Unit - 5

Properties of Pure Substance

Q1) Explain the difference between 2 stroke and four stroke engine ?

A1)

Difference Between Two Stroke and Four Strokes | |

Two Strokes | Four Stroke |

| It has two revolutions of the crankshaft during one power stroke |

Ii. It generates high torque | It generates less torque |

Iii. Its uses port for fuel’s outlet and inlet | It uses valves for outlet and inlet of a fuel |

Iv. Its engines result in lesser thermal efficiency | Its engines result in higher thermal efficiency |

v. It has a larger ratio in terms of power to weight | It has a lesser ratio in terms of power to weight |

Vi. It generates more smoke and shows less efficiency | It generates less smoke and shows more efficiency |

Vii. Requires more lubricating oil as some oil burns with the fuel | Requires less lubricating oil |

Viii. Due to poor lubrication, more wear and tear occurs | Less wear and tear occurs |

Ix. Engines are cheaper and are simple for manufacturing | Engines are expensive due to lubrication and valves and are tough to manufacture |

x. Engines are basically lighter and are noisy | Engines are basically heavier because its flywheel is heavy and are less noisy |

Q2) Explain the difference between Compressed ignition engine or Diesel engine and spark ignition engine or Petrol engine ?

A2)

S.no | Parameter | SI Engine | CI Engine | ||||

1. | Definition | It is an engine in which the spark is used to burn the fuel. | It is an engine in which heat of compressed air is used to burn the fuel. | ||||

2. | Fuel used | Petrol is used as fuel. | Diesel is used as fuel. | ||||

3. | Operating cycle | It operates on Otto cycle. | It operates on Diesel cycle. | ||||

4. | Compression ratio | Low compression ratio.(6 to 10) | High compression ratio.(15 to 25) | ||||

5. | Thermal efficiency | Low thermal efficiency because of low compression ratio .Up to 26 %. | High thermal efficiency because of high compression ratio up to 40%. | ||||

6. | Method of ignition | Spark plug is used to produce spark for the ignition. | Heat of compressed air is used for the ignition. | ||||

7. | Engine Speed | High speed engines. | Low speed engines. | ||||

8. | Pressure generated | Low pressure is generated after combustion. About 10 bar | High pressure is generated | ||||

9. | Constant parameter during cycle | Constant volume cycle. | Constant pressure cycle. | ||||

10. | Intake | Air + fuel. | Only air. | ||||

| Weight of engine | Si engine has less weight. | CI engine are heavier. | ||||

12. | Noise production | It produces less noise. | It produces more noise. | ||||

13. | Production of hydrocarbon | Less Hydrocarbon is produced. | More hydrocarbons is produced. | ||||

14. | Starting | The starting of SI engine is easy. | The starting of CI engine is difficult. | ||||

15. | Maintenance cost | Low | High | ||||

16. | Vibration problem | Less | Very High | ||||

17. | Cost of engine | Less cost | High cost | ||||

18. | Volume to power ratio | Less | High | ||||

19. | Fuel supply | Carburettor | Injector | ||||

20. | Application | It is used in light commercial vehicles like motorcycle, cars. | It is used in heavy duty vehicles likes bus, trucks, ships etc. | ||||

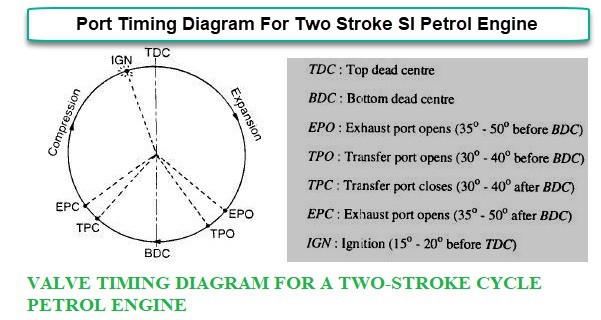

Q3) Explain valve timing diagram of two stroke S.I engine?

A3)

In the valve timing diagram, as shown we see that the expansion of the charge (after ignition) starts as the piston moves from TDC towards BDC.

