Unit – 4

First law of flow processes

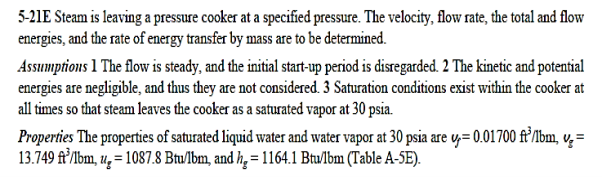

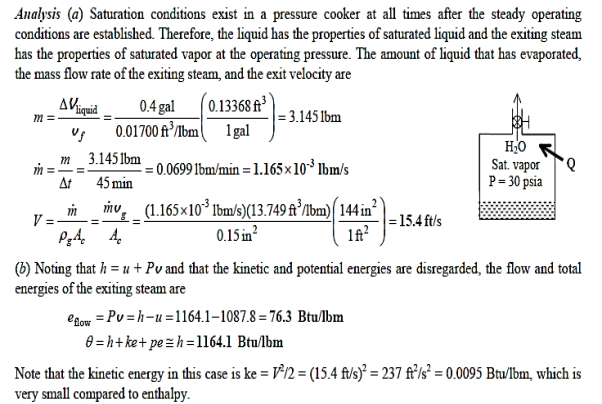

Q1) Steam is escaping from a pressure cooker with a 30 psi operating pressure. After the steady operating conditions are established, the amount of liquid in the cooker decreases by 0.4 gal in 45 minutes, and the cross-sectional area of the exit aperture is 0.15 in2. Calculate (a) the steam mass flow rate and exit velocity, (b) the total and flow energies of the steam per unit mass, and (c) the rate at which energy leaves the cooker via steam.

A1)

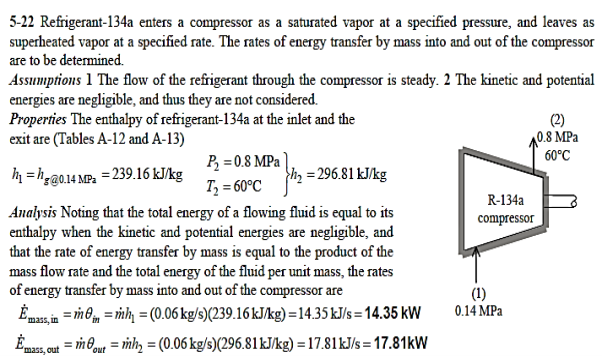

Q2) At a rate of 0.06 kg/s, refrigerant-134a enters a refrigeration system as saturated vapour at 0.14 MPa and exits as superheated vapour at 0.8 MPa and 60°C.Calculate the energy transfer rates into and out of the compressor based on mass. Assume that the kinetic and potential energies are zero.

A2)

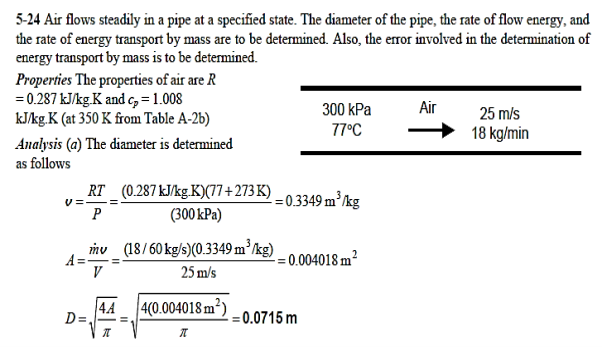

Q3) At 300 kPa, 77°C, and 25 m/s, air flows consistently through a pipe at a rate of 18 kg/min. Determine (a) the pipe diameter, (b) the flow energy rate, (c) the rate of energy transmission by mass, and (d) the error involved in section (c) if the kinetic energy is ignored.

