Unit - 5

Waste Water Treatment

Q1) What are the Physical Characteristics of Sewage?

A1)

The physical status of the sewage can be studied under the following norms:

A: The colour of the sewage

- The colour of the fresh sewage is determined by the contents in it i.e. vegetables, food contents etc. when the decomposition starts, the colour becomes black.

- The sewage from the septic is blackish from the beginning. The industrial sewage i.e. the effluent from different industries has different colours e.g. Red, yellow, white, black etc.

- The colour depends upon the manufacturing process and the type of raw material used e.g. the paper and pulp industry has the effluent of different color than that of the chemical industry.

B: The odour of sewage

- Like colour, the odour also varies from domestic to industrial and from one type of industry to another type e.g. The domestic sewage, when fresh has oily odour bat after say two to four hours, once the sulphur compounds are produced like, hydrogen sulphide, very offensive, foul odour is developed.

- Together with the quality of material in the sewage, the temperature is another parameter to fix the time required to change the odour, higher temperature, brings fast change in the normal odour of the sewage, as it needs less time for decomposition.

C: The temperature of sewage

- In case of domestic sewage the change in the sewage temperature is very less, but the industrial sewage has a very high temperature.

- It depends mainly upon the type of industry and the manufacturing e.g. In case of chemical industries, the temperature of the effluent is almost 70°C and in case of paper and pulp industry, the average temperare is about 40°C.

D: The Turbidity of the Sewage

- The turbidity of the sewage depends on the proportion of the solid material in the sewage in the suspended state. If the suspended solid material is more the sewage becomes more turbid i. More muddy.

E: The Solids in the Sewage

- On an average the solids in various forms like suspended, dissolved and in the colloidal state hardly cover 00.01 percent of the sewage (99.99% is water only).

- The suspended solids can be filtered out by using either asbestos mats or the filter paper. The filtered sewage is heated to evaporate the water. The remains are the dissolved matters. The colloidal solid matter is non-settleable suspended solids, which do not get settled in the sewage.

Q2) What are the Chemical Characteristics of Sewage?

A2)

- The chemical contents in the sewage mainly depend upon the source of the sewage i.e. the domestic sewage has maximum complex organic material derived from the foods, fruits, vegetables residual parts, from the kitchen sinks.

- Human facces from W.C. And detergents from the wash basin and bathrooms. While the industrial sewage has a lot of chemicals which depends upon the type of industry and the manufacturing process e.g. the leather and the food processing industries have a lot of organic material in the sewage while, the petro-chemical and the plastic manufacturing industries have a high proportion of chemicals in the sewage.

- Normally the fresh sewage is alkaline in nature but as it settles down it gets converted into acidic forms in stale condition.

- The organic compounds can be divided into two types such as, the organic material containing Nitrogea and the Organic Compounds which are free from Nitrogen. e.g. urea, proteins, amino acids etc. are the Nitrogeneous, compounds and sand, gravel, debris etc. are the inorganic material, present in the sewage coming from the street-washing. The sewages coming from the bathroom, kitchen or the industrial plants; have a lot of salts and alkaline, inorganic materials.

- The sewage treatment to remove the chemicals from the sewage changes as the type and the proportion of chemical contents, vary.

Q3) What are the Biological characteristics of sewage?

A3)

- The sewage containing excremental matter has a lot of Bacteria but all of them are not harmful, except the pathogenic teria. The harmless bacteria, help and provide a natural treatment to the sewage and reduce the treatment cost.

- The organism in the sewage can broadly be classified as:

- Macroorganism or Macroscopic organism

- Microorganism or Microscopic organism

- Following living organisms are found in the sewage; the type and the percentage of organisms vary from the source of the sewage.

- Bacteria

- Algae

- The Fungi

- The protozoa

Q4) What are the types of sewerage system?

A4)

On the basis of the system to convey the sewage, the sewerage systems can be further classified. Let us study some of the important systems to know their characteristics, their merits and their limitations or their demerits.

- The Combined System

- The Separate System

- The Partially Separate System

Combined System

- When only one set of sewer is laid to convey both the sanitary sew ge and the storm water, it is known as the combined system.

- This system has the following merits:

- In this system, no flushing or pumping is required because due to mixing of the storm water, it gets the required self-cleaning velocity.

- Due to dilution of the sewage through the storm water i.e. the rainwater, it becomes easy to treat the sewage after it reaches the final point of treatment.

