Unit - 4

Hydraulic Circuits and Contamination Control

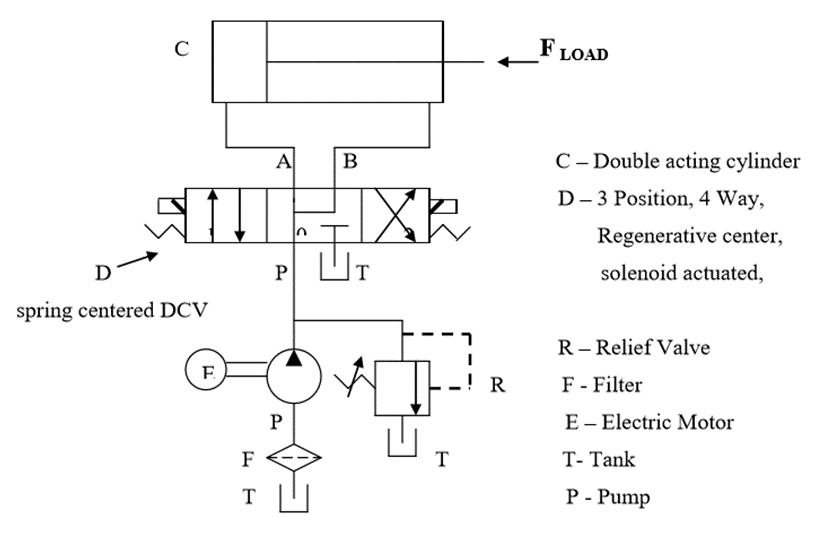

Q1) Explain the Regenerative circuit for Drilling Machine:

A1)

Figure shows an application of regenerative circuit in a drilling machine. Here a 3-position, 4way , regenerative center directional control valve is used. When the DCV is in the springcentered position, port P is connected to A and B and tank port T is blocked. In this position pump flow goes to A and flow from rod end of the cylinder also joins the pump flow to gives rapid spindle advance ( no work is done during this period )

Why does the spring-centered position give rapid extension of the cylinder (drill spindle)? The reason is simple. Oil from the rod end regenerates with the pump flow going to the blank end. This effectively increases pump flow to the blank end of the cylinder during the spring-centered mode of operation. Once again we have a regenerative cylinder. It should be noted that the cylinder used in a regenerative circuit is actually a regular double-acting cylinder. What makes it a regenerative cylinder is the way it is hooked up in the circuit. The blank and rod ends are connected in parallel during the extending stroke of a regenerative center.

When the DCV shifts to 1st position, P is connected to A and B to T gives slow feed (extension) when the drill starts to cut into the work piece. Similarly when the DCV shifts to 2nd position, P is connected to B and A is connected to T, since the ring area is less the cylinder will have fast return motion.

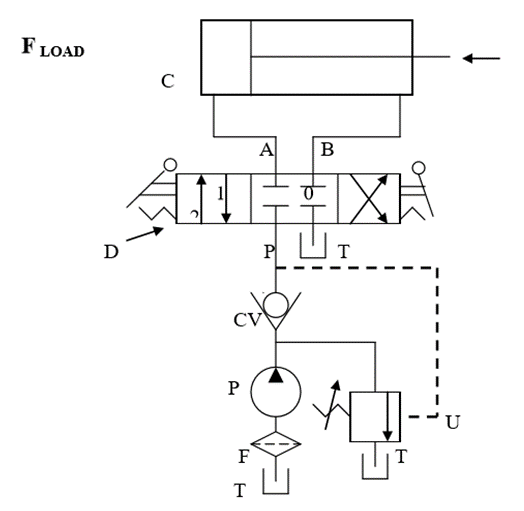

Q2) With the help of neat sketch explain the pump unloading circuit

A2)

C = Double acting cylinder

P = Pump

T = Tank

F = Filter

U = unloadingValve

D =3-position, 4 way ,closed center, Manually operated and Spring Centered DCV

Refer to the above figure, we see a circuit using an unloading valve to unload a pump. The unloading valve opens when the cylinder reaches the end of its extension stroke because the check valve keeps high-pressure oil in the pilot line of the unloading valve. When the DCV is shifted to retract the cylinder, the motion of the piston reduces the pressure in the pilot line of the unloading valve. This resets the unloading valve until the cylinder is fully retracted, at which point the unloading valve unloads the pump. Thus, the unloading valve unloads the pump at the ends of the extending and retraction strokes as well as in the spring-centered position of the DCV.

