Unit 1

Scope of Study of Building Materials

- Explain the building material and their performance and also explain performance and testing.

Building Materials & their performance:

- Building substances ought to serve their meant feature now no longer most effective whilst newly established however additionally for a few perfect durations of time.

- These carrier lifestyles may also remain for the lifestyles of the constructing or, as with paints, for just a few years earlier than renewal.

- It is not unusual place to talk of the sturdiness of a cloth as though it had been a fundamental property, measured because the duration of time it's going to serve satisfactorily.

- The beneficial lifestyles of a cloth in place, however, is constantly associated with the specific aggregate of environmental elements to which it's far subjected, in order that sturdiness, or carrier lifestyles, ought to constantly be associated with the specific situations concerned.

- Experience with conventional substances over a few years allows prediction of the overall performance of the identical cloth below comparable situations.

- Such trial with the aid of using use has supplied a solution to how however now no longer regularly to why substances react as they do.

- When new substances are to be evolved or taken into consideration or whilst conventional substances are for use in untried situations, the capacity to expect overall performance can be significantly constrained until the "why" of beyond revel in, and therefore the essential elements concerned, are understood.

- This is fundamental to the exercising of judgment in design, an aggregate of revel in and analysis.

- Such a technique is likewise vital with inside the improvement and interpretation of any extended take a look at approach designed to enhance prediction of overall performance.

- Most constructing substances are complicated of their chemical and bodily nature, as are the tactics concerned of their reaction to environmental elements.

- Some generalizations can be made in those respects, however, a good way to enhance information of overall performance and offer a foundation for predicting behavior.

Performance and Testing:

- Exact prediction of overall performance calls for whole information of cloth properties, the tactics concerned with inside the interplay of the cloth with its environment, and the environmental elements to which it will likely be subjected. The most effective whole takes a look at of overall performance is trial with the aid of using use.

- Prediction will constantly be constrained with the aid of using loss of whole understanding; trial with the aid of using use could be constrained with the aid of using time and incapability to extrapolate to new situations.

- Test strategies may be used to complement understanding and revel in in predicting overall performance.

- Some take a look at strategies rely upon empirically derived family members among located behavior and a few without problems measured bodily property; others difficulty the cloth to environmental situations simulating the ones to be anticipated in exercise.

- The improvement of higher take a look at strategies and their right utility in exercise can most effective come approximately thru higher information of substances and their overall performance. Such information is likewise prerequisite to the right and vital assessment of beyond revel in.

2. What do you mean by economics of building material?

Economics of Building Material:

- Many clearly happening substances, which include clay, rocks, sand, and wood, even twigs and leaves, had been used to assemble buildings. Apart from clearly happening substances, much man-made merchandise is in use, a few greater and a few much less synthetic.

- The production of constructing substances is a longtime enterprise in many nations and the usage of those substances is usually segmented into precise strong point trades, which includes carpentry, insulation, plumbing, and roofing work. They offer the makeup of habitats and systems which include homes.

- Initial financial value of constructing substances is the acquisition price. This is frequently what governs selection making approximately what substances to use. Sometimes humans think about the electricity financial savings or sturdiness of the substances and spot the fee of paying a better preliminary value in go back for a decrease lifetime value.

- For example, an asphalt shingle roof expenses much less than a steel roof to install, however the steel roof will remaining longer so the lifetime value is much less in step with year. Some substances may also require greater care than others, keeping expenses precise to a few substances may additionally have an impact on the very last selection.

- Risks whilst thinking about lifetime value of a cloth is that if the constructing is broken which includes with the aid of using hearth place or wind, or if the fabric isn't as long lasting as advertised. The value of substances needs to be considered to endure the chance to shop for combustive substances to increase the lifetime. It is stated that, "if it ought to be performed, it ought to be performed well".

3. Explain the requirement of good building stone.

Requirement of Good Building Stone:

The following are the first-class necessities of right constructing stones:

Fig1.1.Different types of stone

1. STRENGTH

- Generally maximum of the constructing stones have excessive power to face up to the burden approaching it.

- Therefore, it isn't of top problem while it comes to test the high-satisfactory of stones. But while the stones are for use in huge structures, it will become vital to test the compressive power of stones.

- Compressive power of constructing stones usually falls in the variety of 60 to 200N/mm2.

2. DURABILITY

- Building stones have to be successful to face up to the detrimental outcomes of herbal forces like wind, rain and heat. It ought to be long lasting and have to now no longer go to pot because of the detrimental outcomes of the above herbal forces.

3. HARDNESS

- When stones are utilized in floors, pavements or aprons of bridges, they grow to be subjected to carrying and abrasive forces as a result of motion of guys or device over them. So, it's far required to check hardness of stone.

- Hardness of stone is decided via way of means of Mosh scale.

4. TOUGHNESS

- Toughness of stones method it capacity to face up to effect forces.

- Building stones have to be difficult sufficient to maintain stresses advanced because of vibrations.

- The vibrations can be because of the equipment established over them or because of the hundreds shifting over them.

- The stone aggregates utilized in the street buildings have to be difficult.

5. SPECIFIC GRAVITY

- The greater the particular gravity of stone, the greater heavier and more potent the stone is. Therefore, stones having better particular gravity values have to be used for the development of dams, maintaining walls, docks and harbors.

- The particular gravity of suitable constructing stone is among 2.4 and 2.8.

6. POROSITY AND ABSORPTION

- Porosity of constructing stones rely upon the mineral constituent and structural formation of the determine rock.

- If stones utilized in constructing creation are porous then rain water can without difficulty input into the pore areas and purpose harm to the stones.

- Therefore, constructing stone have to now no longer be porous. Water absorption of stone is without delay proportional to the porosity of rock.

- If a stone is greater porous then it's going to soak up greater water and purpose greater harm to stone.

- In better altitudes, the freezing of water in pores takes location and it outcomes into the disintegration of the stone.

- Permissible limits of water absorption for a few the normally used constructing stones are as follow.

Types of Stones | Maximum limit of water absorption (%) |

Sandstone | 10 |

Limestone | 10 |

Granite | 1 |

Shale | 10 |

Slate | 1 |

Quartzite | 3 |

7. DRESSING

- Giving required form to the stone is known as dressing.

- It has to be smooth to get dressed in order that the price of dressing is reduced.

- However, the care has to be taken in order that, this isn't being on the price of the desired power and the durability.

8. APPEARANCE

- In case of the stones for use for face works, in which look is a number one requirement, its coloration and capacity to get hold of polish is an essential factor.

- Light cultured stones are greater favored than darkish cultured stones because the coloration are probably to vanish out with time.

9. SEASONING

- Good stones have to be loose from the quarry sap.

- Lateritic stones have to now no longer be used for six to 365 days after quarrying.

- They are allowed to put off quarry sap with the aid of using the motion of nature.

- This procedure of putting off quarry sap is known as seasoning.

10. WORKABILITY

- Stone have to be plausible. Stone is stated to be plausible while the paintings worried in stone working (consisting of cutting, dressing & shaping) is low in cost and smooth to conduct.

11. COST

- Cost is an essential attention in deciding on a constructing material.

- Proximity of the quarry to constructing web website online brings down the price of transportation and consequently the price of stones comes down.

12. FIRE RESISTANCE

- Stones have to be loose from calcium carbonate, oxides of iron, and minerals having exceptional coefficient

4. Give the characteristics of good building stone.

Characteristics of Good Building Stones:

A top constructing stone have to have the subsequent qualities:

Appearance:

- Building Stones used for the face paintings of the constructing have to have best, compact texture.

- Light cultured stone is commonly favored as darkish colorations are susceptible to fade out with time.

- They have to be loose from clay holes, bands or spots of color.

Structure:

- A stone while broken have to now no longer be stupid in look and have to display uniformity of texture.

- It has to be loose from cavities, cracks, and patches of free or smooth material.

- Stratifications that are commonly located in sedimentary rocks have to now no longer be seen to bare eye.

Strength:

- Stones utilized in production have to be sturdy and sturdy to face up to the disintegrating motion of weather.

- Stones with compact best crystalline texture are stronger.

- Compressive power of constructing stones in practice, variety among 60 to 2 hundred N/mm2.

Specific gravity:

- The precise gravity of Building stone is at once proportional to its weight and power.

- Hence the stones having better precise gravity have to now no longer are used for dams, maintaining walls, docks and harbors.

- Specific gravity of a great constructing stone lies among 2.4 to 2.8.