- The house plumbing becomes easy and cheap as only one set of pipeline is required in this system.

- The demerits or the limitation of combined system

- It needs to have higher initial cost of construction.

- This system is not suitable for the areas where the rainy season is limited to a small portion of the year, as the dry-weather-sewage flow will be limited with lesser velocity which would be insufficient to develop self-cleaning velocity. This leads to blocking of the sewers due to siltation.

- It becomes non-economical if the whole sewage is required to be disposed off by pumping.

- In case of heavy rainfalls, the sewers get overflowed which create public health problems.

Separate System:

- In this system, the domestic and the industrial sewage are carried by one set of sewers and the storm and the surface water are carried by another separate set of sewers.

- It has the following merits and demerits or limitations.

Merits of the separate system

- As separate sets are used to convey the sewage and the storm water the quantity of sewage to be treated remains limited, so the design of the treatment plant can be made economical i.e. Needs less cost for treatment.

- The initial cost of the sewers is less in, this system because the foul sewage is carried through the closed sewers while, the storm water, surface flow which is not of foul nature, is carried through the open gatters or drains.

- There no danger of over flowing of sewage and so no danger of sub-soil pollution.

- If the sewage is to be pumped during the process of disposal; this system always is economical, as it has to handle less load.

The demerits or limitations of the separate system

- As the sewage is carried separately, it does not have the capacity, to generate the self-cleaning velocity. So additional flushing points are required to be provided, so get smooth conveying this adds to the cost.

- In case, the storm water enters into the sanitary sewers, it may cause over-flowing condition and also may create extra load on the treatment plant.

- As it has to maintain two sets of sewers, the maintenance cost is always higher than the combined system.

- It is difficult to lay two sets of sewers, in busy lane, mainly at the time of repairs; it creates problem to the heavy traffic.

Partially Separate System:

- It is like separate system only but the only difference between these two system is that in this, a part of the storm. Water is allowed to enter into the sewage carrying sewers while the rest of the surface and storm water is allowed to flow through the separate sewers.

The merits of the partially separate system

- This being an improved "separate system" it has all the advantages of combined and separate systems.

- As, only part of the storm water is allowed to enter the sewage sewers, the size of the sewers are economical i.e. not too large, to increase the cost.

- The house plumbing works also can be carried by one single pipe which can carry the cullage from the bathrooms and kitchens together with the rain water received on the roofs and for the water, from the other sources like toilets can be carried through another pipe line.

- No flushing is necessary because by using a part of the storm-water the quantity of sewage is increased.

The demerits of the partially separate system

- As a part of the storm-water is mixed with the sanitary sewage it needs to have pumping facilities at the point of disposal. This increases the initial cost of this system.

- There is a chance of over-flow condition due to increase in the storm-water.

- During dry-summer seasons this stem does not have self-cleaning velocity. So it needs to have regular cleaning of the sewers that adds the maintenance cost.

Q5) What are the treatments given to sewage?

A5)

Preliminary Treatment:

- It consists of screening i.e. to remove the floating material.

- Grit chambers i.e. to remove sand and grit

- Skimming i.e. to remove oil and grease.

Primary Treatments:

In most of the cases the preliminary and primary treatments are conducted at the same place. So together with the above (given in Section) the primary treatment has one more process called as sedimentation.

- Plain sedimentation

- Primary clarifiers

- Secondary clarifiers

- Coagulation

Secondary Treatments:

- It is mainly confined to the biological treatment.

Tertiary Treatment:

- There treatments are confined will the treatment and disposal the sewage and the sludge with safe, economical and eco-friendly method.

Q6) What is Screen? Explain its Purpose?

A6)

- As mentioned above the waste-water i.e. the sewage has a lot suspended material e.g. The leaves of the plants, paper, timber pieces, gravel, sand, silt etc.

- The large size floating material can be moved by passing the sewage through the screens. This process passing the sewage through the screens in called as screening.

Purpose of Screening:

- It is the first step of treatment of sewage, taken with the following Purpose:

- To remove the floating material, which may clog the pumps used in the further steps of slug treatment.

- To remove the suspended material from the sewage, which may form an ugly sludge banks at the site of sewage disposal.

- To remove the solid material which will clog the trickling filters and may interfere with the activities of aeration.

Q7) What are the types of Screen?

A7)

On the basis of the shape and form the screens can be classified as,

- Racks or bar screens

- Perforated or fine screens

- Communiters or cutting screens

- Cage screen

- Band screen

On the basis of their opening size the screens can be classified as,

- Coarse screen.

