Unit - 1

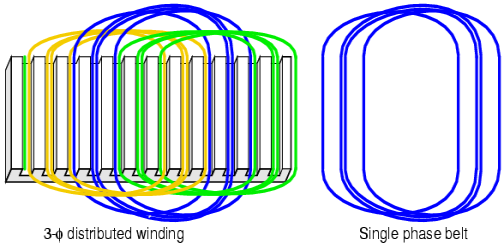

Physical arrangement of windings in stator and cylindrical rotor

Q1) Explain construction of induction motor?

A1)

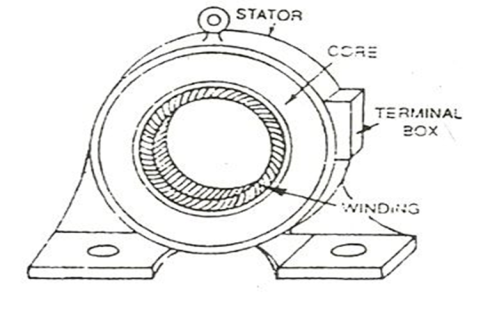

1. The stator is built up of high-grade alloy steel laminations to reduce eddy current losses. It has three main parts, namely outer frame, the stator core and a stator winding.

2. The core of the stator carries three phase windings which are usually supplied from a three-phase supply system.

3. The six terminals of the windings (two of each phase) are connected in the terminal box of the machine.

4. The stator core is built of high-grade silicon steel stampings. Its main function is to carry the alternating magnetic field which produces hysteresis and eddy current losses.

5. The stampings are fixed to the stator frame. Each stamping are insulated from the other with a thin varnish layer.

6.The thickness of the stamping usually varies from 0.3 to 0.5 mm. Slots are punched on the inner side of the stampings.

Fig: induction motor

Q2) Explain Construction and Working Principle of a Rotor?

A2)

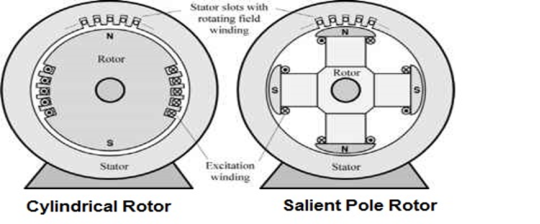

1. In a three-phase induction motor, once an AC is applied to the rotor then the windings of stator strengthen to generate a rotary magnetic flux. The flux generates a magnetic field in the air gap among the stator & the rotor to induce a voltage for generating the current throughout the bars. The circuit of this can be shorted & the flow of current will be in the conductors.

2. The act of the rotary flux & the current generates a force to generate a torque to begin the motor. The rotor in an alternator can be designed with a wire coil enclosed in the region of an iron core.

3. The magnetic component of this can be made with the laminations of the steel to assist stamping conductor slot to exact sizes & shapes. Whenever the current travels in the coil in a magnetic field then it creates a field current in the region of the core.

4. The strength of the field current mainly controls the level of power in the magnetic field. DC (direct current) drives the field current in the direction of the wire coil through a set of slip rings & brushes.

5. Similar to any magnet, the magnetic field generated will include two poles like south & north. The direction of the motor in the clockwise can be controlled through the magnets & magnetic fields fixed in this design, which allows the motor to run in a counter clockwise direction.

Fig: Types of rotor

Q3) Explain the concept of active portion and overhang in single turn coil?

A3)

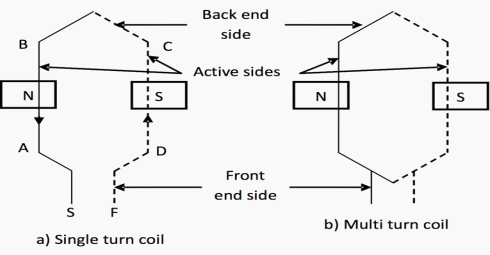

1. It is the part of a coil which lies in the slots under a magnetic pole and EMF is induced in this part only.

2. In Figure, coil sides AB and CD are called as active sides. For a double layer winding, one half portion of the coil drawn with solid line corresponds to the coil side lying on the top of a slot, and the dotted line corresponds to the coil side lying in the bottom layer of another slot.

1. The inactive side of a coil consists of two portions, namely the front end side and the back end side. In Figure 5, the portion of the conductor which joins the two active sides and placed around the core, is called the back end side of the coil.

