Unit - 1

General requirement for water supply

Q1) What are the general requirements of water supply?

A1)

General requirements for water supply are as follows:

Population to be Served:

- Before any water supply scheme is launched, it is necessary to assess the present population and expected increase in the population within period of a decade or two.

- This is necessary to have the population projection figures, because the water supply schemes have some scope for the expansion of collection treatment and supply of water but it has its own limitation and so if the original water supply scheme is launched for a given number of people, after few years, the scheme becomes useless as the treated water is not enough for the growing population e.g. The drinking water supply schemes for Pune city was launched about 30 years back when the population of Pune city was about 25 million.

- Now in 2011, it has reached the figure of 40 million! So there is always problem of shortage of safe drinking water. The quantity and the quality of water supplied to the population of Pune has gone down.

Quality of Water:

- The quality of water provided for the drinking purpose, needs to have the minimum Indian standards.

- The water treatment is a costly business. So before the water supply scheme is launched, it is necessary to locate the right sources of water where the quality of the natural water itself is better.

- Better the quality of water at the source level lesser would be the cost of water treatment.

- So the water samples must collected and analyzed to know the quality of water available at the source.

- If there are more than one source of water the site where the better quality of water is available must be selected for the water supply scheme.

Rate of Consumption

- As already discussed water is needed for various purposes like domestic needs, industrial needs, transportation needs etc.

- Considering all the needs of a given population of a given city or town, per capita consumption rate must be calculated (the factors affecting the variations in the per capita consumption rates also should be taken in mind).

- This calculation will give an average figure of total water needed for a given period for the given population e.g. During the summer and winter monsoon, if the river dams are full, to their capacity. The local civic authority calculate the need and availability of water in the source region and make plans for the future supply of water to the community i.e. one time supply or two time supply within 24 hours.

Q2) What are the sources of water?

A2)

- For making any water supply scheme successful it is necessary to select the right site for the water supply.

- The norms to be used for selection are, the quality of water, the quantity of water and the distance of the source region from the town or city (longer the distance, more would be the cost of transport).

- So the smooth running of the water supply scheme depends upon the correct selection of the source of water to be used for that scheme.

Q3) Explain the quality of water?

A3)

- The quality of water provided for the drinking purpose, needs to have the minimum Indian standards.

- The water treatment is a costly business. So before the water supply scheme is launched, it is necessary to locate the right sources of water where the quality of the natural water itself is better. Better the quality of water at the source level lesser would be the cost of water treatment.

- So the water samples must collected and analyzed to know the quality of water available at the source.

- If there are more than one source of water the site where the better quality of water is available must be selected for the water supply scheme.

Q4) Explain design of intake?

A4)

- While designing and constructing any intake following points must be taken into considerations for safety and proper working of the intake.

- All the necessary safety factors must be considered before the construction of any intake-works, so that it can resist the heavy load created by huge waves, water currents, and impact of submerged or floating material.

- The intake should have sufficient self-weight, to prevent the floating of the structure of the intake. This be down by using broken stones to be filled at the bottom of the construction.

- If the intake work is to be located in a navigation channels; it should be given enough protection by constructing clusters of piles; to avoid the blows from the fishing boats or steam boats.

- The foundation of such intakes must be enough deep to avoid the overturning of the structure.

- The screen should be provided to control the entrance of medium or large size objects, in the inlets. The size of the inlets should be enough large to allow the required quantity of water.

- The location of the inlets should be such that it won't allow air to enter the suction pipe.

- There must be enough number of inlets. If one or two get blocked the water can pass through the remaining inlets.

Q5) Explain Factors Affecting the Location of Intakes?

A5)

While selecting the location of the intakes, the following factors are considered.

- To reduce the cost of conveyance of treated water the intake should be located near the treatment plant.

- The intake should be located in comparatively, pure water zone of the water source to reduce the load of treatment work, to reduce the cost and also the time required for the water treatment.

- The intake should not be located near the curve of the river.

- The intake should never be located on the downstream side of the sewage disposal. This factor is mainly important in case of urban water supply schemes.

- Even during the high floods also the intake must be easily accessible.

- The intake must be located at such location, from where the water is available even during the dry summers.

- In case the source of the intake is a navigable river, the intake must be kept away from the navigable channel to avoid the polluted water.

- The intake site should have more quantity of water available than the present requirement, to make it possible to go for expansion in future.

- The water in the intake should not have high velocity of water, which may cause danger to be structure of the intake, in future.

- As for as possible it must be near the jack well to reduce the cost of transport. It must have the regular and reliable power supply.

Q6) Explain Lake intake?

