Unit 4

Ultra Sonic Testing Methods

Q1) Explain Ultrasonic testing along with its working principle.

A1)

- Ultra sonic testing:

It is a type of non-destructive technique in which an ultrasound transducer is connected to a diagnostic machine which is passed over the object being inspected. This transducer is typically separated from the test object by a couplant such as oil or by water as in immersion testing.

2. Working principle of ultra sonic testing:

This technique is based on the principle that when the sound wave are propagated through the test piece the transmitted or reflected signal is monitored and interpreted depending upon that signal internal defects are identified in metals and non-metals.

The technique is based on the principle that when the sound waves are propagated through a test piece, the transmitted signal is monitored and interrupted.

Q2) What are the procedures of detecting the defects in the material by using ultra sonic testing?

A2) Below are given the following steps which are used for detecting the defect in the material:

- This process consists of several functional units such as the receiver transducer and display devises.

- A receiver is an electronic device that can produce high voltage electrical pulses driven by the receiver.

- The transducer generates a high frequency ultrasonic energy.

- The sound energy is introduced and propagates through the materials in the form of waves.

- When there is discontinuity in the wave path, part of the energy will be reflected back from the flaw surface.

- The reflected wave signal is transformed into an electrical signal by the transducer and is displayed on the screen.

- The reflected signal strength versus the time is displayed from a signal generations, when an echo is received.

- Signal travel time can be directly related to the distance that the signal travelled.

- From the signal, information about the reflector location, size, orientation and other features can sometimes be gained.

Q3) Define piezoelectricity.

A3) The piezoelectricity means electricity from pressure and is derived from Greek word piezoe, which means to press or squeeze and electric means electron which is source of electric charge.

Piezoelectricity is a result of piezoelectric effect, which is a reversible process, in which material exhibiting the property of generation of electric charge from any mechanical strain, also exhibits the property of generation of the mechanical strain from any applied electrical field.

It has founded its application in production and detection of sound waves, high voltage generations, electronic frequency generation, cigarette lighters, watches, sensors, actuators motors, reduction of vibration and noise, infertility treatment etc.

Q4) Define Electromagnetic Acoustic Transducer with neat sketch diagram.

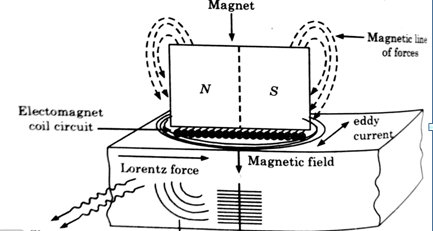

A4) These transducers do not require any of the couplant as it generates the sound energy directly within the material placed in contact with this transducer.

When a current carrying or an electromagnet is used, with an ultra sonic frequency wave, an eddy current is induced in the material kept in proximity to the wire or electromagnet. These eddy currents will experience Lorentz force.

F=J×B

Fig.1: Electromagnetic transducer

Q5) Define Single and Twin Compression transducers, customer transducer and wheel transducer.

A5)

- Single and Twin Compression transducers:

In single compression transducer, straight beam are used to measure thickness and to detect flaws on plates, bars, forgings, castings and extrusions, during testing they are applied directly to the flat surfaces of the test materials.

In twin compression transducer, dual element contact transducer’s measures thickness and detect flaws and corrosions in thin materials especially where near surface resolution is required.

2. Customer Transducer:

Customer transducers are often required for specialist applications. These often contain a number of elements for specific location and angles. This probe is used to test railway track that incorporates both forward and backward facing twin element arrangement either side of conventional twin crystal arrangement.

3. Delay line transducers:

It transmits and receives sound waves with one element coupled to the surface as with compression transducers.

The crystal is held off from the test piece surface by a delay block.

This permits inspection very close to the test piece surface.

Q6) Explain CRO and its working methodology.

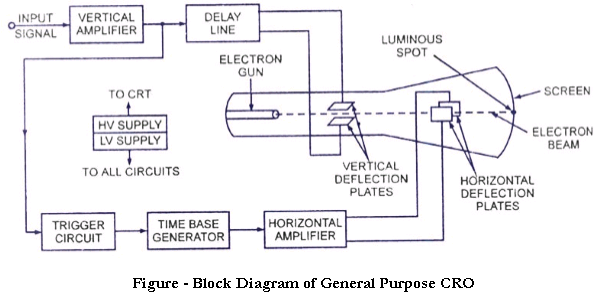

A6) It is one of the most scientific instruments ever developed. CRO provides accurate time and measurement of voltage signals over a wide range of frequencies.