Hardness:

- When stones are applied for floors, pavements, aprons of bridges and weirs of rivers, the stones are subjected to abrasive forces that are resulting from the wear and tear and friction.

- Hence the stones that are for use in such locations have to be examined for hardness.

Fig1.2.Hardness of Stone

Toughness:

- It is the degree of effect that a stone can withstand.

- When the stones are imagined to go through vibrations of equipment and transferring loads, they ought to be tough.

Porosity and Absorption:

- The porous constructing stones aren’t appropriate in creation particularly for uncovered surfaces of structures.

- The rain water which comes down conveys a few acidic gases forming mild acids which receive soaked at the surface.

- Acids react with the elements of stones inflicting them to crumble.

- In bloodless areas water freezes with inside the pores of stones.

- This water reasons the disintegration of stones due to its boom in quantity on freezing.

Fig1.3.Porosity of stone

The types of some of the stones and their maximum limit of water absorption (%) are as follows:

- Sandstone : 10

- Limestone : 10

- Granite : 1

- Trap : 6

- Shale : 10

- Gneiss : 1

- Slate : 1

- Quartzite : 3

Seasoning:

- All freshly quarried stones incorporate a positive quantity of moisture referred to as quarry sap, which makes them tender and simpler to paintings upon. Good stones must be loose from quarry sap. They are allowed to eliminate quarry sap with the aid of using the movement of nature. This procedure of disposing of quarry sap is referred to as seasoning. A length of 6-one year is normally sufficient for correct seasoning.

Weathering:

- It is the quantity to which the face of a stone resists the movement of weather. Stones with properly weathering residences most effective must be used with inside the production of essential buildings.

Fig1.4.Weathering of Stone

Workability:

- Stones are stated to be plausible if the wok that is worried of their cutting, dressing and shaping is taken into consideration as low-budget and smooth to conduct. Know the Current House creation fee

Fire Resistance:

- Building Stones ought to be loose from calcium carbonate, oxides of iron, and minerals having one of a kind coefficients of thermal expansion. Igneous rock goes through fundamental disintegration due to quartz which disintegrates into small debris at a temperature of approximately 575 co. Limestone, however, can face up to a touch better temperature; i.e. as much as 800 oC and then they disintegrate.

5. Explain the crushing strength test on stone and water absorption test on stone.

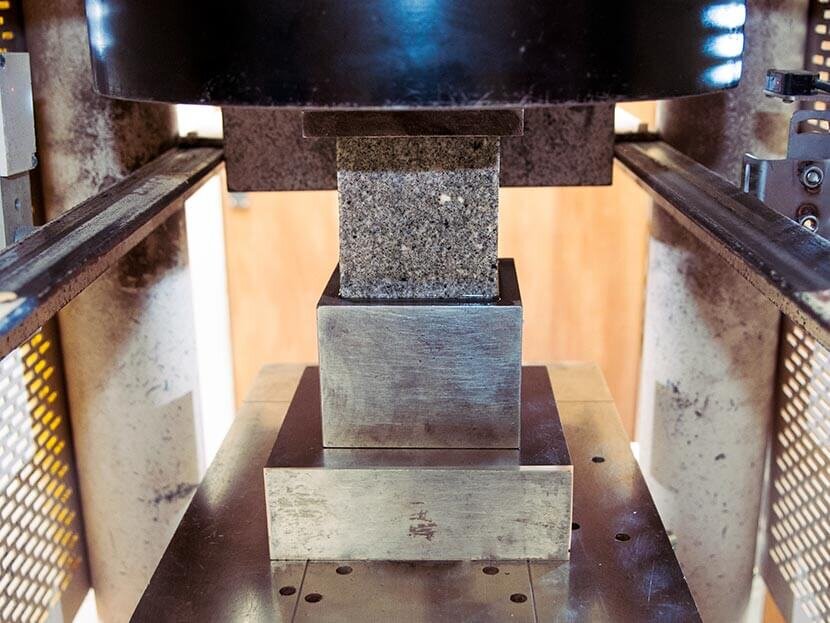

Crushing Strength Test of Stone:

Fig1.5. Compression testing machine

- For accomplishing this check, a specimen of length 40× 40 × 40 mm is ready from determine stone.

- Afterward, the edges are finely dressed and located in water for 3 days.

- The saturated specimen is supplied with a layer of plaster of paris on its pinnacle additionally backside surfaces to get even floor in order that load implemented is shipped uniformly.

- Uniform load distribution might be received satisfactorily with the aid of using presenting a couple of five mm thick plywood in place of the usage of plaster of paris layer additionally.

- The specimen so located withinside the compression trying out system is loaded withinside the fee of 14 N/mm2 in line with minute.

- The crushing load is noted.

- Then crushing energy is identical to this crushing load divided with the aid of using the vicinity wherein the burden is implemented.

- At least 3 specimens ought to be tested, and the common should be taken as crushing energy.

Water Absorption Test of Stone

With this check dice specimen weighing approximately 50 grams are Ready, and the check is executed at the stairs given below:

- Note the load of dry specimens as W1.

- Place the specimen in water for twenty-four hours.

- Take out the specimen, wipe out the floor with a chunk of cloth, and weigh the specimen. Let its weight be W2.

- Suspend the specimen freely in weight and water it. Let its weight be W3.

- Place the specimen in boiling water for five hours. Then take it out, wipe the floor with a cloth, and weigh it. Let this weight be W4. Then,

Percentage absorption with the aid of using weight = (W2 – W1) / W1 x 100 …(1)

Percentage absorption with the aid of using volume = (W2 – W1) / (W2 – W3) x 100…(2)

Percentage porosity with the aid of using volume = (W4 – W1) / (W2 – W3) x 100 …(3)

Density = W1 / (W2 – W1) x 100 ……….(4)

Specific Gravity = W1 / (W2 – W3) x 100 ……….(5)

Saturation Coefficient = Water Absorption / Total Porosity = (W2 – W1) / (W4 – W1)

6. Explain impact test on stone and absorption test on stone, acid test on stone.

Abrasion Test of Stone:

- This check is executed on stones which are used as aggregates for street construction.

- The check end result shows the suitability of stones in opposition to the grinding motion beneathneath traffic. Anyone of the subsequent exams might be carried out to discover the suitability of aggregates:

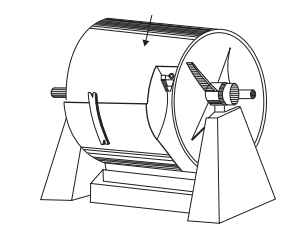

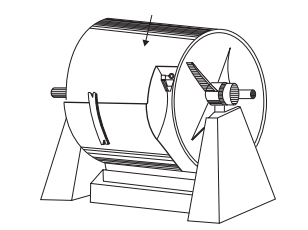

(1) Los Angeles Abrasion Test

(2) Deval Abrasion Test

(3) Dorry’s Abrasion Test.

- However, the Los Angeles abrasion check is favored on account that those check consequences have an excellent correlation with the overall performance of the pavements.

- The Los Angeles apparatus [Below Figure] includes a hole cylinder 0.7 m inner diameter and 0.5 m lengthy with each ends closed.

- It is installed onto a body in order that it may be circled approximately a horizontal axis.

- IS code has standardized the check method for specific gradations of specimens. T

- Together with the required weight of the specimen, a certain wide variety of forged iron balls of forty 8 mm diameter are located withinside the cylinder.

Fig1.6. Los Angeles Testing Machine

- Then the cylinder is turned around at a velocity of 30 to 33 rpm for a designated quantity of times (500 to 1000). Then the combination is eliminated in conjunction with sieved on 1.7 mm. IS sieve. The weight of combination passing is determined.

- Then Los Angeles price is determined as = (Weight of combination passing via sieve / Original weight) x 100

- The following values are encouraged for street works:

For bituminous mixes :30

For base course:50%

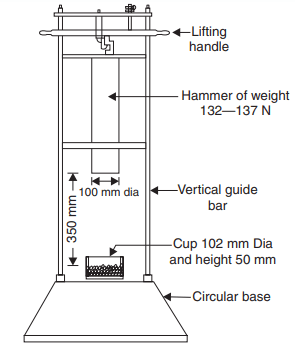

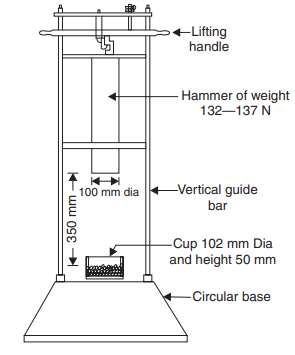

Impact Test of Stone:

- The resistance of stones to effect is determined through carrying out assessments in impacting the trying out machine [Below Figure].

