Unit - 5

Surface contacts

Q1) What is surface contact?

A1)

A floor-to-floor touch definition may be used as an opportunity to trendy touch to version touch interactions among particular surfaces in a version. Certain interplay behaviours may be described most effective via way of means of the usage of floor-to-floor touch.

For a short evaluation of floor-to-floor touch and different varieties of interactions to be had in Abaqus, see Understanding interactions, and About touch interactions. You can outline floor-to-floor touch in any step, which includes the preliminary step.

You can outline touch among edges of a cord or among faces of a stable or shell. Certain connectivity regulations follow to touch surfaces relying at the sort of touch formulation. You can deactivate a floor-to-floor touch interplay in a step and, if desired, reactivate this interplay in a next step.

Q2) What is rolling friction?

A2) The values for the coefficient of rolling friction are pretty much less than that of sliding friction. It normally produces more sound and thermal bi-products. For example- Movement of braking motor car tires on a roadway.

For a transferring strong frame, there are predominant forms of friction that act upon it: The pressure resisting the movement of a rolling frame on a floor is referred to as rolling friction or rolling resistance. Rolling of ball or wheel at the floor is an instance of Rolling friction.

The different form of friction is sliding friction. In this form of friction, there may be a restrict at the frame’s motion as best one facet of the frame is in touch with the floor.

Pushing a field throughout the desk is an instance of Sliding friction. Rolling friction is extensively weaker than sliding friction.

Cause of Rolling Friction

When an item is rolled on a floor, positive matters happen:

The item is deformed on the factor of touch with the floor.

The floor is deformed on the factor of touch with the item.

Q3) What is sliding friction?

A3) We can outline sliding friction because the resistance created with the aid of using any gadgets while sliding towards every other. This friction is likewise called kinetic friction and is described because the pressure this is had to hold a floor sliding alongside some other floor.

It relies upon on variables- one is cloth and the opposite is the burden of the object. Any extrude with inside the floor region in touch does now no longer extrude the sliding friction.

In maximum of the materials, sliding friction is much less than static friction.

There are exceptions that consist of metals having static and sliding friction coefficients and are basically the equal with small surfaces wherein molecular appeal forces take over.

Factors affecting sliding friction

The floor deformation of gadgets.

The roughness or smoothness of the floor of the gadgets.

The unique pace of both object.

The length of the object. Finally, the quantity of strain on both object.

Examples of Sliding Friction

Rubbing each the palms collectively to create heat.

A baby sliding down via a slide in a park.

Q4) Explain friction drives?

A4) The machine is certainly a constantly variable transmission, through transferring the 2 disks positions the output ratio adjustments continually. Although as soon as utilized in early automobiles, nowadays the machine is maximum typically used on scooters, in particular go-peds, in vicinity of a series and tools machine.

It is robotically same to a ball-and-disk integrator, however supposed to address better torque levels. The machine includes disks, usually metal, set at proper angles to every other. One disk is attached to the engine, the alternative to the weight.

The load disk is located in order that its outer rim is pressed towards the pushed disk, and usually has a few kind of high-friction floor implemented to the outer rim to enhance torque switch. In early systems, paper and leather-based become regularly used for this floor. One of the disks, usually the weight side, is set up on a shaft that permits it to be moved on the subject of the pushed disk, permitting it to transport from a role on the middle of the pushed disk to its outer radius.

Q5) What is bearing?

A5) A bearing is a system detail that constrains relative movement to simplest the favoured movement, and decreases friction among transferring parts. The layout of the bearing may, for example, offer at no cost linear motion of the transferring component or at no cost rotation round a set axis; or, it is able to save you a movement via way of means of controlling the vectors of ordinary forces that undergo at the transferring parts. Most bearings facilitate the favoured movement via way of means of minimizing friction.

Bearings are categorized widely in step with the kind of operation, the motions allowed, or to the instructions of the hundreds (forces) implemented to the parts. Rotary bearings keep rotating additives consisting of shafts or axles inside mechanical systems, and switch axial and radial hundreds from the supply of the burden to the shape assisting it.

The best shape of bearing, the apparent bearing, includes a shaft rotating in a hole. Lubrication is used to lessen friction. In the ball bearing and curler bearing, to lessen sliding friction, rolling factors consisting of rollers or balls with a round cross-phase are positioned among the races or journals of the bearing assembly.

Q6) What is lubrication?

A6) Although that is a legitimate definition, it fails to comprehend all that lubrication in reality achieves. Many unique materials may be used to lubricate a floor. Oil and grease are the maximum common. Grease consists of oil and a thickening agent to reap its consistency, whilst the oil is what in reality lubricates. Oils may be artificial, vegetable or mineral-primarily based totally in addition to a aggregate of these.

The utility determines which oil, typically known as the bottom oil, ought to be used. In severe situations, artificial oils may be beneficial. Where the surroundings is of concern, vegetable base oils can be utilized. Lubricants containing oil have components that enhance, upload or suppress houses in the base oil. The quantity of components relies upon at the kind of oil and the utility for which it will likely be used. For instance, engine oil may have a dispersant added. A dispersant continues insoluble depend conglomerated collectively to be eliminated through the clear out upon circulation. In environments that go through extremes in temperature, from bloodless to hot, a viscosity index (VI) improver can be added.