A3)

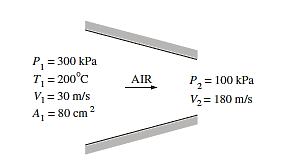

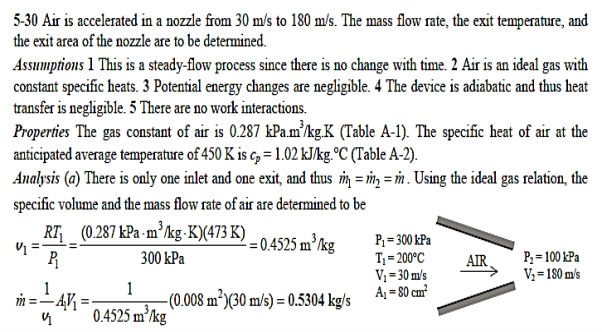

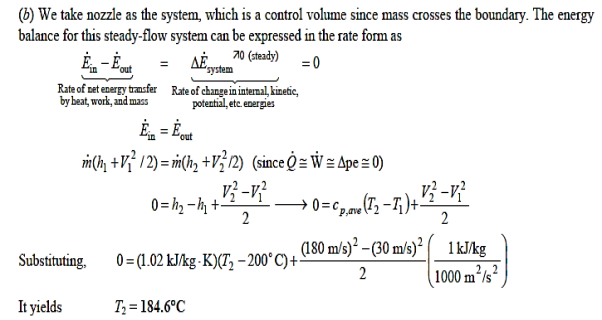

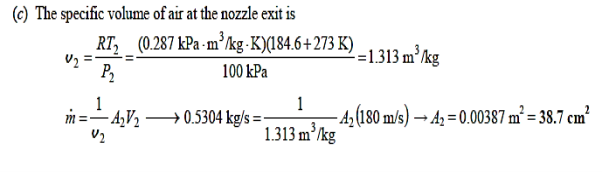

Q4) At 300 kPa, 200°C, and 30 m/s, air enters an adiabatic nozzle and departs at 100 kPa and 180 m/s. The nozzle's inlet area is 80 cm2. Calculate (a) the mass flow rate via the nozzle, (b) the air's exit temperature, and (c) the nozzle's exit area.

A4)

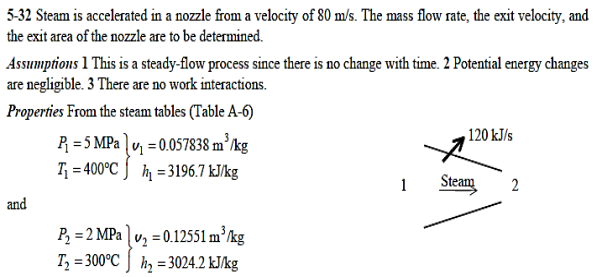

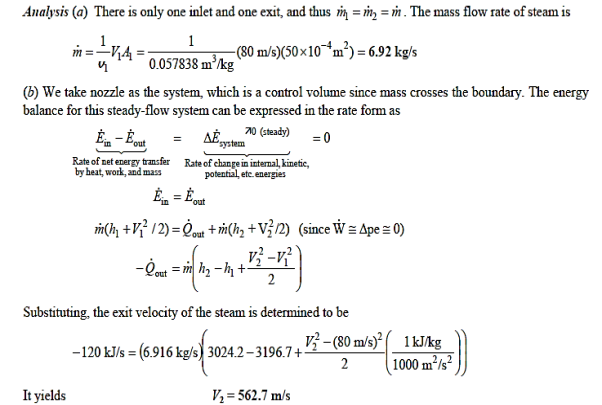

Q5) Steam with a pressure of 5 MPa and a temperature of 400°C enters a nozzle at an average velocity of 80 m/s and leaves with a pressure of 2 MPa and a temperature of 300°C. The nozzle's inlet area is 50 cm2, and heat is lost at a rate of 120 kJ/s. Determine (a) the steam's mass flow rate, (b) the steam's exit velocity, and (c) the nozzle's exit area.

