Unit – 4

Welding

Q1) Explain the types of joining operations.

A1) Assembly is the basic type of manufacturing operation in which two or more separate parts are joined to form a new entity. Components of the new entity are connected either permanently or semi-permanently.

Permanent joining processes include welding, brazing, soldering, and adhesive bonding. They form a joint between components that cannot be easily disconnected.

Certain mechanical assembly methods are available to fasten two (or more) parts together in a joint that can be conveniently disassembled. They are called temporary joining processes. The use of screws, bolts, and other threaded fasteners are important traditional methods in this category.

Other mechanical assembly techniques, called semi-permanent processes, form a more permanent connection than temporary processes. These include rivets, press fitting, and expansion fits.

Special joining and fastening methods are used in the assembly of electronic products. Some of the methods are identical to or are adaptations of the preceding processes, for example, soldering. Electronics assembly is concerned primarily with the assembly of components such as integrated circuit packages to printed circuit boards to produce the complex circuits.

Q2) Explain the oxy-acetylene welding process and write the principle of Gas welding.

A2)

Working principle of Gas Welding:

Q3) What do you mean by Resistance welding processes. Explain.

A3) Resistance welding processes differ from other welding processes in that no fluxes are employed, the filler metal is rarely used, and the joints are often of the lap type. The amount of heat generated in the workpiece depends on the magnitude of the current, the resistance of the current-conducting path, and the time for which the current is made to flow.

This is expressed in terms of joule heating. By the simple application of Ohm’s law, the voltage (V) required for a current flow (I) is given by the relationship

V = IR,

where R is the resistance offered by the workpiece to the flow of current.

The heat generated is, thus, expressed by the formula:

H = IVt

= I (IR) t

= I2 Rt

where, H = heat generated, joules

I = current, rms amperes

R = resistance, ohms

t = time of current flow, seconds.

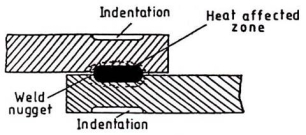

The heat generated is, thus, directly proportional to the resistance offered by any point in the circuit. As the interface of the two surfaces forming the lap joint is the point of greatest resistance, it is also the point of greatest heat. In simple resistance welding processes, a low voltage high amperage current flows from one adjoining plate to the other until the metal at the interface is heated to a high enough temperature to cause localized fusion which under the applied pressure squeezes the molten metal from the two parts to a homogenous mass called the weld nugget, as shown in Fig.

Q4) Explain the Manual metal arc welding.

A4) Manual metal arc welding

In this process, the heat is generated by an electric arc between base metal and a consumable electrode. As the electrode movement is manually controlled hence it is termed as manual metal arc welding. This process is extensively used for depositing weld metal because it is easy to deposit the molten weld metal at right place where it is required, and it doesn’t need separate shielding. This process is commonly used for welding of the metals, which are comparatively less sensitive to the atmospheric gases. This process can use both AC and DC. The constant current DC power source is invariably used with all types of electrodes (basic, rutile and cellulosic) irrespective of base metal (ferrous and non-ferrous). However, AC can be unsuitable for certain types of electrodes and base materials. Therefore, AC should be used in lights of manufacturer recommendations for electrode application. In case of DC welding, heat liberated at anode is generally greater than the arc column and cathode side. The amount of heat generated at the anode and cathode may differ appreciably depending upon the flux composition of coating, base metal, polarity and the nature of arc plasma. In case of DC welding, polarity determines the distribution of the heat generated at the cathode and anode and accordingly the melting rate of electrode and penetration into the base metal are affected.

Q5) Explain TIG and MIG Welding.

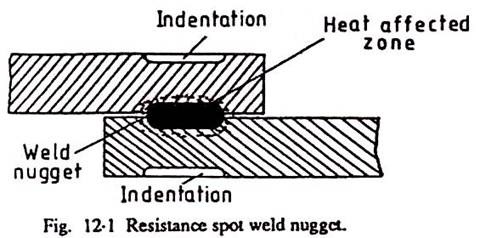

A5) Tungsten inert gas (TIG) welding or gas tungsten arc is an inert gas shielded arc welding using a non-consumable electrode. This electric arc is produced by the passage of current through a conductive ionized inert gas that provides shielding of the electrode, molten weld pool, and solidifying weld metal from contamination by the atmosphere. The process may be used with or without the addition of filler metal using metal rods. (a) The gas tungsten arc welding process, formerly known as TIG (for tungsten g inert-gas) welding. (b) Equipment for gas tungsten-arc welding operations.

