Unit - 4

Equipment Management

Q1) Explain the terms productivity, operational cost, owning and hiring cost and the work motion study?

A1)

1. Productivity

Many phrases are used to describe productivity within side the creation industry: performance factor, manufacturing charge, unit person-hour (p-h) charge and others. Traditionally, productivity has been described as the ratio of enter/output, i.e., the ratio of the center of a related re-source (usually, however now no longer necessarily, expressed in p/hrs) to real output (in developing economic value). To restate this definition to be used within side the creation industry: labor productiveness is the bodily development done in line with p-h, e.g., p/hr in line with linear meter of conduit laid or p/hr in line with cubic meter of concrete poured. The two maximum essential measures of labor productiveness are: • the effectiveness with which labor is used within side the creation process; • the relative performance of labor doing what it is required to do at a given time and place. Examples of the first degree are the labour bucks required to produce a rectangular meter or rectangular foot of living area, or the labour fee of supplying one mattress in a hospital. Another instance is the labour content material required, in line with barrel of output, to construct an oil refinery. In those cases, technological improvements or design upgrades have the maximum widespread impact as it is the effectiveness with which labour is used within side the constructing process that is being measured.

Contractors and prepared labour are, however, extra interested by the second one mea- sure, the relative performance of labour. Examples consist of the variety of rectangular meters of formwork or linear meters of conduit that can be set up according to p-h at a given time and place. Labour performance is the premise of most smooth estimates, as well as the yardstick by which overall performance is measured and monitored.

2. Operational cost

Operational expenses are fee incurred within side the daily operation of an organization (every so often known as sales account expenditure). Operational expenses would possibly include:

1) Wages

2) Utilities.

3) Maintenance and repairs.

4) Rent.

5) Sales.

6) General and administrative expenses.

It is vital to differentiate among operational expenses and capital expenses as there are big accounting and taxation problems which stem at once from how a selected object of expenditure is treated. It can have an effect on whether or not a selected transaction is issue to capital profits tax rather than profits tax, in addition to the viable entitlement to capital allowances, and, of course, there's the problem of the way such remedy influences profitability.

Whilst operational expenses are fee incurred within side the daily operation of an organization, capital expenses are expenses related to one-off expenditure at the acquisition, creation or enhancement of big constant belongings such as land, homes and device in an effort to be of use or gain for multiple monetary year. Whilst it's miles commonly exceptionally clear-cut to discover expenditure to collect or assemble constant belongings, distinguishing among improvements and operational expenses including repairs, maintenance, or substitute may be difficult. Very broadly, improvements ought to either: Significantly prolong the lifestyles of the asset. Significantly growth the cost of the asset. Significantly growth usefulness of the asset

N construction, capital fees and operational fees may be taken into consideration to be related to separate, wonderful stages, with capital fees throughout acquisition and construction, after which a 'handover' to operational fees while the purchaser, takes ownership of the finished development.

Capital fees and operational fees may be visible as competing needs, with better capital fees regularly ensuing in decrease operational fees, as a better pleasant asset can also additionally have decrease upkeep and restore fees, decrease utilities fees, and so on.

Whilst now and again the department among capital and operational fees may be certainly considered one among necessity, primarily based totally at the sources to be had to the purchaser on the time, it could be a calculated choice primarily based totally on evaluation of whole-existence fees.

3. Owning and hiring cost

Owning charges = buy fee of system + financing + taxes – disposal fee (what you get for that system whilst you resell it).

Operating charges = labor + fuel + maintenance + substitute charges of tires, tracks and different components + overhead. Add the proudly owning to the running charges and you've your O&O charges.

Factors that have an effect on the value of proudly owning and working creation device include:

1. The value of the device introduced to the owner.

2. The severity of the situations be neat which the device is used.

4. Work motion study

Work study is a means of enhancing the productivity of the firm by elimination of waste and unnecessary operations.

It is a technique to identify non-value adding operations by investigation of all the factors affecting the job.

Work study is the only accurate and systematic procedure-oriented technique to establish time standards.

Work study, comprises of two areas of study: method study (motion study) and time study (work measurement).

Work study

Method study

Motion study

Work measurement

Time study

Higher productivity

Advantages of Work Study

- It helps to reduce the cost of the product by eliminating waste and unnecessary operations.

- It helps to achieve the smooth production flow with minimum interruptions.

- Meets the delivery commitment

- Reduction in rejections and scrap and higher utilization of resources of the organization

- Helps to achieve better working conditions

- Better workplace layout.

- Helps to establish the standard time for an operation or job which has got application in manpower planning, production planning

Q2) What is simulation techniques for resource scheduling?

A2)

The predicted length of the challenge is calculated via way of means of the usage of a distinctive set of responsibilities in simulation. The agenda is created on the idea of assumptions, so it is able to be used although the scope is modified or the responsibilities aren't clean enough.