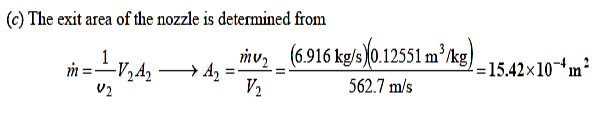

A5)

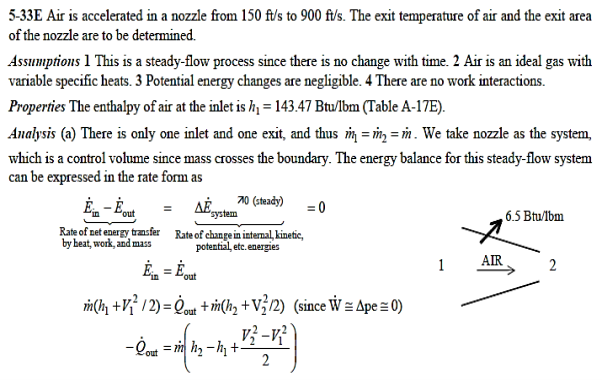

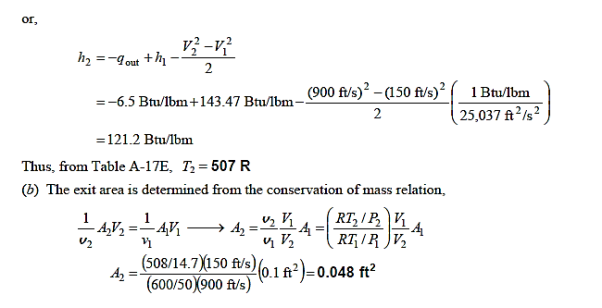

Q6) At 50 psia, 140°F, and 150 ft/s, air enters a nozzle and departs at 14.7 psia and 900 ft/s. The nozzle is predicted to lose 6.5 Btu every pound of air flowing. The nozzle's inlet area is 0.1 ft2. Determine (a) the air temperature at the nozzle's exit and (b) the nozzle's exit area.

A6)

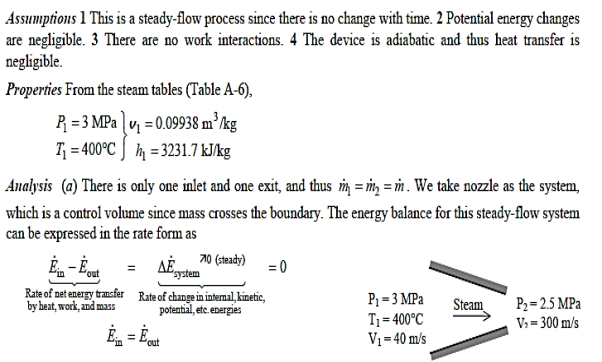

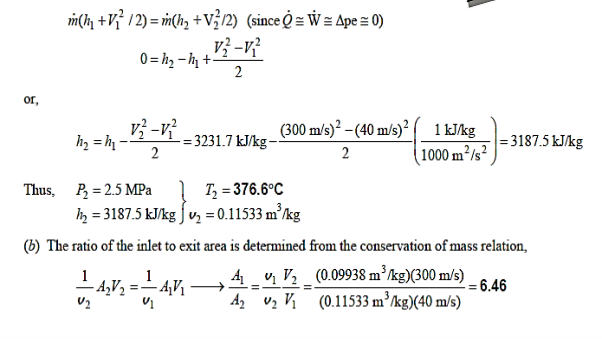

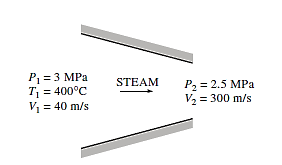

Q7) Steam at a pressure of 3 MPa and a temperature of 400°C enters an adiabatic nozzle at a steady 40 m/s and exits at 2.5 MPa and 300 m/s. Calculate (a) the exit temperature and (b) the A1/A2 ratio of the inlet and exit areas.