Electrode: In TIG welding, tungsten refers to the element used on the electrode. The function of the electrode is to serve as one of the electric terminals which supply the heat required to the weld. Care must be taken so that the tungsten electrode does not come in contact with the weld pool in any way to avoid its contamination resulting in the faulty weld. Pure tungsten is less expensive and will carry less current. Some other elements may be added to the tungsten, like cerium, lanthanum, thorium, and zirconium creating electrode alloys to improve arc stability, emissivity, and bring higher melting points. The electrode may contain 1 to 2% thoria (thorium oxide) mixed along with the core tungsten or tungsten with 0. 15 to 0. 40% zirconia (zirconium oxide). The thoriated tungsten electrodes carry a high current, and more desirable as they can strike, and maintain a stable arc. The zirconia added with tungsten is better than pure tungsten but inferior to the thoriated tungsten electrode.

Tungsten inert gas welding set up: It consists of a welding torch at the center of which is the tungsten electrode. The inert gas supplied to the welding zone through the annular path surrounding the tungsten electrode to effectively displace the atmosphere around the weld puddle.

MIG

This is also known as Metal inert-gas arc welding (MIG) because it utilizes a consumable electrode. Other gas-shielded arc-welding processes are utilizing consumable electrodes such as flux-cored arc welding, all of which coming under MIG. It’s quite stable for thicker sheets because filler metal requirement in the welding process makes gas-tungsten arc welding (GTAW or TIG) difficult to use, which is more suitable for thin sheets. (a) Schematic illustration of the gas metal-arc welding process, formerly known as MIG (for metal inert-gas) welding. (b) Basic equipment used in gas metal-arc welding operations.

The consumable electrode is in the form of a wire reel fed at a constant rate through the feed rollers. The welding torch is connected to the gas supply cylinder, which provides the necessary inert gas. The electrode and the work piece are connected to the welding power supply. The power supply is always of the constant voltage type. The current from the welding machine is changed by the rate of feeding of the electrode wire. Normally, DC arc-welding machines are used for GMAW with electrode positive (DCEP). The DCEP increases the metal- deposition rate, and also provides a stable arc and smooth electrode metal transfer. With DCEN the arc becomes highly unstable, and also results in spatter. But special electrodes having calcium, and titanium oxide mixtures as coatings are found to be good for steel with DCEN.

Q6) Write the causes and remedies of welding defects.

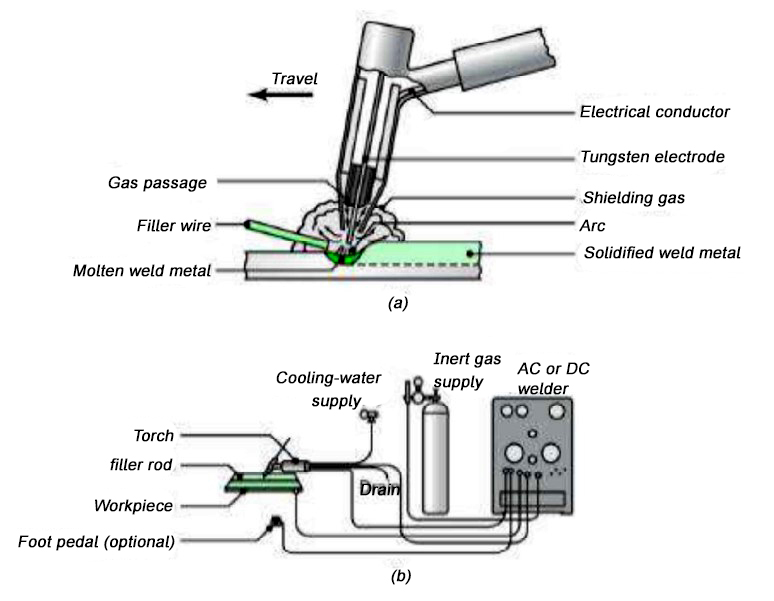

A6) Welding Defects can be defined as the irregularities formed in the given weld metal due to wrong welding process or incorrect welding patterns, etc. The defect may differ from the desired weld bead shape, size, and intended quality. Welding defects may occur either outside or inside the weld metal. Some of the defects may be allowed if the defects are under permissible limits but other defects such as cracks are never accepted.

Defects in welding joints are classified into 2 broad categories i.e., those that occur internally and those that occur externally.