- It includes a body with publications in which a steel hammer weighing 13.5 to 15kg can freely fall from a peak of 380 mm.

Fig1.7. Impact Testing Machine

- Aggregates of length 10 mm to 12.5 mm are stuffed in a cylinder in three identical layers, each layer being tamped 25 times.

- The identical is then transferred into the cup and once more tamped 25 times.

- The hammer is then allowed to fall freely onto the specimen 15 times.

- The specimen is then sieved thru a 2.36 mm sieve.

- Then, Impact value = W2 / W1 where,W2 = Weight of Fines. W1 = Original Weight.

- The advocated effect values for diverse works are:

(a) for carrying course ≯ 30%

(b) for bituminous macadam ≯ 35

(c) for water-certain macadam ≯ 40%

Acid Test of Stone:

Fig1.8.Testing of Stone

- This check is generally performed on sandstones to test the presence of calcium carbonate, which weakens the climate resisting quality.

- In this check, a pattern of stone weighing approximately 50 to 100 gm is taken and saved in an answer of 1 percentage hydrochloric acid for seven days.

- The answer is agitated at intervals. A suitable constructing stone keeps its sharp edges and maintains its floor intact.

- If edges are broken, and powder is fashioned at the floor, it shows the presence of calcium carbonate.

- Such stones can have negative climate resistance.

7. Explain common building stones.

Common Building Stones:

1.Granite:

Composition:

- It is igneous rock.

- Its important constituent minerals are Quartz, (tough and least stricken by carbon dioxide and water) Felspar (crystalline, lustrous, without problems attacked via way of means of atmospheric agencies) and Mica (darkish gray, black or brown in color, soft, without problems stricken by chemical compounds and atmospheric agencies).

Characteristics:

- Its precise gravity is 2.64 and absorption much less than 1%.

- It has mottled appearance.

- Significantly robust and durable.

- Finely grained granite takes a quality polish.

- Crushing energy varies from a hundred and ten to 140MN/m^2

- It has least hearth place resistance because it cracks below a robust hearth place.

- Its color relies upon upon that of feldspar.

Uses:

- Fine grained granite is appropriate for decorative columns,plinth etc. because it takes a polish.

- Owing to the hardness, weight and sturdiness of granite it’s far taken into consideration maximum appropriate for the development of sea partitions, mild houses, bridge piers, etc.

2.Basalt or Trap:

Composition:

- It is an igneous rock (silicious range).

- The Main elements are silica, alumina and feldspar

Characteristics:

- Very tough and difficult.

- Heavier than granite.

- Has greenish gray to darkish gray color.

- Crushing energy varies from 70 to eighty MN/m2.

- Specific gravity = 2.96.

Uses:

- Suitable for paving units and as a avenue metal.

- Used for the manufacture of synthetic stone.

- Used as mixture in concrete.

Occurrence:

- Madhya Pradesh and Deccan traps (alongside western coast) and Rajmahal trap (Bihar).

3. Slate:

Composition:

- It is a metamorphic rock (Argillaceous range).

- It consists of alumina combined with sand or carbonate of lime.

Characteristics:

- Its precise gravity is 2.8.

- A suitable slate is tough, difficult and quality grained.

- It has gray or darkish blue color.

- It may be cut up into skinny sheets.

- Its crushing energy varies from 60 to 70 MN/m2.

- It is non-absorbent.

- When struck with a mild hammer, it produces a pointy metal ring.

- Its sturdiness is suitable.

Uses:

- Used for making electric transfer boards.

- Because of its non-absorbent property, it’s far appropriate to be used in cisterns, urinals partitions, etc.

Occurrence:

- Gurgoan (Haryana), Gurdaspur (Punjab), Cuddadh (Andhra), Chanda (Maharashtra), Chindwara (M.P), Bijapur (Mysore), Alwar (Rajasthan), Chamba, Simla, Kangra (Himachal Pradesh), Baroda (Gujarat).

4. Gneiss:

Composition:

- It is a metamorphic rock.

- It is likewise from time to time referred to as stratified granite because it happens in really parallel layers.

- Its elements are similar to granite, i.e., quartz and 1eveled1.

Characteristics:

- It may be without problems cut up into slabs.

- It is greater effortlessly labored than granite.

- As it’s far to be had in one-of-a-kind colorings, it’s far used for decorative and ornamental purposes.

- It is fairly suitable cloth for road paving.

Occurrence:

- It is essentially located in Madras State, Mysore and Bihar.

5. Sandstone:

Composition:

- It is a sedimentary rock of silicious range.

- It carries sand or quartz cemented via way of means of lime, mica, magnesium, aluminium, oxide of iron or via way of means of a combination of those substances.

- Sometimes fragments of limestone, mica or 1eveled1 also are gift.

Characteristics:

- Its shape suggests sandy grains.

- Its typical colorings are white, gray, brown, purple etc.

- Its precise gravity is 2.25.

- Crushing energy varies from 35 to forty MN//m2.

- Fine grained stones are robust and durable.

- The sandstone of skinny-bedded range is referred to as flag stone.

- It splits effortlessly into big slabs alongside the bedding.

- The rock composed of angular sharp-edged sand grains is referred to as grit; it is satisfactorily robust and heavy and is utilized in heavy engineering works.

- The sandstone that may be reduce effortlessly with mallet and hammer into blocks for constructing is referred as loose stone.

- Its sturdiness relies upon upon the character of a cloth.

- The amount of sandstone is negative if it’s far porous or carries lime.

Uses:

- The quality grained and compact range is appropriate for ashlar work, mouldings, carvings etc.

- The tough and coarse-grained stone is hired for rubble work.

Occurrence:

- The pleasant range stones that may effortlessly be quarried in big wonderful blocks are to be had in Mirzapur; Chunar; Fatehpur Sikri; Gwalior (M.P.); Hemanagar close to Ahmedabad (Gujarat); Nagpur (Maharashtra); Kangra and Dharamsala (H.P.), Shahpur and Kasauli Rajpur, and Jabalpur; Dehri; Mandhum and Ranchi (Bihar); Cuttack and Mysore.

6. Limestone:

Composition:

- It is a sedimentary rock of calcareous range.

- When in natural kingdom it carries CaCO3, however regularly is blended with MgCO3 and small quantity of silica and alumina.

- When each MgCO3 and CaCO3 are gift almost in identical percentage it’s far called Dolomite.

Characteristics:

- Its precise gravity is 2.6.

- It is to be had in brown, yellow and darkish gray colorings.

- Crushing energy = 52MN/m2.

Uses:

- It is utilized in big portions in blast furnaces, bleaching, tanning and different industries.

- If compact and quality grained it could be used as stone masonry for partitions and paving set in floor.

- It is used as avenue metal (while higher substances like trap, basalt or granite aren’t to be had).

Occurrence:

- It is located in Alwar (Rajasthan), Hoshiarpur (Punjab), Simla (H.P.), Mirzapur, Ranchi (Bihar) and Mysore etc.

8. What do you mean by brick? Explain manufacturing method of brick.

Bricks:

Manufacturing method of clay bricks:

In the method of producing bricks, the subsequent 4 wonderful operations are involved:

- Preparation of clay

- Moulding

- Drying

- Burning

Preparation of clay:

The clay for bricks is ready withinside the following order:

- Unsoiling

- Digging

- Cleaning

- Weathering

- Blending

- Tempering

- Un-Soiling: The pinnacle layer of soil, approximately two hundred mm in depth, is taken out and thrown away. The clay in pinnacle soil is complete of impurities and subsequently it’s miles to be rejected for the motive of making ready bricks.

- Digging: The clay is then dug out from the ground. It is unfold at the 1eveled ground, only a little deeper than the overall degree of ground. The peak of thousands of clays is ready six hundred mm to 1200 mm.

- Cleaning: The clay, as received withinside the method of digging, ought to be wiped clean of stones, pebbles, vegetable matter, etc. If those debris are in excess, the clay is to be washed and screened. Such a method clearly will show to be tough and expensive. The lumps of clay ought to be transformed into powder shape withinside the earth crushing roller.

- Weathering: The clay is then uncovered to environment for softening or mellowing. The length of publicity varies from few weeks to complete season. For a massive project, the clay is dug out simply earlier than the monsoon and its miles allowed to climate during the monsoon.

