Unit - 3

Introduction to Tension Members

Q1) What is Tension Members?

A1)

When an anxiety member is subjected to axial tensile pressure, then the distribution of strain over the pass-segment is uniform.

The complete internet place of a member is efficaciously used on the most permissible uniform strain.

Therefore, a tensile member subjected to axial tensile pressure is used to be green and not pricey member.

The method of the layout of an anxiety member is defined under with assist of instance problems.

Tension members are structural elements which are subjected to axial tensile forces. Examples of anxiety members are bracing for homes and bridges, truss members, and cables in suspended roof systems.

In an axially loaded anxiety member, the strain is given by:

F = P/A

Where in P is the importance of the burden and A is the pass-sectional place.

The strain given by this equation is exact, understanding that the pass segment isn't adjoining to the factor of utility of the burden nor having holes for bolts or other discontinuities.

For instance, given an eight x 11 five plate this is used as an anxiety member (segment a-a) and is hooked up to a gusset plate with 7/eight-inch-diameter bolts (segment b-b):

Design

To layout anxiety members, it is crucial to examine how the member might fail beneath Neath each yielding (excessive deformation) and fracture, which can be taken into consideration the restriction states.

The restriction nation that produces the smallest layout energy is taken into consideration the controlling restriction nation.

It additionally prevents the shape from failure.

Using American Institute of Steel Construction standards, the last load on a shape may be calculated from one of the following combinations:

1.4 D

1.2 D + 1.6 L + 0.5 (Lr or S)

1.2 D + 1.6 (Lr or S) + (0.5 L or 0.8 W)

1.2 D + 1.6 W + 0.5 L + 0.5 (Lr or S)

0.9 D + 1.6 W

L= 14

- D… is the dead load or the weight of the structure itself

- L… is the live load which vary for different structures

- S… is the snow load

- W… is the wind load

The central problem of designing a member is to find a cross section for which the required strength doesn't exceed the available strength:

Pu < ¢ Pn

Where,

Pu is the sum of the factored loads.

To prevent yielding

0.90 Fy Ag > Pu

To avoid fracture,

0.75 Fu Ae > Pu

Therefore

The design must consider the loads applied to this member, the design forces acting on this member (Mu, Pu, and Vu) and the point where this member would fail.

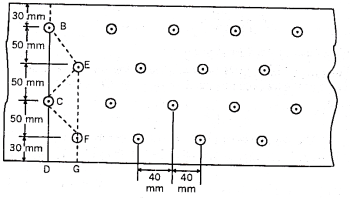

Q2) Determine the tensile strength of the 12 mm thick plate shown in Fig Rivets used for the connection are 20 mm diameter. Allowable tensile stress is 150 N/mm2.

A2)

Diameter of the rivet hole = 20 + 1.5 = 21.5 mm

The critical section to be considered is a section like ABCDE.

Effective width at critical section = b – nd = 180 – (3 x 21.5) = 115.5 mm

Effective net area = 115.5 x 12 mm2 = 1386 mm2

Strength of plate = 1386 x 150 = 207900 N = 207.9 kN.

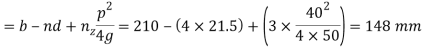

Q3) Find the strength of the 12 mm thick plate shown in Fig. All the holes are 21.5 mm as gross diameter. Take ft=150 N/mm2.

A3)

Gross diameter of rivet hole = 21.5 mm

The effective net width will be computed along the various chain lines

Staggered pitch p = 40 mm

Gauge distance g = 50 mm

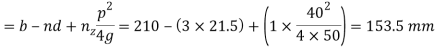

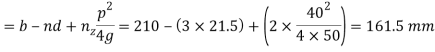

Net width corresponding to the chain ABCD = 210 – (2 x 21.5) = 167 mm

Net width corresponding to the chain ABECFG

Net width corresponding to the chain ABEFG

Net width corresponding to the chain ABECD

Therefore, minimum net width = 148mm

Safe load = Safe stress × Area of minimum net effective section

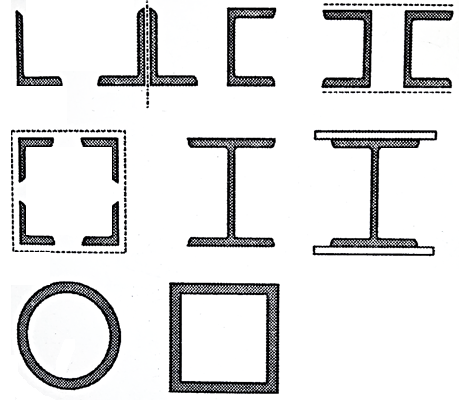

Q4) What are types of Tension Members?

A4)

1. Wires and cables:

Wires ropes are completely used for hoisting functions and as guy wires in metal stacks and towers. Strands and ropes are shaped via way of means of helical winding of wires.