A6)

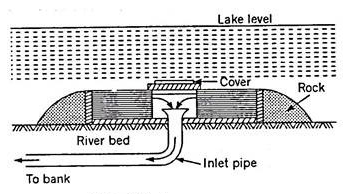

Fig 1: Lake Intake

- These intakes are constructed at the bed of the lake and they are of submersible types. These intakes are constructed below the slow water level of the lake to allow the drawing of water during dry-summers also.

- It consists of a pipe which has been laid over the bed of the lake, one of the ends of this pipe is fitted with bell mouth, which is covered with mesh. It has given a protection by the crib of timber or concrete.

- This mouth of the pipe is fitted at the middle point of the lake. The water collected from the mouth of the pipe with mesh, is carried to the bank of the lake by using the gravity force.

- This water carried by pipe is collected in a sump-well and from the sump-well it is carried into the treatment plant.

- These intakes have a lot of advantages e.g. They do not create obstruction to navigation.

- There no danger of blocking of the intakes due to floating bodies. To get the water up to the banks, if required more than one pipes can be laid down on the bed of the lake.

Q7) Explain River intake?

A7)

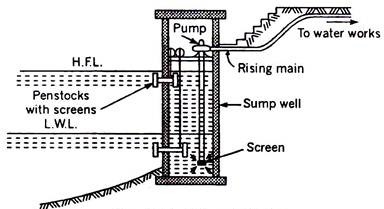

- Just the opposite to the lake intakes, the river intakes are always constructed in the upstream side.

- This can get almost fresh and pollution free water and needs less money and time for water treatment.

Fig 2: River Intake

- In case of the river intake, a circular masonry having 4 to 7 metres diameter, is constructed, along the bank of the river.

- The site is selected on the basis of equality of water available even during the dry summer season.

- The water is allowed to enter in the lower portion of the intake. It is known as sump-well.

- It draws water from the penstocks. These penstocks are fitted with the screen to control the entry of the floating solid material.

- These pen-stocks are placed on the downward sides of the river, to avoid the entry of the suspended solids.

- More than one pen stocks are provided in the intake tower, so they can be at the water level in any season of the year.

- The valves of the penstocks are opened or closed by the wheels fitted at the pump house.

Q8) Explain Reservoir intake?

A8)

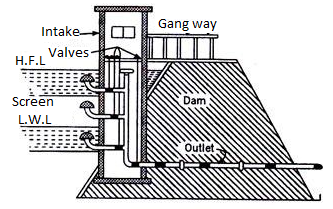

- All the rivers do not have the same amount of water flow. During rainy season they are over flooded and during hot dry summer, they are either partly or fully dry.

- So all the river cannot be used in the natural condition for the supply of water to the community. So, the dams are constructed on the rivers to create artificial reservoirs. In this case the intake tower is constructed on the sloping side of the dam.

Fig 3: Reservoir Intake

- The intake tower is placed at such a point that it can get water supply in sufficient quality even during the dry summer season. The intake points are fixed at different levels to get water, in all seasons though the level of water may get reduced.

- All the intake pipes are joined to a vertical pipe, which is fitted inside the intake tower. All the intake pipes have screens to prevent any floating or suspended material.

- The water collected in the vertical pipe is carried to other side of the dam by using outlet pipe. At the top of the tower, sluice valves are fitted to control the flow of water. The valve tower is connected to the top portion of the dam by foot-bridge gang-way, for reaching the place.

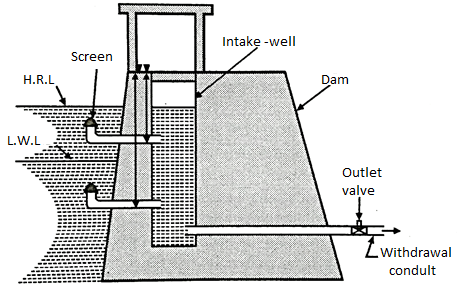

- In case of the earthen dam intake, towers are constructed separately outside the dam but in case of R.C.C. Masonry dams, it is constructed inside the wall of the dam but the intake pipes are kept at various levels, outside the dam and the outlet valves are fixed, outside the wall of the dam, on the withdrawal conduit.

Fig 4: Intake construction with the dam

Q9) Explain Canal intake?

A9)

- In case of the canals, the water level remains almost same throughout the year so the intake pipes are kept at one level only. The intake structure is constructed on the bank of the canal.

- The chamber is constructed in bricks, partly in the canal and partly in the wall of the bank of the canal. On one side of the chamber, the opening of the pipe has a coarse screen, for the entrance of water. At the end of the pipe inside the chamber, a bell mouth is fitted with a hemispherical fine screen.