- Medium screen.

- Fine screen.

On the basis of their shape they can be classified as,

- Disc screens.

- Band screens.

- Drum screens.

- Wing or cage screens.

On the basis of their functioning they can be classified as,.

- Hand cleaned screens.

- Mechanical cleaned screens.

On the basis of the site of the screens, they can be classified as,

- Fixed screens.

- Moving screens.

- Movable screens.

Q8) Explain Grit Chamber?

A8)

- The sewage has an inorganic material which is called as "Grit".

- The grit includes sand, slit, clay, glass pieces, ash egg shells cinder etc. naturally the grit varies, as the sources vary i.e. The grit of domestic sewage has different solids than the industrial wastage.

- On an average the size of the grit is small i.e. about 0.2 mm diameter. The specific gravity of grit is between 2.0 and 2.6. The grit has more settling velocity than any organic matter and it is non-putrescible.

- Due to this, settling property of the non-putrescible grit, with higher specific gravity, grit can be removed in a separate tank and the organic putrescible solids are removed in a separate tank, by the method of differential sedimentation.

Need to Remove Grit:

The grit causes a lot of problems, like

- Erosion of pump impellers

- It settles in the conveying conduits (and block them).

- It settles down with sludge and when the sludge is digested, the grit does not undergo any stabilisation, so after the treatment, the quality of the final product is still poor.

- If the grit is deposited with the sludge, without any treatment it forms the sludge bank which creates a lot of problems.

Functions of Grit Chambers / The Purpose of Architecture:

- The purpose of providing grit chambers in the sewage treatment process is to remove the inorganic materials mentioned in the introduction.

- To remove this grit, from the sewage the velocity of the flow is reduced to allow the heavy, inorganic matter to settle down, at the bottom of the grit chamber and the lighter organic matter flows down for the further separate treatment.

Location of Grit Chambers:

- Grit chambers, generally are placed after the bar screen and before organic matter settling tank. In some cases the grit chambers are placed before the screen. The location of the grit chambers depends upon, the volume of grit in the sewage, which is to be removed the local requirements.

Nature of Grit:

- The weight of the dry grit is about 1300 kg per m while in case of the wet-grit it is about 1600 kg per m the voids in the grit are about 30 % to 40% of the total volume of grit.

Sources of Grit:

- As mentioned earlier, the type and volume of grit depends upon its source, like

- Domestic

- Industrial

- Transport service station

- The above three sources are man made but the 1" rainfall of the season also brings in the grits laying on the land surface, into the natural stream water.

Volume of the Grit:

- The volume of grit in the sewage depends upon the following factors,

A: The area of unpaved surfaces in the locality.

B: The characteristics of the ground.

C: The type of the grit chamber (its design and the capacity)

D: Intensity of cleaning street (i.e. higher the intensity more will be the volume of grit)

E: Location of the grit chambers.

F: Methods of cleaning the street

G: The frequency and intensity of storms

H: Provision of catch basin

I: System of sewage, i.e. combined or separate.

Q9) What is Sedimentation Chamber?

A9)

- At the source the water may have some suspended material of large or medium or small size, it is always economical to remove such suspended matter at the source by using the method sedimentation.

- The suspended matter makes the water turbid, so before it is carried for the further treatments, by using the sedimentation method, it is better to remove, such undesired impure material from the water.

Advantages of Plain Sedimentation:

- In this process the load is reduced. So the further process, it need less time and energy.

- After this process, less variable quality of water is made available.

- The clearing cost of the coagulation basis is reduced.

- There is not loss of chemical with the sludge. For the further processes, less quantity of chemical are required, so it reduces the cost of treatment.

Chemically Assisted Sedimentation:

- It is Chemically Assisted Primary Sedimentation (CAP) method. In this method some chemicals are used to increase the processes of coagulation flocculation and finally, the sedimentation.

- This method is applied mainly in the Urban Waste Water Treatment Plants (UWWTP).

Sedimentation Tanks and their Design:

- In the process of sedimentation, the inorganic impurities are removed and the water is kept ready for the further processes before it is used for the drinking purpose.

- The sedimentation tanks are designed for giving total rest or a partial rest to the flowing water.

- As the water is allowed to settle down, the heavy inorganic material also settles down on the bed of the tank, the remaining, lighter impurities are removed from the top of the tank.