A strand includes person wires wound helically around the important core. These aren't endorsed in bracing gadget as they cannot withstand compression. The benefits of twine and cable are flexibility and power.

2. Bars and rods:

These are most effective varieties of anxiety participants. Bars and rods are regularly used as anxiety participants in bracing gadget, as sag rods to aid purling among trusses. Presently those aren't preferred of with the designers due to the fact massive drift they purpose in the course of sturdy winds and annoying noise induces via way of means of the vibrations.

3. Plates and flat bars:

These are used regularly as anxiety participants in transmission towers, foot bridges, etc. These also are utilized in columns to hold the component participants of their accurate position. E.g.- lacing flats, batten plates, give up tie plates etc. Single and built-up structural shapes:

- Open sections inclusive of angles, channels and I section.

- Compound and built-up sections inclusive of double angles and double channels with are without extra plates and jointed with a few connections’ gadget.

- Closed sections inclusive of circular, square, rectangular or whole sections.

4. Behavior of Tension Members The load-deformation conduct of participants subjected to uniform tensile pressure is just like the load-deflection conduct of the corresponding simple cloth. The common pressure-stress conduct of slight metal below axial tensile load is proven.

The higher yield factor is merged with the decrease yield factor for convenience. The cloth indicates a linear elastic conduct within side the preliminary Behavior region (O to A).

The cloth Behavior undergoes Behavior enough Behavior yielding Behavior in component A to B. Further deformation ends in a boom in resistance, in which the cloth stress hardens (from B to C).

The cloth reaches its last pressure at factor C. The pressure decreases with boom in in addition deformation and breaks at D. The excessive power metal participants do now no longer showcase the properly described yield factor and the yield region. For such materials, the 0.2 percentage evidence pressure is normally taken as the yield pressure (E).

Q5) Explain Net Sectional Area and Effective Net Area?

A5)

Tension member may consist of single structural shape or a built-up section. Single angle may be found economical in most of the situation.

However, a single angle with bolted connection will produce eccentricity about both the planes, whereas a single angle with welded end connections may produce eccentricity about one plane only.

Double angle sections are used as a tie member, in a roof truss. The tension member in bridge trusses are made of built-up Channels and I-section.

Tubular members are used in a roof truss. Structural 'T' section may be used as chord members of lightly loaded truss. I-sections, channel sections and built-up sections are used in bridges where greater rigidity is required. Rods and bars are used as tension members in the bracing systems. See Fig.

Q6) What are types of failure?

A6)

Different types of failure in tension member

- Gross section yielding

- Net cross section

- Block shear failure

- Gross section yielding:

Steel member (plates, angle) without bolt holes can sustain loads up to the ultimate load without failure. However, the member will elongate considerably (10 to 15 % of its original length) at this load and hence make the structure unserviceable.

Where,

Fy = yield strength of the materials in MPa

Ag = gross area of cross section in mm2

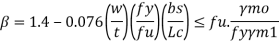

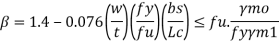

2. Net section rupture:

This occurs where tension member connected to the main or other member by bolts or weld. The holes made in members for bolts will reduce the cross section, and hence net area will govern the failure in this case.

Where

w = outstanding lag effect

Bs = shear lag width

For preliminary sizing the rupture strength of net section may be approximately taken as

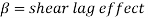

3. Block shear failure:

Block shear failure considered as a potential failure made at the ends of an axially loaded tension member. In this failure mode, the failure of the member occurs along a path involving tension on one plane and shear on a perpendicular plane along the fasteners.

Where,

Avg= minimum gross and net area

Fu and fu = ultimate and yield stress due to the materials resp.

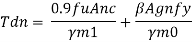

Q7) Explain Design Strength of Tension Members?

A7)

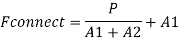

1) Design strength due to gross section yielding (IS800-2007, Cl.6.2)

Steel members (plates, angles, etc) without bolt holes an sustain loads up to ultimate load without failure. However, the members will elongate considerably (10to15% of its original length) at this load and hence make the structure unserviceable. Hence the design strength Tdg is limited to the yielding of gross section which is given by,

Where

= yield strength of the material in MPa

= yield strength of the material in MPa

= gross area of cross section in mm^2

= gross area of cross section in mm^2

= 1.10= partial safety factor for failure at yielding

= 1.10= partial safety factor for failure at yielding

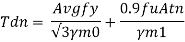

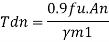

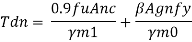

2) Design strength due to net section rupture

This occurs when the tension member is connected to the main or other members by bolts or weld. The holes made in members for bolt will reduce the cross section and hence net area will govern the failure in this case.

