Unit - 2

Introduction to Material Testing

Q1) Explain mechanical behavior and mechanical characteristics.

A1) Mechanical Behavior and mechanical characteristics:

- The mechanical homes of a cloth have an effect on the way it behaves as its miles loaded.

- The elastic modulus of the fabric influences how lots it deflects beneath a load, and the electricity of the fabric determines the stresses that it may face up to earlier than it fails.

- The ductility of a cloth additionally performs a big position in figuring out while a cloth will wreck as its miles loaded past its elastic limit.

- Because each mechanical machine is subjected to hundreds at some point of operation, it's miles critical to apprehend how the substances that make up the ones mechanical structures behave.

- Some of the mechanical homes of substances which might be applicable to the layout and evaluation of mechanical structures are defined below:

- Stress and Strain

- Stress-Strain Curve

- True Stress and Strain

- Hooke's Law

- Poisson's Ratio

Stress and Strain:

- The dating among pressure and pressure in a cloth is decided through subjecting a cloth specimen to an anxiety or compression check. In this check, a step by step growing axial pressure is implemented to a check specimen, and the deflection is measured because the load is increased.

- These values may be plotted as a load-deflection curve. The deflection withinside the check specimen is depending on each the fabric's elastic modulus in addition to the geometry of the specimen (region and length). Since we're fascinated fabric conduct without regard to geometry, it's miles beneficial to generalize the records to put off the impact of geometry.

Stress-Strain Curve:

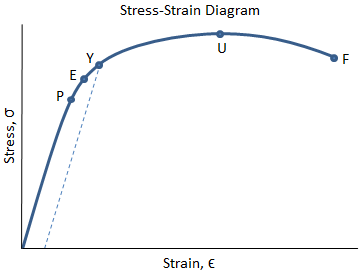

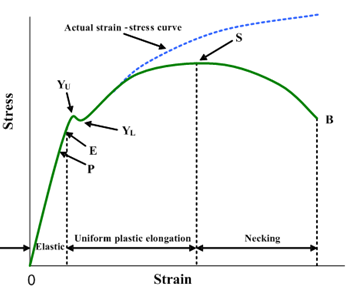

- The values of pressure and pressure decided from the tensile check may be plotted as a pressure-pressure curve, as proven below:

Stress-Strain Diagram

- There are numerous factors of hobby withinside the diagram above:

- P: This is the proportionality restriction, which represents the most cost of strain at which the strain-pressure curve is linear.

- E: This is the elastic restriction, which represents the most cost of strain at which there may be no everlasting set. Even aleven though the curve isn't linear among the proportionality restriction and the elastic restriction, the fabric remains elastic on this location and if the burden is eliminated at or under this factor the specimen will go back to its unique length.

- Y: This is the yield factor, which represents the cost of strain above which the pressure will start to growth rapidly. The strain on the yield factor is referred to as the yield electricity, Sty. For substances without a well-described yield factor, it's miles usually described the use of the 0.2% offset technique wherein a line parallel to the linear part of the curve is drawn that intersects the x-axis at a pressure cost of 0.002. The factor at which the road intersects the strain-pressure curve is precise because the yield factor.

- U: This factor corresponds to the last electricity, Stu, that is the most cost of strain at the strain-pressure diagram. The last electricity is likewise known as the tensile electricity. After accomplishing the last strain, specimens of ductile substances will showcase necking, wherein the cross-sectional vicinity in a localized location of the specimen reduces significantly.

- F: This is the fracture factor or the damage factor that is the factor at which the fabric fails and separates into pieces.

- Stress-pressure curves are normally wanted while reading an engineered component. However, strain-pressure records won't constantly be without problems available. In this case, it in all fairness trustworthy to approximate a fabric's strain-pressure curve the use of the Ramberg-Osgood equation.

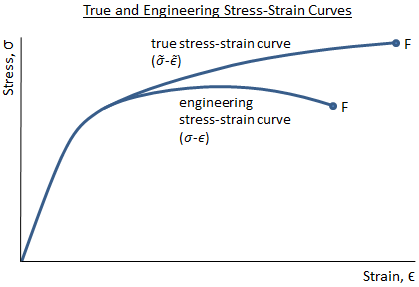

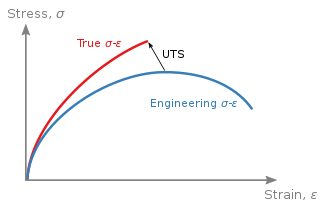

True Stress and Strain:

- Engineers usually paintings with engineering strain that is the pressure divided via way of means of the unique vicinity of the specimen earlier than loading: σ = P/A0.

- However, as a fabric is loaded, the vicinity decreases. The actual strain is the cost of strain withinside the fabric thinking about the real vicinity of the specimen.

- Because the vicinity decreases as a fabric is loaded, actual strain is better than engineering strain.

- The parent under suggests an engineering strain-pressure curve compared to a real strain-pressure curve.

- Because the engineering strain is calculated as pressure divided via way of means of unique vicinity (that is a constant), the engineering strain-pressure curve has the equal form because the load-deflection curve.

- The engineering strain-pressure curve drops after the last electricity is reached due to the fact the pressure that may be supported via way of means of the fabric drops because it starts off evolved to neck down.

- However, the strain cost withinside the actual strain-pressure curve constantly will increase because the pressure will increase.

- This is due to the fact the immediately cost of vicinity is used while calculating actual strain.

- Even while the pressure supported via way of means of the fabric drops, the discount withinside the specimen vicinity outweighs the discount in pressure, and the strain maintains to growth.

True Stress-Strain Diagram

- It ought to be stated that the engineering pressure and the proper pressure are basically the equal withinside the linear-elastic area of the pressure-pressure curve.

- Because engineers generally function inside this linear-elastic area (it's far unusual to layout a shape this is supposed to function past the elastic restrict), it's far legitimate to paintings with engineering pressure rather than proper pressure.