- The amount of impurities removed from these tanks, depends upon various factors like, design of the tank, the period of detention, the particle's size, the actual velocity of the flow of water etc. On an average, in these tanks, about 60% of the suspended and 75% of the bacterial impurities are removed.

- To make the method more effective coagulants are added into the water, before placing the water in the sedimentation tanks.

- Finally from these sedimentation tanks, the water is allowed to pass through the process of filtration for the further purification of the water.

Q10) Explain the Classification of Sedimentation tanks?

A10)

On the basis of the nature of working, the sedimentation tanks can be classified as, fill and draw type tanks and continuous flow type tanks. Let us study the characteristics of each type of the sedimentation tank.

- Fill and draw type tank

- Continuous flow type tanks

1. Fill and draw type tank

- These tanks are also called as Quiescent type or Intermittent type of tanks.

- The process is very easy; these tanks are allowed to be filled to their capacity and the water is allowed to settle down for a given period of time, which varies on the basis of the size and capacity of the tank to hold water.

- Once the water gets settled, the suspended matter settles down on the floor of the tank and then the water is allowed to flow out of the tank.

- After water goes out of the tank, it is cleared by taking out the settled down silt water and are kept ready for another filling.

- If this method is to be used, which needs the rest period of about 24 hrs, it is necessary to have at least another tank for the continuous supply of water.

- Third tank as a standby is useful to run this method successfully.

2. Continuous flow type tanks

- The working of this type of tank is very easy. From one edge the impure water is flown into the tank and from the other end it goes out the velocity of the water is adjusted in such manner, that the suspended, impurities are allowed to settle down.

- When the an anlity of such impurities in a form of sludge or sill, becomes sizable, by using the valves at the bottom of the tank, it is cleared and cleaned for the next filling.

Q11) Explain Design of the Sedimentation Tank / Fill and draw type?

A11)

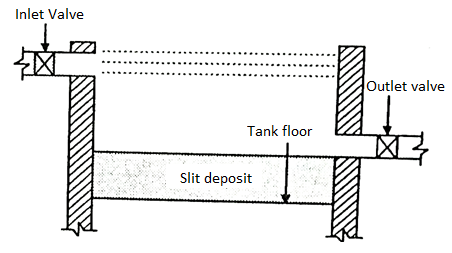

- As shown in the Fig., the cubical contents of the tank represent the capacity to store the water to be treated. The bottom part has the arrangement to be called the silt and sludge.

- The inlet or the outlet valves are fixed in opposite directions the inlet near top of the tank and outlet valve is set near the top of the silt deposition zone, near bottom of the tank.

Fig.: Section

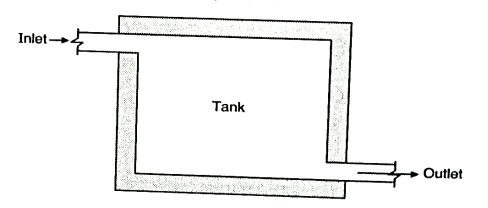

Fig.: Plan-Fill and Draw Type Tank

Efficiency of sedimentation:

- Among all the factors controlling the efficiency of sedimentation two factors are important as given below:

- The velocity of water: If the velocity is brought to zero i.e. it the water is stable by gravity the suspended solids settle down easily.

- The type of suspended solids: The efficiency depends up of the proportion and type of solids.

Q12) Explain continuous flow type sedimentation tank?

A12)

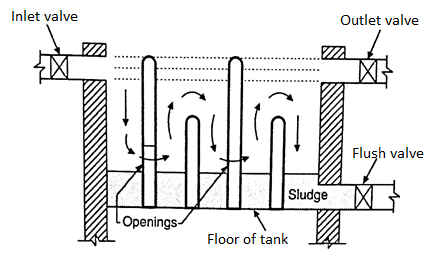

Fig.: Section

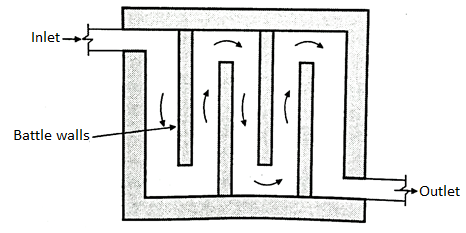

Fig.: Plan- Continuous Flow Type Tank

- As shown in Fig. In this method, the tank has the inlet on one side and out let valve on the other side. They are placed at the same level.