Q7) What are the friction clutches?

A7) Mechanism which enables rotary motion of shaft to be transmitted to the second shaft axis, which is coincident with the first. OR

Clutch is a device to connect driving and driven shafts of a machine, where the driven shaft can be disconnected almost instantaneously from the driving shaft as desired by the operator or driver.

Q8) What are the requirements of friction clutch?

A8)

Requirements of clutch:

- Torque Transmission

- Gradual Engagements

- Heat Dissipation

- Dynamic Balancing

- Vibration Damping

- Size

- Inertia

- Ease of operation

1. Torque Transmission

- The clutch should be able to transfer the maximum torque of engine under all conditions.

- Usually designed to transmit 125 to 150% of maximum engine torque.

2. Gradual Engagement: Clutch should take the drive gradually without occurrence of sudden jerks.

3. Heat Dissipation: During clutch application large amount of heat is generated, the rubbing surfaces should have sufficient area and mass to absorb the heat generated. The design of clutch should ensure proper ventilation or cooling for adequate dissipation of heat.

The friction clutches work on the fact that friction is caused when two rotating discs come into contact with each other.

Q9) Explain belt and rope drives.

A9) Belt Drives:

The belt drive is used to transmit power from one shaft to another by means of pulleys which rotate at the same speed or at different speed.

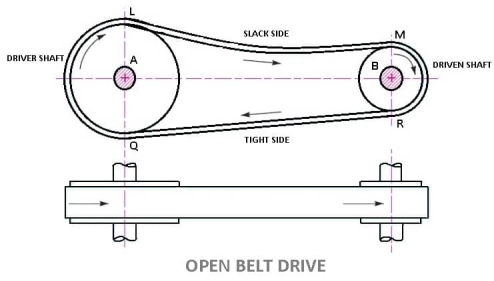

I) Open and Cross belt drive

Open Belt Drive:

- In these types of belt drive, the belt is employing when the two parallel shafts have to rotate in the same direction.

- When the shafts are far apart, the lower side of the belt should be the tight side and the upper side must be the slack side.

- This is because, when the upper side becomes the slack side, it will sag due to its own weight and thus increase the arc of contact.

- In open belt drive, belt proceeds from top of one pulley to the top of other pulley without crossing.

- Contact angle (or wrap angle) between the belt and pulley is comparatively small (always below 180º in smaller pulley).

Length of Open Belt Drive Formula:

= π (r1 + r2) + 2x + (r1 – r2)2 /x ……………. (In terms of pulley radii)

= π/2 (d1 + d2) + 2x + (d1 – d2)2/ 4x ……….… (In terms of pulley diameters)

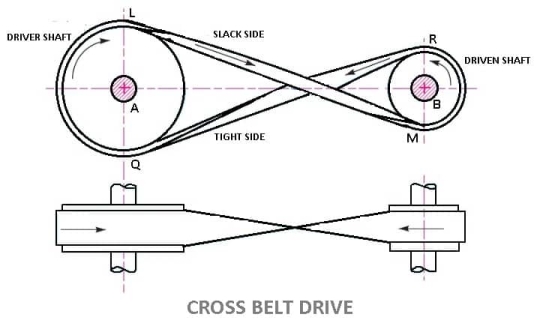

Cross Belt Drive

- In this type of belt drives, the belt is employing when two parallel shafts have to rotate in the opposite direction. At the junction where the belts cross, it rubs against itself and wears off.

- To avoid excessive wear, the shafts must be placed at a maximum distance from each other and operated at very low speeds.

- Contact angle between the belt and pulley is comparatively large (always above 180º in smaller pulley).

- In crossed belt drive, belt proceeds from top of one pulley to the bottom of other pulley and thus crosses itself.

- Here belt bends in two different planes in every rotation during its operation

- Cross belt drive can be advantageously applied for horizontal, inclined and vertical positions of driving and driven shafts.

- It can transmit more power as wrap angle is more.

Q10) What are the advantages of rope drives?

A10)

Advantages of the rope drive

- Significant power transmission.

- It can be used for long distance.

- Ropes are strong and flexible.

- Provides smooth and quiet operation.

- It can run any direction.

- Low-cost and economic.

- Precise alignment of the shaft not required

Q11) Explain friction in brakes.

A11)

Brake refers to a tool that in general performs the function of slowing down or bringing to a halt an item in movement including a vehicle, a bike, train, an airplane, or roller-coaster. One of the maximum mentioned braking structures are those utilized in vehicles. A friction brake plays its characteristic through urgent a brake pad towards the shifting component.

As a end result of it, a friction pressure opposing the course of the shifting component develops. In the process, warmness is generated from the kinetic power of the shifting item. The phenomena of friction in braking structures had been notably blanketed on account that the start of the twentieth century. The reputation of the subject emanates from the belief that brakes constitute one of the essential protection additives in cars and their failure should cause catastrophic consequences.

During the complete braking action, it's far important that the friction pressure is excessive and stable. This ought to practice to any circumstance consisting of a extensive variety of touch temperatures, touch pressures and relative velocities among the static and shifting elements of the break, consisting of any environmental changes.