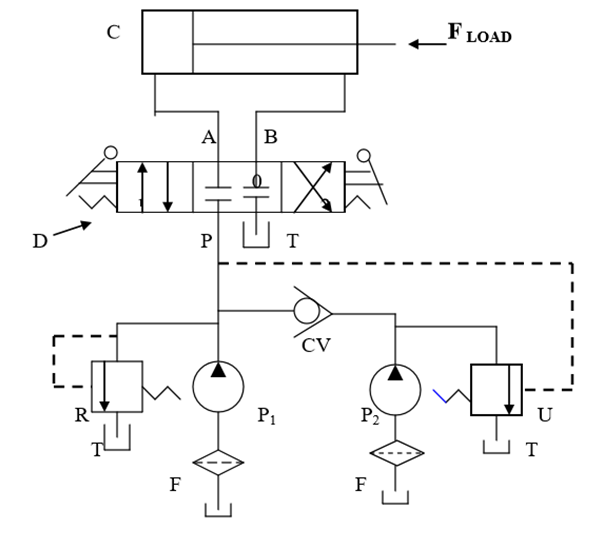

Q3) With the help of circuit diagram explain Double Pump Hydraulic system

A3)

Double pump Hydraulic system

Figure shows a circuit that uses two pumps, one high-pressure, low-flow pump and the other low-pressure, high-flow pump. One can find application in a punch press in which the hydraulic ram must extend rapidly over a large distance with very low pressure but high flow requirements. However, during the short motion portion when the punching operation occurs, the pressure requirements are high due to the punching load. Since the cylinder travel is small during the punching operation, the flow-rate requirements are also low.

The circuit shown eliminates the necessity of having a very expensive high-pressure, high-flow pump. When the punching operation begins, the increased pressure opens the unloading valve to unload the low-pressure pump. The purpose of the relief valve is to protect the high-pressure pump from overpressure at the end of the cylinder stroke. The check valve protects the low-pressure pump from high pressure, which occurs during the punching operation, at the ends of the cylinder stroke, and when the DCV is in its spring-centered mode.

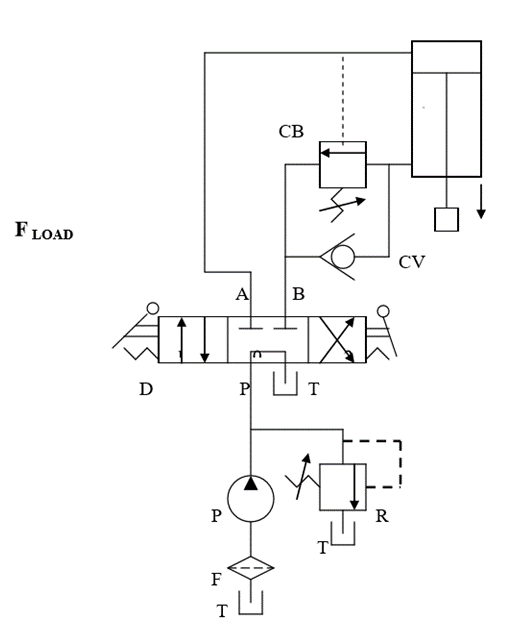

Q4) Explain the application of Counter Balance Valve

A4) Figure illustrates the use of a counterbalance or back-pressure valve to keep a vertically mounted cylinder in the upward position while the pump is idling i.e when the DCV is in its center position. During the downward movement of the cylinder the counterbalance valve is set to open at slightly above the pressure required to hold the piston up ( check valve does not permit flow in this direction ). The control signal for the counterbalance valve can be obtained from the blank end or rod end of the cylinder. If derived from the rod end, the pressure setting of the counter balance valve equals FL/ (AP-Ar ). If derived from blank end the pressure setting equals FL / AP. This pressure is less and hence usually it has to be derived from blank end. This permits the cylinder to be forced downward when pressure is applied on the top. The check valve is used to lift the cylinder up as the counterbalance valve is closed in this direction. The Tandem -center directional control valve unloads the pump. The DCV is a manually -actuated, spring-centered valve with tandem-center flow path configuration

