Unit 03

Metals, Alloys and Corrosion

Q-1Enlist the physical properties of metals.

State: Metals are solids at room temperature with the exception of mercury, which is liquid at room temperature (Gallium is liquid on hot days).

Luster: The ability to reflect the light of a metal surface is called as luster.

Malleability: Metals have the ability to withstand hammering and can be made into thin sheets known as foils. For example, a sugar cube sized chunk of gold can be pounded into a thin sheet that will cover a football field.

Ductility: Metals can be drawn into wires. For example, 100 g of silver can be drawn into a thin wire about 200 meters long.

Hardness: All metals are hard except sodium and potassium, which are soft and can be cut with a knife.

Valency: Metals typically have 1 to 3 electrons in the outermost shell of their atoms.

Conduction: Metals are good conductors because they have free electrons. Silver and copper are the two best conductors of heat and electricity. Lead is the poorest conductor of heat. Bismuth, mercury and iron are also poor conductors

Density: The mass of every single volume of a metal is the metal density.

Melting and Boiling Points: Metals have high melting and boiling points.

Q-2Describe alloys.

It is the mixture of metallic solid solution that composed of two or more elements. E.g.: Brass, pewter, phosphor bronze, steel. Alloys typically refer to metals that are formed from the mixture of two or more elements. One of those elements must be a metallic element, but other constituents may not always be metallic. Alloys give single solid phase microstructure. The partial solutions give two or more than those phases that may or may not be the homogenous in distribution.

Q-3Explain non-ferrous alloys.

A metal is defined as non-ferrous it means that it does not have a significant amount of iron in its chemical composition. That means nearly all metal alloys have some trace, or non-significant, amount of iron in their composition. This does not make them ferrous alloys though. Non-ferrous alloys generally have iron compositions of less than one percent as measured by weight. If iron constitutes a large percentage of a metal, such as if it is the first or second most abundant element in the metal’s chemical composition, then the metal is considered ferrous.

Q-4Explain ferrous alloys.

Ferrous alloys are metals that consist mostly of iron that is Fe. Steel is an iron-based alloy containing typically less than 1% carbon, where iron frequently contains 2% or more carbon. They are produced in larger quantities than any other metallic material. Their mechanical properties can be improved by heat treating and, in the case of steels, by working. Stainless steels were developed to resist corrosion and generally contain 12% or more chromium, and may contain nickel in any amount up to or even exceeding the chromium content based upon the mechanical properties desired and application.

Q-5Explain stainless steel and its properties.

Stainless steel is a family of alloy steels usually containing 10 to 30% of chromium. In conjunction with low carbon content, chromium imparts remarkable resistance to corrosion and heat. Other elements such as nickel, molybdenum, titanium, aluminium, niobium, copper, nitrogen, phosphorus or selenium, may be added to increase corrosion resistance to specific environments, enhance oxidation resistance, and impart special characteristics.

Properties of Stainless Steel:

- Corrosion resistant.

- High tensile strength.

- Very durable.

- Temperature resistant.

- Easy formability and fabrication.

- Low-maintenance

Attractive appearance.

Q-6Explain copper alloy and its applications.

Copper alloys are those metal alloys that have copper as their principal component. They possess high resistivity against corrosion. The best-known traditional types are bronze; where tin is a significant addition, and brass, using zinc instead. Both of these are imprecise terms, having both been commonly referred to as latten’s in the past.

Applications:

- Power transmission lines

- Architectural applications

- Cooking utensils

- Spark plugs

- Electrical wiring, cables and busbars

- High conductivity wires

- Electrodes

Q-7Explain Alnico and its composition.

Alnico is the name for an iron alloy that primarily consists of iron, aluminium, nickel & cobalt. Alnico alloys have ferromagnetic properties which makes it strong permanent magnets. These magnets also show excellent stability in a wide range temperature. There are effective in temperatures up to 1000∘F.

Composition of alnico is

1. Al (Aluminum)

2. Ni (Nickel)

3.Co (Cobalt)

sometimes it also includes titanium

Q-8Explain dry or chemical corrosion.