- They are separated by baffle walls creating separate chambers. At the bottom of the tank the arrangement is made to settle the sludge and silt. Tops

- After a given period of time the sludge is taken out through the flush valve which is kept at the bottom level of the tank.

Q13) Explain Design of Sedimentation Tank / Horizontal Flow?

A13)

Following are the various steps involved in the design of sedimentation tank having horizontal flow:

- Various assumptions in the design

- Detention time (

)

) - Displacement efficiency (

)

) - Flow through period (

).

). - Weir loading

- Zones in sedimentation tank

- Inlet zone

- Outlet zone

- Sludge zone:

- Settling zone

1. Various assumptions in the design

- Flow should be steady and uniform in the settling zone.

- The suspended particles should settle in the same manner as they settle in a quiescent tank within the settling zone.

- Particles reaching the sludge zone should be effectively removed.

- Incoming flow should be distributed uniformly over the cross-sectional area of the tank.

- The concentration of suspended particles of each size should be uniform throughout the cross section at right angle to the flow.

2. Detention time (to)

- The theoretical time for which the water is detained in the settling tank is called as detention time (t0).

Where, V = Volume of the tank = length x breadth x height

Q = Discharge of water

- Detention time varies from 4 to 8 hours and this variation depends upon type of suspended solids.

3. Displacement efficiency ( )

)

- The ratio of flow through period to the detention period is termed as displacement efficiency.

- Displacement efficiency varies from 0.25 to 0.5 for plain sedimentation tank. A flow through period (t) should be equal to at least 30% of the detention period (t) for well designed tank.

4. Flow through period (t)

- Actual time of travel of flow from the inlet to the outlet of settling tank is termed as flow through period.

- Because of short circuiting: td<to

5. Weir loading

- Water falling over the weir is called as weir loading. It is expressed as the quantity of water discharged per hour or per day per unit length of weir.

- Weir loading should not be more than 450 kilo litre/day/m in general.

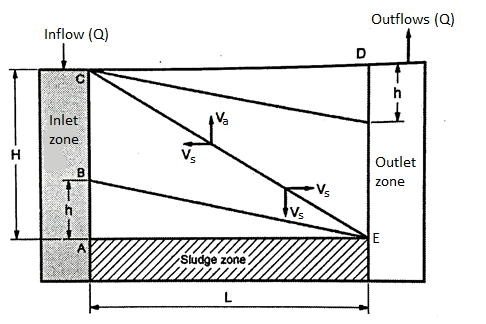

6. Zones in sedimentation tank

- It is considered to have four zones in the tank for proper designing the sedimentation tank.

- Following are the four zones to be assumed and for the design of sedimentation tank.

- Fig. Show these four zones. In the vertical cross section of tank.

Fig.: Four Zones in the Vertical Cross Section of Sedimentation tank

(i) Inlet zone

- Raw water enters in the sedimentation tank through inlet zone.

(ii) Outlet zone

- Effluent water comes out from the sedimentation tank with residual turbidity through outlet zone.

(iii) Sludge zone

- Sediments settle at the bottom in sludge zone.

(iv) Settling zone

- Discrete particles settle down in settling zone under the force of gravity. In this zone, velocity of flow is low so as to have laminar flow and there is no turbulence.

Q14) A settling tank is designed for an overflow rate of 5000 lit/m²/hr. What percentage of particles of diameter (i) 0.06 mm and (ii) 0.03 mm will be removed in this tank. Temperature of water is 20°C and specific gravity of particles is 2.65.

A14)

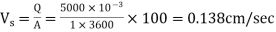

Given: Overflow rate (Q) = 5000 lit/m2/hr

Temperature (t)= 10°C.

Specific gravity (

d=Diameter of particles = 0.06 mm and 0.03 mm

Step 1: To find settling velocity ( )

)

Q = 5000 liters/hr

= ∵1

∵1

=

A=1

∴

Step 2: To find percentage of particles of diameter of 0.06mm and 0.03 mm to be removed

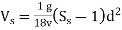

(a) For 10°C, Equation

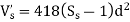

Reduces to  =418(Ss-1)

=418(Ss-1)

Where, V = Kinematic viscosity of water in centistokes

∴For 10°C,

= 2.48 mm/sec

= 0.248 cm/sec

∴% settled= ×100

×100

=

=179.71>100%

Hence all the particle of 0.06 mm diameter will settle.

