Unit – 1

Introduction

Q1) What do you understand by manufacturing process? Classify various manufacturing processes.

A1) Manufacturing Process

Manufacturing process is that part of the production process which is directly concerned with the change of form or dimensions of the part being produced. It does not include the transportation, handling or storage of parts, as they are not directly concerned with the changes into the form or dimensions of the part produced.

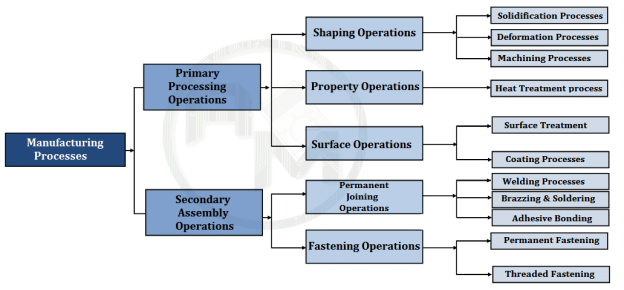

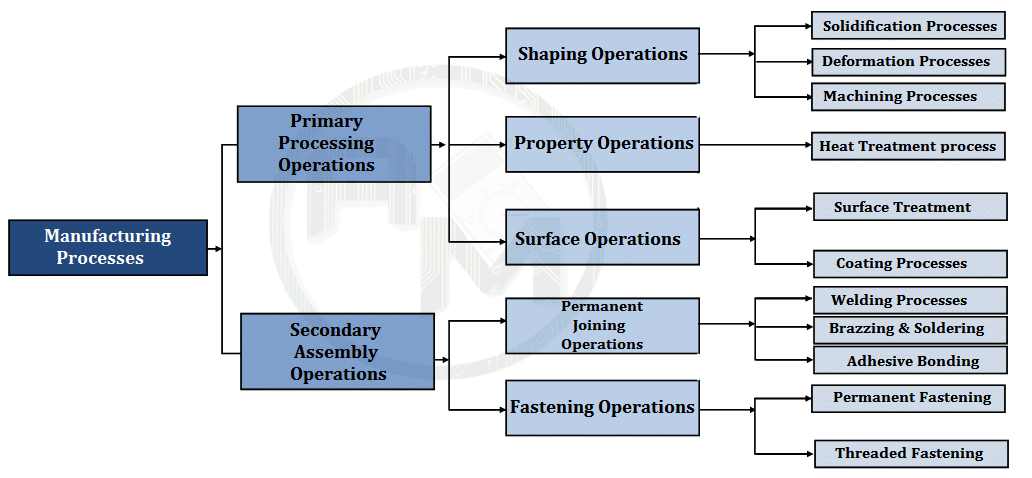

Classification of Manufacturing Processes

All processes used in manufacturing concern for changing the ingots into usable products may be classified into six major groups as primary shaping processes, secondary machining processes, metal forming processes, joining processes, surface finishing processes and processes effecting change in properties. These are discussed as under.

Primary Shaping Processes

Primary shaping processes are manufacturing of a product from an amorphous material. Some processes produce finish products or articles into its usual form whereas others do not, and require further working to finish component to the desired shape and size. Castings need re-melting of scrap and defective ingots in cupola or in some other melting furnace and then pouring of the molten metal into sand or metallic moulds to obtain the castings. Thus the

intricate shapes can be manufactured. Typical examples of the products that are produced by casting process are machine beds, automobile engines, carburetors, flywheels etc. The parts produced through these processes may or may not require to undergo further operations.

Some of the important primary shaping processes is:

(1) Casting, (2) Powder metallurgy, (3) Plastic technology, (4) Gas cutting, (5) Bending and (6) Forging.

Secondary or Machining Processes

The secondary processes require the use of one or more machine tools, various single or multi-point cutting tools (cutters), job holding devices, marking and measuring instruments, testing devices and gauges etc. for getting desired dimensional control and required degree of surface finish on the workpieces. The example of parts produced by machining processes includes hand tools machine tools instruments, automobile parts, nuts, bolts and gears etc.