Valve timing diagram for 2 stroke petrol engine

Valve timing diagram for 2 stroke petrol engine

- First of all, the exhaust port opens a fraction of the crank revolution, the transfer port also opens and the fresh fuel-air mixture enters into the engine cylinder. This is done as the fresh incoming charge helps in pushing out the burnt gases.

- Now the piston reaches BDC and then starts moving upwards. As the crank moves a little beyond BDC, first the transfer port closes and then the exhaust port also closes. This is done to suck fresh charge through the transfer port and to exhaust the burnt gases through the exhaust port simultaneously.

- Now the charge is compressed with both ports closed and then ignited with the help of a spark plug before the end of the compression stroke. This is done as the charge requires some time to ignite. By the time the piston reaches TDC, the burnt gases (under high pressure and temperature) push the piston downwards with full force, and the expansion of the burnt gases takes place.

- It may be noted that the exhaust and transfer ports open and close at equal angles on either side of the BDC position.

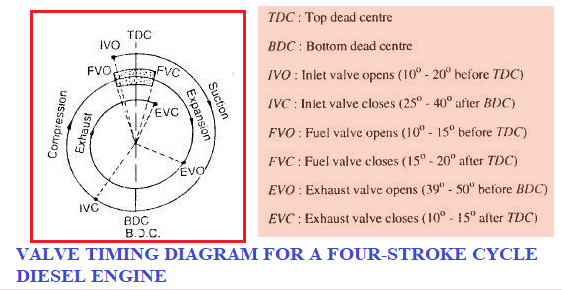

Q4) Explain valve timing diagram of four stroke C.I engine ?

A4)

In the valve timing diagram as shown we see that the inlet valve opens before the piston reaches TDC; or in other words while the piston is still moving up before the beginning of the suction stroke.

Valve timing diagram for 4 stroke CI Engine

- Now the piston reaches the TDC and the suction stroke starts. The piston reaches the BDC and then starts moving up. The inlet valve closes, when the crank has moved a little beyond the BDC.

- This is done as the incoming air continues to flow into the cylinder although the piston is moving upwards from BDC. Now the air is compressed with both valves closed. The fuel valve opens a little before the piston reaches the TDC. Now the fuel is injected in the form of very fine spray, into the engine cylinder, which gets ignited due to the high temperature of the compressed air. The fuel valve closes after the piston has come down a little from the TDC. This is done as the required quantity of fuel is injected into the engine cylinder. The burnt gases (under high pressure and temperature) push the piston downwards, and the expansion or working stroke takes place.

- Now the exhaust valve opens before the piston reaches BDC and the burnt gases start leaving the engine cylinder.

- Now the piston reaches BDC and then starts moving up thus performing the exhaust stroke. The inlet valve opens before the piston reaches TDC to start suction stroke. This is done as the fresh air helps in pushing out the burnt gases.

- Now the piston again reaches TDC, and the suction starts. The exhaust valve closes when the crank has moved a little beyond the TDC. This is done as the burnt gases continue to leave the engine cylinder although the piston is moving downwards.

Q5) Explain different kind of thermal efficiency in internal combustion engine ?

A5)

There are different kind of efficiency are there

- Indicated power (I.p): The power actually developed by engine cylinder or Indicated power is defined as the power developed by combustion of fuel in the combustion chamber (ip).

Indicated power (I.p): brake power + friction power

The indicated power (I.P.) of the engine can be calculated as follows:

I..P. = (pm x 105 x L. x A x N x n x k )/60

Pm = Inicated mean effective pressure in bar

L = Length of stroke in metre

A = Piston areas in m2

N = Speed in R.P.M.

n = Number of working stroke per minute.

n = 1 for two stroke engine

n= 1 / 2 for four stroke engine

k= number of cylinders

Ii. Brake power ( B.P): The power available at crankshaft is called brake power . It is measured by means of brake mechanism either prony or rope brake.

For prony brake = 2 Π N T / 60 Watt

For rope brake =(w-s) Π (D+d)N / 60

Iii Mechanical efficiency : it is ration of brake power to indicated power

Efficiency = B.P / I.P

i.v Indicated thermal efficiency : It is the ration of indicated work done to the energy supplied by the fuel .