Q2) Explain Hookes law, poisons ration. What do you mean by elasticity?

A2) Hooke's Law:

- Below the proportionality restrict of the pressure-pressure curve, the connection among pressure and pressure is linear.

- The slope of this linear part of the pressure-pressure curve is the elastic modulus, E, additionally called the Young's modulus and the modulus of elasticity.

- Hooke's regulation expresses the connection among the elastic modulus, the pressure, and the pressure in a cloth withinside the linear area:

σ = E ε

Wherein is the cost of pressure and ε is the cost of pressure.

Poisson's Ratio:

- As load is implemented to a cloth, the cloth elongates and the cross-sectional region is reduced.

- This discount in cross-sectional region is referred to as lateral pressure, and it's far associated with the axial pressure through Poisson's ratio, ν.

- Poisson's ratio handiest applies withinside the elastic area of the pressure-pressure curve, and it's far generally approximately 0. Three for maximum metals.

- The theoretical most restrict of Poisson's ratio is 0.5.

Elasticity:

When an outside pressure is implemented on a frame and it undergoes a few deformations. If the frame returns lower back to its unique form and length on whole elimination of the burden, the frame is referred to as elastic frame. This belonging through which any cloth regains its unique form and length whilst load performing on it's far absolutely eliminated is referred to as elasticity.

Elasticity: The belongings of a cloth through which it returns lower back to its unique position (i.e., form and length) at the elimination of outside pressure or load, is referred to as elasticity.

A frame will go back lower back to its unique form and length whilst the deformation as a result of the outside pressure, is inside positive restrict. There is a restricting cost of pressure upto and inside which the deformation triggered absolutely disappears at the elimination of outside pressure. The cost of pressure similar to this restricting pressure is referred to as elastic restrict of the cloth.

Elastic Limit: It is described because the cost of pressure upto and inside which the cloth goes back lower back to their unique position (i.e., form and length) at the elimination of outside pressure.

If the cost of outside pressure is such that it exceeds the elastic restrict, then the frame will now no longer absolutely regain its unique position. The frame loses its belongings of elasticity to a few extents. And if the outside pressure performing at the frame is eliminated, in that situation the frame will now no longer go back to its unique form and length and there may be a residual deformation withinside the cloth.

Q3) Give the characteristics of elasticity, principles of elasticity.

A3) Principle of Elasticity:

1. Continuity of cloth

2. Homogeneity and isotropy

3. Linear elasticity

4. Small deformation

5. Static loading

6. No preliminary nation of pressure

1. Continuity of cloth

- A strong is a continuum, it has been given its extent with none holes, gaps or any interruptions. Stress and pressure are non-stop feature.

2. Homogenity and isotropy

- Homogenous cloth has been given bodily feature equal in places (concrete, steel, timber). Isotropy way that cloth has were given characteristics undepended at the direction (concrete, steel).

3. Linear elasticity

- Elasticity is the capacity of cloth to get lower back after disposing of the reasons of modifications (as an instance load) into the former (unique) nation. If there may be valid direct share among pressure and pressure then we communicate approximately hookes regulation= that is bodily linearity.

4. Small deformation

- Changes of a form of a shape are small with component to the its length.

- Then we will use numerous mathematical simplifications, which typically result in linear dependency.

5. Static loading

- Its way step by step developing of load (now no longer dynamic effects).

6. No preliminary nation of pressure

- In the preliminary nation there are all stresses same to zero.

Characteristic of Elasticity:

Stress:

- When an item is subjected to an outside pressure, the item has a tendency to accumulate inner resistance inside itself (cloth). This resistance is named as “pressure”.

- In short, pressure may be described as load according to unit region.

- Stress may be labeled into 4 types:

Compressive pressure

Tensile pressure

Bending pressure

Shear pressure

Stress = Load/Area = W/A = N/mm2

Where, N = Newton

Strain:

- When an item is subjected to an outside load, the inner resistance that is constructed up with the item itself isn't sufficient to face up to the outside load consequences into deformation of the item.

- This alteration or deformation of the item is referred to as pressure.

- The formulation for pressure is given as follows:

Strain = Change in length/Original length

- Strain has no unit.

Modulus of Elasticity:

- We recognize that pressure is immediately proportional to pressure withinside the elastic restrict.

- The ratio of pressure to pressure is a regular that is denoted as k.

Stress/Strain = K

- This regular is the degree of the pliability of the cloth, therefore referred to as “modulus of elasticity”.

- The formulation for modulus of elasticity is given through,

E = modulus of elasticity = Stress/Strain = N/mm2

- Denotations and their values:

- Modulus of elasticity for concrete = Ec = 2 x 10^five N/mm2

- Modulus of steel = Es = 5700 (rectangular root of fck) N/mm2

Where, fck = feature compressive power of concrete

Q4) Explain plastic deformation of metal. Explain in detail tensile test.

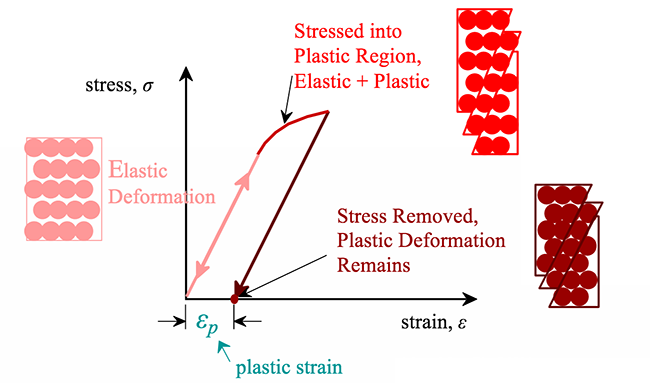

A4) Plastic Deformation of Metals:

- It is the deformation which persists even after the burden is eliminated.

- Plastic deformation is discovered at stresses exceeding the elastic restrict.