Earned Value Management (EVM) Technique

1. Planned Value (PV)

2. Earned Value (EV)

3. Actual Cost (AC

1. Planned Value (PV)

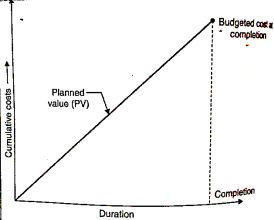

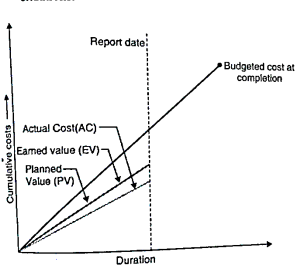

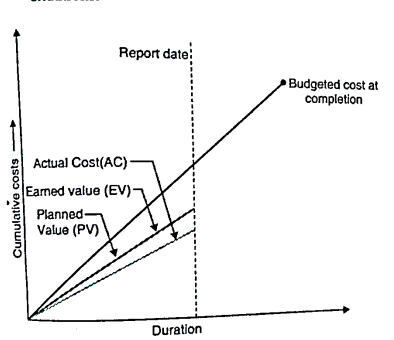

The first step in the application of EVM methodology is to develop the project baseline cost curve called planned value curve. It is the plot of cumulative budgeted cost of activities (defined in the project work breakdown structure) at the periodic intervals (for example, monthly) of the project duration.

The cumulative costs at various project intervals are obtained from the month-wise summary of cost incurred on the activities. Since this baseline cost curve is obtained based on the budgeted cost of activities and as per planned' project schedule.

This planned value curve is also termed as budgeted cost of work as scheduled (BCWS)

2. Earned value

The term earned value (EV) indicates the value of work earned and this is obtained as the cumulative values of the quantum of the work actually executed in the activities multiplied by the corresponding budgeted unit costs of the respective activities.

The quantum of the work executed in the activities at any given point of time (review date) could be as per planned quantity or at variance from the planned quantity.

The earned value increases cumulatively as the activities gets completed along the project duration. This earned value plot is also called 'budgeted cost of work performed' (BCWP)

3. Actual Cost (AC)

The actual cumulative cost of activities at any given point of time (review date) is obtained from the quantum of work actually executed in the activities multiplied by the actual unit costs of the work in respective activities.

For well controlled project situations, the actual quantum of work and their actual unit cost shall adhere to the planned quantum of work and their budgeted unit cost.

Otherwise, they may be at variance with respect to the planned quantum of work and their budgeted unit price indicating favorable or unfavorable project situations.

Major effort in the EVM methodology à incomplete the actual cost from the collected on the cost of various resources utilized (manpower, material, equipment, etc) in the activities.

The actual cumulative cost curve is developed progressively with the completion of activities during the course of project implementation.

This actual cost curve is also termed as actual cost of work performed (ACWP)

Q3) Explain construction Equipment for earth moving?

A3)

There are diverse kinds of earthmoving equipments utilized in production; few of the pivotal ones are defined below. Excavators are heavy production system which includes a boom, dipper (or stick), bucket and cab on a rotating platform called the “residence”.

The residence sits atop an undercarriage with tracks or wheels. They are an herbal development from the steam shovels and frequently mistakenly known as electricity shovels. All motion and features of a hydraulic excavator are completed thru the usage of hydraulic fluid, with hydraulic cylinders and hydraulic motors.

Due to the linear actuation of hydraulic cylinders, their mode of operation is basically extraordinary from cable-operated excavators which use winches and metallic ropes to perform the movements.

1) Backhoe loader

A backhoe loader, additionally known as a loader backhoe, digger in layman’s terms, or colloquially shortened to backhoe inside the enterprise, is a heavy gadget car that includes a tractor-like unit outfitted with a loader-fashion shovel/bucket at the front and a backhoe at the back.

Due to its (relatively) small length and versatility, backhoe loaders are very not unusual place in city engineering and small creation tasks (inclusive of constructing a small house, solving city roads, etc.) in addition to growing countries. This sort of system is just like and derived from what's now called a TLB (Tractor-Loader-Backhoe), that's to say, an agricultural tractor outfitted with the front loader and rear backhoe attachment.

2) Bulldozer

A bulldozer is a tractor prepared with a large metallic plate (called a blade) used to push huge portions of soil, sand, rubble, or different such cloth at some point of creation or conversion paintings and normally prepared on the rear with a claw-like device (called a ripper) to loosen densely compacted materials. It is mostly a crawler (non-stop tracked) tractor. Bulldozers may be determined on a huge variety of sites, mines and quarries, army bases, heavy enterprise factories, engineering tasks and farms.

3) Skid-steer loader

A skid loader is a small, inflexible-body, engine-powered system with elevate fingers used to connect a huge kind of labor-saving gear or attachments.

