Unit-1

Introduction to Various Design Philosophies

Q1) Explain introduction to various design philosophies of R.C structure?

A1) Concrete is strong in compression but week in tension

Steel is reinforced suitable at the place where concrete is weak in tension such combination of steel and concrete

The purpose of R.C structure is increase strength of concrete section and to reduce the size of structural member

Various design philosophies of R.C structure are

Reinforced concrete is used to construct various structures

Fig no 1Building

Fig no 1Building

Fig no 2 Fig no 3

Flyover Water tank

Q2) Explain various type of RCC structure also limitations of WSM over LSM

A2) Following are the various methods for RCC structure

1. Working stress methodology (WSM).

2. Ultimate load methodology (ULM).

3 Limit state methodology (LSM).

Limitations of WSM strategies over LSM

Q3) Explain advantages and disadvantages of RCC

A3) Advantages of reinforced concrete

1. Strength

It has excellent Tensile likewise as compressive strength a pair of malleability

2. Ductility

Ductility of structures is increase thanks to steel reinforcement

3. Durability

R.C. structures are more durable

4. Mould ability

The flexibility of reinforcement and therefore the liquidness of concrete makes the R.C. member to be mould in any form thus it's appropriate for architectural demand.

5. Porosity

RC members are impermeable to wet

6. Fire place resistance

R.C. structures are additional fireplace resistance than alternative materials such as steel and wood

7. Economy

R.C.C is cheaper than steel and pre stressed concrete

Disadvantages of R.C.C

RCC has followed disadvantages

1. Weight of R.C. structures are measure over different materials

2. Significant formwork is needed for R.C. members

3. RC structures take a lot of times to realize its full strength

Q4) Explain the working stress methods, ultimate load methods, limit state methods

A4) Working Stress Method (WSM)

Ultimate Load Method

Load factor= Collapse load / working load

Limit State methods

Q5) What are the assumption created in working stress methods

A5) Assumptions created in working stress method

Q6) Explain the comparison between balanced, under reinforced. Over reinforced section

A6) Comparison between various sections

S R NO | Description | Balanced Section | Under reinforcement section | Over reinforcement section |

1 | Steel | Steel provided as per requirements | Steel provide less than requirements | Steel provided more than requirements |

2 | Neutral axis | X =XC | X<XC | X>XC |

3 | Actual stress of concrete | ( | ( | ( |

4 | Actual stress in steel | ( | ( | ( |

5 | Moment of resistance | MR =T*Z =C*Z | MR = T*Z | MR =C*Z |

6 | Economic | economical | More economical | costlier |

7 | Safety | More safe | Fails in tension | Fails in compression |

Q7) A reinforced concrete beam section of size 300 mm x 700 mm effective depth is reinforced with 3 bars of 20 mm diameter in tension. The concrete mix and HYSD steel reinforcement used are of grade M20 and Fe415 respectively.

A7) Find

1) Depth of neutral axis.

2) Type of reinforced section.

3) Moment of resistance.

4) Maximum stress induced in material WSM is recommended.

Answer:

Given,

b = 300 mm

d = 700 mm

To find: x, MR and σc b c

Sol2

For M20, σc b c = 7 N/mm2 and m = 280 / 3 *  c b c = 230/ 3* 7 = 13.33

c b c = 230/ 3* 7 = 13.33

For Fe415, σs t = 230 N/mm2

Area of steel = n *  /2 * d 2 = 942.5 mm 2

/2 * d 2 = 942.5 mm 2

Step 1: Depth of critical neutral axis:

c b c / (

c b c / ( s t /m) = X c / (d –X c)

s t /m) = X c / (d –X c)

0.406 = X c / (700 – X c)

700 = x c + 2.464 X c

X C = 202

Step 2: Actual depth of neutral axis (x):

= m. A s t( d – x)

= 13.33x942.5 (700– x)

150 x2 = 8.794 x 106 – 12563.53x

150 x2 + 12563.53x - 8.794 x 106 = 0

Solving quadratic equation, we get

x = 203.85 mm

Step 3: Type of beam section:

Since, x > X c, then section is over reinforced section and will be fails

in compression.