- Blending: The clay is made unfastened and any aspect to be introduced to its miles unfold out at its pinnacle. The mixing suggests intimate or harmonious mixing. It is executed with the aid of using taking small part of clay whenever and with the aid of using turning it up and down in vertical direction. The mixing makes clay suit for the subsequent degree of tempering.

- Tempering: In the method of tempering, the clay is added to a right diploma of hardness and its miles made suit for the subsequent operation of moulding. The water in required amount is introduced to clay and the entire mass is kneaded or pressed beneath the toes of guys or cattle. The tempering ought to be achieved exhaustively to achieve homogeneous mass of clay of uniform character.

Moulding:

The clay which is ready as above is then dispatched for the subsequent operation of moulding.

Following are the 2 approaches of moulding:

- Hand moulding

- Machine moulding.

Hand Moulding:

- In hand moulding, the bricks are moulded via way of means of hand i.e., manually.

- It is followed wherein manpower is reasonably-priced and is effortlessly to be had for the producing technique of bricks on a small scale.

- The moulds are square packing containers which might be open at pinnacle and backside. They can be of timber or metallic.

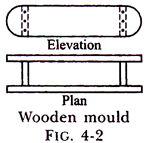

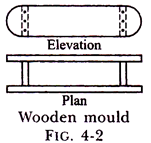

- A regular timber mold is proven in fig.

- It needs to be organized from well-pro timber.

- The longer aspects are saved barely projecting to function handles.

- The strips of brass or metallic are once in a while constant on the rims of timber moulds to cause them to greater durable.

Fig.1.9:Wooden mold

- Hence the moulds are to be made large than the dimensions of Steel mold absolutely burnt bricks. The moulds are consequently made longer via way of means of approximately eight to twelve in line with cent in all directions. The specific percent of boom in dimensions of mold is decided via way of means of real test on clay for use for making ready bricks.

- The bricks organized via way of means of hand moulding are of types:

(a) Ground-moulded bricks

(b) Table-moulded bricks.

Machine Moulding:

- The moulding will also be performed via way of means of machines It proves to be good value while bricks in big amount are to be synthetic on the identical spot in a brief time. It is likewise beneficial for moulding difficult and robust clay.

- These machines are extensively categorized in categories:

(a) Plastic clay machines

(b) Dry clay machines.

(a) Plastic Clay Machines:

- Such machines incorporate a square starting of length same to period and width of a brick. The pugged clay is positioned withinside the system and because it comes out via the starting, it's miles reduce into strips via way of means of wires constant in frames.

- The association is made in any such manner that strips of thickness same to that of the brick are obtained. As the bricks are reduce via way of means of twine, they may be additionally referred to as the twine reduce bricks.

(b) Dry Clay Machines:

- In those machines, the robust clay is first transformed into powder shape. A small amount of water is then delivered to shape a stiff plastic paste. Such paste is positioned in mold and pressed via way of means of system to shape difficult and well-formed bricks. These bricks are referred to as the pressed bricks and that they do now no longer nearly require drying. They may be dispatched immediately for the method of burning.

- The twine reduces and pressed bricks have everyday shape, sharp edges and corners. They have cleaned outside surfaces. They are heavier and more potent than regular hand-moulded bricks. They bring awesome frogs and show off uniform dense texture.

9. Give the classification of brick.

Classification of Bricks Based on Quality:

On the premise of fine, Bricks are of the subsequent types

First Class Brick:

- The length is standard.

- The colour of those bricks is uniform yellow or crimson.

- It is properly burnt, ordinary texture, uniform form.

- The absorption capability is much less than 10%, crushing energy is, 280kg/cm2 (mean) wherein it's far 245 kg/cm2 (minimal).

- It doesn’t have efflorescence.

- It emits a metal sound while struck through any other comparable brick or struck through a hammer.

- It is tough sufficient to face up to any fingernail expression at the brick floor if one attempts to do with a thumbnail.

- It is unfastened from pebbles, gravels or natural matters.

Second Class Brick:

- The length is standard, colour is uniform yellow or crimson.

- It is properly burnt, barely over burnt is acceptable.

- It has a ordinary form; efflorescence isn't always appreciable.

- The absorption capability is greater than 10% however much less than 15%.

- Crushing energy is 175kg/cm2(mean) wherein the minimal is 154 kg/cm2.

- It emits a metal sound while struck through any other comparable brick or struck through a hammer.

- It is tough sufficient to face up to any fingernail expression at the brick floor if one attempts to do with a thumbnail.

- It is used for the development of one-storied buildings, transient shed while meant sturdiness isn't always greater than 15 years.

Third Class Brick:

- The form and length aren't ordinary.

- The colour is gentle and mild crimson colored.

- It is below burnt, barely over burnt is acceptable.

- It has massive efflorescence.

- The texture is non-uniform.

- The absorption capability is greater than 15% however much less than 20%.

- The crushing energy is 140kg/cm2(mean) wherein the minimal crushing energy is 105kg/cm2.

- It emits a stupid or blunt sound while struck through any other comparable brick or struck through a hammer.

- It leaves fingernail expression while one attempts to do with the thumbnail.

(2) Classification of Bricks Based on Raw Materials:

On the premise of uncooked substances bricks are of the subsequent kinds:

Burnt Clay Brick:

- It is received via way of means of urgent the clay in molds and fried and dried in kilns.

- It is the maximum used bricks. It calls for plastering while utilized in production works.

Fly ash clay Brick:

- It is synthetic while fly ash and clay are molded in one thousand diploma Celsius.

- It includes a excessive extent of calcium oxide in fly ash.

- That is why commonly defined as self-cementing.

- It commonly expands while getting into touch with moisture.

- It is much less porous than clay bricks. It proved a clean floor so it doesn’t want plastering.

Concrete Brick:

- It is product of concrete.

- It is the least used bricks.

- It has low compression energy and is of low pleasant.

- These bricks are used above and under the damp evidence course.

- These bricks are used may be used for facades, fences and inner brickworks due to their sound discounts and warmth resistance qualities.

- It is likewise referred to as mortar brick.

- It may be of various colorings if the pigment is brought in the course of manufacturing.

- It ought to now no longer be used underground.

Sand-lime Brick:

- Sand, fly ash and lime are combined and molded below pressure.

- During moist mixing, a chemical response takes region to bond the mixtures.

- Then they're positioned withinside the molds.

- The shadeation is greyish because it gives something of a classy view.

- It gives a smoother end and uniform look than the clay bricks.

- As a result, it additionally doesn’t require plastering.

- It is used as a load bearing participant as it's far immensely strong.

Firebrick:

- It is likewise referred to as refractory bricks.

- It is made of a in particular designed earth.

- After burning, it may face up to very excessive temperature without affecting its shape, length, and energy.

- It is used for the liner of chimney and furnaces wherein the same old temperature is predicted to be very excessive.

10. Explain the various test methods on clay bricks.

Testing Methods of clay bricks:

The following are the assessments that wishes to be accomplished at the brick:

Site assessments on bricks

- Hardness Test

- Dimensional Tolerance Test

- Soundness Test

- Impact Test

- Colour Test

Laboratory Tests on bricks

- Water Absorption Test

- Compressive Strength Test

- Efflorescence Test

- Warpage Test

Site Tests for Evaluating Quality of Bricks

The following assessments may be accomplished at web page with none device required. These assessments will supply a concept approximately the pleasant of bricks.

Hardness Test

- Hardness take a look at is accomplished to test hardness of brick. This is an oblique take a look at to recognize its compressive energy and to recognize how properly the brick is kilned. This is examined via way of means of the use of a pointy gear or finger nail and scratching in opposition to the brick floor. If there may be no affect of the scratch at the brick floor, the brick is satisfactorily tough and healthy to be used

Dimensional Tolerance Test

- Dimensional Tolerance take a look at is used to test the shape & length brick. In this take a look at 20 bricks are organized them alongside its length, breadth, and height. The dimensions are in comparison to every different and in comparison, with the usual dimensions.

Sound (Ringing) Test

- Sound take a look at of a brick is subject take a look at to apprehend the pleasant of bricks received. In this take a look at, two bricks are struck with every different. Good pleasant bricks commonly don’t damage and ought to produce a steel sound (bell ring) sound while struck with every different.

Impact Test

- In this check the bricks are allowed to fall from a peak of one meter on ground (now no longer tough floor). Good high-satisfactory brick shouldn’t break. In case it breaks, it’s higher now no longer to apply for production.