Skid-steer loaders are normally four-wheel motors with the wheels automatically locked in synchronization on every aspect, and wherein the left-aspect power wheels may be pushed independently of the proper-aspect power wheels.

The wheels normally haven't any separate guidance mechanism and preserve a hard and fast instantly alignment at the frame of the system.

Turning is completed via way of means of differential guidance, wherein the left and proper wheel pairs are operated at exclusive speeds, and the system turns via way of means of skidding or dragging its fixed-orientation wheels throughout the ground.

The extraordinarily inflexible body and sturdy wheel bearings save you the tensional forces as a result of this dragging movement from destructive the system.

4) Motor grader

A motor grader is a production gadget with a protracted blade used to create a flat floor at some stage in the grading process. Although the earliest fashions have been towed at the back of horses or different powered equipment, maximum current graders comprise an engine, so are known, technically erroneously, as “motor graders”.

Typical fashions have 3 axles, with the engine and cab located above the rear axles at one give up of the car and a 3rd axle on the front give up of the car, with the blade in between.

Most motor graders force the rear axles in tandem however a few additionally upload the front wheel force to enhance grading capability. Many graders additionally have optionally available attachments for the rear of the gadget which may be ripper, scarified, blade, or compactor.

5) Trencher

A trencher is a bit of production system used to dig trenches, mainly for laying pipes or electric cables, for putting in drainage, or in training for trench warfare. Trenchers might also additionally variety in length from walk-at the back of models, to attachments for a skid loader or tractor, to very heavy tracked heavy system.

6) Loader

A loader is a heavy system gadget utilized in production to transport apart or load substances which includes asphalt, demolition debris, dirt, snow, feed, gravel, logs, uncooked minerals, recycled material, rock, sand, woodchips, etc. into or onto some other kind of machinery (which includes an unload truck, conveyor belt, feed-hopper, or railroad car).

There are many sorts of loader, which, relying on layout and application, are known as via way of means of numerous names, such as bucket loader, the front loader, the front-quit loader, pay loader, scoop, shovel, bypass loader, wheel loader, or skid-steer.

7) Wheel tractor-scraper

A wheel tractor-scraper is a bit of heavy system used for earthmoving. The rear a part of the scraper has a vertically portable hopper with a pointy horizontal the front area which may be raised or lowered.

The front area cuts into the soil, like a carpenter’s aircraft slicing wood, and fills the hopper. When the hopper is complete its miles raised, closed, and the scraper can deliver its load to the fill location wherein its miles dumped. With a kind known as an ‘raising scraper’ a conveyor belt movements cloth from the slicing area into the hopper.

8) Dragline excavator

A dragline excavator is a bit of heavy system utilized in civil engineering and floor mining. Draglines fall into wide categories: the ones which are primarily based totally on standard, lifting cranes, and the heavy devices which must be constructed on-site.

Most crawler cranes, with an brought winch drum at the front, can act as a dragline. These devices (like different cranes) are designed to be dismantled and transported over the street on flatbed trailers. Draglines utilized in civil engineering are nearly continually of this smaller, crane kind.

These are used for road, port production, pond and canal dredging, and as pile riding rigs. Paver A paver (paver finisher, asphalt finisher, paving system) is a bit of production system used to put asphalt on roads, bridges, parking masses and different such places. It lays the asphalt flat and presents minor compaction earlier than its miles compacted through a roller.

9) Compactor

A compactor is a system or mechanism used to lessen the dimensions of cloth consisting of waste cloth or biomass via compaction. A trash compactor is regularly utilized by a domestic or commercial enterprise to lessen the extent of trash it produces.

A baler-wrapper compactor is regularly used for making compact and wrapped bales on the way to enhance logistics. Normally powered through hydraulics, compactors take many shapes and sizes. In landfill web sites for example, a huge tractor (normally a transformed the front give up loader with a few variations of a bulldozer blade attached) with spiked metal wheels known as a landfill compactor is used to force over waste deposited through waste series vehicles (WCVs).

Q4) Explain earth compaction?

A4)

Soil compaction is used to density a soil via way of means of decreasing the void space, or the quantity of air, among soil debris. In different words, soil compaction takes place whilst soil debris is pressed collectively to lessen the distance among them.

The ensuing fairly compacted soils, with only a few spaces, have a better unit weight than non-compacted soils.

Compaction decreases the probability of agreement after a building, roadway, runway or parking zone is built that could bring about untimely pavement failure, expensive protection or repairs. Soil compaction is an essential a part of the development procedure because it presents a robust running platform.

A robust soil base is the inspiration and all different components of the assignment rely upon its power and performance, each at some point of production and as soon as the pavement shape is in place.