- In comparison of elastic deformation, which relies upon basically on pressure withinside the handiest cases, plastic deformation is generally a feature of pressure, temperature, and the fee of straining.

- Plastic deformation is related to the displacement of the atoms withinside the grains and reasons in the end everlasting modifications in form of the cloth.

- Tensile, compressive and torsional stresses can reason plastic deformation.

- Plastic deformation method is typically implemented in crucial metallurgical operations of shaping.

- The operations encompass rolling of boiler plates, drawing of wire, extrusion of smartphone cables, stamping of car components etc.

- In metals the plastic deformation typically takes area through the method of “slipping”.

Plastic Deformation of Metals

Tensile Test:

- A tensile check, additionally called an anxiety check, is one of the maximum essential and not unusual place varieties of mechanical trying out.

- A tensile check applies tensile (pulling) pressure to a cloth and measures the specimen's reaction to the strain.

- By doing this, tensile checks decide how sturdy a cloth is and what kind of it could elongate.

- Tensile checks are commonly performed on electromechanical or prevalent trying out instruments, are easy to perform, and are absolutely standardized.

Why perform a tensile test or tension test?

- We can study lots approximately a substance from tensile trying out.

- By measuring the cloth at the same time as its miles being pulled, we are able to reap a whole profile of its tensile residences.

- When plotted on a graph, this records outcomes in a strain/pressure curve which suggests how the cloth reacted to the forces being carried out.

- The factor of destroy or failure is of plenty interest, however different crucial residences encompass the modulus of elasticity, yield electricity, and pressure.

Ultimate Tensile Strength

- One of the maximum crucial residences we are able to decide approximately a cloth is its remaining tensile electricity (UTS).

- This is the most strain that a specimen sustains throughout the check.

- The UTS may also or might not equate to the specimen's electricity at destroy, relying on whether or not the cloth is brittle, ductile, or well-known shows residences of both.

- Sometimes a cloth can be ductile while examined in a lab, however, while positioned in provider and uncovered to excessive bloodless temperatures, it can transition to brittle behavior.

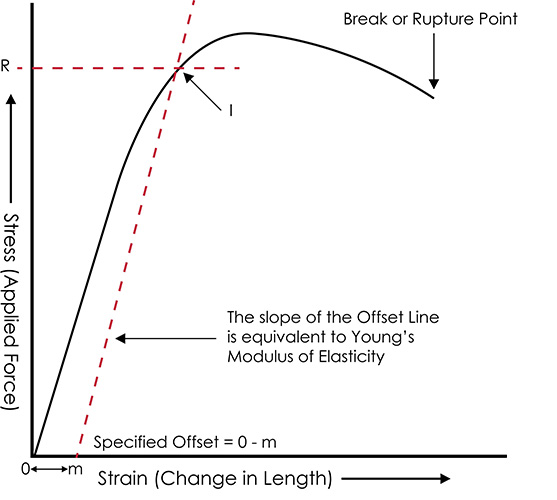

Q5) What do you mean by Hookes law and explain standards for different materials.

A5) Hooke's Law

- For maximum materials, the preliminary part of the check will showcase a linear dating among the carried-out pressure or load and the elongation exhibited via way of means of the specimen.

- In this linear vicinity, the road obeys the connection described as "Hooke's Law" in which the ratio of strain to pressure is a constant, or Hooke's law.

- E is the slope of the road on this vicinity in which strain (σ) is proportional to pressure (ε) and is referred to as the "Modulus of Elasticity" or "Young's Modulus."

Stress Vs Strain graph

Testing Equipment

- Tensile exams are carried out on widespread checking out machines.

- These machines are to be had in a lot of unique sizes and pressure capacities starting from 0.02 N to 2,000 kN.

- Most low pressure checking out is carried out on a tabletop gadget which includes Instron's 6800 Series, at the same time as better pressure programs require ground version frames which includes the ones observed in Instron's Industrial Series.

- A widespread checking out gadget need to be geared up with checking out software program and application-unique grips and add-ons, which includes extensometers.

- The kind of fabric being examined will decide the kind of add-ons needed, and an unmarried gadget may be tailored to check any fabric inside its pressure variety without a doubt through converting the fixturing.

Tensile Testing Machine

Standard for Different Material:

Though there are numerous ASTM and ISO requirements used for tensile testing, those are a number of the maximum common:

- ASTM D638 - Tensile Testing of Plastics

- ISO 527-2 - Tensile Testing of Plastics

- ASTM D412 - Tensile Testing of Elastomers

- ISO 37 - Tensile Testing of Elastomers

- ASTM E8/E8M - Tensile Testing of Metallic Materials

- ISO 6892 - Tensile Testing of Metallic Materials

True Stress-Strain Interpretation of Tensile Test:

- Stress-Strain Diagram expresses a courting among a load implemented to a fabric and the deformation of the material, because of the load.

- Stress-Strain Diagram is decided through tensile check.

- Tensile assessments are carried out in tensile check machines, offering managed uniformly growing anxiety force, implemented to the specimen.

- The specimen’s ends are gripped and stuck withinside the gadget and its gauge period L0 (a calibrated distance among marks at the specimen surface) is constantly measured till the rupture.

- Test specimen can be spherical or flat withinside the cross-section.

- In the spherical specimens its miles accepted, that L0 = 5 * diameter.

- The specimen deformation (strain) is the ratio of the boom of the specimen gauge period to its unique gauge period:

δ = (L – L0) / L0

- Tensile strain is the ratio of the tensile load F implemented to the specimen to its unique cross-sectional location S0:

σ = F / S0

Standard tensile test specimen

- The preliminary immediately line (0P) of the curve characterizes proportional dating among the pressure and the deformation (strain).

- The pressure fee on the factor P is known as the restrict of proportionality:

σp= FP / S0

- This conduct conforms to the Hook’s Law:

σ = E*δ

- Where E is a constant, referred to as Young’s Modulus or Modulus of Elasticity.