Some of the common secondary or machining processes are—

(1) Turning, (2) Threading, (3) Knurling, (4) Milling, (5) Drilling, (6) Boring, (7) Planning, (8) Shaping, (9) Slotting, (10) Sawing, (11) Broaching, (12) Hobbing, (13) Grinding, (14) Gear cutting, (15) Thread cutting and (16) Unconventional machining processes namely machining with Numerical Control (NC) machines tools or Computer Numerical Control (CNC) machines tools using ECM, LBM, AJM, USM setups etc.

Q2) What do you mean by Industrial safety and write its objectives?

A2)

Industrial safety is primarily a management activity which is concerned with:

Objectives of Industrial Safety:

Q3) What are the causes of Industrial Accident?

A3)

Causes of Industrial Accidents are:

1. Unsafe conditions: The causes of industrial accident that pertain to unsafe conditions may include insufficient workplace lighting, excessive noise, slippery or unsafe flooring, extreme temperature exposure, inadequate protection when working with machinery or hazardous materials, unstable structures, electrical problems, machine malfunction or failure and so on.

a. The job itself

b. Work schedules

c. Psychological conditions

d. Machinery & Equipment

2. Unsafe Acts: The causes of industrial accidents that pertain to unsafe acts may include actions or failures to act which results in injury.

3. Miscellaneous Causes

Q4) Write the principles of plant layout.

A4)

Principle of Plant Layout are as follows:

1.Principle of Minimum Movement:

2.Principle of Flow:

3.Principle of Space:

4.Principle of Safety:

5.Principle of Flexibility:

6.Principle of Interdependence:

7.Principle of Overall Integration:

8.Principle of Minimum Investment:

Q5) Explain the Product or Line Layout and write its advantages and disadvantages.

A5) Product or Line Layout:

Under this, machines and equipment’s are arranged in one line depending upon the sequence of operations required for the product. The materials move from one workstation to another sequentially without any backtracking or deviation. Under this, machines are grouped in one sequence. Therefore, materials are fed into the first machine and finished goods travel automatically from machine to machine, the output of one machine becoming input of the next.

e.g., in a paper mill, bamboos are fed into the machine at one end and paper comes out at the other end. The raw material moves very fast from one workstation to other stations with a minimum work in progress storage and material handling.

The grouping of machines should be done keeping in mind the following general principles.

a) All the machine tools or other items of equipment’s must be placed at the point demanded by the sequence of operations.

b) There should no points where one line crossed another line.

c)All the operations including assembly, testing, packing must be included in the line.

Fig. Use of repetitive or continuous processing

Advantages of Product Layout:

1. Low cost of material handling, due to straight and short route and absence of backtracking.

2. Smooth and uninterrupted operations.

3. Continuous flow of work.

4. Lesser investment in inventory and work in progress.

5. Optimum use of floor space.

6. Shorter processing time or quicker output.

7. Less congestion of work in the process.

8. Simple and effective inspection of work and simplified production control. 9. Lower cost of manufacturing per unit.

Disadvantages of Product Layout:

1. High initial capital investment in special purpose machine

2. Heavy overhead charges

3. Breakdown of one machine will hamper the whole production process

4. Lesser flexibility as specially laid out for particular product.

Q6) Explain the Process or Functional Layout in detail.

A6) Process or Functional Layout:

In this type of layout machines of a similar type are arranged together at one place. E.g., Machines performing drilling operations are arranged in the drilling department, machines performing casting operations be grouped in the casting department. Therefore, the machines are installed in the plants, which follow the process layout.

The work, which has to be done, is allocated to the machines according to loading schedules with the object of ensuring that each machine is fully loaded.

Used when the operations system must handle a wide variety of products in relatively small volumes (i.e., flexibility is necessary)

The grouping of machines according to the process has to be done keeping in mind the following principles –

1. The distance between departments should be as short as possible for avoiding long distance movement of materials.

2.The departments should be in sequence of operations

3.The arrangement should be convenient for inspection and supervision.

Fig. Process layout

Advantages of Process Layout:

1. Lower initial capital investment in machines and equipment’s. There is high degree of machine utilization, as a machine is not blocked for a single product.