Types of Soil Compaction Equipment

Compaction device has been utilized in creation for the reason that early twentieth century. Steamrollers actually paved the manner for today’s cutting-edge device. Soil compaction device is available in a whole lot of patterns with extraordinary alternatives which includes unmarried or double drums, vibratory mechanisms or dozer blades. All varieties of compaction device assist to boom the soil density ensuing in a boom within side the bearing electricity of the soil or material. Smooth rollers use static pressure, once in a while together with vibration and impact, to compact soil. Smooth rollers aren't the best sort of compactor utilized, however greater than possibly used within side the very last compaction step to offer an easy floor for creation.

Pad foot and Tamping foot rollers use manipulative pressure to interrupt the herbal bonds among debris for higher compaction, specifically in cohesive soils. They have tapered ft so that they do now no longer fluff the soil reducing the cap potential of soil to take in extra water content material must its rain.

On small to medium soil compaction jobs or especially gravel soils, pneumatic rollers use staggered rubber tires with various air stress in which the floor of bladed granular soils wishes to be sealed.

These gadgets normally have ballast structures that permit weight to be introduced or reduced as had to meet compaction goals. Tire stress also can be altered to assist meet compaction goals.

In restricted zones a rammer may be used to density soil. Tamping rammers are light-weight and transportable gadgets which can be able to speedy making use of consecutive affects to a soil.

Q5) What is mean by hauling equipment?

A5)

If you're new to creation and drilling, it’s essential to apprehend the styles of system so that it will be used at the job.

Hauling system, in particular, is used to transport constructing/drilling resources, soil, and different substances. Below is a top-level view of the styles of hauling system generally utilized in creation and more:

- Cranes

Equipped with twine ropes, sheaves, and a hoist, cranes are used to raise and pass substances and resources in the course of creation. Cranes also are beneficial for demolishing homes and different structures. In creation, the two simple styles of cranes are cell and fixed.

Mobile cranes – Consist of trusses hooked up onto cell platforms, inclusive of vans or flatcars.

Fixed cranes – Are capable of raise heavier hundreds and feature higher attain because of their expanded stability.

Tower cranes, utilized in high-upward push constructing creation, are an instance of a set crane hooked up on pinnacle of a metallic tower.

2. Bulldozers

Though normally used to consult the complete vehicle, the time period bulldozer sincerely refers back to the front-hooked up dozer plate, that's connected to a separate tractor.

The bulldozer is used to loosen difficult soils and shift dirt, and might paintings on difficult terrain. It is likewise fantastic for growing pilot roads, as it may clean land from timber and stumps. Bulldozers may be wheel-primarily based totally or track-primarily based totally.

For muddy or sandy terrains, track-kind bulldozers are best, because the tracks distribute the bulldozer’s weight over a bigger area, decreasing the chance of sinking.

3. Excavators

Excavators are automobiles prepared with a digging bucket connected to the give up of an extendable arm.

One of the greater flexible varieties of hauling equipment, excavators are used to dig holes, demolish buildings, and raise and cargo heavy elements amongst others. Due to their huge size, excavators require the fewest passes while loading vans with materials.

4. Loaders

These automobiles are used to load free materials, including sand, dirt, or gravel, and take them to some other machine, including an unload truck or conveyor belt. Oftentimes, those vacation spot machines are at a better elevation than the area of the materials.

Loaders also can be used to move different machinery. Similar to bulldozers, loaders may be track-primarily based totally or wheel-primarily based totally, and the choice relies upon at the terrain to be labored on.

5. Shovels

Shovels are used for digging and loading rocks and soil for mineral extraction. The cap potential to dig into very difficult cloth and raise huge objects, including boulders, are their finest strengths.

Shovels may be electric powered power or hydraulic powered. Electric shovels use a revolving deck with an energy plant, even as hydraulic shovels have a less difficult energy machine that calls for fewer components.

6. Tractors

Though maximum normally used for pulling and pushing different device in construction, the wonderful benefit of tractors is the to be had elements that may be used to perform specific jobs.

Available additives consist of the short hitches, backhoes, buckets, and blades. Similar to bulldozers and loaders, tractors may be track-primarily based totally or wheel-primarily based totally. Like different track-primarily based totally device, those tractors are capable of paintings thru muddy terrains. However, they function at a lot slower speed.

7. Trucks

Their excessive tour speeds permit for faster transportation of substances while touring on set up roads. Their low hauling expenses additionally permit for flexibility while figuring out the full hauling potential or within side the occasion of an alternate in destination/route. Dump vehicles – Used to transport clay, dirt, soils, and sands.

Side and rear sell off vehicles put off substances thru the frame connected to the chassis of the truck. Bottom sell off vehicles have gates that open from the lowest to put off substances. For harder terrain, articulated sell off vehicles are used.

Hauling vehicles – Used to move a fleet of device (for general, military, or carrier construction) from one area to another.

Q6) Explain Hoisting Equipment?