Design strength in tension of a plate

Q8) What is Slenderness Ratio (λ) and Displacement?

A8)

Slenderness ratio:

1. A tension member in which a reversal of direct stress occurs due to loads other than wind or seismic forces is maximum effective slenderness ratio is 180

2. A member subjected to compressive force resulting only from a combination of wind or earthquake action, provided the deformation of such a member does not adversely affect the stresses in any part of the structure is maximum effective slenderness ratio is 250

3. A member normally acting as a tie in a roof truss or a bracing member which is not considered effective when subject to reversal of stress resulting from the action of wind or earthquake force is maximum effective slenderness ratio is 350.

4. Member always in tension is maximum effective slenderness ratio is 400.

Displacement:

The displacement, this is growth in duration of hysteria member, below carrier load is given through Δ = PL/E Ag,

In which Δ = Elongation of member in mm,

P= un factored axial load in N,

L = duration of member in mm,

E = elastic modulus = 2×105MPa,

Ag = gross pass sectional location of member in mm2.

Q9) Explain Design of Tension Member?

A9)

The following steps can be accompanied within side the layout of axially loaded anxiety participants.

- Corresponding to the loading on the shape of which the anxiety member is a part, the tensile pressure within side the member is first computed.

- The internet vicinity required for the member is decided via way of means of dividing the tensile pressure within side the member via way of means of the permissible tensile pressure.

- Now, an appropriate phase having gross vicinity approximately 20 in step with cent to twenty-five in step with cent extra than the predicted vicinity is decided on. For the member decided on deductions are made for the vicinity of rivet holes and the internet powerful vicinity of the phase is decided. If the internet vicinity of the phase of the member so decided is extra than the internet vicinity requirement predicted in step i, the layout is taken into consideration safe.

- The slenderness ratio of an anxiety member shall now no longer exceed 400. In the case of an anxiety member vulnerable to reversal of pressure because of the motion of wind or earthquake, slenderness ratio shall now no longer exceed 350. If the reversal of pressure is because of masses others than wind or earthquake, the slenderness ratio shall now no longer exceed 180.

- Gross section yielding:

Steel member (plates, angle) without bolt holes can sustain loads up to the ultimate load without failure. However, the member will elongate considerably (10 to 15 % of its original length) at this load and hence make the structure unserviceable.

Where,

Fy = yield strength of the materials in MPa

Ag = gross area of cross section in mm2

6. Net section rupture:

This occurs where tension member connected to the main or other member by bolts or weld. The holes made in members for bolts will reduce the cross section, and hence net area will govern the failure in this case.

Where

w = outstanding lag effect

Bs = shear lag width

For preliminary sizing the rupture strength of net section may be approximately taken as

7. Block shear failure:

Block shear failure considered as a potential failure made at the ends of an axially loaded tension member. In this failure mode, the failure of the member occurs along a path involving tension on one plane and shear on a perpendicular plane along the fasteners.

Where,

Avg= minimum gross and net area

Fu and fu = ultimate and yield stress due to the materials resp.

Q10) What is Lug Angles?

A10)

Lug perspective is small piece of perspective used to attach outstand legs of the contributors to the gusset plate.

The motive of lug perspective is to lessen the period of connection to the gusset plate and to lessen shear lag effect.

If lug perspective is used then the unconnected period of predominant perspective behaves like a linked leg and whole pass phase area of the perspective become effective in resisting anxiety. So, if lug perspective is used, then efficiency of the anxiety member will increase as it reduces shear lag effect.

If lug perspective is used the consequent response at bolt vicinity 1 and a pair of by skip via CG of pass phase Since motion and response by skip via CG of perspective, pressure and pressure distribution are uniform consequently no shear lag

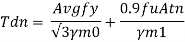

DESIGN OF LUG ANGLE

Bolt 1- bolt connecting essential perspective and gusset plate.

Bolt 2- bolt connecting out stand legs of essential perspective and lug perspective. Bolt 3- bolt connecting lug perspective and gusset plate.

Since lug perspective is used, there is no shear lag effect in essential perspective and lug perspective. Entire cross section area of lug perspective is powerful in resisting tension.

The bolt connecting outstand legs of essential perspective and lug perspective (bolt 2) must start in advance of all other bolt to make certain that outstand leg of essential perspective transfers the weight to the lug perspective effectively.

The minimal range of bolts for use in lug perspective (bolt 3) is identical to 2

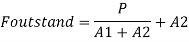

When angle section is used as main member

1) Force is connected in leg

Where,

A1= Gross sectional area of connected leg

A2= Cross sectional area of outstand or unconnected leg

So applied P is shared by two legs in proportional to their area

2) Force in outstand leg

3) Design force for lug angle = 1.2 X F outstand

4) No. Of bolt at 1 = n1 = F connect / Rv

5) No. Of bolts at 2 = n2 = (1.4 X F outstand)/ Rv

6) No. Of bolt =n3= (1.2 X F outstand)/ Rv

Q11) What is Splices?

