Unit-5

APPLIED THERMODYNAMICS

Q 1) What are the advantages of gas turbine?

A 1) Gas turbines:

i. The mechanical efficiency of gas turbines is very high in the range of 90-95%. Power development is based on rotary components.

ii. The overall weight of gas turbine per unit power produced is less.

iii. Gas turbine can produce speed as high as 40,000 rpm.

iv. Gas turbine does not require a flywheel as torque produced is continuous and uniform.

v. Work developed by a gas turbine per kilogram weight of air is more.

vi. The components of gas turbine can be made lighter because the pressure developed in this case is quite low, about 4-6 bar.

vii. The ignition system is much simple.

viii. The lubrication system is much simpler.

ix. Cheaper fuel such as paraffin can be used.

x. The exhaust gases from gas turbines are less polluting since air is used (A/F = 90)

xi. They are much suitable for use in aircrafts due to low specific weight.

Q 2) What are the assumptions made IN BRAYTON CYCLE?

A 2) Following are the assumptions made IN BRAYTON CYCLE:

i. The compression and expansion of a working substance are reversible adiabatic.

ii. There is no variation in the specific heat of working substance.

iii. Pressure losses throughout the cycle are neglected.

iv. Heat losses are neglected.

Q 3) Explain limitations of gas turbine?

A 3) Following are the limitations of a gas turbine:

(a) The overall efficiency of the gas turbine plant is very low.

(b) Gas turbine rotor speed is found very high.

(c) Gas turbine cannot be operated reversibly.

(d) The weight-to-power ratio of gas turbine is low.

(e) Self-starting of gas turbine is not possible.

Q 4) Explain Reheating of Gas turbine Plants?

A 4) Reheating is applied in a gas turbine in such a way that it increases the turbine work without increasing the compressor work or melting the turbine materials. When a gas turbine plant has a high pressure and low pressure turbine a reheater can be applied successfully. Reheating can improve the efficiency up to 3 % A reheater is generally is a combustor which reheat the flow between the high and low pressure turbines.

In jet engines an afterburner is used to reheat. It is attached at the exhaust of the turbine. As a result the thrust is increased. But it takes a lot of fuel to increase the thrust.

Q 5) Explain Combination of intercooling, reheating and regeneration?

A 5)

• The net work of a gas-turbine cycle is the difference between the turbine work output and the compressor work input.

• It can be increased by either decreasing the compressor work or increasing the turbine work, or both.

• The work required to compress a gas between two specified pressures can be decreased by carrying out the compression process in stages and cooling the gas in between: multi-stage compression with intercooling.

• Similarly the work output of a turbine can be increased by: multi-stage expansion with reheating.

• As the number of stages of compression and expansion are increased, the process approaches an isothermal process.

• A combination of intercooling and reheating can increase the net work output of a Brayton cycle significantly.

Q 6) How the Brayton actual cycles differ from the ideal ones ?

A 6) The Brayton actual cycles differ from the ideal ones on accounts of:

Q 7) Explain Specific advantages of a three- or two-stage compressor design?

A 7) Specific advantages of a three- or two-stage compressor design include:

Q 8) What is the Governing of Steam Turbine?

A 8) Governing of Steam Turbine:

The method of maintaining the turbine speed constant irrespective of the load is known as governing of tubines.The device used for governing of turbines is called Governor. There are 3 types of governors in steam turbine,

1. Throttle governing

2. Nozzle governing

3. By-pass governing

Q 9) Explain Closed Cycle Gas Turbine?

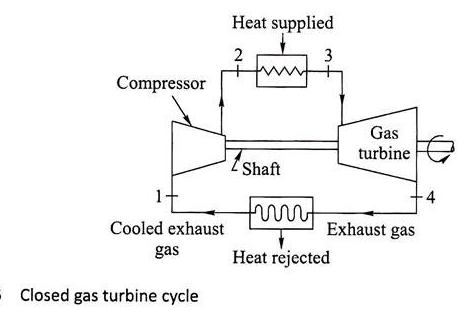

A 9) In case of a closed cycle gas turbine, a fixed mass of working substance is allowed to flow inside the cycle. The working substance, i.e., air or gases, is confined inside the plant and it never leaves the plant.

Hence, the gas turbine is said to be a closed cycle. Figure 1 shows the system diagram of a simple closed cycle gas turbine plant. It consists of a compressor, heater, gas turbine, and a cooler. The compressor shaft and turbine shaft are coupled for the transfer of power. The working substance is compressed by the compressor.

Fig 1 closed gas turbine cycle

Q 10) Explain Open Cycle Gas Turbine?

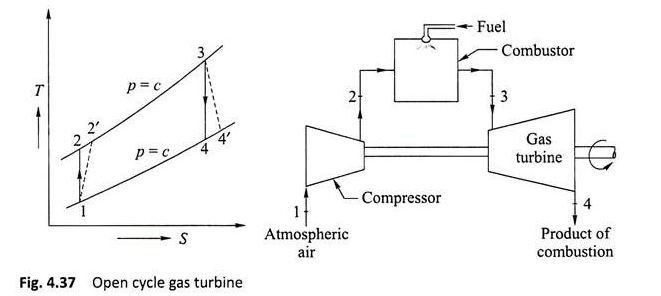

A 10) Figure 2 shows the cycle of operation of an open cycle gas turbine. A simple open cycle gas turbine plant consists of an air compressor, combustion chamber, and a gas turbine.

Fig 2 open cycle gas turbine

Initially, the plant is started with the help of an auxiliary engine or electric motor. Atmospheric air is drawn in the compressor and compressed to a high pressure, and relatively high temperature, and is then supplied to a combustion chamber or combustor in which liquid or gaseous fuel is injected into the compressed air stream and the fuel is ignited.