A6)

Types of Hoisting Equipment in Construction: The hoisting is the lifting of the fabric towards gravity and perhaps carried out with an extensive variety of system from the small hand-operated easy screw or hydraulic-jack to fashionable excessive powered cranes and elevators.

Hoisting is lifting a weight from one area and shifting it to every other area that is at an affordable distance. Big initiatives consisting of the development of dams, commercial buildings, etc. require hoisting system.

Hoisting system consists of jacks, winches, chain hoists, and cranes. Crane is the simplest unmarried device which, as an unmarried piece, is able to offering three- dimensional motion of the weight.

Types of hoisting equipment

1) Pulley and sheave block

2) Chain hoists

3) Mobile cranes

4) Winch

5) Jack

6) Shear leg

7) Tower cranes

8) Whirler cranes

9) Derrick cranes

10) Gantry cranes

1) Movable pulley

A pulley is a wheel on an axle or shaft this is designed to aid motion and alternate of course of a cable or belt alongside its circumference. Pulleys are utilized in plenty of methods to raise loads, observe forces, and to transmit power. In nautical contexts, the meeting of the wheel, axle, and helping shell is known as a “block.”

A pulley can also be known as a sheave or drum and can have a groove among flanges round its circumference. The power detail of a pulley machine may be a rope, cable, belt, or chain that runs over the pulley in the groove.

2) Rope and pulley

The pulley and sheave blocks appropriate for lifting tough surfaces and heavy loads. For this purpose, the chains and cord ropes are used. The alloy chains are excellent ideal for hoisting operation.

The weakest factor of this machine is the weight hook. The hook fails with the aid of using straightening. Once the hook receives elongated or straightened, it ought to be replaced. A traditional sheave and pulley block

3) Chain hoist

The chain hoists are the famous mechanism for lifting masses of up to tones. The device includes units of chains, specifically the hand and cargo chain. The hand chains are specially beneficial for the remote location, wherein an electric powered motor or different kinds of mechanical equipments aren't available.

The pull carried out thru the hand chain is transmitted to the weight chain with a multiplication thing of over 20. The load to be lifted is held via way of means of a load hook whilst any other hook (referred to as help hook) on the top, help the mechanism. The hooks, however, ought to now no longer be interchanged because the help hook is made tons more potent than the weight. There is hook. 4 kinds of hand-operated chain hoists are in use:

- Differential

- Screw geared

- Spur geared

- Pull lift

4) Mobile crane

Mobile crane is utilized in huge production tasks for lifting heavy loads. It is used for loading and unloading for cloth in coal mines. Loading and unloading of ships. To take the burden from floor degree and vicinity it into the trucks

5) Electric winch

A winch is a mechanism within side the form of a cylinder or drum, over which rope or chain is wound. If a winch is used best for elevating and lowering, it's far every now and then called hoist. The winches are of types: hand winches strength winches

6) Tower crane

These are the crane of swing activity kind and are set up on excessive metallic towers. The top of the tower perhaps 25 to 30 m and those cranes are located to be appropriate within side the production of tall homes in congested areas. The floor location required for such cranes may be very small. This crane is an aggregate of desk bound and cellular units.

This combines the benefits of a log growth of derrick crane and mobility of the cellular crane. The rotating shape has an outer framework. The growth is hooked up to the front give up of this framework. The counterweight is supplied on the rear give up. On the diagonally contrary corners of the base, separate vehicles are supplied, which offer motion to the imperative shaft

7) Derrick crane

The derrick cranes are of types, namely: Guy derrick and Stiff leg derrick

The man derrick includes a vertical mast. This mast is supported via way of means of the wide variety of fellows and may revolve thru 360°.

While revolving, the radius of revolution must be such that the revolving shape isn't always obstructed via way of means of the fellow wires. The strength is provided via way of means of a diesel engine or via way of means of an electric powered motor.

A normal derrick cranes. This derrick may be built as much as two hundred tones capacity. In stiff leg kind derricks, the fellow wires are changed via way of means of trussed shape. This kind of derricks is appropriate for masses from 10 to 50 tones.

8) Overhead gantry crane

The Gantry cranes or overhead cranes are the crucial machines in factories and workshops. In massive workshops, there are separate machines for fabrications or upkeep of the gadget parts. The gadget or the components, which can be to be repaired, may be transferred to the vicinity of fabrication or meeting with the assist of Gantry cranes. Hoisting gadget assists within side the lifting and positioning of massive, heavy masses in lots of industries, including:

1) Automotive

2) Chemicals

3) Commercial

4) Printing

5) Manufacturing

6) Newspaper Paper

7) Steel Warehousing and distribution

Hoisting gadget offers lots of benefits:

Customizable – Hoisting gadget may be custom designed with underneath the hook attachments, cease effectors or specialized tooling to address a numerous sort of merchandise and masses

Ergonomics – By doing the heavy lifting, hoisting gadget takes the stress off operators, decreasing fatigue and reducing the chance of injury

Flexible – Hoisting gadget may be without difficulty re-outfitted for longer lifting capability

Q7) What is conveying equipment?

