Unit-2

APPLIED THERMODYNAMICS

Q1) Write Advantages of Re‑heating.

A1)

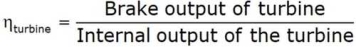

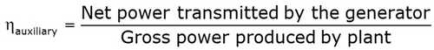

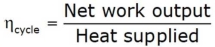

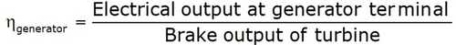

Q2) Write Efficiency of Steam Power Plant and Overall efficiency of the steam per plant?

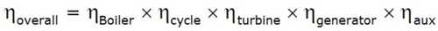

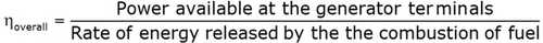

A2) Efficiency of Steam Power Plant and Overall efficiency of the steam per plant is given by

Q3) Write Characteristics of Ideal Working Fluid?

A3)

1) The fluid ought to have high critical temperature and the saturation pressure at the temperature of heat rejection ought to be over the climatic pressing factor.

2) Specific heat of fluid ought to be little.

3) The saturated vapors line of T-s outline near the turbine extension measure.

4) The freezing point of the fluid should be below the room temperature

5) The liquid ought to be synthetically steady, non-poisonous, non-destructive, not exorbitantly viscous and low in expense.

Q4) Explain Positive Effects of Lowering the Condenser Pressure?

A4) To drain the benefit of higher effectiveness Rankin Cycle needs to work on lower condenser pressure generally below atmospheric. but, the limit for lower condenser-pressure is defined by the cooling water temperature corresponding to saturation pressure of the area.

In the above T-s outline it tends to be effortlessly seen that the coloured area is the increase in net work output by virtue of bringing down the condenser pressure from P4 to P4'.

Q 5) Explain Negative Effects of Lowering the Condenser Pressure?

A 5) The effect of bringing down the condenser-pressure isn't comes with no results. In this way following are the unfavourable impacts of bringing down the condenser pressure:

Q 6) Explain Net Effects of Lowering the Condenser Pressure?

A 6) The overall net impact is more towards positive side, since the increase in heat input necessity in the boiler is negligible however the increment in net work output is more because of diminishing in condenser pressure. Likewise the dryness fractions of the steam in the last phases of the turbine are not permitted to drop past 10-12%.

Q7) Explain Negative Effects of Increasing the Steam Temperature?

A7) Increasing the steam temperature results in small increase in heat input. There is a limit to which the steam can be superheated and used in the power cycle. These limiting factors are related to metallurgical proveness at high temperature and economic viability.

Presently in supercritical power generating units, steam temperature at turbine inlet is around 620oC. Decision of any further increase in steam temperature can be judiciously taken only after doing the metallurgical due diligence and evaluation of the cost-implications.

Q 8) Discuss points in Cycle Analysis?

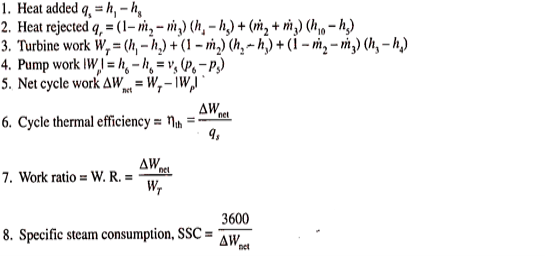

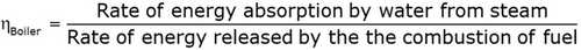

A 8) From mass flow rates, energy balance equations and enthalpy values, we can determine the amounts of steam extracted i.e., ṁ2 and ṁ3, and then the pertinent cycle parameters. We assume mass flow rate of 1 kg/s at turbine inlet (point 1).

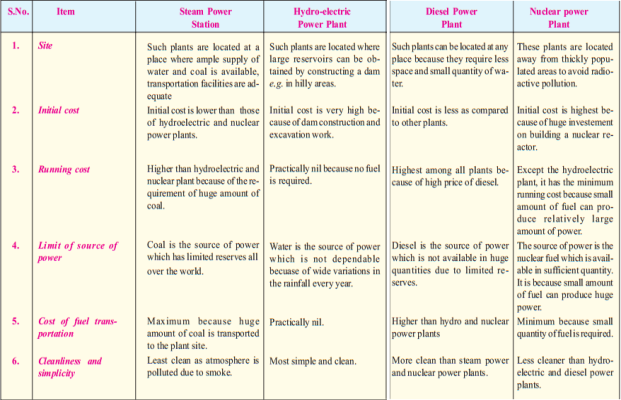

Q 9) Write difference between different Kind of power plant?

A 9)

Q 10) Explain cogeneration cycle?

A 10) Cogeneration cycle

Cogeneration or Combined Heat and Power (CHP) is the sequential generation of two dissimilar forms of useful energy from a single primary energy source, typically mechanical energy and thermal energy. Mechanical energy may be used either, to drive an alternator for generating electricity, or rotating equipment such as motor, compressor, pump or fan for delivering a variety of services. Thermal energy may be used either for direct process applications or for indirectly generating steam, hot water and hot air for dryer or chilled water for process cooling. This cycle provides a wide range of technologies for application in various domains of economic activities. Overall efficiency of energy use in cogeneration mode can be up to 85% and above in some cases. Process 1-2: The steam is continuously taken out from the turbine and passed on to the process heater.

Process 1-3, which shows the isentropic expansion of remaining steam in the turbine from pressure p1 to p3.

Process 3-4: At constant pressure p3 and temperature T3, the drain steam from the steam turbine is condensed in the condenser.

Process 4-5: Water from the hot-well or the surge tank which is at low pressure is pumped into the boiler at high pressure. Here the pumping process 4-5 is isentropic.

Process 2-6: Steam which could have been a waste is used as a process heat to produce electricity.

Process 6-7: Water from the process heater which is at low pressure is pumped into the boiler at high pressure.

Process 8-1: Here the water is totally evaporated into steam and this steam goes into the turbine.