Unit 4

Unit 4

Introduction to Manufacturing Systems

Question 1) which material is used in belts of belt drive?

Answer 1) MATERIALS USED FOR BELTS:

The Materials used for belts and ropes must be strong, flexible, and durable. It must have high coefficient of friction: like

1- Leather belts

2- Cotton belts

3- Rubber belts

4- Balata belts

Question 2) Explain Creep in Belts?

Answer 2)

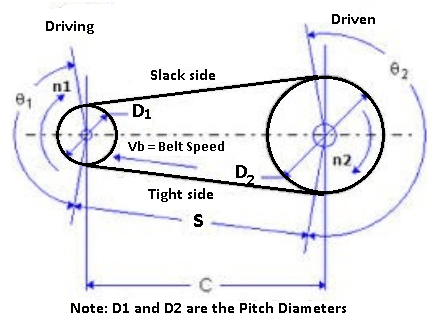

Consider as an open belt drive rotating in the clockwise direction. The portion of the belt leaving the driven and entering the driver is known as the tight side and a portion of the belt leaving the driver and entering the is known as the slack side.During rotation, there is an expansion of a belt on a tight side and contraction of the belt on the slack side.

Due to this uneven expansion and contraction of the belt over the pulleys, there will be a relative movement (motion) of the belt over the pulleys this phenomenon is known as Creep in a belt.

Question 3) Explain Slip in Belts?

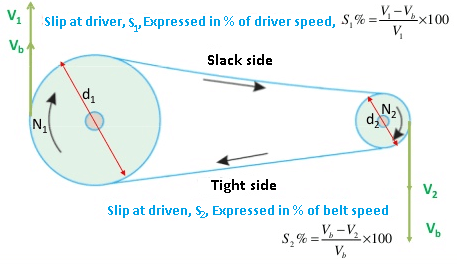

Answer 3)Consider an open belt drive rotating in a clockwise direction, this rotating of the belt over the pulleys is assumed to be due to firm frictional grip between the belt and the pulleys.

When this frictional grip becomes insufficient, there is a possibility of forwarding motion of driver without pulley with it, this is known as the slip in a belt.

Therefore slip may be defined as the relative motion between the pulley and the belt in it. This reduces the velocity ratio and usually expressed in % and it is denoted by S.

Belt slip is caused due to the following reasons:

(a) Continuous run of the belt, pulley rim surface becomes very smooth,

(b) Decrease in the coefficient of friction in between the two surfaces.

(c) Increase in the length of belt due to constant operation.

(d) Large difference in the tension of the tight side (T1) and the slack side (T2).

Question 4) Explain the difference between belt drive and chain drive?

Answer 4)Belt Drive vs Chain Drive:

Belt Drive | Chain Drive | ||

1) Belt drive is used for transferring the power. | The chain drive is also used for transferring power. | ||

2) The belt drive is powered by only a belt. | The chain drive is powered by a chain loop. | ||

3) Belt drives are made up of synthetic material. This is not stronger as compared to the belt drive. | Chain drives are made up of metal which is stronger and more durable. | ||

4) Belt drives are used in mills. | The chain drive is used in bicycles, motorcycles, and many more engines. | ||

5) In belt drive, little difficulties have when it gets damaged. | It is easier to change or fix when its get damage | ||

6) Low or medium in price | Price is high | ||

7) The belt drive is not the lubricating system | The chain drive is a lubricating system. | ||

8) The belt drive is quieter than the chain drive. | The chain drive is not quittered than a belt drive. | ||

Question 5) What are the different types of chains?

Answer 5)

In the field of Mechanical Engineering chains can be classified into three broad categories and those are:

- Hoisting Chains

-Oval Link Chains

-Stud-Link Chains

2. Conveyor Chains

3. Power transmission Chain

-Block Chain

-Roller Chain

-Silent Chain or Inverted Tooth Chain

Question 6)Write applications of chain drives?

Answer 6)

Applications of chain drives

They are used for power transmission

They are used in transportation industry

They are used in wood working machinery

They are used in agricultural machinery

They are used in oil well drilling rigs

They are used in building construction

They are used in material handling equipment

They are used for lifting load

They are used for carrying materials

Question 7) what are the different materials used to manufacture the gears?

Answer 7) Materials used to manufacture gears:

Tempered steel is one of the most common materials for different types of gears, and aluminium is also common. Other materials used are:

- High strength steels

- Forged stainless steels

- Copper-based alloys

- Cast or forged aluminium alloys

- Cast iron or grey cast iron

- Magnesium alloys

Question 8) what are the applications and utilities of gears?

Answer 8) Applications & Utilities of Gears

The different types of gears are present in many sectors, such as:

- The agricultural sector, in which they play a key role in carrying out mechanized tasks, such as sowing, ploughing or irrigation, as well as in the tractors themselves.

- In the automotive field, their function is usually to act as transmitters of forces and to regulate speed.

- As for naval vehicles, gears operate on fishing boats, submarines, workboats or yachts.

- In the generation of wind power, gears increase the speed of generators, a function that is also used by cement manufacturing industries. Roller mills are used for the transport of slabs and for wire rolling mills.

- In addition, there are four applications of gears that are particularly emblematic, and which are implemented in countless sectors and fields:

Question 9) Describe all the characteristics of gears?

Answer 9)

Characteristics of Gears by Type

Note: If applicable, “A” indicates advantageous characteristics and “D” indicates disadvantageous characteristics | |

Type of Gear | Characteristics |

Spur |

|

Helical |

|

Bevel |

|

Worm |

|

Rack and Pinion |

|

Question 10) What are the parameters we should consider in gear selection process?

Answer 10)Gear Selection Considerations

Gears are employed in a variety of mechanical devices, and, consequently, several different types and designs are available. The suitability of each type of gear and its exact design for a motion or power transmission application is dependent on the specifications and requirements of the application. Some of the principal factors which may be considered when designing and choosing a gear include:

1) Operational and environmental conditions

2) Dimensional restrictions

3) Transmission requirements

4) Design standards

5) Costs

Question 11) Explain the difference between open belts drive and crossed belt drive?

Answer 11) Differences between open belt drive and crossed belt drive

Open Belt Drive | Crossed Belt Drive |

In open belt drive, belt proceeds from top of one pulley to the top of other pulley without crossing. | In crossed belt drive, belt proceeds from top of one pulley to the bottom of other pulley and thus crosses itself. |

In open belt drive, driving shaft and driven shaft rotate in same direction. | In crossed belt drive, driving shaft and driven shaft rotate in opposite direction. |

Contact angle (or wrap angle) between the belt and pulley is comparatively small (always below 180º in smaller pulley). | Contact angle between the belt and pulley is comparatively large (always above 180º in smaller pulley). |

Length of the open belt is smaller as compared to cross belt. | For the same pulley diameter and same centre distance between driver and driven shafts, longer belt is required in cross belt drive. |

Here belt remains in same plane in every rotation during its operation. | Here belt bends in two different planes in every rotation during its operation. |

Here belt does not rub with itself. So belt life is considerably high. | Here belt rubs with itself and thus life of the belt reduces. |

Open belt drive is suitable when driving and driven shafts are in horizontal or little bit inclined. | Cross belt drive can be advantageously applied for horizontal, inclined and vertical positions of driving and driven shafts. |

Power transmission capacity is small due to smaller wrap angle. | It can transmit more power as wrap angle is more. |