Unit 1

Introduction

Q1) Define Non- Destructive Testing.

A1) Non-destructive testing refers to a method of detecting internal flaws in engineering materials without breaking them.

It can be also be defined as the use of non-invasive technique to determine the integrity of a material component or structure or quantitatively measuring some characteristics of an object.

NDT is aimed at extracting information on the physical, chemical, mechanical or metallurgical state of material or structures without damaging its intended utility value.

It is aimed at extracting information on the physical, chemical, mechanical or metallurgical state of materials or structures without damaging its utility value.

Q2) Explain Scope and Advantages of Non-destructive testing.

A2) Scope of NDT:

- In mechanical or optical-strain distribution, surfaces flaws, cracks, gagging, dimensions etc.

- In Automotive-engine parts, frames and other accessories.

- Aviation field-space and air frame.

- New big sector power plant-propeller, engines, gas turbines, heat exchangers, etc.

- Railways for rail/wheel/corrosion inspection.

- Construction of bridges, structures.

- Manufacturing of machine parts, casting, forging etc.

- Medical applications.

- Submarines and Naval ships.

2. Advantages of NDT:

- It ensures the integrity and reliability of a product.

- Time and money saving, because these are fast methods.

- Higher customer’s satisfaction and preventing accidents and saving lives.

- Production, inspection and labour costs are reduced.

- Maintain a uniform quality level; NDT can help to establish a quality level.

- Products demand increased.

- Easy material handling and one way process control.

- Alloy identification, degree of cure, corrosion etc. are detected by NDT.

- NDT plays very important parts in the designing of lighter, stronger and less costly reliable parts.

Q3) Difference between NDT and Destructive testing.

A3)

S.No | NDT | Destructive testing |

1. | The use of non-invasive technique is to determine the integrity of a material or component. | Destructive testing includes measuring various mechanical or chemical properties such as tensile strength or chemical composition. |

2. | NDT mostly deals in modern technologies to identify the specimen. | Destructive testing deals in physical testing. |

3. | After testing, NDT will allow the parts to be used for its intended purpose. | Destructive testing will render the part unusable for its intended purpose. |

4. | NDT can be performed on the component which is in service. | Generally performed when component or material sample can no longer be used in service or is readily replaceable. |

5. | Result interpretation is difficult. | Easy in result interpretation. |

6. | Skilled personnel required | Can be performed by without very skilled personnel. |

7. | Some methods involve environmental hazard and expensive equipments | Non-environmental hazards associated and equipments are less costly. |

Q4) Explain Magnetic Particle Testing and Penetrate testing.

A4)

- Magnetic particle Testing:

This method employs the role of magnetic field which may be produced by any of the magnetizing technique. Then a powdered magnet or liquid magnet called as magnetic ink is spread over the surface to be inspected.

Surface or near surface defects cuts the magnetic flux line, which generates a new magnetic pole, at the defect point. This concentrates the iron particles near imperfection or defect giving a clear visualization of defect.

2. Penetrate testing:

In this method, test specimen is coated with liquid of fluorescent dye solution. Then excess penetrant is removed very carefully and developers are applied.

These developers acts as blotter and draws out the trapped penetrant from defect to open surface. These penetrants are now easily visible because of colour contrast between penetrant and developer with fluorescent dyes. Ultraviolet lights are used which make the bleed out penetrant readily seen.

Q5) What is flaw and defect? Explain along with its classification.

A5) 1. Flaws:

Any discontinuity in the normal physical composition of part which does not have any major effect on the performance of that part is said to be flaw.

Example: Poles, scratches, cracks etc.

2. Defects:

Any interruptions in the normal physical composition of parts, that is, reject able known as defect.

These interruptions may occur in the base metal, weld materials or HAZ discontinuities, which do not meet the requirements of the codes or specifications used to invoke and control an inspection, are referred to as defects.

Classifications of defects:

- Cracks:

A crack is a fissure produced in a metal by tearing action.

2. Surface defects:

These defects are intergranular. These defects are due to improper temperature, friction, corrosion, rust, dirt etc.

3. Blow holes, porosity, slag, flakes, solid inclusion.

4. Pock marks and rough surfaces:

Spatter occurs in arc or gas welding as metal particles which are expelled during welding. These particles do not form part of the actual weld.

5. Buldge formation, wavy edges, zipper cracks etc.

6. Distortions, sub-surfaces cracks

Q6) Define Visual inspection in terms of Non destructive Testing.

A6) Visual inspection is commonly defined as the examination of material, component or product for conditions of non-conformance using light and eyes, alone or in conjunction with various aids.

