Unit 4

Joining/Fastening Processes

Q1 Explain welding process. Give its advantages and limitations.

ANS: Welding is referred a material joining process where two or more parts are joined at their contacting surfaces through appropriate application of heat and pressure. Most of the welding processes are achieved via means of heat alone or with pressure alone. In few welding processes, filler material is introduced to facilitate bonding. The assemblage of elements which are joined by welding is known as weldment. Welding is most commonly related to metal parts, whereas the process is additionally used for joining plastics.

Advantages of welding:

Limitations of welding:

Q2 . Classify welding process.

ANS: Welding is referred a material joining process where two or more parts are joined at their contacting surfaces through appropriate application of heat and pressure. Most of the welding processes are achieved via means of heat alone or with pressure alone. In few welding processes, filler material is introduced to facilitate bonding. The assemblage of elements which are joined by welding is known as weldment. Welding is most commonly related to metal parts, whereas the process is additionally used for joining plastics.

Advantages of welding:

Limitations of welding:

Welding processes are divided into two major groups:

(1) fusion welding (liquid-state welding) and (2) solid-state welding.

Fusion Welding Process:

Fusion-welding processes make use of heat to melt the parent metals. In most of fusion welding operations, a filler metal is introduced to accelerate the process and offer strength to the welded joint. When there is no filler metal added, in a fusion-welding operation, is termed as an autogenous weld. The fusion category contains the most globally used welding processes that can be divided into the following types:

Solid State Welding Process:

Solid-state welding is a joining processes where joint results through application of pressure alone or by a mixture of heat and pressure. If heat is used for welding, the temperature in the operation is below the melting point of the metals that are being welded. There is no use of filler metal in solid state welding. Solid state welding is categorized into following types:

Q3 Define power density, heat transfer factor and melting factor.

Power Density:

ANS: Power density can be referred as power transferred to the work per unit of the surface area.

Power density is given by,

Where,

P is the power entering the surface.

A is the surface area in which power is entering

Heat Transfer Factor

Heat transfer factor is defined as the ratio of the original heat received by the workpiece to the total heat generated at the source. It is denoted by  .

.

Melting factor

Melting factor is defined as the heat used for welding to the heat received at the workpiece. It is denoted by  .

.

Hence, heat available at welding is given by,

Where,

is the net heat available for welding process

is the net heat available for welding process

H is total heat generated at the source of heat.

Q4 A heat source transfers 3000 W to the surface of a metal part. The heat impinges the surface in a circular area, with intensities varying inside the circle. The distribution is as follows: 70% of the power is transferred with in a circle of diameter = 5 mm, and 90% is transferred within a concentric circle of diameter = 12 mm. What are the power densities in (a) the 5-mm diameter inner circle and (b) the 12-mm-diameter ring that lies around the inner circle?

Q5 The power source in a particular welding setup generates 3500 W that can be transferred to the work surface with a heat transfer factor = 0.7. The metal to be welded is low carbon steel, whose melting temperature, from Table 29.2, is 1760oK. The melting factor in the operation is 0.5. A continuous fillet weld is to be made with a cross-sectional area = 20mm2. Determine the travel speed at which the welding operation can be accomplished.

ANS:

Let us first find the unit energy required to melt the metal

and solving for the conditions of the problem

Q6 What are the design considerations in welding?

ANS:

If an assembly is to be permanently welded, the following guidelines should be followed by designer

The following design considerations apply to arc welding:

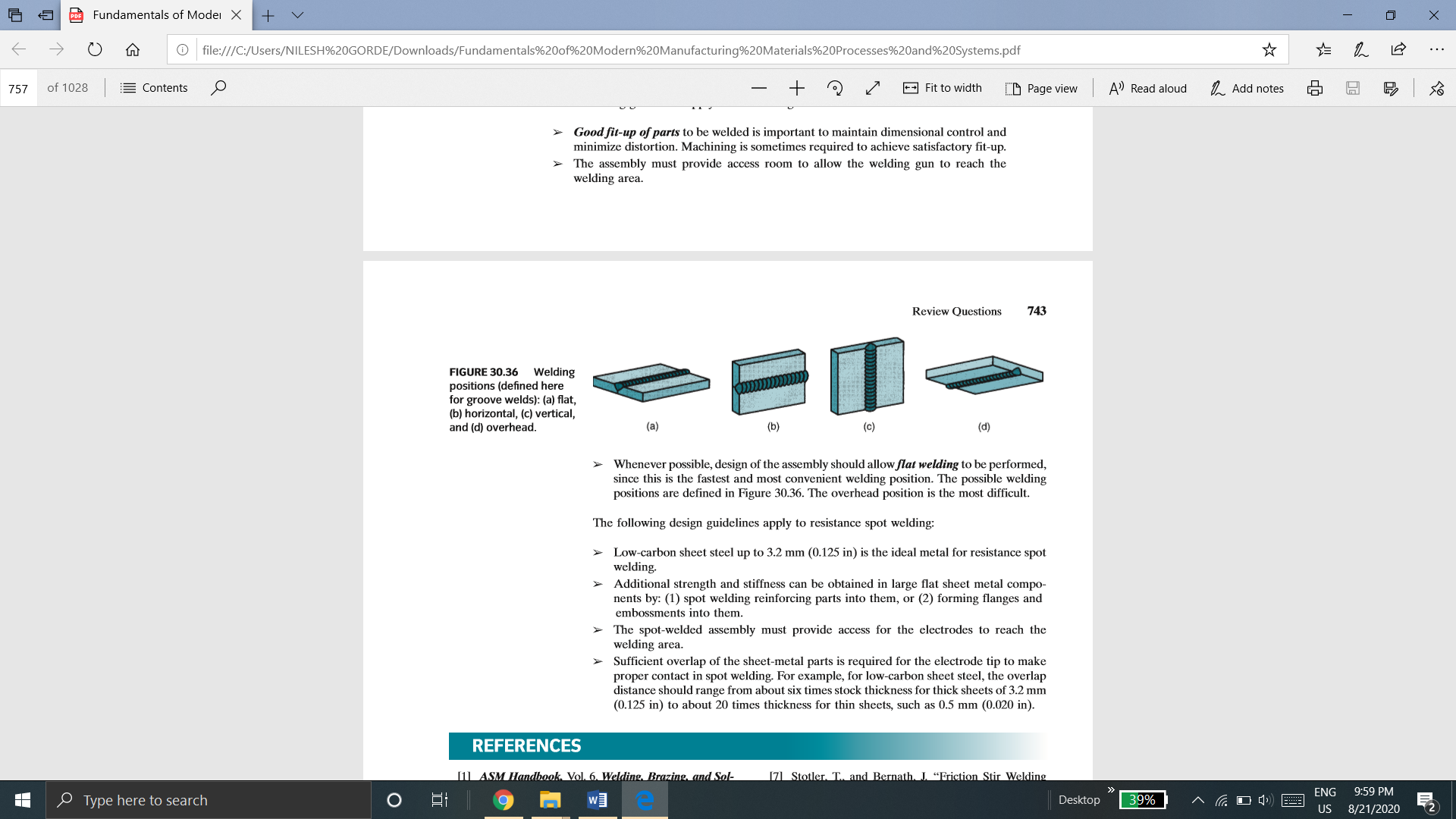

Figure Welding positions (defined here for groove welds): (a) flat, (b) horizontal, (c) vertical, and (d) overhead.

The following design guidelines apply to resistance spot welding:

Q7 What is solid and liquid state welding? Explain Brazing process.

ANS: Solid and liquid state joining process is referred to the joining process in which filler metal is melted or is in liquid state and is used for to create a bond between two solid metals.

Three different processes which are brazing, soldering and adhesive bonding are included in solid and liquid state joining process. The physical phenomenon associated with each of these processes is same but differ only in the metallurgical aspect. In these processes, the bulk material is not melted. A molten filler metal is used to provide a joint. The working temperature of these process is generally below the melting point of the base or parent metal.

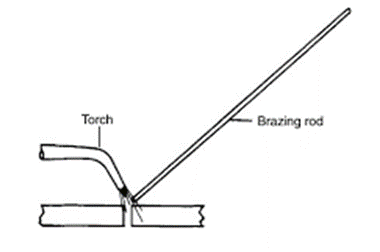

Brazing

Brazing is a joining process where a filler metal is melted and disbursed through a capillary action among the two surfaces of the metal parts to be joined. Here, the distance between two mating surfaces is very less. Melting of the base metals doesn’t occur in brazing. In brazing only the filler material is melted. In brazing the filler metal (also called the brazing metal), has a melting temperature that is above 450oC but below the melting point of the base metals to be joined. The brazed joint is much stronger compared to the filler metal from which it has been created upon solidification. This is because of the less part clearances used in brazing. The other reasons for stronger brazed bond is the metallurgical bonding that takes place among base and filler metals as well as the geometric constrictions which are imposed at the joint via base parts.

Q8 Explain adhesive bonding. Give its conditions.

ANS: Adhesive bonding is referred to a joining process where a filler material is used to hold two or more than two closely spaced parts together via means of a surface attachment. The filler material which helps in binding of these parts together is the referred to as adhesive. Adhesive is a nonmetallic substance, generally a polymer. Adherends are the parts that are being joined together.

A large number of commercially available adhesives are cured by various mechanisms and are suited to the bonding of various materials. Curing is defined as the process where the physical properties of adhesive are changed from a liquid to a solid, generally by chemical reaction, to achieve the surface attachment of the parts. The chemical reaction involves polymerization, condensation, or vulcanization. Curing is often motivated by heat or a catalyst, and pressure is sometimes applied between the two parts to activate the bonding process. If heat is required, the curing temperatures are relatively low, and so the materials being joined are usually unaffected. The curing or hardening of the adhesive requires time, called curing time or setting time. In some cases, setting time is generally significant.