A7)

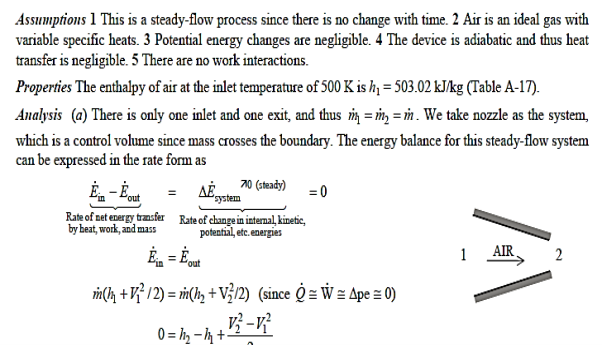

Q8) With a velocity of 120 m/s, air at 600 kPa and 500 K enters an adiabatic nozzle with a 2:1 inlet-to-exit area ratio and departs with a velocity of 380 m/s. Determine (a) the air's exit temperature and (b) the air's exit pressure.

A8)

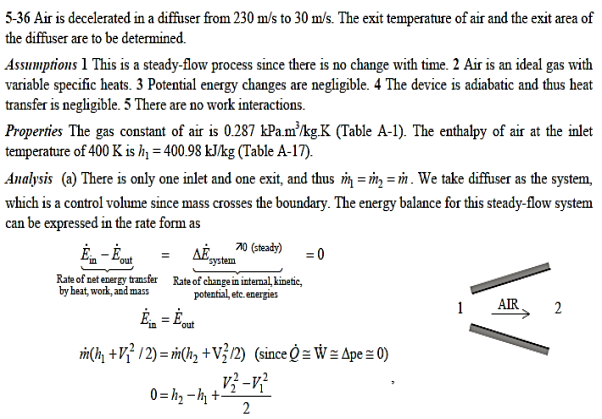

Q9) Air at a pressure of 80 kPa and a temperature of 127°C enters an adiabatic diffuser at a velocity of 6000 kg/h and leaves at a pressure of 100 kPa. As it travels through the diffuser, the airstream's velocity drops from 230 to 30 m/s. Determine (a) the air's departure temperature and (b) the diffuser's exit area.

A9)

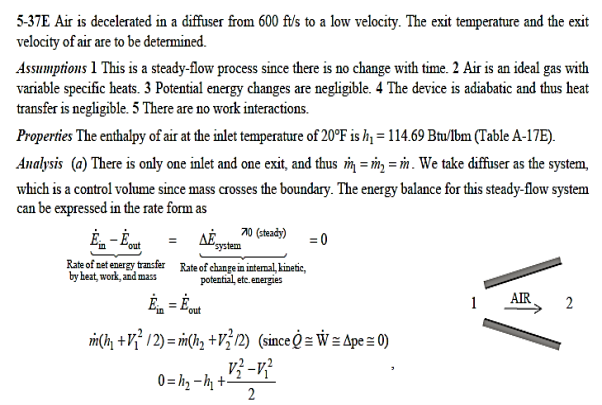

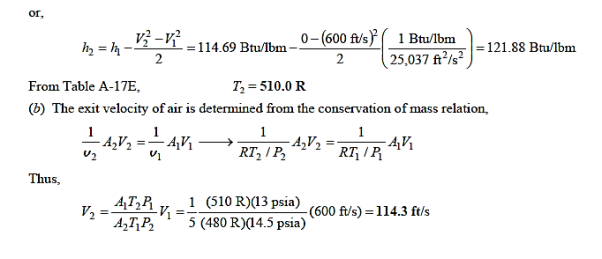

Q10) At a pressure of 14.5 psia and a temperature of 20°F, air enters an adiabatic diffuser at a constant velocity of 600 ft/s and departs at a low velocity. The diffuser's departure area is 5 times its intake area. Determine (a) the air's exit temperature and (b) the air's exit velocity.