External Welding Defects

External defects are also known as surface of visual defects because they manifest themselves on the surface itself. They include surface cracks, overlaps, undercuts, porosity, and spatter. We will discuss each one of them in the next section.

i. Cracks

Cracks are the most common defects and they can occur anywhere on the surface of the weld material. Some cracks can also be present inside the weld material especially on areas that are affected by direct heat (HAZ). Cracks presents themselves in two major types:

Causes of Cracks

Remedies

ii. Overlaps

Overlap results when the weld pool overflows on the surface of the weld metal. The molten metal does not fuse with the base metal leading to an overlap which may extend to form an angle not exceeding 90 degrees.

Causes of Overlaps

Remedies

iii. Undercuts

Undercuts presents themselves as narrow gutters on the base metal next to the weld metal near the edge. This occurs when the base metal melts away from the weld area reducing the thickness of the base metal and the result is a weakened workpiece. These undercuts run parallel to the metal weld.

Causes of Undercuts

Remedies

iv. Porosity

Porosity is a condition that manifests itself inform of gases or air bubbles that are trapped in the weld metal. It is mainly as a result of contamination of the weld metal which is weakened and it can actually collapse with time.

Causes of Porosity

Remedies

v. Spatter

Spatter occurs when metal particles from the weld is stuck on the area adjacent to the weld area. This defect is common in gas metal arc welding and it is sometimes very hard to remove the particles.

Causes of Spatter

Remedies

Q7) Explain the Internal Welding Defects of welding.

A7) Internal Welding Defects:

These are defects that occur at some depth in the material. They are visually invisible since they are not present on the surface but they carry equal weight as the external ones. These defects include incomplete fusion, slag inclusion, and incomplete penetration.

i. Incomplete Fusion

Lack of fusion or incomplete fusion occurs when the weld metal and the base metal are not accurately welded due to improper melting resulting into unfilled gap. Improper fusion can also occur between layers within the weld itself. Although this is an internal problem, it can be manifested on the outer surface too if the outer sidewall is not properly fused with the parent metal.

Causes of Incomplete fusion

Remedies

ii. Incomplete Penetration

Incomplete penetration results when the depth of the weld is not sufficient. As such, the metal grove is not filled fully meaning that the weld does not extend through the entire joint.

Causes of an Incomplete Penetration

Remedies

vi. Slag Inclusion

Slag inclusions are compounds such as oxides that are mainly trapped in the weld or on the surface of the weld zone. These compounds are byproducts of welding processes such as stick welding and arc welding. In addition, insufficient cleaning can leave some slag behind which reduces the strength of the weld and also it can act as a starting point of serious cracking. Serious slag inclusion may require you to do a re-weld.

Causes of Slag Inclusion

Remedies

Q8) Explain the soldering process in detail.

A8) Soldering

soldering is a process of joining two metals by using another low temperature metal alloy. The metal used for the joining purpose is called solder. Solders are of two types:

hard solder is an alloy of copper and zinc whereas the soft solder is an alloy of tin and lead.

Process

The surfaces to be joined are cleaned and are placed on each other. A fluxes employed to prevent oxidation. Zinc chloride is commonly used for this purpose. The soldering iron is heated either electrically or by some external heat. Then the heart and is dipped into the flux and solder is pressed against the surfaces to be joined. A joint is formed by melting the solder.

Applications

soldering is widely used for sheet metal work and in radio and television work for joining wires.

Advantages

Disadvantages

Q9) Explain the Brazing process in detail.

A9) Brazing

The process of joining two metal surfaces by heating, and adding a non-ferrous alloy with a melting point above 400-degree Celsius is known as brazing.

Process

The surfaces to be joined are cleaned from all oil, dirt oxides. Then both the surfaces are placed in the joining position. Flux is sprinkled or placed on it. The heat is given to the surface and the filler metal. The molten filler metal flows to the surfaces to be joined. On cooling, a brazing joint is formed. The filler metals used are copper, copper alloy, silver alloy, and Aluminium alloys. In brazing, the filler metal melts but the surfaces to be joined remain unmelted. The various methods used to melt the filler metal, and flux are:

Applications

Brazing is used for electrical items, radiators, heat exchangers comma pipes, and pipe fittings, and tooltips.

Advantages

Disadvantages

Q10) Compare Brazing and soldering process.

A10)

SR. No. | Brazing | Soldering |

1 | Filler metal has the melting point above 400°c | Filler metal has the melting point below 400°c |

2 | More stable joints can be made | Less stable joints can be made |

3 | High pressure and temperature do not affect the joint | Joints are affected by high temperature and pressure |

4 | Equipment cost is more | Equipment cost is very low. |