- The fee of Young’s Modulus is decided in particular with the aid of using the character of the cloth and is almost insensitive to the warmth remedy and composition.

- Modulus of elasticity determines stiffness - resistance of a frame to elastic deformation because of a carried-out force.

- The line 0E withinside the Stress-Strain curve shows the variety of elastic deformation – elimination of the burden at any factor of this a part of the curve outcomes in go back of the specimen period to its authentic fee.

- The elastic conduct is characterized with the aid of using the pliancy restrict (pressure fee on the factor E):

σel= FE / S0

- For the maximum substances the factors P and E coincide and consequently σel=σp.

- The preliminary immediately line (0P) of the curve characterizes proportional dating among the pressure and the deformation (strain).

- The pressure fee on the point P is known as the limit of proportionality:

σp= FP/S0

- This conduct conforms to the Hook’s Law:

σ= E*δ

Where E is a constant, recognized as Young’s Modulus or Modulus of Elasticity.

- The fee of Young’s Modulus is decided in particular with the aid of using the character of the cloth and is almost insensitive to the heat treatment and composition.

- Modulus of elasticity determines stiffness- resistance of a frame to elastic deformation because of a carried-out force.

- The line0Ein the Stress-Strain curve shows the variety of elastic deformation– elimination of the burden at any factor of this a part of the curve outcomes in go back of the specimen period to its authentic fee.

- The elastic conduct is characterized with the aid of using the elasticity restrict (pressure fee on the point E.

σel= FE/S0

- For the maximum substances the points P and E coincide and therefore σel=σp.

Stress-Strain diagram for mild steel

- A factor in which the strain reasons unexpected deformation with none boom withinside the pressure is referred to as yield restrict (yield strain, yield strength.

σy= FY / S0

- The maximum strain (factor YU), taking place earlier than the unexpected deformation is referred to as higher yield restrict.

- The decrease strain value, inflicting the unexpected deformation (factor YL) is referred to as decrease yield restrict.

- The generally used parameter of yield restrict is clearly decrease yield restrict.

- If the burden reaches the yield factor the specimen undergoes plastic deformation – it does now no longer go back to its authentic duration after elimination of the burden.

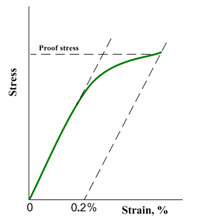

Showing Proof stress

- Hard steels and non-ferrous metals do now no longer have described yield limit, consequently a pressure, similar to a particular deformation (0.1% or 0.2%) is typically used as opposed to yield limit.

- This pressure is known as evidence pressure or offset yield limit (offset yield strength):

σ0.2%= F0.2% / S0

- The approach of acquiring the evidence pressure is proven withinside the picture.

- As the burden boom, the specimen keeps to go through plastic deformation and at a sure pressure cost its cross-segment decreases due to “necking” (factor S withinside the Stress-Strain Diagram).

- At this factor the pressure reaches the most cost, that is known as final tensile strength (tensile strength):

σt= FS / S0

- Continuation of the deformation effects in breaking the specimen - the factor B withinside the diagram.

- The real Stress-Strain curve is received via way of means of contemplating the authentic specimen cross-segment as opposed to the unique cost.

- Other essential feature of metals is ductility - cap potential of a fabric to deform below anxiety without rupture.

- Two ductility parameters can be achieving from the tensile test.

- Relative elongation - ratio among the boom of the specimen period earlier than its rupture and its unique period:

δ = (Lm– L0) / L0

Where Lm– most specimen period.

- Relative discount of region - ratio among the lower of the specimen cross-segment region earlier than its rupture and its unique cross-segment region:

ψ= (S0–Smin) / S0

Where Smin– minimal specimen cross-segment region.

True Stress-Strain Graph

Q6) Explain what do you mean by hardness test in detail

A6) Hardness Test:

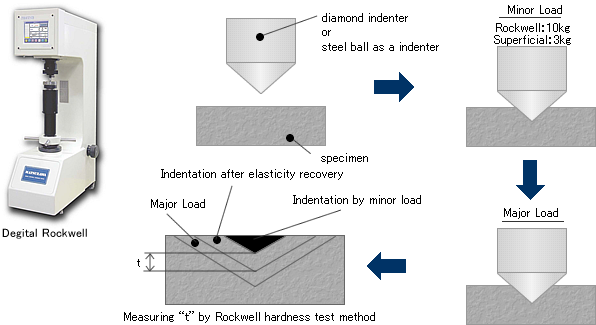

- HARDNESS-It is described because the resistance of a metallic to plastic deformation in opposition to Indentation, scratching, abrasion of cutting.

- The hardness of a fabric through this Rockwell hardness check technique is measured through the intensity of Penetration of the indenter.

- The intensity of Penetration is inversely proportional to the hardness.

- Both ball or diamond cone styles of indenters are used on this check. There are 3 scales at the system for taking hardness readings.

- Scale “A” with load 60 kgf or 588.four N and diamond indenter is used for appearing checks on skinny metallic and shallow case hardened metallic.

- Scale “B” with load a hundred kgf or 980.7 N and 1.588 mm dia ball indenter is used for appearing checks on gentle metallic, malleable iron, copper and aluminum alloys.

- First minor load is implemented to overcome the movie thickness at the metallic surface.

- Minor load additionally removes mistakes withinside the intensity of measurements because of spring of the system body or putting down of the specimen and desk attachments.

- The Rockwell hardness is derived from the dimension of the intensity of the impression

- EP = Depth of penetration because of Minor load of 98.07 N.

- Ea = Increase extensive of penetration because of Major load.

- E = Permanent growth of intensity of indentation below minor load at 98.07 N even

- After elimination of Major load.

- This technique of check is appropriate for completed or machined components of easy shapes.

Procedure:

- Select the burden through rotating the Knob and connect an appropriate indenter.