Visual inspection often also involves, shaking, listening, feeling, and sometimes even smelling the component being inspected.

It consists of major two processes:

- The first is search process.

- The second process is of combining relevant knowledge, sensory input and the pertinent logical process to provide identification that some anomaly or pattern represents a flow that possesses a risk to the performance of the part.

It can be performed by direct or indirect methods during various stages of manufacturing or after the component has been placed in service.

It can be done manually or by the help of digital detectors and computer technology which is known vision inspection.

Q7) What are the major classifications of Visual Inspection?

A7) Visual inspection is commonly defined as the examination of material, component or product for conditions of non-conformance using light eyes.

There are basically two major classifications of Visual Inspection. They are mentioned below:

- Manual inspection:

- It is a method of inspection in which eyes and light are used either with or without any help of optical aids.

- It is used in very small production systems.

- It is a lesser reliable method of inspection but at low cost. So it is useful for small industries.

b. Automated vision inspection:

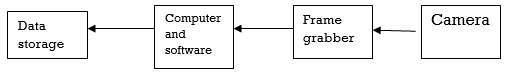

It is the technology and method which uses an imaging system and a computer to analyze an image and provide imaging based automatic inspection and analysis for automatic inspection, process control and other industries.

Machine can eliminate the human effort. It also allows process equipment to be utilized twenty four hours in a day. Here given the block diagram of automated vision inspection.

Q8) What is Boroscope? Mention the important equipments used in visual inspection.

A8) Borescope:

- Borescope is a designed to enable the inspector to inspect the inside portion of a bore or narrow tube, a chamber etc.

- It is high precision optical system, which consists of complex arrangements of lenses, light sources, prisms through which light is passed.

- It is long tubular, optical device that illuminates and allows the inspection of surfaces inside narrow tubes or difficult to reach chambers.

- Source is located in front of object lens to give illumination for the test piece being examined.

- As the length of Borescope is increased the image become less brilliant because of light losses.

- Generally observed visual area is 25 mm diameter at 25 mm distance.

The equipments required for visual inspection are:

- Borescope

- Magnifying microscope

- Optical microscope

- C.C.T.V. (Closed Circuit Television)

- Flexiscope

- Endoscope

- Holography

- Rulers

- Optical comparators

- Micrometers

Q9) What is ringing or hammer test?

A9)

- This test is based on the principle of interpretation of sound.

- In this test the object is ringed so as to get the sound from the object, with the interpretation of which, the soundness of object is judged.

- The working principle of this test is based on the difference between the pitch and sound quality of sound emanating from a healthy and unhealthy casting.

The procedure for ringing test is conducted in following manner:

- The casting is suspended in the air, clear from all sides and floor.

- The casting is then struck gently with a hammer at different locations of the casting.

- The action will produce a ringing sound from the casting. The sound is carefully noted either by ear or with the help of an electronic device.

- Presence of a defect in the casting will produce a sound that will be different from the sound produced by a healthy one. Thus, the healthiness of a casting can be judge by the quality of the ringing sound produced by it.

- This test is effective only when the large defects are present in the casting.

- It is not suitable to detect small defects as it will be very difficult to differentiate between the sound qualities produced by healthy casting from the sound produced from a casting having very small defects.

Uses of this test:

- Blacksmiths for checking the utensils of iron.

- Swords smith for swords.

- Bell makers for bells

- To test the structural welds

Limitations:

- Hammer test is effective only when there are large defects in the casting.

In this test method the object is ringed so as to get the sound from the object, with the interpretation of which the soundness of object is judged.

Q10) Explain chalk test or oil whitening testing:

A10)

- Oil whitening inspection can be said at the earliest application of penetrant based inspections.

- In earlier time, this technique was used for the inspection of railroad axles, wheels couplers, and locomotive parts.

- The methods involved use of an oil usually made of dark lubrication oil to find surface defects.

- The oil whitening test can be summarized as follows:

- Dark heavy oil is diluted with kerosene stored in a large tanks and the part to be inspected is submerged in the oil bath.

- Appropriate dwell time is permitted to allow the mixture to enter the defects.

- After that the part is removed from the oil bath and the surface is cleaned properly to remove the excess oil.

- Surfaces of the part are now coated with a fine coating of chalk powder. A fine suspension of chalk powder in alcohol or kerosene is used for this purpose.

- Evaporation of the kerosene leaves very fine thin, white powder coating showing the presence of discontinuities in the parts.

- The oil and whitening technique was continued until around 1940. After that it was slowly replaced by magnetic for testing of ferromagnetic parts.