(I) Dry or Chemical Corrosion-

The reaction of metal with water vapour or gas at high temperature causes the metal to corrode chemically. This is the redox process in which the electron of the metal is passed directly to the substance in the environment. The metal corrodes generally in the metal which is in higher contact with water.

3Fe + 4H2O Fe3O4 + 4H2

3Fe + 4H2O Fe3O4 + 4H2

3Fe + 2O2 Fe3O4

3Fe + 2O2 Fe3O4

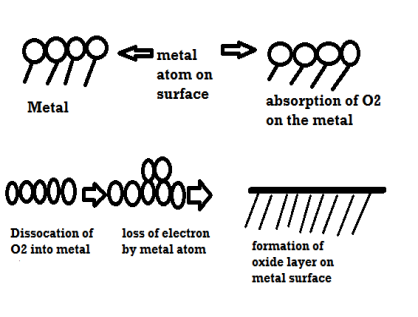

I)Due to oxygen

Mechanism of dry corrosion due to O2 gas there are 4 types: -

- Absorption of oxygen molecules on the metal surface

- Dissociation of oxygen atom into metal atom

- Loss of e- by metal atom

- Formation of oxide layer on the metal surface.

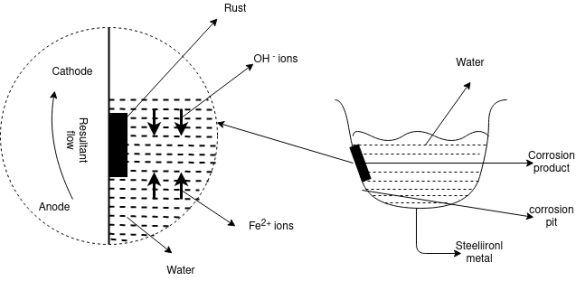

(II)Wet or Electrochemical corrosion- Mechanism

Corrosion occurs due to the electrochemical process of oxidation and reduction process. In the corroding solution electrons are released by the metal and that is gained by teh elements in the corroding solution. The release of electron from metal is called as the oxidation while vice-versa that is gain of electron by elements is reduction. The regular electron flow in the corrosion reaction can be measured and controlled electronically. This is why controlled electrochemical experimental methods are used to characterize the corrosion properties of metal.

Q-9Explain Absorption of oxygen.

Absorption of Oxygen If electrolyte is neutral or alkaline aqueous solution, corrosion takes place by absorption of O2 rusting of iron in water containing dissolved oxygen occurs by oxygen absorption mechanism. At anodic area iron will dissolve by oxidation. The surface of iron is usually coated with the thin film of iron oxide. But if this iron oxide film develops some cracks, anodic areas are created on the surface ; while the metal act as cathodes. Here the anodic areas are small surface while rest of the surface of the metal forms large cathodes.

At anode,

Fe →Fe2+→2e-

The electrons flow to cathodic area through and will be accepted by O2.

At Cathode

Fe2+ +2OH→Fe (OH)2

If enough O2 is present, ferrous hydroxide easily oxidizes to ferric hydroxide 2Fe (OH) 2 + ½ O2 +H2O→2Fe(OH)3

Ferric hydroxide rusts This product called yellow rust, which is nothing but Fe2O3.H2O If O2 is limited, the corrosion product will be black unhydrous magnetite, Fe3O4. If environment is aqueous solution of NaCl containing dissolved O2 NaCl →H2O→Na+ + Cl-

At cathode

Na+ + OH→NaOH

At anode

Fe2+ + 2Cl→FeCl2

Ferrous Chloride Both the products NaOH, FeCl2 are soluble in water they react with each other and ferrous hydroxide precipitates which further oxidizes to ferric hydroxide Fe(OH)3. 4 Fe (OH)2 + 2H2O + O2 →4Fe(OH)3 -Fe2O3. H2O yellow rust.

Q-10What is differential aeration principle?

The uneven supply of oxygen to the same metal component leads to the formation of oxygen concentration cells that is called as the differential aeration theory of corrosion. It is the type of electrochemical corrosion that affects the metals such as steel and iron. The less oxygenated part behaves anodic while the more oxygenated part cathodic. Since cathodic reactions involve consumption of oxygen, the more oxygenated part behaves cathodic and less oxygenated pan behaves anodic. The reaction occurs because oppositely charged electrons flow between the smaller anode and larger cathode. Positively charged cations meeting negatively charged anions forming corrosion product and a resulting pit in the metal, otherwise known as pitting corrosion. In a gutter, pipe, tank or similar the anode is just below the waterline. This is where the oxidation occurs, corrosion product forms and a pit develop weakening the metal.