- The outlet carries the water the other side of the canal bank and from that point the water is taken to the treatment plant. To control the flow of water a sluice valve is provided. It is operated by a well fitted on the top of the masonry chamber.

Fig 5: Canal Intake

Q10) What is Pumping of Water?

A10)

- The pumps are the mechanical method used to carry and lift the water above the level of the source. The pumps are necessary under the following conditions:

- To lift the water from the source and then pump it to the treatment plant.

- During the treatment in the plant, the pumps are required to lift the water in various sub-limits of the plant.

- The pumps are required for washing the filters to improve their efficiency.

- The pumps are used to mix the chemical solution with the water brought in for treatment.

- The pumps are used for filling the over head tanks and for the elevated reservoirs used for distribution of water.

- The pumps are used to increase the pressure in the pipelines.

- Finally the pumps are used to pump the treated water in the mains for distribution.

- So depending upon the heights of the source region and the treatment plant, the need of pumps goes on increasing.

Q11) Explain Displacement pumps?

A11)

- A vacuum is created by the mobile parts of the pumps. It is done mechanically i.e. the water is withdrawn in the pump, by the pressure, the mechanical part is displaced and the water is forced out of the chamber through a valve.

- The backflow of water is prevented by using suitable types of valves. On the basis of the function of these pumps, they are further divided as, Reciprocating pumps and Rotary pumps.

- Reciprocating pumps:

- These pumps also can be further divided as,

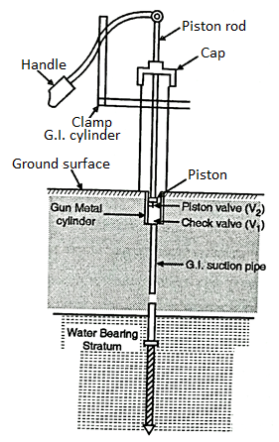

Simple hand operated reciprocating pumps:

Fig 6: Hand Operated reciprocating pump

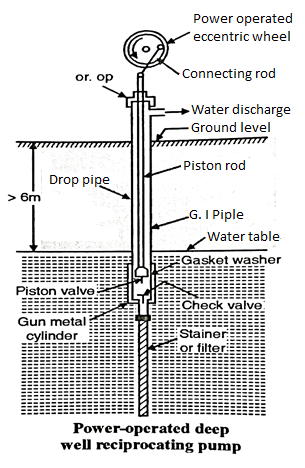

Power operated deep well reciprocating pumps:

Fig 7: Rotary pump with gear

Fig 8: Rotary pump with cams

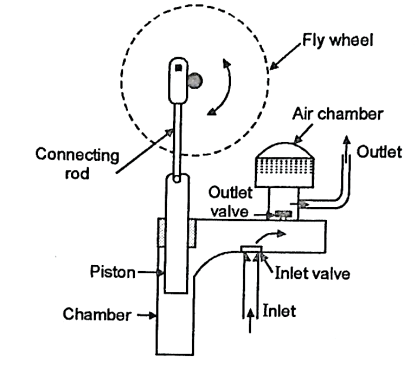

Single-acting reciprocating pumps:

Fig 9: Single acting Reciprocating pump

Double-acting reciprocating pumps:

Fig 10: Double acting reciprocating pump

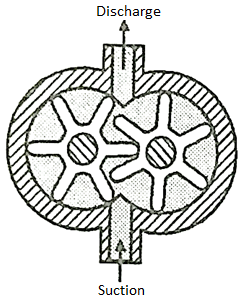

b. Rotary pumps:

- In these pumps the revolving blades are fit very closely, in the casing and these blades push to water by their displacement. The water is pushed in the upward direction, through the discharge pipe. The rotary pumps are of two types such as

- Rotary pumps with gear and

- Rotary pumps with cams.

Fig 11: Types of rotary pump

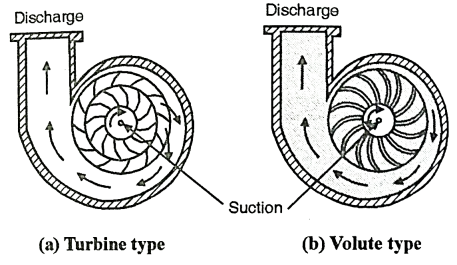

Q12) Explain Centrifugal pump?

A12)

These pumps are designed to work on the principles of centrifugal force.

The water entering inside the pump is revolved at a very high speed, by using impeller.

Due to the centrifugal force the water is sent to the periphery.

Fig 12: Centrifugal pump

On the basis of the function, the centrifugal pumps are classified as,

- Volute pumps: In these pumps the velocity of the water remains same at all the points in the channel which makes the water to rise in the delivery pipe at a higher rate.