Color Test

- Well kilned (burnt) clay brick is of uniform in color in the course of its segment and sun sunglasses of red. Black bricks are over burnt, now no longer of accurate high-satisfactory.

Laboratory Tests to Determine the Quality of Bricks

Water Absorption Test

- Absorption check is carried out to decide the quantity of moisture content material that the brick absorbs. If the bricks soak up extra than 20% of the burden of dry brick, then the brick need to now no longer be used for production as they soak up water from the cement mortar decreasing the general brickwork electricity. In this check five bricks are taken from the pattern and dry weight of every brick is taken. Weights are once more recorded after completely immersing the bricks in water for 25. Water absorption is calculated primarily based totally on each those weights. Detailed Procedure for Water Absorption of a Brick

Compressive Strength Test

- Compressive Strength of a brick is decided through setting a brick withinside the compressive trying out device and loading the pinnacle face (frog face) until failure. The brick frog face if packed with mortar and cured for a duration of four days earlier than. A minimal compressive electricity of 3.five N/mm2 need to be received as in keeping with IS codes. If the compressive electricity of the brick is much less than 3.five N/mm2, the ones bricks need to now no longer be used for production purposes. Detailed Procedure for Calculating Compressive Strength of a Brick

Efflorescence Test

- Efflorescence is a fine, white, powdery deposit of water-soluble salts left at the floor of masonry because the water evaporates. A accurate brick shouldn’t comprise soluble salts in it. In this check bricks are immersed in water for twenty-four hrs after which allowed to dry completely. If any white or gray patches seem at the brick floor, then the brick consists of soluble salts.

Warpage Test

- Warpage check is to decide how flat the brick floor is. If the bricks are heated and cooled correctly, Warpage need to be beneath permissible limits. A convex warpage and a concave warpage check is.

Unit 1

Scope of Study of Building Materials

- Explain the building material and their performance and also explain performance and testing.

Building Materials & their performance:

- Building substances ought to serve their meant feature now no longer most effective whilst newly established however additionally for a few perfect durations of time.

- These carrier lifestyles may also remain for the lifestyles of the constructing or, as with paints, for just a few years earlier than renewal.

- It is not unusual place to talk of the sturdiness of a cloth as though it had been a fundamental property, measured because the duration of time it's going to serve satisfactorily.

- The beneficial lifestyles of a cloth in place, however, is constantly associated with the specific aggregate of environmental elements to which it's far subjected, in order that sturdiness, or carrier lifestyles, ought to constantly be associated with the specific situations concerned.

- Experience with conventional substances over a few years allows prediction of the overall performance of the identical cloth below comparable situations.

- Such trial with the aid of using use has supplied a solution to how however now no longer regularly to why substances react as they do.

- When new substances are to be evolved or taken into consideration or whilst conventional substances are for use in untried situations, the capacity to expect overall performance can be significantly constrained until the "why" of beyond revel in, and therefore the essential elements concerned, are understood.

- This is fundamental to the exercising of judgment in design, an aggregate of revel in and analysis.

- Such a technique is likewise vital with inside the improvement and interpretation of any extended take a look at approach designed to enhance prediction of overall performance.

- Most constructing substances are complicated of their chemical and bodily nature, as are the tactics concerned of their reaction to environmental elements.

- Some generalizations can be made in those respects, however, a good way to enhance information of overall performance and offer a foundation for predicting behavior.

Performance and Testing:

- Exact prediction of overall performance calls for whole information of cloth properties, the tactics concerned with inside the interplay of the cloth with its environment, and the environmental elements to which it will likely be subjected. The most effective whole takes a look at of overall performance is trial with the aid of using use.

- Prediction will constantly be constrained with the aid of using loss of whole understanding; trial with the aid of using use could be constrained with the aid of using time and incapability to extrapolate to new situations.

- Test strategies may be used to complement understanding and revel in in predicting overall performance.

- Some take a look at strategies rely upon empirically derived family members among located behavior and a few without problems measured bodily property; others difficulty the cloth to environmental situations simulating the ones to be anticipated in exercise.

- The improvement of higher take a look at strategies and their right utility in exercise can most effective come approximately thru higher information of substances and their overall performance. Such information is likewise prerequisite to the right and vital assessment of beyond revel in.

2. What do you mean by economics of building material?

Economics of Building Material:

- Many clearly happening substances, which include clay, rocks, sand, and wood, even twigs and leaves, had been used to assemble buildings. Apart from clearly happening substances, much man-made merchandise is in use, a few greater and a few much less synthetic.

- The production of constructing substances is a longtime enterprise in many nations and the usage of those substances is usually segmented into precise strong point trades, which includes carpentry, insulation, plumbing, and roofing work. They offer the makeup of habitats and systems which include homes.

- Initial financial value of constructing substances is the acquisition price. This is frequently what governs selection making approximately what substances to use. Sometimes humans think about the electricity financial savings or sturdiness of the substances and spot the fee of paying a better preliminary value in go back for a decrease lifetime value.

- For example, an asphalt shingle roof expenses much less than a steel roof to install, however the steel roof will remaining longer so the lifetime value is much less in step with year. Some substances may also require greater care than others, keeping expenses precise to a few substances may additionally have an impact on the very last selection.

- Risks whilst thinking about lifetime value of a cloth is that if the constructing is broken which includes with the aid of using hearth place or wind, or if the fabric isn't as long lasting as advertised. The value of substances needs to be considered to endure the chance to shop for combustive substances to increase the lifetime. It is stated that, "if it ought to be performed, it ought to be performed well".

3. Explain the requirement of good building stone.

Requirement of Good Building Stone:

The following are the first-class necessities of right constructing stones:

Fig1.1.Different types of stone

1. STRENGTH

- Generally maximum of the constructing stones have excessive power to face up to the burden approaching it.

- Therefore, it isn't of top problem while it comes to test the high-satisfactory of stones. But while the stones are for use in huge structures, it will become vital to test the compressive power of stones.

- Compressive power of constructing stones usually falls in the variety of 60 to 200N/mm2.

2. DURABILITY

- Building stones have to be successful to face up to the detrimental outcomes of herbal forces like wind, rain and heat. It ought to be long lasting and have to now no longer go to pot because of the detrimental outcomes of the above herbal forces.

3. HARDNESS

- When stones are utilized in floors, pavements or aprons of bridges, they grow to be subjected to carrying and abrasive forces as a result of motion of guys or device over them. So, it's far required to check hardness of stone.

- Hardness of stone is decided via way of means of Mosh scale.

4. TOUGHNESS

- Toughness of stones method it capacity to face up to effect forces.

- Building stones have to be difficult sufficient to maintain stresses advanced because of vibrations.

- The vibrations can be because of the equipment established over them or because of the hundreds shifting over them.

- The stone aggregates utilized in the street buildings have to be difficult.

5. SPECIFIC GRAVITY

- The greater the particular gravity of stone, the greater heavier and more potent the stone is. Therefore, stones having better particular gravity values have to be used for the development of dams, maintaining walls, docks and harbors.

- The particular gravity of suitable constructing stone is among 2.4 and 2.8.

6. POROSITY AND ABSORPTION

- Porosity of constructing stones rely upon the mineral constituent and structural formation of the determine rock.

- If stones utilized in constructing creation are porous then rain water can without difficulty input into the pore areas and purpose harm to the stones.

- Therefore, constructing stone have to now no longer be porous. Water absorption of stone is without delay proportional to the porosity of rock.

- If a stone is greater porous then it's going to soak up greater water and purpose greater harm to stone.

- In better altitudes, the freezing of water in pores takes location and it outcomes into the disintegration of the stone.

- Permissible limits of water absorption for a few the normally used constructing stones are as follow.

Types of Stones | Maximum limit of water absorption (%) |

Sandstone | 10 |

Limestone | 10 |

Granite | 1 |

Shale | 10 |

Slate | 1 |

Quartzite | 3 |

7. DRESSING

- Giving required form to the stone is known as dressing.

- It has to be smooth to get dressed in order that the price of dressing is reduced.

- However, the care has to be taken in order that, this isn't being on the price of the desired power and the durability.

8. APPEARANCE

- In case of the stones for use for face works, in which look is a number one requirement, its coloration and capacity to get hold of polish is an essential factor.

- Light cultured stones are greater favored than darkish cultured stones because the coloration are probably to vanish out with time.

9. SEASONING

- Good stones have to be loose from the quarry sap.