C = Double acting cylinder mounted vertically

P = Pump

CB = Counter Balance Valve

CV = Check Valve

T = Tank

F = Filter

R = Relief Valve

D =3-position, 4 way , Tandem center, Manually operated and Spring return DCV

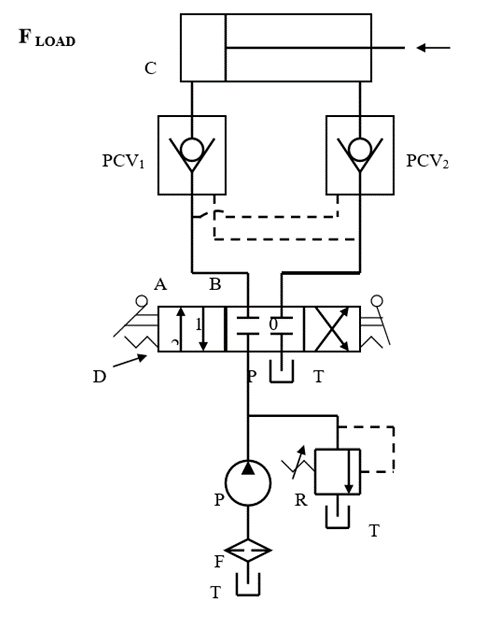

Q5) Explain the application of pilot check alve for locking double acting cylinder

A5) In many cylinder applications, it is necessary to lock the cylinder so that its piston cannot be moved due to an external force acting on the piston rod. One method for locking a cylinder in this fashion is by using pilot check valves, as shown in Fig 5.13. The cylinder can be extended and retracted as normally done by the action of the directional control valve. If regular check valves were used, the cylinder could not be extended or retracted by the action of the DCV. An external force, acting on the piston rod, will not move the piston in either direction because reverse flow through either pilot check valve is not permitted under these conditions

C= Double acting cylinder

P = Pump

PCV1 & PCV2 = Pilot Check Valve

R = Relief Valve

T = Tank ; F = Filter

D =3-position, 4 way , closed center, manually operated DCV

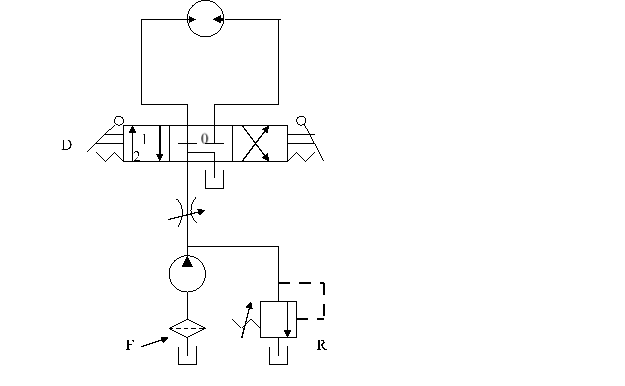

Q6) Explain the speed control circuit for hydraulic motor

A6) Figure shows a circuit where speed control of a hydraulic motor ( Bi -directional motor) is accomplished using a flow control valve to control the fluid flow to the motor.

In the spring-centered position of the tandem four-way valve, the motor is hydraulically locked. When the four-way valve is actuated into the 1st position, the motor rotates in one direction. Its speed can be varied by adjusting the setting of the throttle of the flow control valve. In this way the speed can be infinitely varied as the excess oil goes to the tank through the pressure relief valve. When the four-way valve is deactivated, the motor stops suddenly and becomes locked. When the 2nd position of the four-way valve is in operation, the motor turns in the opposite direction. The pressure relief valve provides overload protection if, for example, the motor experiences an excessive torque load.

Speed control of Hydraulic motor using Flow control valve.