- Turbine pumps: In case of these pumps, the velocity of water is reduced, before it enters in the casing. So these pumps convert the velocity head into pressure head.

- These pumps are classified on the basis of the number of impeller used i.e. the centrifugal pump using one impeller is known as single stage pump and where more than one impellers are used are known as "Double or Multi-stage pumps"

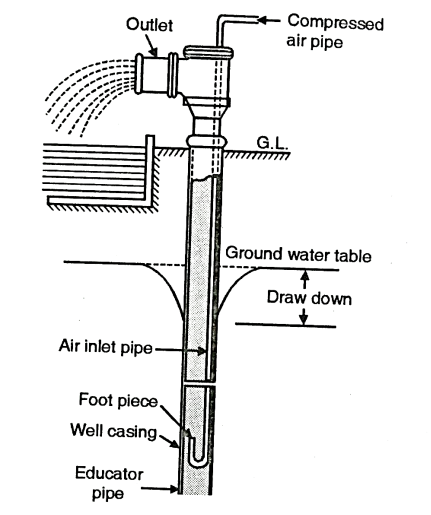

Q13) Explain Air lift pumps?

A13)

Fig 13: Air Lift Pumps

- These types of pumps are used when the water, which is to be lifted, has a lot of suspended material or the pH of water is more than 7 i.e. it is alkaline.

- These pumps are used to pull the water from the small or deep wells. They are very simple and easy to operate as they have no moving submerged parts.

- The pump consists of a vertical pipe which is known as educator pipe, which is placed in the casing pipe.

- The air inlet pipe is lowered in this vertical pipe i.e. in the educator pipe, the outlet is kept in the upward direction. At the top end of the air-lift pipe, the compressor is connected.

- The compressed air is pushed through the air-inlet pipe. The density of water is reduced due the mixing of compressed air and so it gets lifted up and it come through the outlet. The mechanism of this pump is easy to operate and cost also is less.

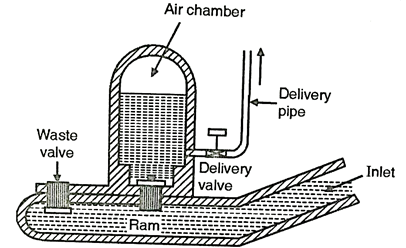

Q14) What is Impulse pump?

A14)

- This is also known as Hydraulic ram and it works on the principles of impulse. By using the hydraulic ram, the water can be lifted to a great height.

- This pump has an inlet pipe, waste valve, delivery valve, ram, air chamber and the delivery pipe. When it is not operating the waste valve is kept open and the delivery valve remains closed (due to the gravity force).

Fig 14: Impulse Pump

Advantages of the Impulse pump:

- The ram has a very long durability.

- The working is very simple.

- No external power is required to it is very cheap to operate.

Disadvantages of the Impulse pump

- When it is in operation, it creates a noise.

- Wastage of water is very high.

- It varies between 6:1 and 2:1.

Q15) Explain Transportation of water?

A15)

- After the purification of water in the water treatment plant it is required to be conveyed to the actual users i.e. to the urban or suburban centres.

- This supply of water is made either through the gravity conduits or through the pressure conduits.

- The water, when transported through the open channels, it is to be conveyed under the atmospheric pressure. This is a very cheap method; it has a lot of losses through evaporation and percolation.

- It also has the danger of surface contamination. So the gravity conduits have both the quantitative and qualitative losses of water, so it is better and safer to convey the water through the closed pressure conduits i.e. through pipe lines.

Q16) Explain advantages and disadvantages of Centrifugal pump?

A16)

Advantages of centrifugal pumps:

- As they are compact, they need less space.

- They can be fixed to a high speed driving mechanism.

- Due its rotary motion, no noise is produced.

- The cost of production and so the price is low.

- Due easy mechanism, the operations as well as the repairs are easy.

Disadvantages of centrifugal pumps:

- The flow rate of water cannot be controlled. They cannot be used without the prime movers.

- The efficiency is reduced because of the air leakages on the suction side.

- They have the high efficiency only for low head and low discharge.

Q17) Explain advantages and disadvantages of Rotary pump?

A17)

Advantages of rotary pumps:

- They are self primed.

- Their efficiency is high at low to moderate head (up the discharge of 2000 lit/per min.)

- They have no valves and are easy to construct.

- They give steady flow.

- They can be used for private use in the building and also for the fire protection.

Disadvantages of rotary pumps:

- The basic cost of the pump is high.

- Due to the abrasion of cams and gears, the maintenances cost increases.

- They are unable to pump the water having suspended material.