TOE

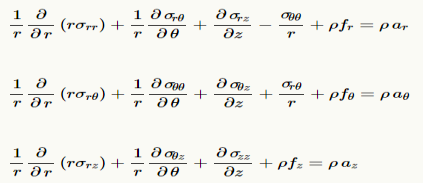

Unit 3Polar coordinatesQ 1) Explain Equilibrium in Cylindrical Coordinates?A 1)The equilibrium equations in cylindrical coordinates contain several additional terms, such as  and

and  that further complicate matters.

that further complicate matters.

Q 2) What is Stress?A 2)In mechanics, stress is defined as a force applied per unit area. It is given by the formulaσ=FAWhereσ is the stress appliedF is the force appliedA is the area of force applicationThe unit of stress is N/m2 Stress applied to a material can be of two types. They are:● Tensile Stress: It is the force applied per unit area which results in the increase in length (or area) of a body. Objects under tensile stress become thinner and longer.

● Compressive Stress: It is the force applied per unit area which results in the decrease in length (or area) of a body. The object under compressive stress becomes thicker and shorter.Q 3) What is Strain?A 3) According to the strain definition, it is defined as the amount of deformation experienced by the body in the direction of force applied, divided by initial dimensions of the body. The relation for deformation in terms of length of a solid is given below.ϵ=δl/L Where,ϵ is the strain due to stress applied

δl is the change in length

L is the original length of the material.The strain is a dimensionless quantity as it just defines the relative change in shape.Depending on stress application, strain experienced in a body can be of two types. They are:● Tensile Strain: It is the change in length (or area) of a body due to the application of tensile stress.

● Compressive Strain: It is the change in length (or area) of a body due to the application of compressive strainQ 4) Explain Proportional Limit?A 4)It is the region in the stress-strain curve that obeys Hooke’s Law. In this limit, the ratio of stress with strain gives us proportionality constant known as young’s modulus. The point OA in the graph is called the proportional limit.Q 5) Explain Elastic Limit?A 5) It is the point in the graph up to which the material returns to its original position when the load acting on it is completely removed. Beyond this limit, the material doesn’t return to its original position and a plastic deformation starts to appear in it.Q 6) Explain Yield Point?A 6) The yield point is defined as the point at which the material starts to deform plastically. After the yield point is passed, permanent plastic deformation occurs. There are two yield points (i) upper yield point (ii) lower yield point.Q 7) What is Hooke’s Law?A 7)In the 19th-century, while studying springs and elasticity, English scientist Robert Hooke noticed that many materials exhibited a similar property when the stress-strain relationship was studied. There was a linear region where the force required to stretch the material was proportional to the extension of the material. This is known as Hooke’s Law.Hooke’s Law states that the strain of the material is proportional to the applied stress within the elastic limit of that material.Mathematically, Hooke’s law is commonly expressed as:F = –k.xWhere,F is the forcex is the extension lengthk is the constant of proportionality known as spring constant in N/mQ 8) What are the types of strain?A 8) There are three types of strain and they are:Normal strain: Normal strain is defined as the ratio of change in dimension to its original dimension. Consider an iron bar of length L and let dL be the change in the length of the bar. According to normal strain, e = dL/L.Shear strain: The shear strain is defined as the angular distortion between two mutually perpendicular planes. It is represented by ℽ.Volumetric strain: Volumetric strain is defined as the ratio of change in actual volume to the original volume.Q 9) What is the difference between stress and strain?A 9) Stress is defined as the force experienced by the object which causes a change in the object while a strain is defined as the change in the shape of an object when stress is applied.Stress is measurable and has a unit while a strain is a dimensionless quantity and has no unit.The words stress and strain are derived from the Latin words “strictus” and “stringere” which means “to draw tight” and “to bind tightly” respectively.Stress can occur in the absence of strain whereas strain does not occur in the absence of stress.Q 10) What are the SI units for stress and strain?A 10)The SI unit of stress is Newton per square meter. Or we can express the same in terms of Pascal.

1 Pascal = 1 Pa = 1 N.m-2.

While there is no unit for strain. It is a dimensionless quantity. This is because it is the ratio of change of length to the original length, and therefore it is unit less.

and

and  that further complicate matters.

that further complicate matters.

|

● Compressive Stress: It is the force applied per unit area which results in the decrease in length (or area) of a body. The object under compressive stress becomes thicker and shorter.Q 3) What is Strain?A 3) According to the strain definition, it is defined as the amount of deformation experienced by the body in the direction of force applied, divided by initial dimensions of the body. The relation for deformation in terms of length of a solid is given below.ϵ=δl/L Where,ϵ is the strain due to stress applied

δl is the change in length

L is the original length of the material.The strain is a dimensionless quantity as it just defines the relative change in shape.Depending on stress application, strain experienced in a body can be of two types. They are:● Tensile Strain: It is the change in length (or area) of a body due to the application of tensile stress.

● Compressive Strain: It is the change in length (or area) of a body due to the application of compressive strainQ 4) Explain Proportional Limit?A 4)It is the region in the stress-strain curve that obeys Hooke’s Law. In this limit, the ratio of stress with strain gives us proportionality constant known as young’s modulus. The point OA in the graph is called the proportional limit.Q 5) Explain Elastic Limit?A 5) It is the point in the graph up to which the material returns to its original position when the load acting on it is completely removed. Beyond this limit, the material doesn’t return to its original position and a plastic deformation starts to appear in it.Q 6) Explain Yield Point?A 6) The yield point is defined as the point at which the material starts to deform plastically. After the yield point is passed, permanent plastic deformation occurs. There are two yield points (i) upper yield point (ii) lower yield point.Q 7) What is Hooke’s Law?A 7)In the 19th-century, while studying springs and elasticity, English scientist Robert Hooke noticed that many materials exhibited a similar property when the stress-strain relationship was studied. There was a linear region where the force required to stretch the material was proportional to the extension of the material. This is known as Hooke’s Law.Hooke’s Law states that the strain of the material is proportional to the applied stress within the elastic limit of that material.Mathematically, Hooke’s law is commonly expressed as:F = –k.xWhere,F is the forcex is the extension lengthk is the constant of proportionality known as spring constant in N/mQ 8) What are the types of strain?A 8) There are three types of strain and they are:Normal strain: Normal strain is defined as the ratio of change in dimension to its original dimension. Consider an iron bar of length L and let dL be the change in the length of the bar. According to normal strain, e = dL/L.Shear strain: The shear strain is defined as the angular distortion between two mutually perpendicular planes. It is represented by ℽ.Volumetric strain: Volumetric strain is defined as the ratio of change in actual volume to the original volume.Q 9) What is the difference between stress and strain?A 9) Stress is defined as the force experienced by the object which causes a change in the object while a strain is defined as the change in the shape of an object when stress is applied.Stress is measurable and has a unit while a strain is a dimensionless quantity and has no unit.The words stress and strain are derived from the Latin words “strictus” and “stringere” which means “to draw tight” and “to bind tightly” respectively.Stress can occur in the absence of strain whereas strain does not occur in the absence of stress.Q 10) What are the SI units for stress and strain?A 10)The SI unit of stress is Newton per square meter. Or we can express the same in terms of Pascal.

1 Pascal = 1 Pa = 1 N.m-2.

While there is no unit for strain. It is a dimensionless quantity. This is because it is the ratio of change of length to the original length, and therefore it is unit less.

0 matching results found