A7)

A conveyor gadget is a not unusual place piece of mechanical managing device that actions substances from one area to another. Conveyors are mainly beneficial in programs regarding the shipping of heavy or cumbersome substances. Conveyor structures permit brief and green shipping for an extensive style of substances, which cause them to very famous within side the fabric managing and packaging industries. They additionally have famous purchaser programs, as they're frequently discovered in supermarkets and airports, constituting the very last leg of item/ bag transport to customers.

Many types of conveying structures are to be had and are used in keeping with the numerous wishes of various industries. There are chain conveyors (ground and overhead) as well. Chain conveyors encompass enclosed tracks, I-Beam, towline, power & free, and hand driven trolleys.

Conveyor structures are used giant throughout a number industries because of the sever blessings they provide. Conveyors are capable of thoroughly shipping substances from one degree to another, which while achieved with the aid of using human hard work might be strenuous and expensive. They may be hooked up nearly anywhere, and are tons more secure than the use of a forklift or different gadget to transport substances. They can pass masses of all shapes, sizes and weights. Also, many have superior protection capabilities that assist save you accidents. There are a number of alternatives to be had for walking conveying structures, consisting of the hydraulic, mechanical and completely computerized structures, which can be ready to healthy character needs. Conveyor structures are typically used in lots of industries, consisting of the Mining, car, agricultural, computer, electronic, meals processing, aerospace, pharmaceutical, chemical, bottling and canning, print completing and packaging.

Although an extensive type of substances may be conveyed, a number of the maximum not unusual place consist of meals gadgets including beans and nuts, bottles and cans, car components, scrap metal, tablets and powders, timber and fixtures and grain and animal feed. Many elements are essential within side the correct choice of a conveyor device. It is essential to recognize how the conveyor device could be used beforehand. Some character regions which are useful to take into account are the specified conveyor operations, including shipping, accumulation and sorting, the cloth sizes, weights and shapes and in which the loading and pickup factors want to be.

1) Pneumatic

Every pneumatic machine makes use of pipes or ducts known as delivery traces that bring a combination of substances and a circulation of air.

These substances are unfastened flowing powdery substances like cement and fly ash. Products are moved via tubes with the aid of using air stress. Pneumatic conveyors are both provider structures and dilute-section structures; provider structures absolutely push gadgets from one access factor to 1 go out factor, which includes the money-changing pneumatic tubes used at a financial institution drive-via window.

Dilute-section structures use push-pull stress to manual substances via diverse access and go out factors. Air compressors or blowers may be used to generate the air flow. Three structures used to generate high-speed air circulation: Suction or vacuum structures, utilizing a vacuum created within side the pipeline to attract the fabric with the encircling air. The machine operated at a low stress that is almost 0.4–0.five atm. beneath atmosphere, and is applied specially in conveying mild unfastened flowing substances. Pressure-kind structures, wherein a fine stress is used to push fabric from one factor to the next. The machine is right for conveying fabric from one loading factor to some of unloading factors. It operates at a stress of 6 atm. And upwards.

Combination structures, wherein a suction machine is used to deliver fabric from some of loading factors and a stress machine is hired to supply it to some of unloading factors.

2) Vibrating

A vibrating conveyor is a system with a stable conveying floor that is became up at the facet to shape a trough. They are used drastically in food-grade packages to deliver dry bulk solids in which sanitation, wash down, and occasional upkeep are essential. Vibrating conveyors also are appropriate for harsh, very hot, dirty, or corrosive environments.

They may be used to deliver newly-formed steel elements which may also attain upwards of 1,500 °F (820 °C). Due to the constant nature of the conveying pans vibrating conveyors also can carry out obligations which include sorting, screening, classifying and orienting elements.

Vibrating conveyors had been constructed to deliver fabric at angles exceeding 45° from horizontal the usage of unique pan shapes. Flat pans will deliver maximum substances at a five° incline from horizontal line.

3) Flexible

The bendy conveyor is primarily based totally on a conveyor beam in aluminum or stainless steel, with low-friction slide rails guiding a plastic multi-flexing chain. Products to be conveyed journey without delay at the conveyor, or on pallets/carriers. These conveyors may be labored round limitations and preserve manufacturing strains flowing. They are made at various tiers and may paintings in more than one environment. They are utilized in meals packaging, case packing, and pharmaceutical industries and additionally in massive retail shops which includes Wal-Mart and Kmart.

4) Spiral

Like vertical conveyors, spiral conveyors boost and decrease substances to distinctive tiers of a facility. In contrast, spiral conveyors are capable of delivery fabric hundreds in a non-stop flow.