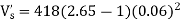

(b) For 10°C, Vs’ =418 (Ss -1) d²

= 418 (2.65-1) (0.03)²

= 0.620 mm/sec

= 0.062 cm/sec

∴ % settled = ×100=44.92%

×100=44.92%

% settled particles of 0.03 mm is 44.92% and which is to be removed.

Q15) Design a circular sedimentation tank fitted with mechanical sludge remover for water works, which has to supply water at the rate of 135 lpcd for population of 50000 persons. Use detention period as 4.5 hrs and water depth in the tanks as 3.3 metres.

A15)

Given: Population of the town = 50000 persons

Per capita demand= 135 litres/day,

Detention period=4.5 hrs

Water depth (H) = 3.3 m

Step 1: To find quantity of water to be treated

Quantity of water to be treated = 50,000 x 135 = 6.75 x 106 liters/day

Step 2: Quantity of water to be treated by the sedimentation tank

Quantity of water to be treated by the sedimentation tank during detention period of 4.5 hours.

=1.265 x 106 liters

=1265.625 cu.m ∵1m= 1000 liters

∴Q = 1266 cu.m say

Step 3: To find the diameter (D) of the tank

The capacity of circular tank having diameter D and water depth H is given by,

Q = D2 (0.011 D+ 0.785 H)

Q = D² (0.11 D +0.785 x 3.3)

1266 =D² (0.11 D + 2.5905)

1266= 0.011 D³ +2.5905 D²

∴0.011 D³ +2.5905 D² + 1266 = 0

Solving above equation, we get,

D = -237.53 and D = 1.019

D = -237.53 is not valid

D = 1.019= 1.02 m

D = 1.02 m

Step 4: To determine the size of tank

Providing an extra depth of 1.2m for sludge storage and free board, the size of the tank is 1.02 m diameter x (3.3 +1.2=4.5 m depth)

∴Size of the tank = (1.02 m diameter x 4.5 m depth).

Q16) Explain Principle and Design of Activated Sludge Digestion?

A16)

- The Activated sludge process was developed in the year 1914 in England, by Ardern and Lockett. It was named so, because the process is involved in the production of an activated mass of micro-organism, which is capable of stabilizing the waste aerobically, through a lot of modifications have taken place in the process the fundamental principles have remained the same.

- The term Activated sludge, indicates that the sludge is obtained, by settling the sewage in presence of abundant oxygen.

- The sludge is biologically active and it has a number of aerobic bacteria and some other micro-organism having an unusual property of oxidising the organic matter.

Properties of Activated Sludge:

- A: They have the fertilizing constituents

- B: The degree of aeration is indicated by the colour of the activated sludge. i.e. Light brown colour indicates, under aerated sludge. Golden brown colour indicates, well-aerated sludge and Muddy-brown colour indicates, over-aerated sludge.

- It can hold the moisture up to 95% to 97%/

Process of Activated Sludge:

- Step 1: The activated sludge is mixed with raw or partially treated sewage.

- Step 2: When the activated sludge is mixed properly with the sewage having sufficient quantity of oxygen, the micro-organisms in the activated sludge, go on multiplying vary rapidly.

- Step 3: This helps to oxidize the organic solids in the sewage.

- Step 4: Suspended and colloidal matter the sewage, gets coagulated to form a readily settle able precipitate.

- Step 5: When the precipitate settles down, the effluent is cleared from any type of organic matter; so if required the effluent is given the treatment chlorination. The part of the sludge is sent for recirculation and the remaining sludge goes to the digestion tanks.

- Step 6: This digested sludge is totally harmless and can be sent to the drying beds.

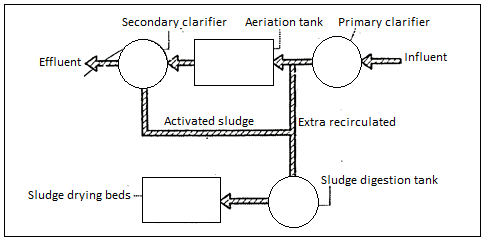

Flow Chart of the Activated Sludge Process:

Fig.: Flow Chart of Activated sludge process

- The flow chart of the activated sludge. Process indicates the stages of purification of the effluent as given below.

- Step 1: The influent is sent to the primary clarifier for proper mixing of the activated sludge and the raw or the settled sewage.

- Step 2: A part of this well mixed sewage is sent to sludge digestion tank for extra recirculation, through which it is sent to the drying beds.