A10)

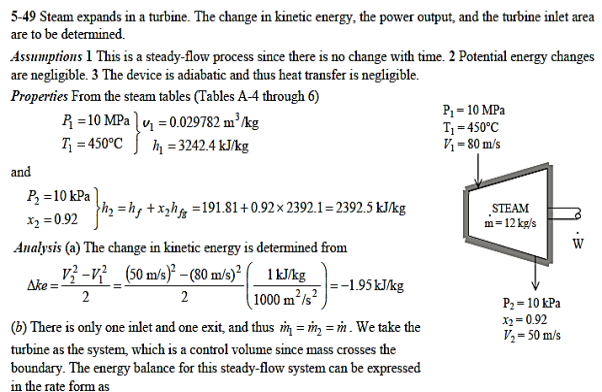

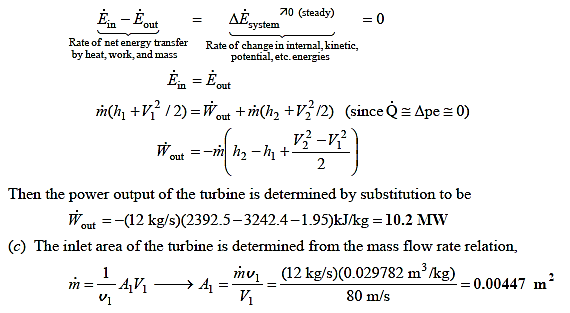

Q11) An adiabatic turbine produces a steady stream of steam. The steam has an entrance pressure of 10 MPa, a temperature of 450°C, and a velocity of 80 m/s, with an exit pressure of 10 kPa, a quality of 92 percent, and a speed of 50 m/s. The steam has a mass flow rate of 12 kg/s. Calculate the (a) kinetic energy change, (b) power output, and (c) turbine inlet area.

A11)

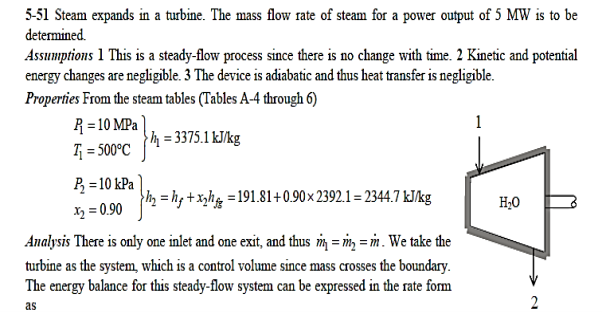

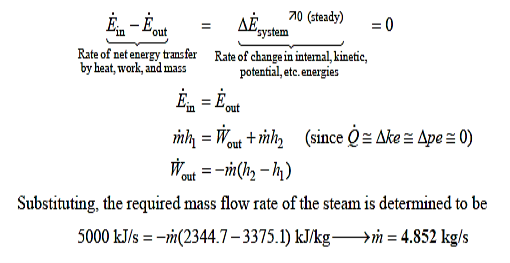

Q12) Steam enters an adiabatic turbine at a pressure of 10 MPa and a temperature of 500°C and departs at a pressure of 10 kPa with a quality of 90%. Calculate the mass flow rate required for a 5 MW power output while ignoring changes in kinetic and potential energy.

A12)

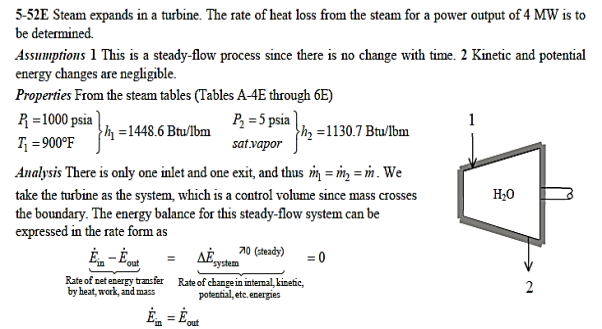

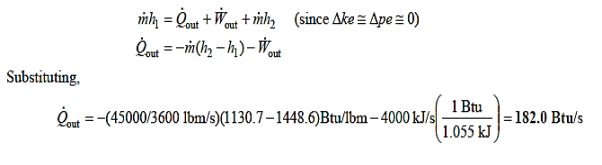

Q13) Steam flows at a rate of 45,000 lbm/h through a turbine, entering at 1000 psia and 900°F and leaving as saturated vapour at 5 psia. Determine the rate of heat loss from the steam if the turbine generates 4 MW of power.