2. The portions which are used to connect other coils are called front end side. These ends have two leads called as starting end S and finishing end F of a coil.

3. Overhang:

1. The overhang is defined as the configuration that the rotor length is longer than the stator length in the axial direction in this paper.

2. In general, the overhang structure is used to enhance air-gap flux and improve power density while utilizing free space caused by the stator end winding.

Fig: active portion and overhang of coil

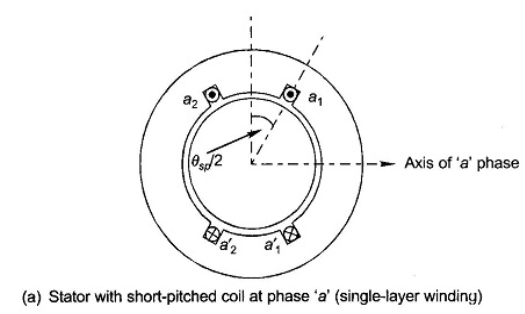

Q4) Explain the concept of full pitched coils?

A4)

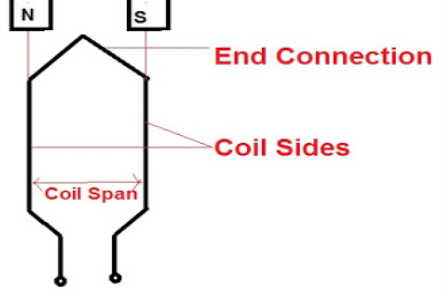

1. Coil pitch or coil span is defined as the angular distance between the two coil sides of one coil. It is expressed in terms of electrical space degree.

2. Coil pitch is 180 electrical space degree for full pitch coil and less than 180 degree for short pitch coil.

3. When the angular distance between the two coil sides is one pole pitch, it is called full pitch coil.

4. This means that both the coil sides are lying under the pole in full pitch coil. Figure below shows a full pitch coil.

5. The electrical space angle between the active coil length or coil side is equal to one pole pitch.

6. Since 1 pole pitch is the angular distance between the two consecutive poles which is equal to 180 electrical degree, therefore the coil span for full pitch coil is also equal to 180 electrical degree.

Fig: full pitched coils

Q5) What are concentrated windings?

A5)

1. A winding is called concentrated winding when the number of slots per pole per phase is fractional and strictly lower than 1.

2. Concentrated type of winding can be done when the total number of poles in the armature is equal to the number of slots of the armature coil.

3. Look at the image, the winding the total coils is wound in the single slots.

4. All the turns of this type of winding have the same magnetic axis, for example, the transformer winding.

5. This type of winding gives maximum output voltage but not exact sinusoidal because it is independent of pitch and distribution factor.

Fig: concentrated windings

Q6) What are Distributed windings? And explain its advantages?

A6)

1. Distributed winding is distributed along the air gap. In this winding poles are not equal to the number of slots. It does not have the same magnetic axis.

2. The emf induced in the distributed winding is less due to the presence of pitch factor and distribution factor.

3. Distributed windings are used in DC machine, synchronous machine and induction machine.

Advantages of Distributed Winding:

1. It reduces harmonics present in the generated emf which also improves the sine waveform.

2. It reduces armature reaction and improves cooling.

3. The coil is distributed over the slots, so the core (copper and iron) is fully used.

4.It improves the mechanical strength of the winding.

Fig: distributed winding

Q7) What are Sinusoidally distributed windings?

A7)

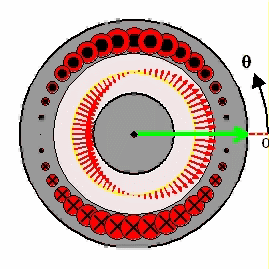

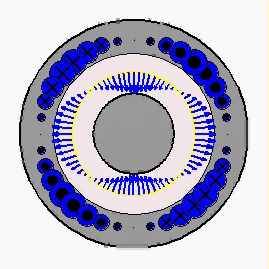

1. A sinusoidally distributed winding is excited with a sinusoidal current. The resulting pulsating radial flux density distribution is shown plotted along a circular path in the air gap (which is greatly enlarged for visual purposes.

2. When the windings are excited with balanced 3-phase sinusoidal currents, the combined effect is equivalent to having a single sinusoidally distributed winding excited with a constant current and rotating at the stator frequency.