- Step 3: The remaining well-mixed sewage is sent to the Aeration Tank (or Aeration Chamber) for proper agitation

- Step 4: The agitated or aerated sewage and sludge is sent to the 2nd clarifier. In this secondary clarifier the sludge is allowed to settle down. A part of this activated sludge is sent back to the process of recirculation (to be carried in the sludge digestion tank) and through that it goes to the final sludge drying beds and the effluent is sent to natural stream (which is harmless and does not pollute the natural surface stream).

Q17) What is Final Disposal of Sludge and effluents?

A17)

- The sludge or the garbage needs to be disposed very carefully to avoid any type of pollution and to avoid any unhygienic conditions and to prevent any type of public health problems.

- The method to be used for disposing the sludge depends upon its nature (quality) and its volume.

- It is necessary to have a careful analysis of the sludge before any method of disposal of that sludge is selected.

- Following are the methods used to disposed off the dry sludge and the garbage.

- Controlled tipping

- Disposal into sea

- Filling of the low-lying areas.

- Incineration

- Mechanical compost plant

- Pulverization

- Trenching

Controlled Tipping:

- In this method, the sludge is tipped in hollows to a depth of about one to two metres.

- In these hollows the coarse material is tipped at their bottoms and finer material at their tops. These tips are covered by ash or earth for about one day.

- This leads to the action of fermentation through the anaerobic bacteria's under the seal and this action is completed within a period of one year.

- After the process of fermentation is completed, the site of disposal of sludge is free from any type of germs and the site is available for any future development. Generally for a depth of about 2 meters, for the controlled tipping.

- The requirement of area is about 0.50 m² and it may vary upto 0.60 m²/per capita/per year.

Disposal into Sea Advantages:

- It can be used by the settlements which are located near the sea coast. It is a cheap method but it needs a careful disposal of the sludge into the sea. Following point, must be observed before disposing the garbage or sludge into the sea.

- A: It must be discharged at such point and at such time that due waves, currents tides it should not return to the coast.

- B: It must be carried away from the coast for about 15 to 20 km away and the depth of the sea-floor must be atleast 30 metres or more, where in the sludge is not be disposed off. The direction of the ocean current also should be thought about.

- It is a cheap, easy method to dispose off the sludge, but is has following disadvantages.

Disadvantages of Disposal into Sea:

High tide conditions

- During the high tides, the bulky but light material, which float on the surface of sea water are brought back on the coast.

Transport of garbage or sludge

- The sludge is needed to be transported into the deep sea for getting it disposed off.

- During the S.W. Monsoon season it becomes difficult for the ships or barges to carry out the transport in the stormy weather conditions.

- Under such conditions, the sludge is required to be stored (till the sea/weather conditions calm down) or to be treated by some other methods.

Filling of Low-lying Areas

- In this method the sludge is collected, conveyed and dumped in the areas which are low lying, near the locations.

- It is covered with a blanket of ash or earth to avoid the flies and vermin. If, the low lying area is available in ample this method can be applied which is a cheap method.

Advantages of filling methods:

- No separation of sludge is required.

- It is most economical method and still a simple method.

- By using this method, the areas under, water logging conditions can be reclaimed.

- No by products are developed so no further methods of disposal or treatment is required.

Disadvantages of filling method

- The insecticides are to be used to prevent fly nuisance.(This adds to the cost).

- If the garbage or sludge has undesirable matter like plastic, unused medicine, paints, sanitary material etc, it creates a problem to the nearby settlements, as some of the soluble toxic material may step down to pollute the underground water, which is used for drinking and other domestic requirements and can create the health problem.

- Low-lying areas are not easily available.

- Due to mixing of material a gas is developed which is called as fill gas. It has a foul odour and it may explode.

Incineration Method

- In the incineration plant the refuse is burnt. It is used for the hazardous waste.

- The initial cost of incineration plant is high still it has a lot of advantages as given below.

Advantages:

- It needs less labour supply.

- The heat generated through the incineration can be used for some other purpose.

- It takes the care of the public health.

- The cost goes reducing as it is used for a longer period of time.

Disadvantages:

- If it is not operated properly it may lead to develop smoke, odour, and ash.

- Skilled labour is required to run the plant.

- It needs to be located away from the settlements to avoid the air-pollution, but, so it adds to the transport cost.

Mechanical Composting Plant:

- It converts the waste into the useful manure. The purpose of this method is to develop a plant which can produce methane to support the chemical fertilisers. (to reduce the cost of agricultural inputs). It has following advantages.