- Clean the check-piece and vicinity n the unique anvil or paintings desk of the system.

- Turn the capstan wheel to raise the check specimen into touch with the indenter point.

- Further flip the wheel for 3 rotations forcing the check specimen in opposition to the indenter. This will make sure that the Minor load of 98.07 N has been implemented

- Set the pointer at the Scale dial at the best position.

- Push the lever to use the Major load. A Dash Pot furnished withinside the loading mechanism to make sure that the burden is implemented gradually.

- As quickly because the pointer involves relaxation pull the cope with withinside the opposite route slowly. This releases the Major, however now no longer Minor load. The pointer will now rotate withinside the opposite route.

- The Rockwell hardness may be examining off the size dial, on the best scale, after the pointer involves relaxation.

Rockwell Hardness Testing Machine

Observations:

- Material of test piece =

- Thickness of test piece =

- Hardness Scale used =

- Minor Load =

- Major Load=

Test No. | 1 | 2 | 3 | 4 |

Hardness value

|

|

|

|

|

Precautions:

- For checking out cylindrical check specimen, use V-kind platform.

- Calibrate the device now and again the usage of fashionable check blocks.

- For skinny metallic fees location some other sufficiently thick metallic piece among the check specimen and the platform to keep away from any harm which may also probably arise to the platform.

- After making use of Major load, anticipate someday to permit the needle to return back to rest. The ready time range from 2 to 8 seconds.

- The floor of the check piece needs to be clean or even and unfastened from oxide scale and overseas matter.

- Test specimen need to now no longer be subjected to any heating or bloodless working.

- The thickness of check piece or of the layer below check need to be as a minimum eight instances the everlasting growth of intensity of “E”.

- The distance among the facilities of adjoining indentation needs to be as a minimum four indentation to the brink of the check piece need to be as a minimum 2. Five instances the diameter of the indentation.

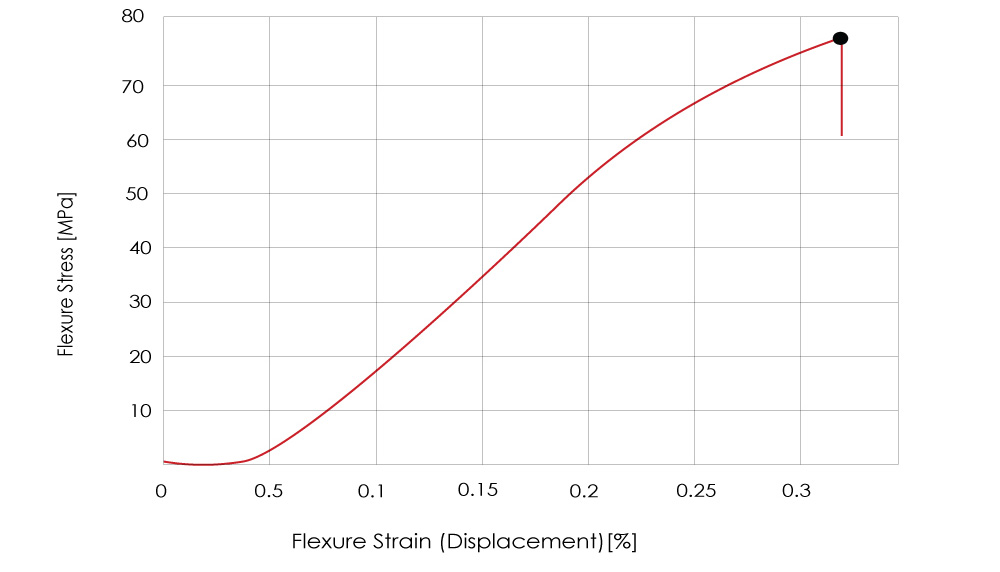

Q7) Explain what do you mean by bending test.

A7) Bending Test:

- Bend checking out, occasionally referred to as flexure checking out or transverse beam checking out, measures the conduct of substances subjected to easy beam loading.

- It is usually completed on tremendously bendy substances consisting of polymers, wood, and composites.

- At its maximum fundamental degree, a bend check is completed on a prevalent checking out device via way of means of setting a specimen on help anvils and bending it thru carried out pressure on 1 or 2 loading anvils if you want to degree its properties.

- Bend or flex exams observe pressure with both an unmarried top anvil on the midpoint, that's a three-factor bend check, or top anvils equidistant from the middle, a four-factor bend check.

- In a three-factor check the region of uniform strain is pretty small and focused below the middle loading factor.

- In a four-factor check, the region of uniform strain exists among the internal span loading points (generally 1/2 of the duration of the outer span).

- Depending at the kind of fabric being tested, there are numerous distinctive flex furnishings that can be appropriate.

Why Perform a Bend Test?

- Engineers regularly need to apprehend diverse elements of fabric’s conduct, however an easy uniaxial anxiety or compression check won't offer all essential information.

- As the specimen bends or flexes, its miles subjected to a complicated mixture of forces inclusive of anxiety, compression, and shear. For this reason, bend checking out is usually used to assess the response of substances to sensible loading situations.

- Flexural check facts may be specifically beneficial while a fabric is for use as a help structure.

- For example, a plastic chair desires to provide help in lots of directions. While the legs are in compression while in use, the seat will want to resist flexural forces carried out from the character seated.

- Not most effective do producers need to offer a product that may maintain anticipated loads, the fabric additionally desires to go back to its unique form if any bending occurs.

Performing a test and calculating results

- Bend exams are usually completed on a prevalent checking out device the usage of a three or four factor bend fixture.

- Variables like check pace and specimen dimensions are decided via way of means of the ASTM or ISO fashionable being used.

- Specimens are usually inflexible and may be manufactured from diverse substances consisting of plastic, metallic, wood, and ceramics.

- The maximum not unusual place shapes are square bars and cylindrical-formed specimens.

- A bend check produces tensile strain withinside the convex aspect of the specimen and compression strain withinside the concave aspect.