Joint strength in adhesive bonding is determined by the strength of the adhesive itself and the strength of attachment between adhesive and each of the adherends.

Following are the conditions for adhesive bonding

Q9 Explain the fundamentals of Rapid Prototyping process.

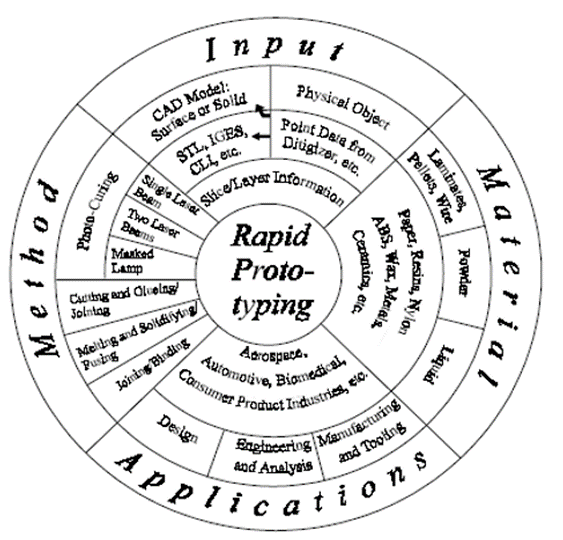

ANS: Fundamentals of Rapid Prototyping

The Rapid Prototyping Wheel depicting the 4 major aspects of RP

b. Method

The method employed by all vendors can be generally categorized into the following types:

• cutting and gluing or joining,

• photo-curing,

• melting and solidifying or fusing and joining or binding.

Photo-curing can be further divided into categories of

• single laser beam,

• masked lamp

• double laser beams and

c. Material

d. Application

• Design

• Engineering, Analysis and Planning

• Tooling and Manufacturing

Q10 Explain the basic steps in rapid prototyping.

ANS: Basic Steps in Rapid Prototyping Process

i) CAD Model Creation:

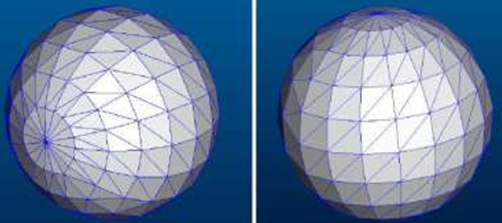

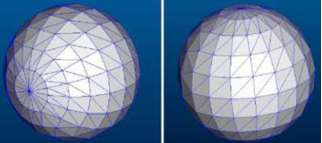

ii) Conversion to STL Format:

iii) Slice the STL File:

iv) Layer by Layer Construction:

v) Clean and Finish:

Q11 Classify Rapid Prototyping.

ANS: Classification of Rapid Prototyping

Based on initial form of material used, the rapid prototyping systems are broadly classified into three categories.

a) LIQUID-BASED

a) Stereolithography (SLA)

b) Polyjet Modelling

b) SOLID-BASED

a) Fused Deposition Modelling (FDM)

b) Laminated Object Modelling (LOM)

c) POWDER-BASED

a) Selective Laser Sintering (SLS)

b) 3D- Printing

Q12 Write a note on Rapid Tooling

ANS: Rapid-prototyping techniques have made possible much faster product development times, and they are having a major effect on other manufacturing processes. When proper materials are being used, rapid-prototyping machinery can create blanks for investment casting or similar processes. Hence that metallic parts may now be received fastly and economically, even for lot sizes as little as one part.

Such techniques also can be applied to create molds for operations (like injection molding, sand and shell mold casting, and also forging), thereby significantly reducing the lead time between design and manufacture.

Many approaches have been devised for the fast production of tooling (RT) via means of rapid-prototyping processes.

Rapid tooling is the process of manufacturing the tools using the rapid prototyping technique. It is widely used in many areas of industries.

The advantages to rapid tooling include the following:

The principal shortcoming of RT is the potentially decreased tool or pattern life as compared to the ones acquired from machined tool and die materials, like tool steels or tungsten carbides.

The easiest method of making use of rapid-prototyping operations to different manufacturing processes is in the direct generation of patterns or molds.

Classification of Rapid Tooling:

A] Classification method of tooling:

a. Direct Tooling

Direct Tooling is a process of making the tool, die or mold directly from the CAD data, using rapid prototyping process. For example, in injection molding, the main cavity, cores, runner, ejection system, etc. can be produced directly using rapid prototyping process.

b. Indirect Tooling

Indirect tooling is the process of making the master patterns for making tool, die or mold from CAD data, using rapid prototyping process.

It is not a tool production process but is a pre-production process. SLA, which gives a good accuracy and surface finish, is used as indirect tooling process.

B] Classification based on Material used:

a. Hard Tooling

Hard tooling is the process of making the tool, die or mold from hard materials like steel, using rapid prototyping process.

b. Soft Tooling

Soft tooling is the process of making the tool, die or mold from soft materials like silicon rubber, epoxy resin, low melting point alloys, etc. using rapid prototyping process.