A helical spiral or screw rotates inside a sealed tube and the velocity makes the product within side the conveyor rotates with the screw. The tumbling impact affords a homogeneous blend of debris within side the conveyor, that's important while feeding pre-blended elements and keeping blending integrity.

Industries that require a better output of substances - meals and beverage, retail case packaging, pharmaceuticals - normally comprise those conveyors into their structures over trendy vertical conveyors because of their cap potential to facilitate excessive throughput.

Q8) Explain concrete production equipment?

A8)

With correct fine concrete production gadget, a production enterprise can get fine production paintings completed in a lesser quantity of time. It can, therefore, reduce down on its exertion’s prices and growth earnings via way of means of giving the fine production offerings to its customers in a quicker way. With development in technologies, these days some of concrete production gadget are to be had within side the market.

For each production site, there exists a various variety of production equipment for quicker, simpler and more secure constructions. Today, numerous producers are presenting incredible concrete production gadget. It is pivotal to pick the gadget that renders extra feasibility on your production project. Given beneath are one of a kind forms of concrete gadget utilized in production.

1) Concrete batching plant

A concrete batching plant is a device wherein elements of concrete are combined and mixed homogeneously to gain concrete of favored electricity and fine. Concrete batching flora may be categorized as desk bound concrete batching flora and cell concrete batching flora, primarily based totally at the region of the plant.

Mobile batching flora may be used moist or dry and has a big selection of configurations and manufacturing kinds consisting of Ready Mix, Precast & Pre stressed, Central Mix, and RCC.

Mobile Concrete Batching plant fashions at the moment are absolutely automatic. The towing association within side the plant allows it to be towed through tractor or equal power. The new plant fashions contain good enough potential gravel & sand hoppers, weighing conveyor suspended on digital load cells, reversible drum kind mixer unit, cement bin with screw conveyor, rubber belt kind charging conveyor, cement batcher, PLC primarily based totally manage panel.

Modern cell flora such as transportable shaft mixers are designed to be transportable and for this reason are established on a towable chassis with wheels for optimum mobility and short setup. The compact layout boosts the manufacturing potential and suits in skinny plot sizes.

The new concrete batching flora at your task site, the plant may be absolutely erected and operational in much less than 4 hours. All additives are on board and the whole plant is pre-stressed out and plumbed for air and water. All flora examined at our manufacturing unit to make sure trouble-unfastened start-up and operation.

2) Concrete mixers

Concrete mixers may be divided into vast classes Batch Mixer and Continuous Mixer. Continuous mixers are utilized in huge production web sites such as, for production of dams, bridges, etc., which entails using huge loads of concrete and additionally calls for non-stop glide of concrete. Batch mixer is one of the maximum not unusual place styles of mixer and its miles extensively used to combine the concrete ingredients.

It includes a revolving drum with blades or baffles equipped inside it. In this sort of mixer, all of the substances of the preferred percentage are blended and fed into the hopper of the revolving drum.

Modern batch mixers include a ribbon or paddle agitator. The blend is held in steady suspension presenting for brilliant uniform blend of the product. Paddle assemblies blend the usage of a tumbling movement and feature much less product shearing all through the technique. Batch mixers are best for an extensive form of applications, in particular in which manufacturing portions are small, strict manage of blend composition is required, formulations alternate often or batch traceability is necessary.

Continuous mixers offer a greater good value alternation for massive capability to fulfill technique requirements. The cutting-edge non-stop mixer can manage as much as five specific substances at one time, blending powders with any other powder, powder with a liquid or numerous drinks collectively to create a homogeneous product freed from any agglomerates or lumps. He weighing, loading, blending and discharge steps take region concurrently and constantly in a non-stop blending system.

These permits for decrease blending times, constant blending performance (no batch-to-batch variation), reduced electricity utilization and automated manage. All blenders, mixers and agitators can now be custom constructed to efficaciously and cost-correctly meet every software requirement.

3) Concrete pump

There are in particular styles of concrete pumps, line pumps and growth concrete pumps. The line pump is hooked up on a truck and positioned on a trailer. Line pumps commonly pump concrete at decrease volumes than growth pumps and are used for smaller quantity concrete putting packages which include swimming pools, sidewalks, and single-own circle of relatives’ domestic concrete slabs and maximum floor slabs. The 2nd kind is growth concrete pumps. These pumps are connected to a truck and use a remote-managed articulating robot arm.

They are frequently used on huge production web sites and pump at very excessive volumes. With the addition of system and generation below those divisions numerous subdivision classes of concrete pumps have advanced namely, cellular desk bound pump, Truck Mounted Static Pump, Truck Mixer Concrete Pump and plenty of more.

Q9) Explain Tunneling Equipment?

A9)

The technique of tunnel creation relies upon on such elements because the floor conditions, the groundwater conditions, the period and diameter of the tunnel drive, the intensity of the tunnel, the logistics of helping the tunnel excavation, the very last use, and the form of the tunnel and suitable hazard management.

