Unit - 3

Three Phase Induction Motor

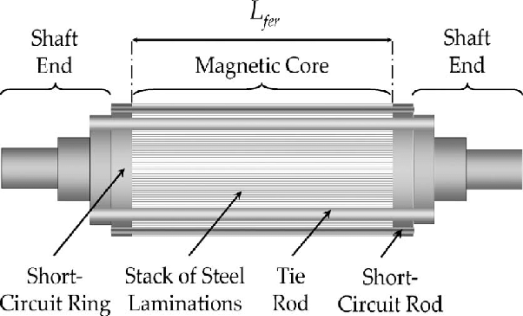

Q1) Explain the Construction of squirrel cage induction motor?

A1)

1. Squirrel cage motor is one of the types of induction motors. In order to generate motion, it hardens electromagnetism.

2. As the output shaft is connected to the rotor inner component which is looking like a cage. Hence it is called squirrel cage.

3. The two-end caps i.e., circular in shape is joined by rotor bars. These are acted based on the EMF i.e., generated by the stator.

4. This EMF is also generated outer housing that is made of laminated metal sheets and wire coiling.

- The two main parts of any type of induction motor are the stator and the rotor. The squirrel cage is a simple method of pulling an electromagnetic induction effect.

1. Parts that are required for the construction of squirrel cage induction motor are stator, rotor, fan, bearings.

2. The stator consists of mechanically and electrically 120 degrees apart three-phase winding with metal housing and core. In order to provide the path of low reluctance for flux generated by Ac current, the winding is mounted on the laminated iron core.

3. Rotor converts given electrical energy into mechanical output.

4. The shaft, a core, short-circuited copper bars are the parts of the rotor. In order to avoid hysteresis and eddy currents that are leading to power loss, the rotor is laminated.

5. And I order to prevent cogging, conductors are skewed which also helps to give a good transformation ratio.

6. A fan attached at the back of the rotor for heat exchange helps in maintaining under a limit of the temperature of the motor. For the smooth rotation, bearings are provided in the motor.

Fig: squirrel cage induction motor

Q2) Explain the types of squirrel cage induction motors in detail?

A2)

1. Class-A Design

These type motors have low resistance, reactance, slip, and higher efficiency at full load. The main disadvantage is high starting current which is 5 to 8 times of full-load current at rated voltage. These motors are widely used in small ratings for machine tools, centrifugal pumps, fans, blowers, etc.

2. Class B Design

These motors have high reactance and operate 5-150KW range. These motors can be replaced with class A motors for new installations because of its characteristics which are similar to Class A motors and have the same staring current. (Around 5 times the full-load current at rated voltage).

3. Class C Design

These motors are known as double cage motors that high starting torque with the low starting current. Applications of class C motors are, driving air compressors, conveyors, reciprocating pumps, crushers, mixers, large refrigerating machines, etc.

4. Class D Design

These motors are squirrel cage motors with high resistance. Hence, they give high starting torque with the low starting current. These motors have low operating efficiency and limited to drive intermittent loads involved in high accelerating duty and high-impact loads such as punch presses, shears, bulldozers, small hoists, etc.

5. Class E Design

These motors operate with low starting torque, normal starting current, and also low slip at rated load.

6. Class F Design

These motors are operated with low starting torque, low starting current, and normal slip.

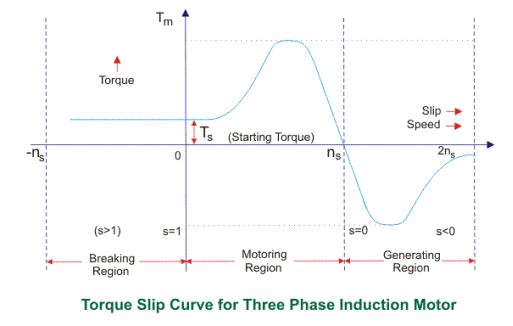

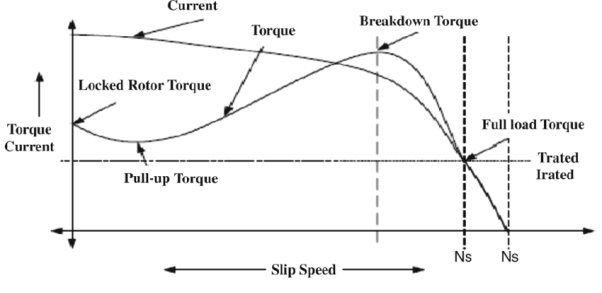

Q3) Explain torque slip characteristics of induction motor in detail?