Step 4: Moment of resistance:

MR = C* Z

MR =  c b c/ 2 .b .x. (d –

c b c/ 2 .b .x. (d –  x/3)

x/3)

= 300 X 203.85 (700–203.85 /3)

= 135.29 x 106 N.mm = 135.29 K N. m

Step 5: maximum stress induced in material:

Since the section fails in compression,

c b c max = 7 N/ mm 2

c b c max = 7 N/ mm 2

Corresponding maximum stress in steel:

=  c b c /

c b c / s t/m) = x – (d-x)

s t/m) = x – (d-x)

= 93.33/  s t = 0.41086

s t = 0.41086

s t max= 227.1 N/mm2

s t max= 227.1 N/mm2

Q8) What are assumption in limit state design

A8) ASSUMPTION IN LIMIT STATE DESIGN

F y/1.15Es + 0.002 f y

Q9) What are the design steps for finding ultimate moment of resistance

A9) DESIGN STEPS

Given

Grade of concrete

Grade of steel

Size of beam

Reinforcement provided

If X u = X u max …………….balanced

If X u< X u max …………….under reinforced

If X u> X u max …………….over reinforced

Equating the compression force and tension force

0.36 * f c k * b * X u * + A s c * f s c = 0.87 * f y * A s t

From this find X u

M u = 0.36 * f c k * b * X u * (d- 0.42 * X u) + A s c * f s c * (d- d’)

This equation is valid for balanced and under reinforced section

If the section is over reinforced section then take X u = X u max in above equation and use the same equation for finding M u .Do not increase the depth of the beam for over reinforced section.

Given

Grade of concrete and steel

Size of beam

Ultimate moment

M u is given

For balanced section X u = X u max

M u limiting = 0.36 * f c k * b * X u max * (d- 0.42 * X u max)

So M u 2 = M u – M u limiting

A s t limit = M u limit / 0.87 * f y * (d – 0.42 * X u max)

A sc = M u2/ f s c (d- d’)

As t 2 = A s c * f s c/ 0.87 f y

As t =A s t limit + A s t 2

Where

d = effective depth of beam

d’= distance between extreme compression fiber to the center of comp reinforced

b = width of beam

X u = depth of actual neutral axis

X u max = depth of critical neutral axis

A s t = total area of tensile reinforced in mm2

F c k = characteristic compressive strength of concrete

F y = characteristic strength of steel

M u limit = limiting M R of a section without compression reinforced in K N m

M u = ultimate M R

A s c= area of compression reinforcement

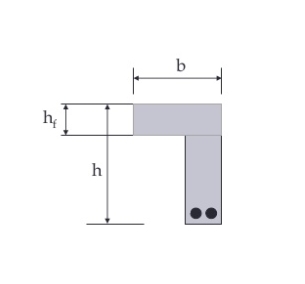

Q10) Explain L beam brief

A10)L BEAM

Fig no 4 L BEAM

In bending the beam take the tension force and slab take compression force since the L beam receive their load from one side only they are subjected to consideration amount of torsion moments so L beam are subjected to bending moments shear force and torsion moments

Moment carried by flange of L beams

The moment M1 causes torsion in the beam and is known as the torsion moments which is restricted by the rectangular portion only and the flanged does not contribute to torsion moment of resistance

Moment carried by flanged of L beam and the slab

The central load W cause bending moments in the beam which is joined restricted by the rectangular portion of the beam as well as the flanged

Changes in floor level may be accommodated by either an L beam or building up one side of an inverted T beam

Code recommends that effective width of the flanged of beam may be taken as follows

2. for isolated L beams ,lesser of

Where

b f = effective width of flanged

b w =breadth of rib

b = actual width of flanged

I o = distance between points of zero moments in beam

The design principles to be followed while designing L beam

Given

Step 1: determine width of flanged

Steps 2: fixed up a suitable depth

Steps 3: calculate MR of the section assuming the failure of concrete to occur .if the moment of resistance is greater than bending moments assumed depth is ok otherwise either increases the depth of the section or provide additional reinforcement in compression side in addition to the tension side

Steps 4: calculate the amount of tension steel for actual bending moments treating it as a balanced section

Steps 5: check for the shear and provide shear reinforced

Steps 6: check of deflection

Steps 7: check for end anchoring and development length