- Lateritic stones have to now no longer be used for six to 365 days after quarrying.

- They are allowed to put off quarry sap with the aid of using the motion of nature.

- This procedure of putting off quarry sap is known as seasoning.

10. WORKABILITY

- Stone have to be plausible. Stone is stated to be plausible while the paintings worried in stone working (consisting of cutting, dressing & shaping) is low in cost and smooth to conduct.

11. COST

- Cost is an essential attention in deciding on a constructing material.

- Proximity of the quarry to constructing web website online brings down the price of transportation and consequently the price of stones comes down.

12. FIRE RESISTANCE

- Stones have to be loose from calcium carbonate, oxides of iron, and minerals having exceptional coefficient

4. Give the characteristics of good building stone.

Characteristics of Good Building Stones:

A top constructing stone have to have the subsequent qualities:

Appearance:

- Building Stones used for the face paintings of the constructing have to have best, compact texture.

- Light cultured stone is commonly favored as darkish colorations are susceptible to fade out with time.

- They have to be loose from clay holes, bands or spots of color.

Structure:

- A stone while broken have to now no longer be stupid in look and have to display uniformity of texture.

- It has to be loose from cavities, cracks, and patches of free or smooth material.

- Stratifications that are commonly located in sedimentary rocks have to now no longer be seen to bare eye.

Strength:

- Stones utilized in production have to be sturdy and sturdy to face up to the disintegrating motion of weather.

- Stones with compact best crystalline texture are stronger.

- Compressive power of constructing stones in practice, variety among 60 to 2 hundred N/mm2.

Specific gravity:

- The precise gravity of Building stone is at once proportional to its weight and power.

- Hence the stones having better precise gravity have to now no longer are used for dams, maintaining walls, docks and harbors.

- Specific gravity of a great constructing stone lies among 2.4 to 2.8.

Hardness:

- When stones are applied for floors, pavements, aprons of bridges and weirs of rivers, the stones are subjected to abrasive forces that are resulting from the wear and tear and friction.

- Hence the stones that are for use in such locations have to be examined for hardness.

Fig1.2.Hardness of Stone

Toughness:

- It is the degree of effect that a stone can withstand.

- When the stones are imagined to go through vibrations of equipment and transferring loads, they ought to be tough.

Porosity and Absorption:

- The porous constructing stones aren’t appropriate in creation particularly for uncovered surfaces of structures.

- The rain water which comes down conveys a few acidic gases forming mild acids which receive soaked at the surface.

- Acids react with the elements of stones inflicting them to crumble.

- In bloodless areas water freezes with inside the pores of stones.

- This water reasons the disintegration of stones due to its boom in quantity on freezing.

Fig1.3.Porosity of stone

The types of some of the stones and their maximum limit of water absorption (%) are as follows:

- Sandstone : 10

- Limestone : 10

- Granite : 1

- Trap : 6

- Shale : 10

- Gneiss : 1

- Slate : 1

- Quartzite : 3

Seasoning:

- All freshly quarried stones incorporate a positive quantity of moisture referred to as quarry sap, which makes them tender and simpler to paintings upon. Good stones must be loose from quarry sap. They are allowed to eliminate quarry sap with the aid of using the movement of nature. This procedure of disposing of quarry sap is referred to as seasoning. A length of 6-one year is normally sufficient for correct seasoning.

Weathering:

- It is the quantity to which the face of a stone resists the movement of weather. Stones with properly weathering residences most effective must be used with inside the production of essential buildings.

Fig1.4.Weathering of Stone

Workability:

- Stones are stated to be plausible if the wok that is worried of their cutting, dressing and shaping is taken into consideration as low-budget and smooth to conduct. Know the Current House creation fee

Fire Resistance:

- Building Stones ought to be loose from calcium carbonate, oxides of iron, and minerals having one of a kind coefficients of thermal expansion. Igneous rock goes through fundamental disintegration due to quartz which disintegrates into small debris at a temperature of approximately 575 co. Limestone, however, can face up to a touch better temperature; i.e. as much as 800 oC and then they disintegrate.

5. Explain the crushing strength test on stone and water absorption test on stone.

Crushing Strength Test of Stone:

Fig1.5. Compression testing machine

- For accomplishing this check, a specimen of length 40× 40 × 40 mm is ready from determine stone.

- Afterward, the edges are finely dressed and located in water for 3 days.

- The saturated specimen is supplied with a layer of plaster of paris on its pinnacle additionally backside surfaces to get even floor in order that load implemented is shipped uniformly.

- Uniform load distribution might be received satisfactorily with the aid of using presenting a couple of five mm thick plywood in place of the usage of plaster of paris layer additionally.

- The specimen so located withinside the compression trying out system is loaded withinside the fee of 14 N/mm2 in line with minute.

- The crushing load is noted.

- Then crushing energy is identical to this crushing load divided with the aid of using the vicinity wherein the burden is implemented.

- At least 3 specimens ought to be tested, and the common should be taken as crushing energy.

Water Absorption Test of Stone

With this check dice specimen weighing approximately 50 grams are Ready, and the check is executed at the stairs given below:

- Note the load of dry specimens as W1.

- Place the specimen in water for twenty-four hours.

- Take out the specimen, wipe out the floor with a chunk of cloth, and weigh the specimen. Let its weight be W2.

- Suspend the specimen freely in weight and water it. Let its weight be W3.

- Place the specimen in boiling water for five hours. Then take it out, wipe the floor with a cloth, and weigh it. Let this weight be W4. Then,

Percentage absorption with the aid of using weight = (W2 – W1) / W1 x 100 …(1)

Percentage absorption with the aid of using volume = (W2 – W1) / (W2 – W3) x 100…(2)

Percentage porosity with the aid of using volume = (W4 – W1) / (W2 – W3) x 100 …(3)

Density = W1 / (W2 – W1) x 100 ……….(4)

Specific Gravity = W1 / (W2 – W3) x 100 ……….(5)

Saturation Coefficient = Water Absorption / Total Porosity = (W2 – W1) / (W4 – W1)

6. Explain impact test on stone and absorption test on stone, acid test on stone.

Abrasion Test of Stone:

- This check is executed on stones which are used as aggregates for street construction.

- The check end result shows the suitability of stones in opposition to the grinding motion beneathneath traffic. Anyone of the subsequent exams might be carried out to discover the suitability of aggregates:

(1) Los Angeles Abrasion Test

(2) Deval Abrasion Test

(3) Dorry’s Abrasion Test.

- However, the Los Angeles abrasion check is favored on account that those check consequences have an excellent correlation with the overall performance of the pavements.

- The Los Angeles apparatus [Below Figure] includes a hole cylinder 0.7 m inner diameter and 0.5 m lengthy with each ends closed.

- It is installed onto a body in order that it may be circled approximately a horizontal axis.

- IS code has standardized the check method for specific gradations of specimens. T

- Together with the required weight of the specimen, a certain wide variety of forged iron balls of forty 8 mm diameter are located withinside the cylinder.

Fig1.6. Los Angeles Testing Machine

- Then the cylinder is turned around at a velocity of 30 to 33 rpm for a designated quantity of times (500 to 1000). Then the combination is eliminated in conjunction with sieved on 1.7 mm. IS sieve. The weight of combination passing is determined.

- Then Los Angeles price is determined as = (Weight of combination passing via sieve / Original weight) x 100

- The following values are encouraged for street works:

For bituminous mixes :30

For base course:50%

Impact Test of Stone:

- The resistance of stones to effect is determined through carrying out assessments in impacting the trying out machine [Below Figure].

- It includes a body with publications in which a steel hammer weighing 13.5 to 15kg can freely fall from a peak of 380 mm.

Fig1.7. Impact Testing Machine

- Aggregates of length 10 mm to 12.5 mm are stuffed in a cylinder in three identical layers, each layer being tamped 25 times.

- The identical is then transferred into the cup and once more tamped 25 times.

- The hammer is then allowed to fall freely onto the specimen 15 times.

- The specimen is then sieved thru a 2.36 mm sieve.

- Then, Impact value = W2 / W1 where,W2 = Weight of Fines. W1 = Original Weight.

- The advocated effect values for diverse works are:

(a) for carrying course ≯ 30%

(b) for bituminous macadam ≯ 35

(c) for water-certain macadam ≯ 40%

Acid Test of Stone:

Fig1.8.Testing of Stone

- This check is generally performed on sandstones to test the presence of calcium carbonate, which weakens the climate resisting quality.