Fig: sinusoidally distributed winding

Q8) Explain Distribution factor in detail?

A8)

1. If all the coil sides of any one phase under one pole are bunched in one slot, the winding obtained is known as concentrated winding and the total emf induced is equal to the arithmetic sum of the emfs induced in all the coils of one phase under one pole.

2. But in practical cases, for obtaining smooth sinusoidal voltage waveform, armature winding of alternator is not concentrated but distributed among the different slots to form polar groups under each pole.

3. In distributed winding, coil sides per phase are displaced from each other by an angle equal to the angular displacement of the adjacent slots.

4. Hence, the induced emf per coil side is not an angle equal to the angular displacement of the slots.

5. So, the resultant emf of the winding is the phasor sum of the induced emf per coil side. As it is phasor sum, must be less than the arithmetic sum of these induced emfs.

6. Resultant emf would be an arithmetic sum if the winding would have been a concentrated one.

7. As per definition, distribution factor is a measure of resultant emf of a distributed winding in compared to a concentrated winding.

8. We express it as the ratio of the phasor sum of the emfs in\duced in all the coils distributed in some slots under one pole to the arithmetic sum of the emfs induced.

Q9) Explain Winding factor with example?

A9)

1. Winding factor is a technique that is employed to improve the rms generated voltage or electromotive force (EMF) in a three-phase AC electrical machine so that the output voltage and hence torque does not have any harmonics in it which may reduce efficiency.

2. This is because the armature winding of each phase is distributed in a number of slots. Since the EMF induced in different slots are not in phase, their phasor sum is less than their numerical sum.

3. This reduction factor is called distribution factor Kd. Another factor that can reduce the winding factor is when the slot pitch is smaller than the pole pitch, called pitch factor Kp.

The winding factor can be calculated as

Kw = Kd * Kp

Example:

For a 3-phase 6 slot 4 pole non-overlapping winding motor:

Coil pitch=2π/6 = and 2π/3 (Elec)g Pole pitch =2π/ 4= π (Elec)

Most of 3phase motors have winding factor values between 0.85 and 0.95.

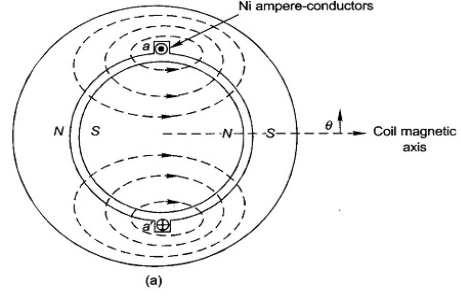

Q10) State and explain Air gap MMF distribution with fixed current through concentrated coil?

A10)

1. A cylindrical rotor with small air gap as shown in the figure below is assumed here. The stator is imagined to wound for two poles with a single N turn full pitch coil carrying current I in the direction indicated.

2. Each flux line radially crosses the air gap twice, Normal to the stator and rotor iron surfaces and it’s associated with constant mmf Ni. On the assumption that the reluctance of the iron path is negligible, half the mmf.

3. 2Ni is consumed to create flux from the rotor to stator in the air gap and the other half is used to establish flux from the stator to rotor in the air gap.

4. MMF and flux radially outwards from the rotor to the stator will be assumed to be positive and that from the stator to rotor is negative.

Fig: MMF of concentrated coil

Q11) State and explain air gap MMF space wave of one distributed winding?

1. Consider now a basic 2 pole structure with a round rotor, with 5 slots/pole/phase (SPP) and a 2 layer winding

2. The corresponding along with the mmf diagram which is now a stepped wave –obviously closer to the sine wave than the rectangular mmf wave of a single concentrated coil.

3. Here the SPP is odd, half the ampere conductors of the middle slot of the phase a and a ’contribute towards establishment of South Pole and half towards North Pole on the stator.

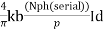

4. At each slot the mmf wave has a step jump of 2Nc Ic ampere conductors Where Nc Is the coil turns and IcIs the conductor current.

Where Ia = phase current =A Ic

It now follow that,

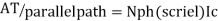

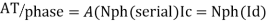

AT/ pole/ phase =

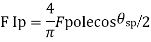

F Ip (concentred winding) =

F Ip (distributed winding) =

Fig: MMF of distributed coil