A3)

The curve can be described in three modes of operation-

Fig: torque slip characteristics diagram

The torque-slip characteristic curve can be divided roughly into three regions:

1. Low slip region

2. Medium slip region

3. High slip region

A. Motoring Mode

1. In this mode of operation, supply is given to the stator sides and the motor always rotates below the synchronous speed.

2. The induction motor torque varies from zero to full load torque as the slip varies.

3. The slip varies from zero to one. It is zero at no load and one at standstill. From the curve it is seen that the torque is directly proportional to the slip.

4. That is, more is the slip, more will be the torque produced and vice-versa. The linear relationship simplifies the calculation of motor parameter to great extent.

B. Generating Mode

1. In this mode of operation induction motor runs above the synchronous speed and it should be driven by a prime mover.

2. The stator winding is connected to a three-phase supply in which it supplies electrical energy. Actually, in this case, the torque and slip both are negative so the motor receives mechanical energy and delivers electrical energy.

3. Induction motor is not much used as generator because it requires reactive power for its operation.

4. That is, reactive power should be supplied from outside and if it runs below the synchronous speed by any means, it consumes electrical energy rather than giving it at the output. So, as far as possible, induction generators are generally avoided.

C. Braking Mode

1. In the Braking mode, the two leads or the polarity of the supply voltage is changed so that the motor starts to rotate in the reverse direction and as a result the motor stops.

2. This method of braking is known as plugging. This method is used when it is required to stop the motor within a very short period of time.

3. The kinetic energy stored in the revolving load is dissipated as heat. Also, motor is still receiving power from the stator which is also dissipated as heat.

4. So as a result of which motor develops enormous heat energy. For this stator is disconnected from the supply before motor enters the braking mode.

5. If load which the motor drives accelerate the motor in the same direction as the motor is rotating, the speed of the motor may increase more than synchronous speed.

6.In this case, it acts as an induction generator which supplies electrical energy to the mains which tends to slow down the motor to its synchronous speed, in this case the motor stops. This type of breaking principle is called dynamic or regenerative breaking.

Q4) Define Starting and maximum torque?

A4)

1. Maximum torque

The developed torque is maximum when the rotor resistance per phase is equal to the rotor reactance per phase under running conditions.

2. Starting torque

Starting torque is the torque transferred by the shaft coupling during run-up (see Start-up process). It is calculated based on the ratio of power (P) to angular velocity (ω) and is represented as a rotational speed function.

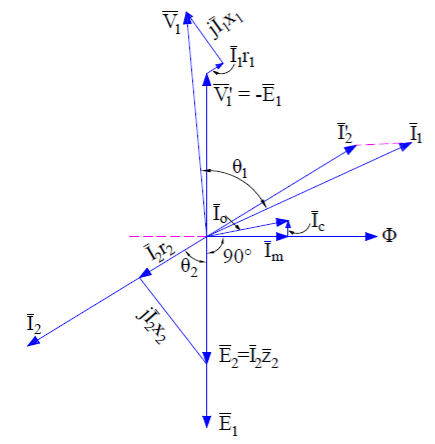

Q5) Explain in detail Phasor diagram of induction machines?

A5)

Induction Motor Phasor Diagram at Standstill Condition:

Before going into the phasor diagram, there are some important points to be taken care:

Per phase value of induced emf E1 in the stator winding is given as below

E1 = √2πf1kw1N1Ø

Where f1 = supply frequency

N1 = Number of series turns per phase

Ø = resultant air gap flux per pole

Kw1 = Stator winding factor

Per phase value of induced emf E2 in rotor winding is given as

E2 = √2πf2kw2N2Ø

Where f2 = frequency of induced emf in rotor = sf1

N2 = Number of series turns per phase

Ø = resultant air gap flux per pole

Kw2 = Rotor winding factor

1. Total air gap mmf Fr of induction motor is the sum of stator mmf (F1) and rotor mmf (F2).

2. Magnetizing current Im taken by stator winding from the supply always remains in phase with the resultant flux Ø. The induced emf always lags behind the resultant flux Ø by 90°.

3. Now we are at a stage to draw the induction motor phasor diagram. Let us take the resultant air gap flux Ø as the reference. This flux Ø will be in phase with the resultant mmf Fr. Also, the induced emf E1 and E2 in stator and rotor winding will lag behind the Ø by 90°. This is shown in the below phasor diagram of induction motor.

Fig: Phasor diagram of induction motor

4. Since the rotor mmf counteracts the stator produced mmf as per Lenz’s law, therefore stator takes extra current from supply to counterbalance the effect of rotor current. Therefore, under normal condition,

Stator mmf = Rotor mmf

N1’I2’ = N2’I2

Where N1’ and N2’ are the effective stator and rotor turns per phase.

5. This component of stator current is called the load component. In addition to load component, stator also takes magnetizing current Im to build magnetic flux in the air gap.