η (ith)= I.P (KJ/s)/ energy in fuel per second (KJ/s)

= I.P / mf x cv

V Brake thermal efficiency: It is the ratio of power obtained at shaft to the energy supplied by fuel.

η (b.t.e)= B.P (KJ/s)/ energy in fuel per second (KJ/s)

= B.P / mf x cv

Vi Air standard efficiency : It is the ratio of work output to heat input

For petrol η= 1- 1/ ry-1

For diesel η = 1- 1/ ry-1 [ py-1 / y(p-1) ]

Where p = cut off ratio = v3 / v2 .

Q6) In an air standard Otto cycle, the compression ratio is 7 and the compression begins at 35oC and 0.1 MPa. The maximum temperature of the cycle is 1100oC. Find

(a) the temperature and the pressure at various points in the cycle,

(b) the heat supplied per kg of air,

(c) work done per kg of air,

(d) The cycle efficiency and

(e) The MEP of the cycle.

A6)

Given T1=35oC=308 K

P1=0.1 Mpa

T3=1100oC=1373 K

r=v1/v2=7

(a) The temperature and the pressure at various points in the cycle,

We know that P2/P1 = (V1 /V2)y = 71.4

Hence, P2=1524 k Pa

We also know that T2 / T1 = (V1/V2) y-1 = 71.4

We get T2=670.8 K

For process, 2-3, P2V2 / T2 = P3V3 / T3

P3 = T3 P2 /T2

P3 = 1373 X 1524 / 670.8

P3 = 3119.34 kPa

Process 3-4 is isentropic T3/T4 = (V4 /V3)y-1 = 71.4-1

T4 = 1372 / 2.178

T4 =630.39 K

(b) The heat supplied per kg of air,

Heat input = Qin= cv (T3-T2)

=0.718(1373–670.8)

= 504.18 kJ/kg

Heat rejected = Q out= cv(T4-T1)

=0.718(630.34–308)

= 231.44 kJ/kg

(c) Work done per kg of air,

The net work output Wnet=Qin-Qout

The net work output, Wnet=Qin-Qout

=272.74 kJ/kg

(d) The cycle efficiency

Thermal efficiency, ηth otto=Wnet/Qin

=0.54 =54 %

Otto cycle thermal efficiency, ηth,otto =1-1/rγ-1

= 1-1/70.4 = 0.54 or 54 %

v1=RT1/P1 =0.287 x 308 / 100=0.844 m3/kg

(e) The MEP of the cycle

MEP = Wnet/(v1–v2) = 272.74/v1 (1-1/r)

=272.74/0.844(1-1/7)

=360 kPa

Q7) In a Brayton cycle or joule based power plant, the air at the inlet is at 27oC, 0.1 MPa. The pressure ratio is 6.25 and the maximum temperature is 800oC. Find

(a) The compressor work per kg of air

(b) The turbine work per kg or air

(c) The heat supplied per kg of air, and

(d) The cycle efficiency

A7)

Given T1 = 27°C = 300 K

P1 = 100 kPa

Rp = 6.25

T3 = 800°C = 1073 K

Since process, 1-2 is isentropic,

T2/T1 = (rp) y-1/y

=6.25 1.4-1 /1.4

= 1.689

T2 = 1.689 X 300

= 506.69 K

(a) The compressor work per kg of air

W comp= cp(T2-T1)

= 1.005(506.69-300)

= 207.72

The compressor work per unit kg of air is 207.72 kJ/kg

Process 3-4 is also isentropic,

T3/T4 = (rp) y-1/y

= (6.25 )1.4-1 /1.4

= 1.689

T4 = T3 / 1.689

= 1073 /1.689

= 635.29K

(b) The turbine work per kg or air

W TURB = cp(T3-T4)

= 1.005 (1073-635.29)

= 439.89 KJ.Kg

The turbine work per unit kg of air is 439.89 kJ/kg

(c) The heat supplied per kg

Heat input, Qin = cp(T3-T2)

= 1.005(1073-506.69)

Heat input per kg of air is 569.14 kJ/kg

(d) The cycle efficiency

Cycle efficiency,

ηth = (Wturb-Wcomp)/Qin

=(439.89-207.72)/569.14

=0.408 or 40.8%

Q7) What is carburettor?