- This creates a place of shear strain alongside the midline.

- To make certain that number one failure comes from tensile or compression strain, the shear strain should be minimized via way of means of controlling the span to intensity ratio; the duration of the outer span divided via way of means of the height (intensity) of the specimen.

- For maximum substances S/d=sixteen is acceptable. Some substances require S/d=32 to sixty-four to maintain the shear strain low enough.

- Maximum fiber strain and most pressure are calculated for increments of load. Results are plotted on a strain-pressure diagram.

- Flexural power is described because the most strain withinside the outermost fiber.

- This is calculated on the floor of the specimen at the convex or anxiety aspect. Flexural modulus is calculated from the slope of the strain vs. Deflection curve.

- If the curve has no linear region, a secant line is suited to the curve to decide slope.

Flexure strain Vs stress graph

- Calculated values including most pressure and most extension may be recorded similar to a regular anxiety or compression check primarily based totally on load molecular and extension readings.

- Stress and stress values are calculated differently, as they contain the flex fixture assist span and loading span (for 4-factor bend checking out).

- It is simply as crucial to file those measurements as it's miles to nicely file the specimen’s dimensions.

- Once those values are entered into Bluebill Universal, calculations including flexural modulus are mechanically calculated whilst requested.

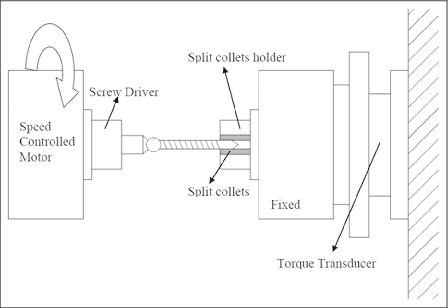

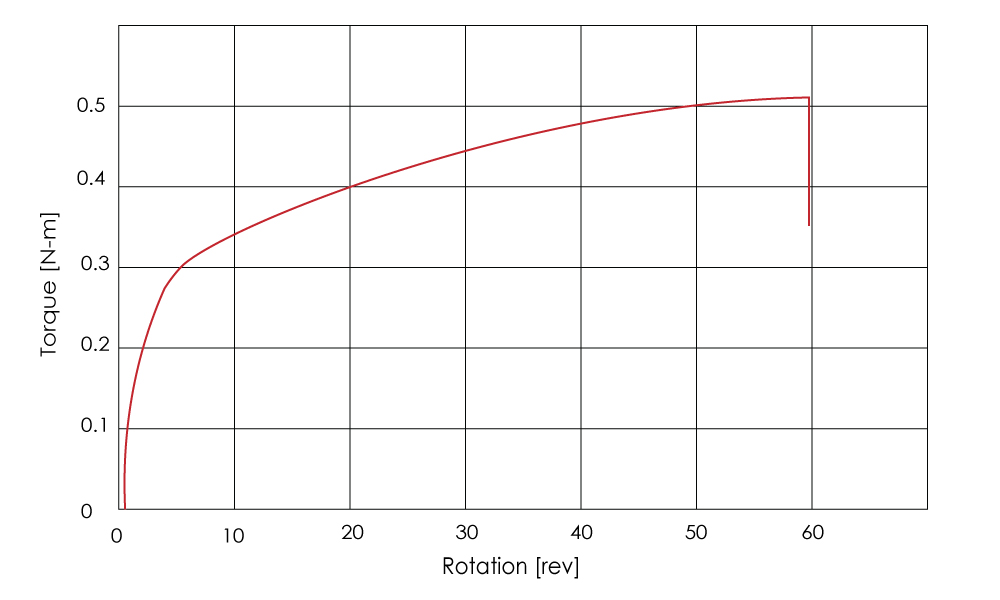

Q8) Explain torsion test.

A8) Torsion Test:

- Torsion checking out is a form of mechanical checking out that evaluates the residences of substances or gadgets at the same time as below strain from angular displacement.

- Torsion checking out may be break up into wonderful categories: checking out uncooked substances like steel wires or plastic tubing to decide residences including shear energy and modulus, or practical checking out of completed merchandise subjected to torsion, including screws, pharmaceutical bottles, and sheathed cables.

- The maximum not unusual place mechanical residences measured through torsion checking out are:

- Modulus of elasticity in shear

- Yield shear energy

- Ultimate shear energy

- Modulus of rupture in shear

- Ductility

Why perform a torsion test?

- Many merchandises and additives are subjected to torsional forces at some stage in their operation.

- Torsion checking out is important whilst engineers want to alternate or replace the substances utilized in those merchandise.

- For example, the steel utilized in automobile pressure trains reviews a complicated blended loading whilst in use, with torsion being the principle component.

- An engineer looking to layout an extra fuel-green automobile can also additionally want to alternate the cloth of the driveshaft in an effort to lessen automobile weight.

- Torsional checking out can assist the engineer perceive the appropriate cloth so that it will own the specified torsional energy at the same time as additionally contributing to the intention of light weighting.

- Many completed merchandises also are subjected to torsional forces at some stage in their operation. Products including biomedical tubing, switches, and fasteners are only some gadgets subjected to torsional stresses of their normal use.

- By checking out their merchandise in torsion, producers are capable of simulate actual lifestyles provider conditions, take a look at product quality, affirm designs, and make sure right production techniques.

Types of torsion tests:

- Torsion assessments may be carried out through making use of best a rotational movement or through making use of each axial (anxiety or compression) and torsional forces.

- Types of torsion checking out range from product to product however can normally be labeled as failure, proof, or product operation checking out.

- Torsion Only: Applying best torsional masses to the check specimen.

- Axial-Torsion: Applying each axial (anxiety or compression) and torsional forces to the check specimen.

- Failure Testing: Twisting the product, component, or specimen till failure. Failure may be labeled as both a bodily spoil or a kink/illness withinside the specimen.