2. The overhead costs are relatively low

3. Change in output design and volume can be more easily adapted to the output of variety of products.

4. Breakdown of one machine does not result in complete work stoppage

5. Supervision can be more effective and specialized.

6. There is a greater flexibility of scope for expansion.

Disadvantages of Process Layout:

Q7) Explain the Fixed Position or Location Layout in detail.

A7) Fixed Position or Location Layout:

In this type of layout, the major product being produced is fixed at one location. Equipment labour and components are moved to that location. All facilities are brought and arranged around one work center. This type of layout is not relevant for small scale entrepreneur.

E.g. – shipbuilding

Fig. Fixed – Position Layout

Advantages Of Fixed Position Layout:

1. It saves time and cost involved on the movement of work from one workstation to another.

2. The layout is flexible as change in job design and operation sequence can be easily incorporated.

3. It is more economical when several orders in different stages of progress are being executed simultaneously.

4. Adjustments can be made to meet shortage of materials or absence of workers by changing the sequence of operations.

Disadvantages of Fixed Position Layout:

Q8) Write the electric safety measures in industries.

A8)

Q9) Explain the following:

1. Forming Processes

2. Moulding Processes

3. Machining Processes

A9)

1. Forming Processes:

In the metal industry, some of the primary forming operations may take place such as the rolling of basic shapes in steel, aluminium etc. Some of the common shapes so obtained from these processes are bars, sheets, billets, I-beams etc. Which are standard shapes. These shapes can be used for further processing. Other forming processes may be drop-forging, stamping, extrusion, press work, punching, drawing etc.

2. Moulding Processes:

Some products require moulding processes such as sand casting, die-casting etc. to get basic shape or form which may or may not require further processing. The selection of the particular process will depend upon to size of the job, quantity to be produced, accuracy, and complexity desired and economy.

3. Machining Processes:

Metal machining is accomplished through basic machine tool processes which involve the generation of cylindrical surfaces, flat surfaces, complex curves and holes. The machine tools selected to accomplish this task depend on the size and shape of the part to be machined, the quality of finish required and production rate required.

The examples of such processes are: turning, shaping, drilling, boring, grinding etc. In these machining operations metal is removed from the part in the form of small chips by the cutting action of tool. The cutting action is accomplished by either rotating or reciprocating action of the tool relating to the part.

Q10) Explain the Classification of manufacturing processes.

A10)

The manufacturing processes can be classified as:

1. Forming Processes

2. Moulding Processes

3. Machining Processes

4. Assembly Processes

5. Finishing Processes

1. Forming Processes:

In the metal industry, some of the primary forming operations may take place such as the rolling of basic shapes in steel, aluminium etc. Some of the common shapes so obtained from these processes are bars, sheets, billets, I-beams etc. Which are standard shapes. These shapes can be used for further processing. Other forming processes may be drop-forging, stamping, extrusion, press work, punching, drawing etc.

2. Moulding Processes:

Some products require moulding processes such as sand casting, die-casting etc. to get basic shape or form which may or may not require further processing. The selection of the particular process will depend upon to size of the job, quantity to be produced, accuracy, and complexity desired and economy.

3. Machining Processes:

Metal machining is accomplished through basic machine tool processes which involve the generation of cylindrical surfaces, flat surfaces, complex curves and holes. The machine tools selected to accomplish this task depend on the size and shape of the part to be machined, the quality of finish required and production rate required.

The examples of such processes are: turning, shaping, drilling, boring, grinding etc. In these machining operations metal is removed from the part in the form of small chips by the cutting action of tool. The cutting action is accomplished by either rotating or reciprocating action of the tool relating to the part.

4. Assembly Processes:

These processes assemble the parts and materials using welding, riveting, soldering, brazing, mechanical fastening and adhesive joining etc.

5. Finishing Processes:

These processes are carried out for the aesthetic aspects, to achieve accuracy, surface finish or to increase life of the product. Such processes include cleaning, blasting, deburring, puffing, honing, lapping, polishing, painting etc.