The heart of the CRO is a cathode ray tube along with the electron gun, fluorescent screen and defecting system.

1. Working:

2. The signal to be displayed is amplified first by vertical amplifier and then applied to vertical deflection plate of CRT.

3. Some portion of vertically amplified signal is applied to sweep trigger as triggering signal.

4. This signal activates the sweep generator as consequences of which, “saw tooth” waves are produced.

5. This saw tooth wave is applied to horizontal amplifier and then applied to the horizontal deflection plate.

6. The maximum voltage Vm= is calculated by the given relationship.

Vm=Vrms/0.707

Vm=Maximum voltage, and Vrms= Effective value of voltage or root mean square value (RMS) of the voltage.

Q7) What are the advantages, disadvantages and limitation of CRO techniques?

A7)

1. Advantages:

- It is well protected from damage if a signal is significantly stronger than expected.

2. Limitations:

- It is relatively fragile and expensive

- It is less accurate

3. Applications:

- It is used for comparing two different generated frequencies.

- It is used determining the shift the shift of phase in the circuit.

- It is used for studying the behaviour of beats.

- It is used for measuring the repetitive signals.

Q8) What are the applications of inspection of NDT in casting and extruded steel part and bar?

A8)

1. Inspection of casting:

It consists of inspecting the surface of the casting with naked eye or sometimes with a magnifying glass or microscope. It can only indicate surface defects such as blow holes, fusion, swells, external cracks, and mismatch. Almost all castings are subjected to certain degree of visual inspection.

Dimensional inspection is carried out to make sure that the castings produced have the required overall dimensions including allowances for machining. It may sometimes be necessary to break a part of the casting to take measurements of inside dimensions.

This is a rough test to indicate a flaw or discontinuity in a casting. The casting is suspended from a suitable support free of all obstructions and tapped at various places on its surface with a small hammer. Any change in the tone produced indicates the existence of a flaw.

2. Extruded steel part and bars:

Ultrasonic non destructive testing (NDT) is a well-established technique that utilizes high frequency sound waves to locate cracks and other hidden flaws in metals, composites, and plastics.

In the metals industry, ultrasonic inspection is not only used to inspect finished parts but also to inspect raw material in the form of bars, billets and plates supplied for further processing.

When employed appropriately by a qualified operator, ultrasonic NDT is quick and reliable, usually requires no test piece preparation other than wetting with ultrasonic couplant or water, and has no specific safety hazards or regulatory licensing requirements associated with its use.

Q9) Describe the role of ultra sonic method in terms of application in rail and dimensional measurement.

A9) There are various applications of ultrasonic testing methods. Here the importance of this testing method in the field of rail and dimensional measurement is given below:

Applications in rails:

- From the beginning of the development of railroads, it is always prone to various service failures.

- For reduction in catastrophic failures, the process of non-destructive testing came into application.

- External defects on rail can be detected by visual inspection.

- But in case of internal, visual inspection fails to provide any information.

- Ultrasonic inspection use roller search units comprising a combination of different transducers at different angles to achieve the best inspection possible.

Dimensional measurement:

- Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements.

- Ultrasonic inspection can be used for flaw detection/evaluation, dimensional measurements, material characterization.

- It is sensitive to both surface and subsurface discontinuities.

- The depth of penetration for flaw detection or measurement is superior to other NDT methods.

- Only single-sided access is needed when the pulse-echo technique is used.

- It is highly accurate in determining reflector position and estimating size and shape.

- Minimal part preparation is required.

- Electronic equipment provides instantaneous results.

- Detailed images can be produced with automated systems.

- It has other uses, such as thickness measurement, in addition to flaw detection.

Q10) Describe the three major steps raised during the ultrasonography of a human body.

A10)

It is an ultrasound based method follows diagnostic imaging technique for examining the body structure using very high frequency sound waves.

Generally, it has three steps:

- Producing a sound wave:

When strong, short electrical pulses are applied to a piezoelectric transducer, the frequencies between 2 to 20 MHz are generated.

This produces sound beams which are then focussed to the body and finally the beam focuses at the desired path. In addition a water based gel is placed between the skin and probe for effective transmission of sound beams.

2. Receiving the echoes:

The reflected sound beams from the internal of human body are received by the transducer, which vibrates the transducer and transform the vibrations into electrical signals.

These signals travel to the oscilloscope or scanner, when they are processed and displayed into a digital image.

3. Displaying the image:

Image displayed on sonographic scanner can be further used for evaluation.