- Proof Testing: Applying a torsional load and maintaining this torque load for a set quantity of time.

- Operational Testing: Testing entire assemblies or merchandise including bottle caps, switches, dial pens, or steerage columns to affirm that the product plays as predicted below torsion masses.

Performing a test and calculating results

- Torsion checking out may be carried out on specialized torsion-best gadget including Instron's MT collection or, extra commonly, on biaxial check gadget including everyday checking out machines able to making use of each linear pressure and torque.

- Instron's Torsion Add-On is a complicated fixture which may be retrofitted to any 594X or 596X device to permit for biaxial checking out of uncooked substances and merchandise.

Schematic View of Torsion test Setup

- The torque vs rotation curve produced by testing raw materials in torsion is in many ways analogous to the force displacement curve captured during axial testing.

- Most materials exhibit a similar linear region, representing the shear modulus, followed by yield and ultimate failure.

Rotation Vs Torque graph

Q9) What do you mean by strength of ceramic?

A9) Strength of Ceramic:

- A ceramic is any of the numerous hard, brittle, heat-resistant and corrosion-resistant substances made with the aid of using shaping after which firing a nonmetallic mineral, which include clay, at an excessive temperature. Common examples are earthenware, porcelain, and brick.

- The crystallinity of ceramic substances degrees from noticeably orientated to semi-crystalline, vitrified, and regularly absolutely amorphous (glasses).

- Most regularly, fired ceramics are both vitrified or semi-vitrified as is the case with earthenware, stoneware, and porcelain.

- Varying crystallinity and electron composition withinside the ionic and covalent bonds purpose maximum ceramic substances to be properly thermal and electric insulators (researched in ceramic engineering).

- With one of these huge variety of feasible alternatives for the composition/shape of a ceramic (almost all the elements, almost all varieties of bonding, and all degrees of crystallinity), the breadth of the challenge is vast, and identifiable attributes (hardness, toughness, electric conductivity) are hard to specify for the organization as a whole.

- General residences which include excessive melting temperature, excessive hardness, bad conductivity, excessive moduli of elasticity, chemical resistance and occasional ductility are the norm, with recognized exceptions to every of those rules (piezoelectric ceramics, glass transition temperature, superconductive ceramics).

- Many composites, which include fiberglass and carbon fiber, at the same time as containing ceramic substances aren't taken into consideration to be a part of the ceramic family.

- Ceramic cloth is an inorganic, non-metallic, regularly crystalline oxide, nitride, or carbide cloth.

- Some elements, which include carbon or silicon, perhaps taken into consideration ceramics.

- Ceramic substances are brittle, hard, sturdy in compression, and vulnerable in shearing and tension.

- They face up to chemical erosion that happens in different substances subjected to acidic or caustic environments.

- Ceramics normally can face up to very excessive temperatures, starting from 1,000 °C to 1,600 °C (1,800 °F to 3,000 °F).

- Glass is regularly now no longer taken into consideration a ceramic due to its amorphous (nanocrystalline) character.

- However, glassmaking entails numerous steps of the ceramic process, and its mechanical residences are much like ceramic substances.

- Traditional ceramic uncooked substances consist of clay minerals which include kaolinite, while greater current substances consist of aluminum oxide, greater generally called alumina.

- The contemporary-day ceramic substances, which might be categorized as superior ceramics, consist of silicon carbide and tungsten carbide.

- Both are valued for his or her abrasion resistance and as a result discover use in programs which include the damage plates of crushing device in mining operations.

- Advanced ceramics also are used withinside the medicine, electric, electronics industries, and frame armor.

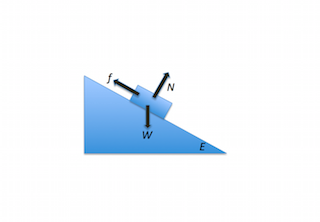

Internal Friction:

- Internal friction is an inner pressure that resists the motion among the debris of a cloth.

- This capacity inner motion may be because of both outside forces orextrade in temperature and deformation.

- This friction pressure is referred to as greater exactly as static inner friction sometimes, and its miles exceptional from the kinetic inner friction pressure.

- The static inner friction pressure acts towards the shear strain among the debris and attempts to preserve them desk bound and in place.

- This inner pressure is higher described in strong substances which include soil, rock, woods etc. and now no longer beverages and gases.

- To higher apprehend the concept, let’s say debris of a soil frame as strong blocks sitting on pinnacle of every different (see the figure).

Internal Friction

- Obviously, due to the gravity pressure, the top block has an inclination to transport down the decrease one and, consequently, makes the entire mass unstable.

- However, this movement gets resisted with the aid of using a counter pressure appearing in opposition to the motion and we name it inner friction (pressure f withinside the figure).

- The pressure f has a relation with the everyday pressure N as beneath:

f = mN

Creep -Fundamentals & Characteristic:

- Shear creep is one of the maximum crucial mechanical behaviors of rock discontinuities.

- The creep mechanism and prediction of place to begin of the accelerating creep degree are essential for organizing the creep version and predicting creep failure.

- In this study, a chain of multi-step creep exams are conducted. The 3 creep tiers of shear creep exams are investigated in element, and a way for predicting the accelerating creep degree is proposed.

- Distinct nonlinear and nearby fluctuations resulting from cracking are discovered withinside the creep curve.

- To describe the transition creep degree and constant creep degree, an empirical creep version is hooked up, and the creep traits associated with the joint roughness coefficient (JRC) and the everyday pressure are explored in element the use of the version’s parameters.

- The creep procedure may be defined as related to the JRC resistance weakening and frictional resistance compensation, and a version additionally hooked up to explain this procedure.

- The frictional resistance cannot catch up on the lack of JRC resistance; consequently, creep failure happens.

- The place to begin of the accelerating creep degree may be anticipated with the aid of using combining the JRC weakening and frictional mobilization version and the empirical creep version.

