor having two circuit connected armature winding with 225 conductors.at normal working temperature the overall armature resistance including brushes is 0.2 ohm. The armature current is 13.3A at the no load speed of 908 RPM.

A4) V=250 P=6 Z=220 A=2

As two circuit armature

N=908 r.p.m

For a DC shunt motor

250= +13.3*0.2 i.e.

+13.3*0.2 i.e.

Back emf is given by

is given by

Q5) Find Torque equation of a D.C. motor

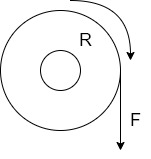

A5) The turning all twisting force about an exists is called torque.

Consider A wheel of radius R meters coated upon circumferential force F Newton as shown in figure (a)

The wheel is rotating at a speed of N r.p.m. then its angular speed is

W =  rad/sec

rad/sec

So work done in one revolution is

W=F×distance travelled in one revolution

= F×  Joules

Joules

P=power developed=

= (F×R) ×

P= T×W watts

Where T=torque in Nm and w = angular speed in rad/sec

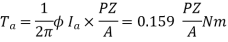

Let  the gross torque developed by the armature of the motor. It is also called armature torque.

the gross torque developed by the armature of the motor. It is also called armature torque.

The gross mechanical power developed in the armature is  as seen from the power equation.

as seen from the power equation.

So if speed of the motor is N r.p.m then

Power in armature=armature torque×w i.e.  .

.

But  in a motor is given by

in a motor is given by

This is the torque equation of D.C. motor.

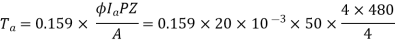

Q6) A 4 pole D.C. motor takes a 50A armature current. The armature has lab connected 480 conductors. The flux per Pole is 20 mWb . Calculate the gross torque developed by the armature of the motor.

A6) P=4, A=P=4, Z=480

=20mWb=

=20mWb=

Nm

Nm

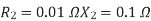

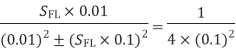

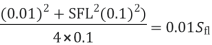

Q7) A 4 pole  , 50 Hz Induction motor has rotor resistances and resistance per phase are 0.01

, 50 Hz Induction motor has rotor resistances and resistance per phase are 0.01 and 0.1

and 0.1  respectively . Rotor induced emf at stand still per phase is 57.75 V .If maximum torque is twice that of full load torque then find full load speed of the motor.

respectively . Rotor induced emf at stand still per phase is 57.75 V .If maximum torque is twice that of full load torque then find full load speed of the motor.

A7) Given,

50Hz I.M.

50Hz I.M.

P=4 F=50 Hz

57.75V

57.75V

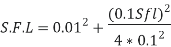

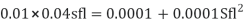

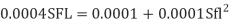

=

=

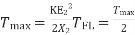

max. slip

max. slip

But,

Therefore ,

SFL=x=0.0267

1.025 =1

=1

=1500rpm

=1500rpm

N=(1-

N=1459.95rpm

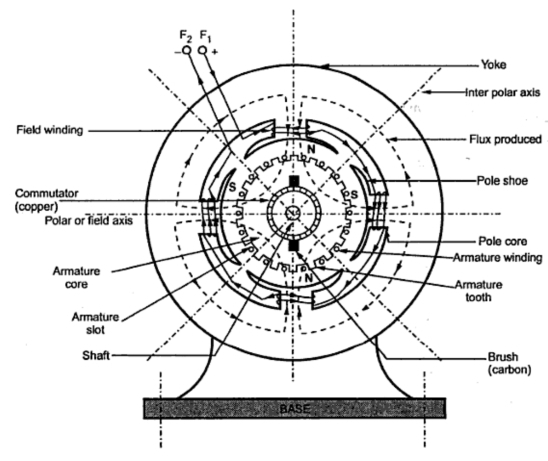

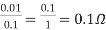

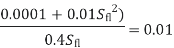

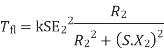

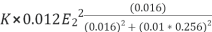

Q8) A 24 pole 50 Hz star connection I.M has rotor resist of 0.016ohm per phase & rotor reactance OF 0.256OHM PER PHASE at stand still conductor .It is achieving its full load torque at a speed of 247rpm.calculate the ratio of

A8) Given P=24 f=50Hz

N=247rpm

=250rpm

=250rpm

= =0.012

=0.012

S=0.012

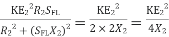

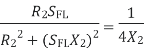

Slip that maximum torque

=0.0625

=

=

Ratio

Ratio