A13)

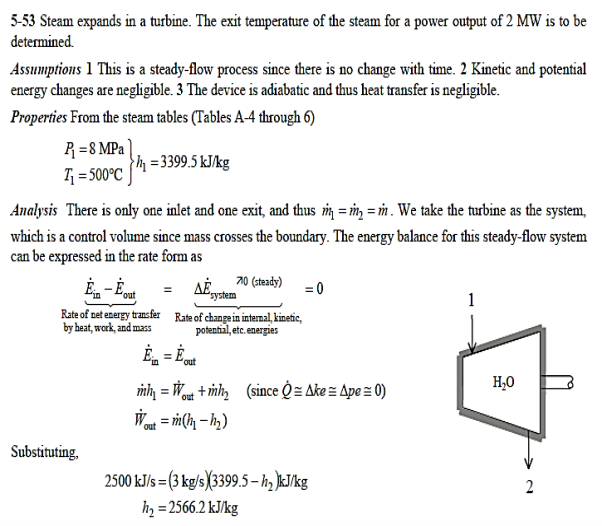

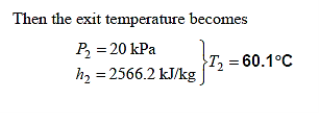

Q14) Steam enters an adiabatic turbine at a rate of 3 kg/s at 8 MPa and 500°C and exits at 20 kPa. Determine the temperature of the steam at the turbine exit if the turbine's power output is 2.5 MW. Changes in kinetic energy are often overlooked.

A14)

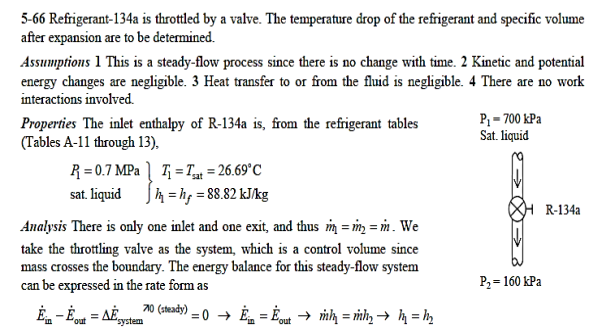

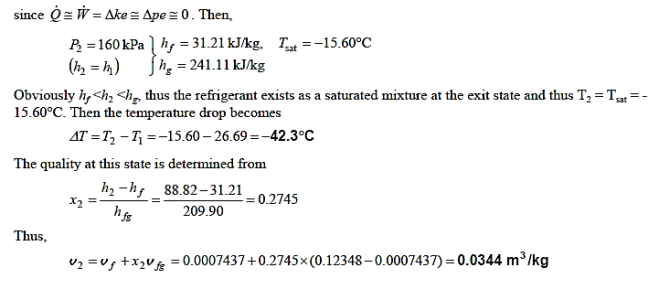

Q15) From a saturated liquid state of 700 kPa to a pressure of 160 kPa, refrigerant-134a is throttled. Calculate the temperature drop and refrigerant specific volume at the end of the process.

A15)

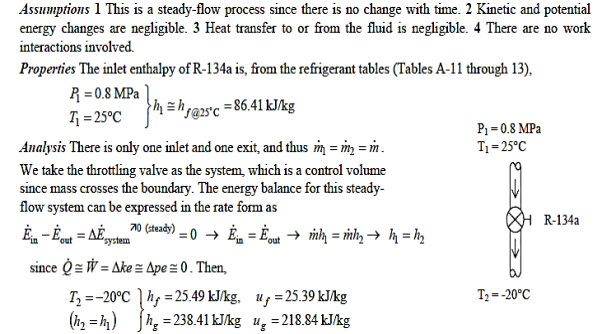

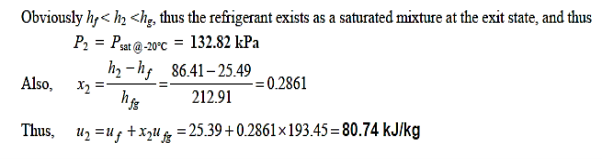

Q16) At 800 kPa and 25°C, refrigerant-134a is throttled to a temperature of 20°C. Calculate the refrigerant's pressure and internal energy in its ultimate state.