6. Thus the total stator current I1 = I2’ + Im. This is shown in the above phasor diagram. I2’ is shown opposite to the rotor current I2 for the reason discussed above.

7. At standstill condition, E2 = I2 (r2 + jx2). The core loss component of stator current Ic is in phase with V1’ or –E1. At standstill condition, the friction and windage loss is zero, therefore the stator no load current is given as

I0 = Im + Ic

Since stator applied voltage V1 must balance the stator back emf V1’ or -E1, stator impedance drop I1(r1 + jx1), therefore we can write

V1 = V1’ + I1(r1 + jx1) ……(1)

Similar equation exists for rotor circuit and can be written as

E2 = I2 (r2 + jx2) ……..(2)

8. The above equations are applied for drawing induction motor phasor diagram as shown in above figure. It can be easily seen from the above phasor diagram that, the power factor (cosɵ) of induction motor at starting is very poor as ɵ is large.

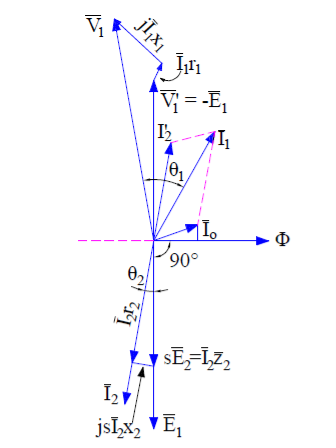

- Induction Motor Phasor Diagram at Full Load Slip:

1. At full load, the slip s of induction is low. The stator voltage equation (1) do not changes when the motor is loaded. But the rotor voltage equation changes with slip. The rotor induced voltage at any slip s becomes sE2 and the rotor circuit reactance becomes sx2. Therefore,

SE2 = I2 (r2 + jsx2)

2. The above rotor equation when implemented, the induction motor phasor diagram will become different from the phasor at standstill condition. The induction motor phasor at full load slip s is shown below.

Fig: Phasor diagram at full load

3. Since at full load condition, some friction and windage loss will exists. This means that stator will have to draw some extra current from the supply main to provide this additional loss.

4. Therefore the total no load current I0 taken by stator is the sum current Ifc and Im. It can be seen from the above phasor diagram that power factor of induction motor improves.

5. Generally at full load the power factor ranges in between 0.8 to 0.9.

Q6) Classify the losses in induction motor in detail?

A6)

A. Iron or Core Losses

1. Iron or core losses are further divided into hysteresis and eddy current losses. Eddy current losses are minimized by using lamination on core.

2. Since by laminating the core, area decreases and hence resistance increases, which results in decrease in eddy currents. Hysteresis losses are minimized by using high grade silicon steel.

3. The core losses depend upon frequency of the supply voltage. The frequency of stator is always supply frequency, f and the frequency of rotor is slip times the supply frequency, (sf) which is always less than the stator frequency.

4. For stator frequency of 50 Hz, rotor frequency is about 1.5 Hz because under normal running condition slip is of the order of 3 %. Hence the rotor core loss is very small as compared to stator core loss and is usually neglected in running conditions.

B. Mechanical and Brush Friction Losses

1. Mechanical losses occur at the bearing and brush friction loss occurs in wound rotor induction motor. These losses are zero at start and with increase in speed these losses increase.

2. In three phase induction motor the speed usually remains constant.

3. Hence these losses almost remain constant.

C. Variable Losses

1. These losses are also called copper losses. These losses occur due to current flowing in stator and rotor windings.

2. As the load changes, the current flowing in rotor and stator winding also changes and hence these losses also change. Therefore, these losses are called variable losses.

3. The copper losses are obtained by performing blocked rotor test on three phase induction motor. The main function of induction motor is to convert an electrical power into mechanical power.

Q7) Derive equation for Efficiency?

A7)

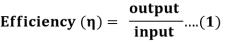

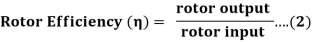

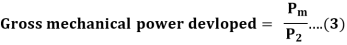

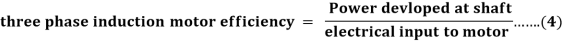

Efficiency of 3 phase induction motor:

Efficiency is defined as ratio of output to that of input

Rotor efficiency of 3 phase induction motor

Gross mechanical power developed /rotor input

Three phase induction motor efficiency

Three phase induction motor efficiency

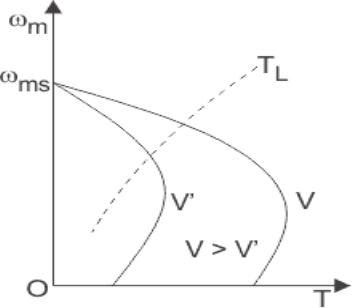

Q8) Explain in detail Variations by parameters in Torque-Speed Characteristics?