Tunnel creation is a subset of underground creation. The choice of the apt device consequently turns into pivotal. Discussed underneath is a number of the maximum used tunnel device utilized in creation.

1) Crawler Excavators

The cutting-edge crawler excavator is designed to dig or grade, or circulate earth and big objects, and is assessed with the aid of using its mode of locomotion. The many varieties of excavators consist of wheeled, walker, towed, and rail excavators. Related to tracked tanks extensively utilized by armies, those crawlers circulate upon the identical rotating wheel systems, however additionally have the cap potential to dig, choose and delivery excavated substances as they proceed.

The crawler excavator additives consist of a prime crawler chassis, rotor support, the primary swivel joints, turntables, the tool weight, the panel, cab, and air-conditioners. Hybrid crawler excavators incorporate numerous capabilities which includes class-main strength output, stability, lifting capacity, and operator comfort. Two short-tail fashions supply exquisite capability for constrained workspaces. All machines provide wonderful gas performance and performance.

These devices are used to create cross-tunnels while explosives are getting used for secondary profiling, and, of course, for direct excavator tunneling.

Wheel loaders newer wheel loader fashions are geared up with a 28.five kilowatt / 38.eight engine as standard. The exhaust after-remedy is done with the aid of using DOC and DPF. Smart Driving PRO is likewise optionally to be had for the all-wheel steer loader.

This is a brand new function with 3 specific working modes that guide and relieve the operator within side the respective packages even as being fuel-efficient. In the Power Mode, the entire engine output is to be had. This presents an excellent foundation for instant loading cycles and additionally for paintings in excavated material. In assessment to the Power Mode, the gadget drives the equal tour pace in Eco Mode with decreased engine pace.

To lessen the noise stage and to store fuel, this operator mode is exceptionally appropriate for stacking paintings wherein the total gadget energy isn't always required. Wheel loaders are particularly designed to be used in tunnel packages.

2) Crawler loaders

New age crawler loaders supply greater horsepower than predecessors. Hydrostatic transmission gives Total Machine Control, which lets in operators to pick out among more than one setting: pace-in-grip and a V-sample manage with foot pedal steering. On-board hydrostatic and hydraulic strain sensors offer operators with strain readings through an in-cab display. Eco Mode optimizes gas financial system via way of means of up to twenty percentage whilst preserving floor pace via way of means of robotically adjusting engine pace and transmission settings primarily based totally at the load. It features in each ahead and reverses directions.

Auto idle lowers engine pace while the system isn't transferring and no features are being activated. An adjustable timer may be set within side the display and paired with auto-shutdown.

Hydrostatic transmission gives operators to pick out among more than one setting: pace-in-grip and a V-sample manage with foot pedal steering. On-board hydrostatic and hydraulic strain sensors offer operators with strain readings through an in-cab display. Operational specs are configured with man or woman extra alternatives to tailor the machines to tunnel packages and conditions.

3) Tunnel boring machine

A tunnel boring machine (TBM), is used to excavate tunnels with a round cross-segment thru a whole lot of soil and rock strata. They will also be used for micro tunneling. They may be designed to bore thru something from difficult rock to sand. Tunnel diameters can variety from one meter (three ft) (executed with micro-TBMs) to 17.6 meters (fifty-eight ft) to date

Tunnels of much less than a meter or so in diameter are normally executed the use of trenchless creation strategies or horizontal directional drilling as opposed to TBMs. TBMs also can be designed to excavate non-round tunnels, consisting of u-fashioned or horseshoe and rectangular or square tunnels. From standstill to excessive pace – the manipulate modules of new fashions permit customers to optimally manipulate an extensive variety of speeds.

The aggregate of two-pace vehicles and the cap potential to apply vehicles in tandem in unfastened circulate unit’s new requirements approximately overall performance and power. With their compact design, the self-rotating cutter heads can drill even thru the toughest rock layers.

4) Horizontal Directional Drilling Machines

Horizontal Directional Drilling Machines (HDD) machines are steerable, trenchless drilling rigs for the set up of pipes, conduits, and cables underground in a shallow arc. They are normally used for installations under waterways and roadways to keep away from traumatic the floor above.

Horizontal drilling machines are usually heavy-responsibility motors equipped with song drives, operator controls, and drilling machinery. Materials used for pipes encompass PVC, polyethylene, polypropylene, ductile iron, and steel. Directional drilling machines are available in various sizes, with the most important machines able to drilling to depths of two hundred ft. And lengths of 6,000 ft.

Horizontal directional drilling machines are divided into 3 classes: large-diameter HDD (maxi-HDD), medium-diameter HDD (midi-HDD), and small-diameter HDD (mini-HDD). There isn't any great distinction within side the operation of those systems. The classes constitute the power length, depth, torque and pullback talents of every system.