- A new approach for figuring out lengthy-time period electricity is likewise proposed primarily based totally at the relationships among the place to begin creep deformation and the shear creep pressure.

- In substances science, creep (every so often known as bloodless flow) is the tendency of a stable fabric to transport slowly or deform completely beneath Neath the have an effect on of chronic mechanical stresses.

- It can arise due to lengthy-time period publicity to excessive stages of pressure which can be nonetheless beneath Neath the yield electricity of the fabric.

- Creep is extra extreme in substances which can be subjected to warmth for lengthy durations and normally will increase as they close to their melting factor.

- The price of deformation is a feature of the fabric's properties, publicity time, publicity temperature and the implemented structural load.

- Depending at the significance of the implemented pressure and its duration, the deformation can also additionally grow to be so big that an issue can now not carry out its feature — as an instance creep of a turbine blade ought to purpose the blade to touch the casing, ensuing withinside the failure of the blade.

- Creep is normally of subject to engineers and metallurgists while comparing additives that perform beneath Neath excessive stresses or excessive temperatures.

- Creep is a deformation mechanism which can or won't represent a failure mode.

- For example, mild creep in concrete is every so often welcomed as it relieves tensile stresses that would in any other case result in cracking.

Q10) Explain brittle fracture of steel temperature transition approach.

A10) Brittle Fracture of Steel-Temperature transition approach:

- Brittle Fracture is the sudden, very fast cracking of device beneath pressure wherein the fabric exhibited very little proof of ductility or plastic degradation earlier than the fracture happens.

- Unlike maximum different tensile disasters, wherein the fabric plastically traces beneath overload situations and will become thinner till the factor of rupture, while a chunk of device suffers a brittle fracture, there may be no thinning or necking down.

- Rather, this harm mechanism regularly reasons cracking without warning, every so often fracturing device into many pieces.

- Brittle fracture is regularly resulting from low temperatures.

- If the metallic temperature is at or beneath its brittle-to-ductile transition temperature, then it is going to be liable to brittle fracture.

- Combine this with an important sized flaw and excessive pressure on that flaw (both implemented or residual), and then you definitely are in all likelihood to revel in a brittle fracture.

- Other elements which could growth the susceptibility to brittle fracture encompass:

Metallurgical Degradation:

- Metallurgical degradation can arise in a few steels at better temperatures and might encompass such things as mood embrittlement, graphitization, sigma section embrittlement, and 885 embrittlement.

Steel Cleanliness and Grain Structure:

- As for metallic cleanliness and grain structure, big grain sizes and metallic contaminants can lessen metallic durability, so it is crucial to be conscious and aware of this in the course of fabric choice and QA/QC.

High Material Thickness

- When it involves fabric thickness, thicker additives have a better diploma of susceptibility to brittle fracture due to the fact they have got better tri-axial stresses.

- Also, thicker substances produce a country of better constraint, and are consequently much less in all likelihood to deform beneath pressure in preference to crack initiation and propagation.

- There are predominant styles of brittle fractures: trans granular and intergranular.

- With transgranular fractures, the fracture travels thru the grain of the fabric. Its adjustments course from grain to grain because of the one-of-a-kind lattice orientation of atoms in every grain, following the direction of least resistance.

- Intergranular fracture, on the alternative hand, happens while a crack travels alongside the grain boundaries, in preference to thru the grains themselves.

- Intergranular fracture normally happens while the section withinside the grain boundary is vulnerable and brittle.

- In order to lessen the hazard of brittle fracture, one has to make sure to preserve substances working at or above their brittle-to-ductile transition temperature in the course of each provider and checking out.

- Likewise at the same time as engaging in repairs, taking steps to set up and discover flaws that would weaken the fabric at the same time as in-provider or in the course of stress checking out will lessen the probabilities of brittle fracture.

Background of Fracture Mechanics:

- In 1983, the National Bureau of Standards (now the National Institute for Science and Technology) and Battelle Memorial Institute1 predicted the prices for failure because of fracture to be $119 billion in keeping with yr in 1982 greenbacks.

- The greenbacks are crucial, however the value of many disasters in human lifestyles and harm is infinitely extra so.

- Failures have been fell for plenty reasons, consisting of uncertainties withinside the loading or surroundings, defects withinside the substances, inadequacies in layout, and deficiencies in creation or maintenance.

- Design in opposition to fracture has a generation of its own, and that is a totally energetic location of contemporary research.

- This module will offer a creation to a crucial component of this field, on account that without a know-how of fracture the techniques in pressure evaluation mentioned formerly could be of little use.

- We will recognition on fractures because of easy tensile overstress, however the fashion dressmaker is counseled once more approximately the want to remember surely as many elements as viable that would result in failure, in particular while lifestyles are at hazard.

- The Module at the Dislocation Basis of Yield (Module 21) suggests how the electricity of structural metals – in particular metallic – may be expanded to very excessive stages with the aid of using manipulating the microstructure a good way to inhibit dislocation movement.

- Unfortunately, this renders the fabric more and more brittle, in order that cracks can form and propagate catastrophically with little or no warning.

- An unlucky range of engineering failures are associated immediately to this phenomenon, and engineers worried in structural layout have to be aware about the processes now to be had to protect in opposition to brittle fracture.

- The crucial issue in designing in opposition to fracture in excessive-electricity substances is that the presence of cracks can regulate the nearby stresses to such a quantity that the elastic pressure analyses accomplished so cautiously with the aid of using the designers are insufficient.

- When a crack reaches a positive important length, it is able to propagate catastrophically thru the structure, despite the fact that the gross pressure is tons much less than could generally purpose yield or failure in a tensile specimen.

- The time period “fracture mechanics” refers to an essential specialization inside stable mechanics wherein the presence of a crack is assumed, and we want to discover quantitative members of the family among the crack length, the fabric’s inherent resistance to crack growth, and the pressure at which the crack propagates at excessive velocity to purpose structural failure.