- In this check, a pattern of stone weighing approximately 50 to 100 gm is taken and saved in an answer of 1 percentage hydrochloric acid for seven days.

- The answer is agitated at intervals. A suitable constructing stone keeps its sharp edges and maintains its floor intact.

- If edges are broken, and powder is fashioned at the floor, it shows the presence of calcium carbonate.

- Such stones can have negative climate resistance.

7. Explain common building stones.

Common Building Stones:

1.Granite:

Composition:

- It is igneous rock.

- Its important constituent minerals are Quartz, (tough and least stricken by carbon dioxide and water) Felspar (crystalline, lustrous, without problems attacked via way of means of atmospheric agencies) and Mica (darkish gray, black or brown in color, soft, without problems stricken by chemical compounds and atmospheric agencies).

Characteristics:

- Its precise gravity is 2.64 and absorption much less than 1%.

- It has mottled appearance.

- Significantly robust and durable.

- Finely grained granite takes a quality polish.

- Crushing energy varies from a hundred and ten to 140MN/m^2

- It has least hearth place resistance because it cracks below a robust hearth place.

- Its color relies upon upon that of feldspar.

Uses:

- Fine grained granite is appropriate for decorative columns,plinth etc. because it takes a polish.

- Owing to the hardness, weight and sturdiness of granite it’s far taken into consideration maximum appropriate for the development of sea partitions, mild houses, bridge piers, etc.

2.Basalt or Trap:

Composition:

- It is an igneous rock (silicious range).

- The Main elements are silica, alumina and feldspar

Characteristics:

- Very tough and difficult.

- Heavier than granite.

- Has greenish gray to darkish gray color.

- Crushing energy varies from 70 to eighty MN/m2.

- Specific gravity = 2.96.

Uses:

- Suitable for paving units and as a avenue metal.

- Used for the manufacture of synthetic stone.

- Used as mixture in concrete.

Occurrence:

- Madhya Pradesh and Deccan traps (alongside western coast) and Rajmahal trap (Bihar).

3. Slate:

Composition:

- It is a metamorphic rock (Argillaceous range).

- It consists of alumina combined with sand or carbonate of lime.

Characteristics:

- Its precise gravity is 2.8.

- A suitable slate is tough, difficult and quality grained.

- It has gray or darkish blue color.

- It may be cut up into skinny sheets.

- Its crushing energy varies from 60 to 70 MN/m2.

- It is non-absorbent.

- When struck with a mild hammer, it produces a pointy metal ring.

- Its sturdiness is suitable.

Uses:

- Used for making electric transfer boards.

- Because of its non-absorbent property, it’s far appropriate to be used in cisterns, urinals partitions, etc.

Occurrence:

- Gurgoan (Haryana), Gurdaspur (Punjab), Cuddadh (Andhra), Chanda (Maharashtra), Chindwara (M.P), Bijapur (Mysore), Alwar (Rajasthan), Chamba, Simla, Kangra (Himachal Pradesh), Baroda (Gujarat).

4. Gneiss:

Composition:

- It is a metamorphic rock.

- It is likewise from time to time referred to as stratified granite because it happens in really parallel layers.

- Its elements are similar to granite, i.e., quartz and 1eveled1.

Characteristics:

- It may be without problems cut up into slabs.

- It is greater effortlessly labored than granite.

- As it’s far to be had in one-of-a-kind colorings, it’s far used for decorative and ornamental purposes.

- It is fairly suitable cloth for road paving.

Occurrence:

- It is essentially located in Madras State, Mysore and Bihar.

5. Sandstone:

Composition:

- It is a sedimentary rock of silicious range.

- It carries sand or quartz cemented via way of means of lime, mica, magnesium, aluminium, oxide of iron or via way of means of a combination of those substances.

- Sometimes fragments of limestone, mica or 1eveled1 also are gift.

Characteristics:

- Its shape suggests sandy grains.

- Its typical colorings are white, gray, brown, purple etc.

- Its precise gravity is 2.25.

- Crushing energy varies from 35 to forty MN//m2.

- Fine grained stones are robust and durable.

- The sandstone of skinny-bedded range is referred to as flag stone.

- It splits effortlessly into big slabs alongside the bedding.

- The rock composed of angular sharp-edged sand grains is referred to as grit; it is satisfactorily robust and heavy and is utilized in heavy engineering works.

- The sandstone that may be reduce effortlessly with mallet and hammer into blocks for constructing is referred as loose stone.

- Its sturdiness relies upon upon the character of a cloth.

- The amount of sandstone is negative if it’s far porous or carries lime.

Uses:

- The quality grained and compact range is appropriate for ashlar work, mouldings, carvings etc.

- The tough and coarse-grained stone is hired for rubble work.

Occurrence:

- The pleasant range stones that may effortlessly be quarried in big wonderful blocks are to be had in Mirzapur; Chunar; Fatehpur Sikri; Gwalior (M.P.); Hemanagar close to Ahmedabad (Gujarat); Nagpur (Maharashtra); Kangra and Dharamsala (H.P.), Shahpur and Kasauli Rajpur, and Jabalpur; Dehri; Mandhum and Ranchi (Bihar); Cuttack and Mysore.

6. Limestone:

Composition:

- It is a sedimentary rock of calcareous range.

- When in natural kingdom it carries CaCO3, however regularly is blended with MgCO3 and small quantity of silica and alumina.

- When each MgCO3 and CaCO3 are gift almost in identical percentage it’s far called Dolomite.

Characteristics:

- Its precise gravity is 2.6.

- It is to be had in brown, yellow and darkish gray colorings.

- Crushing energy = 52MN/m2.

Uses:

- It is utilized in big portions in blast furnaces, bleaching, tanning and different industries.

- If compact and quality grained it could be used as stone masonry for partitions and paving set in floor.

- It is used as avenue metal (while higher substances like trap, basalt or granite aren’t to be had).

Occurrence:

- It is located in Alwar (Rajasthan), Hoshiarpur (Punjab), Simla (H.P.), Mirzapur, Ranchi (Bihar) and Mysore etc.

8. What do you mean by brick? Explain manufacturing method of brick.

Bricks:

Manufacturing method of clay bricks:

In the method of producing bricks, the subsequent 4 wonderful operations are involved:

- Preparation of clay

- Moulding

- Drying

- Burning

Preparation of clay:

The clay for bricks is ready withinside the following order:

- Unsoiling

- Digging

- Cleaning

- Weathering

- Blending

- Tempering

- Un-Soiling: The pinnacle layer of soil, approximately two hundred mm in depth, is taken out and thrown away. The clay in pinnacle soil is complete of impurities and subsequently it’s miles to be rejected for the motive of making ready bricks.

- Digging: The clay is then dug out from the ground. It is unfold at the 1eveled ground, only a little deeper than the overall degree of ground. The peak of thousands of clays is ready six hundred mm to 1200 mm.

- Cleaning: The clay, as received withinside the method of digging, ought to be wiped clean of stones, pebbles, vegetable matter, etc. If those debris are in excess, the clay is to be washed and screened. Such a method clearly will show to be tough and expensive. The lumps of clay ought to be transformed into powder shape withinside the earth crushing roller.

- Weathering: The clay is then uncovered to environment for softening or mellowing. The length of publicity varies from few weeks to complete season. For a massive project, the clay is dug out simply earlier than the monsoon and its miles allowed to climate during the monsoon.

- Blending: The clay is made unfastened and any aspect to be introduced to its miles unfold out at its pinnacle. The mixing suggests intimate or harmonious mixing. It is executed with the aid of using taking small part of clay whenever and with the aid of using turning it up and down in vertical direction. The mixing makes clay suit for the subsequent degree of tempering.

- Tempering: In the method of tempering, the clay is added to a right diploma of hardness and its miles made suit for the subsequent operation of moulding. The water in required amount is introduced to clay and the entire mass is kneaded or pressed beneath the toes of guys or cattle. The tempering ought to be achieved exhaustively to achieve homogeneous mass of clay of uniform character.

Moulding:

The clay which is ready as above is then dispatched for the subsequent operation of moulding.

Following are the 2 approaches of moulding:

- Hand moulding

- Machine moulding.

Hand Moulding:

- In hand moulding, the bricks are moulded via way of means of hand i.e., manually.

- It is followed wherein manpower is reasonably-priced and is effortlessly to be had for the producing technique of bricks on a small scale.

- The moulds are square packing containers which might be open at pinnacle and backside. They can be of timber or metallic.