A8)

Petrol engines are designed to take in exactly the right amount of air so the fuel burns properly, whether the engine is starting from cold or running hot at top speed. Getting the fuel-air mixture just right is the job of a clever mechanical gadget called a carburetor: a tube that allows air and fuel into the engine through valves, mixing them together in different amounts to suit a wide range of different driving conditions.

The carburetor is called the 'Heart' of the automobile, and it cannot be expected that the engine will act right, give the proper horse-power, or run smoothly if its 'heart' is not performing its functions properly.

Q8) The following data was recorded during testing of a Two Stroke gas engine:

Diameter of the piston d= 150 mm

Stroke length L= 180 mm

Clearance volume Vc = 0.89 litre

RPM of the engine N = 300

Indicated mean effective pressure pm= 6.1 bars

Gas consumption m. = 6.1 m3/h

Calorific value of the gas (fuel) CF = 17000 kJ/m3

Determine the followings:

a) Air Standard Efficiency

b) Indicated power (IHP)developed by the engine

c) Indicated thermal efficiency of the engine

A9)

Swept volume Vs = πd2L/4 = π(0.150)2 x 180/4 = 0.00318 m3

Clearance volume Vc= 0.00089 m3

Total volume = Swept volume + clearance volume

= 0.00318 + 0.00089 = 0.00407 m3

Compression ratio γ = Total volume/Clearance volume

= 0.00407/0.00089 = 4.573

a) Air standard Efficiency

η = 1 –1/(r)γ—1 = 1—1/(4.573)1.4—1

= 0.456 = 45.6 %

b) Indicated power IHP = 100 pLAN/60

When p is in bars

= 100 x 6.1x 0.180 x [π(0.150)2/4] 300/60

= 9700 W

(c ) Indicated Thermal Efficiency

ηit = Indicated power in (kJ/s)/Heat supplied in (kJ/s)

= (9700/1000)/(6.1 x 17000/3600)

= 0.3367 = 33.67 %

Q9) A Four Stroke petrol engine have given data below

Air fuel ratio 15.5: 1

Calorific value of fuel 16000 kJ/kg

Air Standard Efficiency: 53%

Mechanical Efficiency: 80 %

Indicated Thermal Efficiency: 37 %

Volumetric Efficiency: 80 %

Stroke/bore ratio: 1.25

Suction pressure: 1 bar

Suction Temperature: 270C

RPM: 2000

Brake Power: 72 kW

Calculate the followings:

a) Brake specific fuel consumption

b) Bore and stroke

A10)

Find compression ratio from air standard efficiency

η = 1 –1/(r)γ—1

0.53 = 1 –1/(r)1.4—1

r = 6.6

IHP = BP/Mech efficiency = 72/0.80

= 90 kW

ηit =IHP/(Sp.Fuel Consp x Cal value)

0.37 = 90/sfc x 16000

Sfc is specific fuel consumption

Sfc = 0.0152 kg/s

a) Brake specific fuel consumption

Brake sfc = sfc IHP/BP

= 0.0152/72

=0.00021 kg/s /kW

Brake sfc = 0.7601 kg/kWh

b) Bore and stroke

Bore and stroke of the engine

Mass of air fuel mixture/kg of fuel = 15.5 +1 = 16.5

Mass of fuel supplied to the engine = 0.0152 x 16.5 = 0.2508

Volume of air fuel mixture = mRT/p

=0.2508 x 287 × 300/ (1×105)

V = 0.2159 m3/s

Swept volume = volume of mixture supplied/vol efficiency

Vs = 0.2159/0.80= 0.2699

Vs = (πd2L/4) n x (rpm/2) /60

Where n is the number of cylinders

= (πd2 x 1.25 d/4)n rpm/120

d= 0.152 m= 152 mm

L = 190 mm

Q10) if a gasoline engine has an efficiency of 30%, what would be the hot reservoir temperature for a Carnot engine having that Engine efficiency if it runs with a cold reservoir temperature of 200 ºC?

A11)

Maximum efficiency of a Carnot engine e max = (Thigh – Tlow)/Thigh

If emax = 0.3, then 0.3 = 1 – (473 K)/Thigh

Thigh = 473/0.7 = 675.7 K = 402.7 oC