A11)

Non-touch/ contact anxiety lap splices wherein anxiety masses are transferred among adjoining bars thru compression struts and hoop stresses within side the concrete immediately surrounding the spliced bars are applied to broaden the yield power of the brand-new bars.

Design policies for anxiety splices are extensively similar to the ones for hanger connections. In buildings, splices have to increase the electricity required through the stresses at factor of splice.

For groove welds, however, the overall electricity of the smaller spliced member has to be developed. In dual carriageway bridges, splices have to be designed for the bigger of the following: 75% of the electricity of the member or the common of the calculated strain at factor of splice and the electricity of the member there. Where a phase modifications length at a splice, the electricity of the smaller phase can be utilized in sizing the splice

In anxiety splices, the electricity of the member has to be calculated for the internet phase. In railroad bridges, anxiety splices in major participants have to have the identical electricity because the participants. Splices in secondary and bracing participants have to increase the common of the electricity of the participants and the calculated stresses on the splices

Compared with compression participants, which might be commonly designed for buckling resistance, anxiety participants are commonly plenty greater narrow and feature a smaller cross-sectional area.

Tension participants which might be possibly to be spliced include:

a. Anxiety chords and internet participants in trusses and lattice girders

b. Anxiety braces and bracing participants

c. Hangers

d. Ropes

Any kind of structural shape - open or hole, unmarried or compound - is suitable for anxiety participants. The maximum not unusual place sections used on this recognize are: rods, flats, channels and angles. For big tensile forces, H and I sections and round or square hole sections may be used.

Tensile pressure is transmitted with the aid of using the plate factors of the structural anxiety member in percentage to their cross-phase areas.

The splice plate(s) related to every plate detail ought to be designed to withstand the applicable tensile pressure component. Most splices in anxiety participants use splice plates and overlapped connections. Butt-welded splices are completed in unique circumstances; end-plated splices aren't regularly used besides for hole sections.

Bolted Splice Plated Connections

There are kinds of bolted splices for anxiety participants, they make use of:

a. Bearing bolts, while no unique attention is given to slide within side the splices

b. Slip-resistant bolts, which save you any slip within side the splice below carrier situations and likely on the last restriction nation of the connection.

Consequently, they offer the joint and the anxiety member with a bigger extensional rigidity. In bolted connections, the last member energy is decreased with the aid of using the bolt holes; it is able to additionally be decreased with the aid of using the partial effectiveness and secondary bending because of eccentricity within side the connection. In layout the have an impact on of the bolt holes is recounted with the aid of using checking the internet phase.

Some account is taken of stress hardening so the layout energy can also additionally nonetheless in shape that of the gross phase. Partial energy and eccentricity results are protected with the aid of using empirical rules. Both subjects are addressed.

Q12) What is Gusset Plate?

A12)

A gusset plate is a skinny metallic object, normally manufactured from steel, this is used to join unbiased contributors of a shape to every different or to a beam to useful resource alignment.

Gusset plates are utilized in joint, bend or in any other case disjointed structural places that require extra help to resist stresses

Gusset plate is a plate for connecting beams and girders to columns.

A gusset plate may be fixed to an everlasting member both through bolts, rivets or welding or a mixture of the three.

They are utilized in bridges and buildings, in addition to different structures

Uses:

Gusset plates are used for diverse systems.

Gusset plates are used to attach beams and columns collectively or to attach truss members. They may be both the handiest manner of connecting the beam and columns or they may be used with bolts and welds.

Gusset plates are consequently utilized in maximum steel weight-bearing systems, however the cloth and length of the gusset plate varies primarily based totally at the structure.

Bridges normally require thick sheets of metallic for his or her gusset plates, however trusses every now and then handiest require small sheets of aluminum for his or her gusset plate.

The length and electricity of the gusset plate relies upon on length and the feature of the structure.

The large the pressure at the connecting members, the bigger the dimensions of the gusset plate

Gusset plates offer a clean manner to retrofit systems which could not competently assist the implemented loads.

Example

The tension member of a roof truss consists of two unequal angles 70 x 45 x 8 with the longer legs connected by 16 mm diameter rivets. Find the safe tension for the member, the angles being one on either side of the gusset plate.

Solution

Gross area of 2 angles, 70 x 45 x 8= 1,712 mm2

Area of 2 rivet holes, 2 x (16 + 1.5) x 8 = 280 mm2

Net area of the member, 1712 – 280 = 1,432 mm2

Therefore, safe tension for the member = 150 x 1432 = 2,14,800 N = 214.8 kN