A8)

1.WRT to diagram in a previous article for torque-speed characteristics, we studied the different parameters related to that curve.

2. Suppose if we have such rotor that has a higher value of the rotor resistance Rr due to this higher value of the resistance the starting torque will also larger, as torque is higher so the slip will also higher.

As we know that this equation.

P conv = (1-s) PAG

3. Due to the higher value of the slip, the power converted from the electrical to mechanical will have less value, due to less power conversion the efficiency of the motor will decreases.

4. From that, we can conclude that such a motor that has higher rotor resistance, has larger starting torque but less efficiency.

5. If the resistance of the rotor is less than the starting torque will also less but the efficiency of the motor will be larger than the motor that has a high value of the rotor’s resistance.

6. The manufacturer of the motor always tries to cooperation among the differing requirements of higher initial torque and suitable efficiency.

7. The solution for this is that if we put some additional resistance in the rotor of the wound motor during its starting for higher torque then during its normal working remove this resistance for good efficiency.

8. But there is a problem for this condition that the wound rotor motor is costly, its repairing price is also larger, need a multifaceted automatic control circuitry than cage rotor motors.

9. Similarly, it is sometimes significant to entirely cover a motor when it is sited in a risky or fiery atmosphere, and this is calmer to do with an entirely self-contained rotor.

10. It would be pleasing to add additional rotor resistance at initial and to eliminate it during normal operation without automatic control circuitry.

11. In the given figure you can see the 2 wound rotor motors characteristic curves, one motor has high resistance rotor and second has less resistance rotor.

12. At higher slip value, the anticipated motor should act like the higher-resistance wound-rotor motor curve and at less slip, it should act like the less-resistance wound-rotor motor curve.

Fig: Variations by parameters in Torque-Speed Characteristics

Q9) Explain the concept of speed control in induction machine?

A9)

Speed control of induction motors can be done in six methods which are

1. Pole changing

2. Stator voltage control

3. Supply frequency control

4. Eddy current coupling

5. Rotor resistance control

-concept

1. We know that the speed of the induction motor is inversely proportional to number of poles. So, it is possible to increase or decrease the speed of the induction motor if the number of the poles are decreased or increased respectively.

2. The motor in which the provision of changing the number of poles is present, they are called ‘pole changing motor’ or ‘multi speed motor’.

3. Another method of controlling the speed of induction motor drives is the stator voltage control. Stator voltage is directly responsible for the rotating speed of the rotor.

4. Torque is proportional to voltage squared and the current is proportional to the voltage. So, if the stator voltage is reduced the speed reduces and similarly if the stator voltage is increased the speed also increases.

5. The speed of an induction motor is proportional to the product of the supply frequency and air gap flux.

Fig: speed control graph

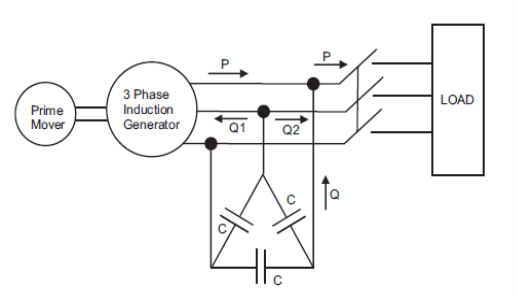

Q10) Explain Generator operation in detail?

A10)

Induction machines are sometimes used as a generator. These are known as induction generators or asynchronous generators. So, under what conditions an induction machine will behave as an induction generator?

An induction machine will behave as an induction generator when:

1. Slip becomes negative due to this the rotor current and rotor emf attains negative value.

The prime mover torque becomes opposite to electric torque.

2. Now let us discuss how we can achieve these conditions. Suppose that an induction machine is coupled with the prime mover whose speed can be controlled.

3. If the speed of the prime mover is increased such that the slip becomes negative (i.e., speed of the prime mover becomes greater than the synchronous speed).

4. Due to this, all the conditions that we have mentioned above will become fulfilled and the machine will behave like an induction generator. Now if the speed of the prime mover is further increased such that it exceeds the negative maximum value of the torque produced then the generating efficiency of the generator vanishes.

5. Clearly, the speed of the induction generator during the whole operation is not synchronous, therefore the induction generator is also called a synchronous generator.

6.An induction generator is not a self-excited machine. Therefore, in order to develop the rotating magnetic field, it requires magnetizing current and reactive power.

7. The induction generator obtains its magnetizing current and reactive power from the various sources like the supply mains or it may be another synchronous generator.

Fig: Generator diagram