A16)

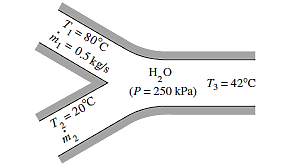

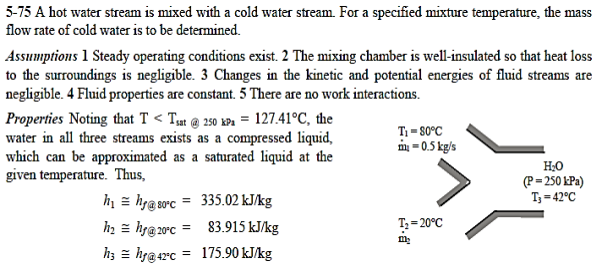

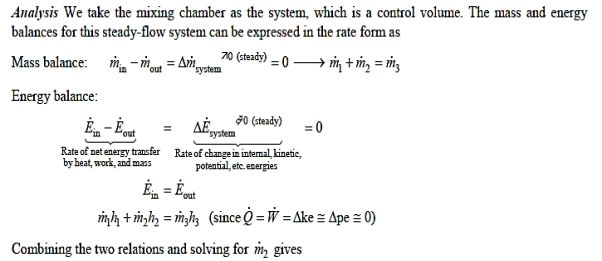

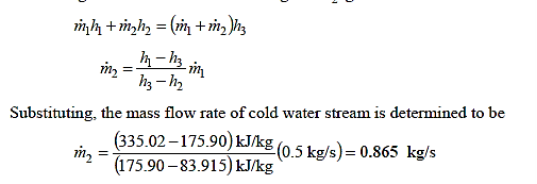

Q17) A stream of 80°C hot water enters a mixing chamber at a mass flow rate of 0.5 kg/s and is mixed with a stream of 20°C cold water. Determine the mass flow rate of the cold-water stream if the combination is to depart the chamber at 42°C. Assume that all of the streams are at 250 kPa.

A17)

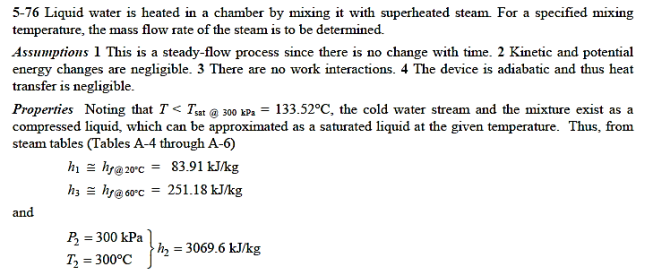

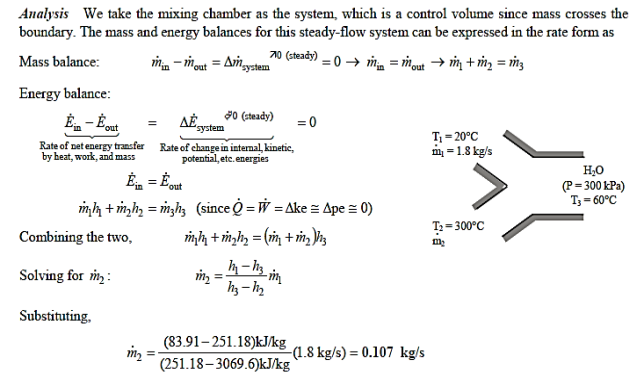

Q18) In a chamber, liquid water with a pressure of 300 kPa and a temperature of 20°C is heated by mixing it with superheated steam with a pressure of 300 kPa and a temperature of 300°C. At a rate of 1.8 kg/s, cold water enters the chamber. Determine the mass flow rate of superheated steam required if the mixture leaves the mixing chamber at 60°C.