- A regular timber mold is proven in fig.

- It needs to be organized from well-pro timber.

- The longer aspects are saved barely projecting to function handles.

- The strips of brass or metallic are once in a while constant on the rims of timber moulds to cause them to greater durable.

Fig.1.9:Wooden mold

- Hence the moulds are to be made large than the dimensions of Steel mold absolutely burnt bricks. The moulds are consequently made longer via way of means of approximately eight to twelve in line with cent in all directions. The specific percent of boom in dimensions of mold is decided via way of means of real test on clay for use for making ready bricks.

- The bricks organized via way of means of hand moulding are of types:

(a) Ground-moulded bricks

(b) Table-moulded bricks.

Machine Moulding:

- The moulding will also be performed via way of means of machines It proves to be good value while bricks in big amount are to be synthetic on the identical spot in a brief time. It is likewise beneficial for moulding difficult and robust clay.

- These machines are extensively categorized in categories:

(a) Plastic clay machines

(b) Dry clay machines.

(a) Plastic Clay Machines:

- Such machines incorporate a square starting of length same to period and width of a brick. The pugged clay is positioned withinside the system and because it comes out via the starting, it's miles reduce into strips via way of means of wires constant in frames.

- The association is made in any such manner that strips of thickness same to that of the brick are obtained. As the bricks are reduce via way of means of twine, they may be additionally referred to as the twine reduce bricks.

(b) Dry Clay Machines:

- In those machines, the robust clay is first transformed into powder shape. A small amount of water is then delivered to shape a stiff plastic paste. Such paste is positioned in mold and pressed via way of means of system to shape difficult and well-formed bricks. These bricks are referred to as the pressed bricks and that they do now no longer nearly require drying. They may be dispatched immediately for the method of burning.

- The twine reduces and pressed bricks have everyday shape, sharp edges and corners. They have cleaned outside surfaces. They are heavier and more potent than regular hand-moulded bricks. They bring awesome frogs and show off uniform dense texture.

9. Give the classification of brick.

Classification of Bricks Based on Quality:

On the premise of fine, Bricks are of the subsequent types

First Class Brick:

- The length is standard.

- The colour of those bricks is uniform yellow or crimson.

- It is properly burnt, ordinary texture, uniform form.

- The absorption capability is much less than 10%, crushing energy is, 280kg/cm2 (mean) wherein it's far 245 kg/cm2 (minimal).

- It doesn’t have efflorescence.

- It emits a metal sound while struck through any other comparable brick or struck through a hammer.

- It is tough sufficient to face up to any fingernail expression at the brick floor if one attempts to do with a thumbnail.

- It is unfastened from pebbles, gravels or natural matters.

Second Class Brick:

- The length is standard, colour is uniform yellow or crimson.

- It is properly burnt, barely over burnt is acceptable.

- It has a ordinary form; efflorescence isn't always appreciable.

- The absorption capability is greater than 10% however much less than 15%.

- Crushing energy is 175kg/cm2(mean) wherein the minimal is 154 kg/cm2.

- It emits a metal sound while struck through any other comparable brick or struck through a hammer.

- It is tough sufficient to face up to any fingernail expression at the brick floor if one attempts to do with a thumbnail.

- It is used for the development of one-storied buildings, transient shed while meant sturdiness isn't always greater than 15 years.

Third Class Brick:

- The form and length aren't ordinary.

- The colour is gentle and mild crimson colored.

- It is below burnt, barely over burnt is acceptable.

- It has massive efflorescence.

- The texture is non-uniform.

- The absorption capability is greater than 15% however much less than 20%.

- The crushing energy is 140kg/cm2(mean) wherein the minimal crushing energy is 105kg/cm2.

- It emits a stupid or blunt sound while struck through any other comparable brick or struck through a hammer.

- It leaves fingernail expression while one attempts to do with the thumbnail.

(2) Classification of Bricks Based on Raw Materials:

On the premise of uncooked substances bricks are of the subsequent kinds:

Burnt Clay Brick:

- It is received via way of means of urgent the clay in molds and fried and dried in kilns.

- It is the maximum used bricks. It calls for plastering while utilized in production works.

Fly ash clay Brick:

- It is synthetic while fly ash and clay are molded in one thousand diploma Celsius.

- It includes a excessive extent of calcium oxide in fly ash.

- That is why commonly defined as self-cementing.

- It commonly expands while getting into touch with moisture.

- It is much less porous than clay bricks. It proved a clean floor so it doesn’t want plastering.

Concrete Brick:

- It is product of concrete.

- It is the least used bricks.

- It has low compression energy and is of low pleasant.

- These bricks are used above and under the damp evidence course.

- These bricks are used may be used for facades, fences and inner brickworks due to their sound discounts and warmth resistance qualities.

- It is likewise referred to as mortar brick.

- It may be of various colorings if the pigment is brought in the course of manufacturing.

- It ought to now no longer be used underground.

Sand-lime Brick:

- Sand, fly ash and lime are combined and molded below pressure.

- During moist mixing, a chemical response takes region to bond the mixtures.

- Then they're positioned withinside the molds.

- The shadeation is greyish because it gives something of a classy view.

- It gives a smoother end and uniform look than the clay bricks.

- As a result, it additionally doesn’t require plastering.

- It is used as a load bearing participant as it's far immensely strong.

Firebrick:

- It is likewise referred to as refractory bricks.

- It is made of a in particular designed earth.

- After burning, it may face up to very excessive temperature without affecting its shape, length, and energy.

- It is used for the liner of chimney and furnaces wherein the same old temperature is predicted to be very excessive.

10. Explain the various test methods on clay bricks.

Testing Methods of clay bricks:

The following are the assessments that wishes to be accomplished at the brick:

Site assessments on bricks

- Hardness Test

- Dimensional Tolerance Test

- Soundness Test

- Impact Test

- Colour Test

Laboratory Tests on bricks

- Water Absorption Test

- Compressive Strength Test

- Efflorescence Test

- Warpage Test

Site Tests for Evaluating Quality of Bricks

The following assessments may be accomplished at web page with none device required. These assessments will supply a concept approximately the pleasant of bricks.

Hardness Test

- Hardness take a look at is accomplished to test hardness of brick. This is an oblique take a look at to recognize its compressive energy and to recognize how properly the brick is kilned. This is examined via way of means of the use of a pointy gear or finger nail and scratching in opposition to the brick floor. If there may be no affect of the scratch at the brick floor, the brick is satisfactorily tough and healthy to be used

Dimensional Tolerance Test

- Dimensional Tolerance take a look at is used to test the shape & length brick. In this take a look at 20 bricks are organized them alongside its length, breadth, and height. The dimensions are in comparison to every different and in comparison, with the usual dimensions.

Sound (Ringing) Test

- Sound take a look at of a brick is subject take a look at to apprehend the pleasant of bricks received. In this take a look at, two bricks are struck with every different. Good pleasant bricks commonly don’t damage and ought to produce a steel sound (bell ring) sound while struck with every different.

Impact Test

- In this check the bricks are allowed to fall from a peak of one meter on ground (now no longer tough floor). Good high-satisfactory brick shouldn’t break. In case it breaks, it’s higher now no longer to apply for production.

Color Test

- Well kilned (burnt) clay brick is of uniform in color in the course of its segment and sun sunglasses of red. Black bricks are over burnt, now no longer of accurate high-satisfactory.

Laboratory Tests to Determine the Quality of Bricks

Water Absorption Test

- Absorption check is carried out to decide the quantity of moisture content material that the brick absorbs. If the bricks soak up extra than 20% of the burden of dry brick, then the brick need to now no longer be used for production as they soak up water from the cement mortar decreasing the general brickwork electricity. In this check five bricks are taken from the pattern and dry weight of every brick is taken. Weights are once more recorded after completely immersing the bricks in water for 25. Water absorption is calculated primarily based totally on each those weights. Detailed Procedure for Water Absorption of a Brick

Compressive Strength Test

- Compressive Strength of a brick is decided through setting a brick withinside the compressive trying out device and loading the pinnacle face (frog face) until failure. The brick frog face if packed with mortar and cured for a duration of four days earlier than. A minimal compressive electricity of 3.five N/mm2 need to be received as in keeping with IS codes. If the compressive electricity of the brick is much less than 3.five N/mm2, the ones bricks need to now no longer be used for production purposes. Detailed Procedure for Calculating Compressive Strength of a Brick

Efflorescence Test