Q-11What is intergranular corrosion?

Intergranular corrosion is strongly associated with the properties and microstructure of a metal. A well-known example of IGC is the sensitization of austenitic 18Cr—8Ni stainless steels. In the temperature range of 538–927°C, insoluble chromium carbides, Cr23C6, precipitate at the grain boundaries. This precipitate is a product of the reaction between chromium and the carbon diffusing along the grain boundaries. Below 538°C, the carbon remains relatively immobile, and above 927°C the chromium carbides are soluble. Formation of chromium-rich precipitates quickly depletes chromium from a region immediately adjacent to the grain boundary. This reduces the alloy’s ability to generate chromium oxide protective films and leads to an increased susceptibility for localized attack in the grain boundary region.

Welding is a common source of localized heating that can sensitize a material. IGC is often observed within the heat affected zone after welding a material susceptible to heat sensitization.

Q-12What are the factors that effects corrosion?

(I)Nature of metal:

Position of metal in galvanic series.

If position is higher in galvanic series then it corrodes faster

While for 2 metal the difference between them shows the corrosion ratio.

(ii)Nature of corroding environment: Iron and steels are the most versatile, least expensive and most widely used materials for the construction of many engineering systems. They are unequaled in their range of mechanical and physical properties with which they can be endowed by alloying and heat treatment. Their main disadvantage is that they have poor corrosion resistance in even relatively mild environments unlike stainless steels. Corrosion can reduce the load-carrying capacity of a component either by reducing its size or by pitting. Pitting not only reduces the effective cross section in the pitted region but also introduce stress raisers, which initiate cracks. Any technique that reduces or eliminates corrosion will extend the life of a component and increase its reliability. In addition to corrosion prevention methods, it is important to design and select materials for improving the overall corrosion performance of components. The three interrelated factors that drive the selection of materials for corrosion control are the corrosivity of the environment, the corrosion resistance of the material and the acceptable rate of attack.

Corrosion failures during service are likely if suitable materials with appropriate coatings are not selected for the fabrication of components of critical systems. Corrosion significantly affects the efficiency of systems. Failures can be minimized or reduced significantly by controlling corrosion. The possible methods of controlling corrosion are the application of coatings, linings, metal cladding and corrosion inhibitors, and alloying. Among these, the application of suitable coatings appears to be a promising method of corrosion control in terms of cost effectiveness and service life. DMR-1700 is a recently developed ultrahigh-strength low-alloy steel with improved mechanical properties compared with other aerospace-grade low-alloy steels. However, its corrosion characteristics have not been investigated in detail, although some corrosion studies have been carried out.

In the present investigation, the effect of the environment on the corrosion characteristics of DMR-1700 steel is studied in detail, the properties of the steel under various environmental conditions are compared and the degradation mechanisms involved are considered. On the basis of the results of the investigation, we recommend the use of the material with a suitable protective coating for the fabrication of components for various applications. In the study, the surface morphologies of the corroded steels in different environments were observed using a scanning electron microscope (SEM) to determine the nature of corrosion. We also successfully developed a high-performance coating for DMR-1700 steel to enhance its resistance against corrosion. The developed coating is discussed, and its application is recommended for effective protection against corrosion. The use of such an advanced material with a high-performance coating will help enhance the efficiency of systems by reducing failures during service.

Q-13Explain Sacrificial Anodic Corrosion with its applications.

The metal surface can be protected from the corrosion by connecting it wire to a more anodic metal. The sacrifice of this more anodic metal to save the metal form corrosion is called as the Sacrificial Anode. The most common metal used for this purpose are Mg, Zn, Al etc.

Applications:

(i) The underground cable and pipeline protection from soil erosion.

(ii) Ships and boat protection from marine corrosion.

Prevention of rusty water by inserting Mg sheets or rods into domestic water boiler or tanks.