A18)

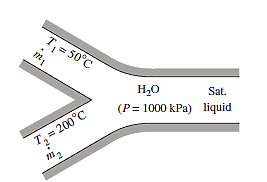

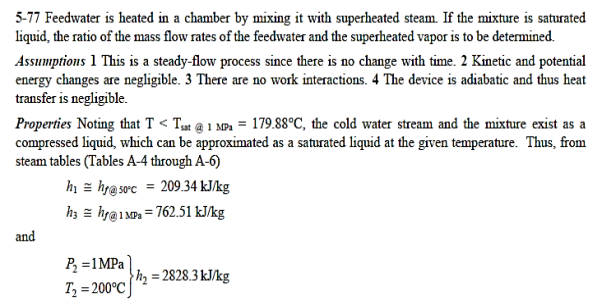

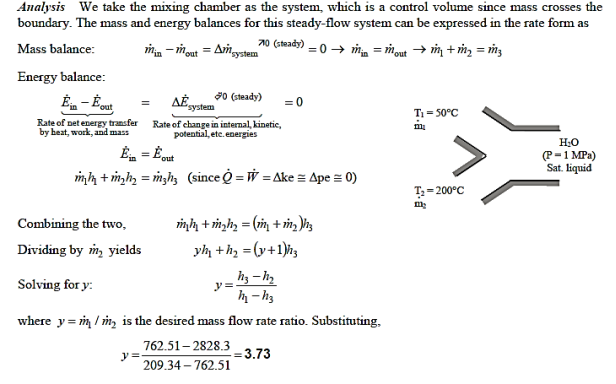

Q19) Open feedwater heaters are commonly used in steam power plants to heat the feedwater by mixing it with steam drained off the turbine at some intermediate point. Consider an open feedwater heater with a 1000 kPa operating pressure. Superheated steam at 200°C and 1000 kPa will be used to heat feedwater at 50°C and 1000 kPa. At the feedwater pressure, the mixture leaves an optimum feedwater heater as saturated liquid. In this scenario, calculate the ratio of the feedwater and superheated vapour mass flow rates.

A19)

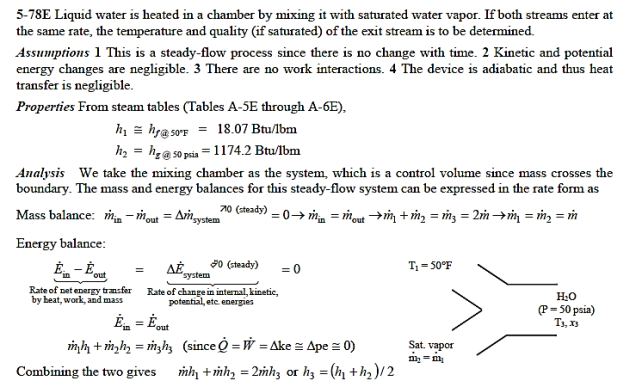

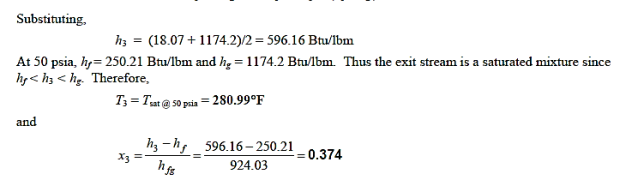

Q20) Water at 50 degrees Fahrenheit and 50 pounds per square inch is heated in a chamber by mixing it with saturated water vapour at 50 pounds per square inch. Determine the temperature and quality of the outgoing stream if both streams enter the mixing chamber at the same mass flow rate.

A20)