M = Bi-directional Hydraulic motor ; P = Pump ; T = Tank; F = Filter

R = Relief Valve; FCV = Flow control Valve

D =3-position, 4 way ,Tandem center, Manually operated and Spring Centered DCV

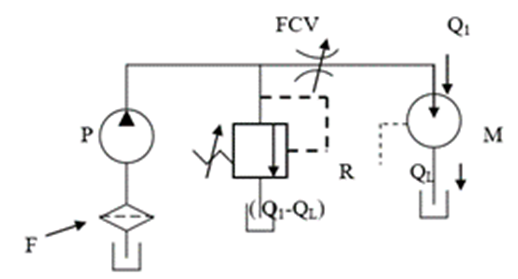

Q7) Explain the speed control circuit for hydraulic motor using meter in and meter out circuit. Write the equations for volumetric efficiency and comment

A7) The speed of hydraulic motor can be controlled either by meter-in control or meter- out control.

Figure shows a unidirectional hydraulic motor speed is controlled by a meter- in circuit. Here the flow control valve is placed between the pump and motor.

Fig. Meter- in Speed control of Hydraulic motor

M = Uni-directional Hydraulic Motor; P = Pump ; T = Tank; F = Filter

R = Relief Valve; FCV = Flow control Valve

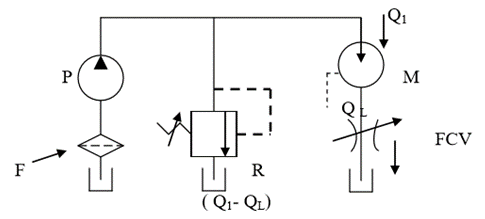

Figure shows a unidirectional hydraulic motor speed is controlled by a meter- out circuit. Here the flow control valve is placed between the motor and tank.

Meter- out Speed control of Hydraulic motor

M = Uni-directional Hydraulic Motor ; P = Pump ; T = Tank; F = Filter

R = Relief Valve; FCV = Flow control Valve

Due to leakage, a hydraulic motor consumes more flow rate than it should theoretically consume. The theoretical flow rate is the flow rate a hydraulic motor would consume if there were no leakage. If Q1(=QA ) is the flow of fluid to the motor, and QL the leakage , Then QT is equal to Q1 – QL .

In meter- in control Q1 is maintained constant despite varying load , QL varies with load , therefore volumetric efficiency varies with load. Hence meter-in system will not give precise control of speed. Whereas in meter – out control Q1 varies with load hence precise control of speed regardless of flow.

Q8) What are the conditions for the two cylinders to be synchronized?

A8) For the two cylinders to be synchronized, the piston area of cylinder 2 must be equal to the difference between areas of the piston and piston rod for cylinder 1. i.e. Ap2 =Ap1 –AR1

Also, the pump should be capable of delivering a pressure force P1ApI in cylinder 1 to overcome the loads F I and F 2 acting on both cylinders. . i.e.P1Apl =FI +F2

Q9) What is the use of bleed-off circuit?

A9) Bleed off circuit is used to .control the flow of fluid in both directions of flow (or) on a specific line and limits speed in only one direction of the cylinder travel.

Q10) What are the sources of contamination?

A10) In general there are four main sources of contamination in hydraulic oil.

- “Native” contamination: These are contaminant particles that were left in the system or any of its components during manufacture or repair and include contaminants such as welding slag, machining swarf, pieces of Teflon tape or excessive sealant.

- Contaminated new oil: New oil may not be clean enough for the system (and is generally not clean enough for a modern, high pressure hydraulic system). The manufacturing process and the subsequent handling and storage introduce contaminants.

- Ingressed contamination: This contaminate may enter with air flowing into the reservoir through the breather cap. Water will build up in the oil of a system operating in humid conditions if there is no protection against this built in to the reservoir. Another common source is dirt particles riding in on a cylinder rod. No rod seal can totally prevent the entrance of particles, this can be a major source of contamination on earth moving equipment operating in extreme conditions. Furthermore, whenever the system is opened in any way such as when a hose is disconnected or fluid is topped up, there is the potential for contamination to ingress.

- Internally generated contaminate: Particles removed from the interior surface of the components will circulate in the system until they are removed. Each impact of one of these particles with a surface causes more damage. This phenomenon is known as the wear regeneration cycle. Included in this is contamination from the catastrophic failure of components within the system.