Advantages of composting

- There are no health hazards.

- Certain plant-diseases can be put under control.

- By using the composing method, the soil properties can be improved. e.g. It has 0.3% of nitrogen, 0.5 to 0.8% of phosphorus, 0.6 to 0.9% of potassium. So, it enriches soil to be used for cultivation.

- Cost of compost is lesser than the chemical fertilisers.

Pulverisation:

- Without changing its chemical composition, in this method, it is converted into powder, which can be used as a fertiliser.

- It has a high density so the transport cost is reduced.

- It can also be used for land re-claimation.

Trenching:

- In this method, the dry refuse is dumped into trenches and it is converted into compost. These trenches are about 3 to 12 metres long, 2 to 3 metres wide and 1 to 2 metres deep.

- The compost developed through this method may prove to be harmful to the soil (if the original refusal has harmful contents).

- Still it is a popular method to dispose off the garbage and other refuse as it is a simple and cheap method of treatment.

Q18) Explain Self purification of streams?

A18)

- Water purification for human intake functions is composed withinside the elimination of various contaminants as chemicals (i.e., pollutants, poisonous metals), organic contaminants (algae, bacteria, fungi, parasites, viruses), suspended solids, and gases.

There are numerous strategies used withinside the water purification technique, which include: (1) bodily methods, which include filtration, sedimentation, or distillation; (2) organic methods, which include sand filters, lively carbon; (3) chemical methods, which include flocculation, chlorination, using ultraviolet light. - Regarding the bodily tactics utilized in water purification, those fluctuate withinside the phenomenon on which the methods are primarily based totally.

- For instance, filtration is primarily based totally at the separation of solids from fluids, with the aid of using interposing a porous medium (filter) which keeps the strong debris and permits the fluid to byskip on the alternative side.

- On the alternative hand, the sedimentation method makes use of the gravitational pressure which determines the solids to shape a deposit at the lowest of the tube containing infected water, even as distillation includes the transformation of the liquid (water) right into a vapor phase, technique that is primarily based totally at the distinction withinside the volatility of the compounds.

- Slow sand filters constitute one instance of organic tactics utilized in water purification, which suggests the usage of 1–2 m deep tubes full of sand, which preserve the impurities gift withinside the filtered water.

- Activated carbon (charcoal), some other applied method, is a microporous carbon with excessive floor place and more advantageous adsorption properties.

- In clinical terms, flocculation is a technique wherein colloids in suspension grow to be destabilized after the addition of a clarifying agent; concerning the water purification technique, the flocculation phenomenon can confer with the destabilization and coagulation of contaminants gift withinside the water. Water

- Chlorination is typically encountered withinside the remedy of water deliver and is composed withinside the addition of chlorine or hypochlorite to kill microbes and to save you the spreading of waterborne diseases.

- The use of electromagnetic light, specially with brief wavelength (in ultraviolet range) is typically utilized in disinfection, because of the truth that it produces gaps withinside the shape of nucleic acids of microorganisms disabling their cell functions.

- This technique is frequently utilized in water decontamination.

Q19) What is B.O.D?

A19)

- It is an important method to know about the biodegradability of the sewage sample and its strength.

- It is an important parameter to design the sewage treatment plants i.e. the size of the trickling filters and activated sludge unts.

- It is an important method to measure the self-purification capacity of the stream.

- It is an indicator of efficiency of the treatment plant i.e. it is used to check the difference between the influent and the effluent as far the B.O.D. Proportion is concerned.

Q20) What is C.O.D?

A20)

C.O.D can be defined as "It is the amount of oxygen required for the chemical oxidation of the organic matter by the strong oxidising agent under the acidic condition".

Test of C.O.D.:

- In the C.O.D. Test a strong oxidising agent is used in an acidic medium and the oxygen equipment of the organic matter that can be oxidised, is measured.

- For that test, Potassium Dichromate (K₂Cr₂O₂) is used, at a high temperature. For the fast reaction, silver sulphate is added.

- Before this test is carried out, the inorganic compounds, (which can interfere with the test) are removed from the sample; which is to be used to the C.O.D. Test.

- On an average, the C.O.D. Of any sewage is always greater thar its B.O.D. Because more compounds can be chemically exidised than the compounds which get oxidised biologically.

- The limiting value of C.O.D. Is about 250 ppm or mg / per litre.