Question Bank

Unit 03

Q-1Mention the roles of lubrication.

The roles of lubricant are -

- Reduce friction

- Prevent wear

- Protect the equipment from corrosion

- Control temperature (dissipate heat)

- Control contamination (carry contaminants to a filter or sump)

- Transmit power (hydraulics)

- Provide a fluid seal

Q-2Explain hydrodynamic lubrication and it’s mechanism.

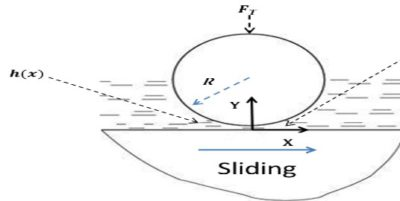

The shaft rotating in a bearing is supported by a layer or wedge of oil so that the shaft is not in contact with the bearing material. It is carried out with the help of liquid lubricants. In this mechanism, two moving and sliding surfaces are separated by thick film of lubricant fluid of about 1000A°, applied to prevent direct surface to surface contact and consequently reduce wearing and tearing of metals. Therefore it is known as thick film or fluid film lubrication or hydrodynamic lubrication. In this case fluid is formed by mixing of hydrocarbon oils and anti-oxidants with long chain polymer so as to maintain viscosity. Fluid film lubrication is useful in delicate and light machines like watches, clocks, guns, scientific equipments.

Lubrication film between the two contact surfaces is thick enough and two contact surfaces are separated completely by viscous oil film. At this time, frictional force of two contact surfaces are determined by viscous resistance of lubricant and it can take a very small value. Under this condition, when shaft also rotates due to the viscosity of the lubricant oil and generates oil pressure at the load area. This phenomenon is called wedge effect. The oil pressure P generated within lubricating oil film is affected by change of temperature and viscosity of lubricating oil, surface roughness, clearance and rotational speed of the shaft.

Q-3Explain boundary lubrication with diagram.

It is carried out with grease and graphite & molybdenum disulphide lubricants. Boundary lubrication is a condition in which the lubricant film becomes too thin to provide total separation. In this type of lubrication a thin film of lubricant is adsorbed on the surface by weak Vander Waals forces. Thin film lubrication is operating at relatively low speed and high pressure. Lubricating oil film between the two contact surfaces is extremely thin and no viscous hydrodynamic oil film exists between the two contact areas, only film of absorbed oil molecules exists.

Q-4Classify the lubricants on the basis of its physical state.

Lubricants are classified on the basis of their physical state:

(i) Lubricating Oil

(ii) Semi-solid Lubricants (grease)

(iii) Solid lubricants

Q-5Explain Lubricating oil and its properties.

Lubricating Oil:

It plays the major role in reduction of friction between two moving metallic surfaces. The lubricating oil provides the fluid film in between the metallic surfaces those results in the friction reduction. Lubricants also act as the cooling medium, corrosion preventer.

Poroperties:

(i) They posses low pressure or high boiling point

(ii) Adequate viscosity for particular service condition

(iii) High oxidation resistance

(iv) They non-corrosive properties

They are further classified as-

Vegetable oils:

The petroleum industry existence took a several decades prior to its existence oil of the vegetable and animal origins were the most commonly used lubricants. They were very good for the use but due to their cost and the property of its to undergo oxidation easily tend to leave its presence. They were used as the blending agent with other lubricating oils to produce desired effects.

Mineral or petroleum oils: They are obtained by the petroleum distillation. The carbon chain varies from 12 to 50 carbon atom. They posses viscosity according to their chain length the shorter chain posses lower viscosity while vice versa for longer chain. This is one of the most widely used lubricants as because of its price and its availability. Crude liquid petroleum oils contain lot of impurities (like wax, asphalt, etc.) and consequently, they have to be thoroughly purified before being put to use.(i) The wax, if not removed, raises the pour-point and renders the lubricating oil unfit for use at low temperatures. (ii) Certain constituents get easily oxidized under working conditions and cause sludge formation. (iii) Some constituents mainly asphalt, undergo decomposition at higher temperatures, causing carbon deposition and sludge formation. A number of processes are used for removing these unwanted impurities by using Dew axing or acid refining or by solvent refining.

Q-6Explain grease.

Lubricating grease is a semi - solid, consisting of a soap dispersed throughout liquid lubricating oil. The liquid lubricant may be petroleum oil or even synthetic oil and it may contain any of the additives for specific requirements. Greases are prepared by saponification of fat with alkali, followed by adding hot lubricating oil while under agitation. The total amount of mineral oil added determines the consistency of the finished grease. The structure of lubricating greases is that of a gel. Soaps are gelling agents, which give an interconnected structure containing the added oil. At high temperatures, the soap dissolves in the oil, whereupon the interconnected structures cease to exist and the grease liquefies. Consistency of greases may vary from a heavy viscous liquid to the of a stiff solid mass. To improve the heat-resistance of grease, inorganic solid thickening agents (like finely divided clay, bentonite, colloidal silica, carbon black, etc.) are added.

Q-7What are the uses of grease?

Grease is used:

(i) in situations where oil cannot remain in place, due to high load, low speed, intermittent operation, sudden jerks, etc. e.g. Rail axle boxes,

(ii) in bearing and gears that work at high temperatures

(iii) in situations where bearing needs to be sealed against entry of dust, dirt, grit or moisture, because greases are less liable to contamination by these

(iv) in situations where dripping or spurting of oil is undesirable, because unlike oils, greases if used do not splash or drip over articles being prepared by the machine.

Q-8Explain graphite and its properties.

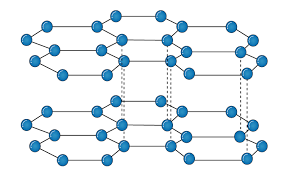

It is an allotropic form of the carbon atom (Allotropy form- When any element is formed in more than one form and in each form they posses different property). In graphite carbon are arranged in hexagonal ring form and each form is arranged upside down to form the layer and are attached together by weak Vander-wall’s forces. Graphite is the most stable form of the carbon. It is the good conductor of heat and electricity. The two major known form of graphite are alpha (Hexagonal) and Beta (Rhombohederal).

Structure:

The carbon atom is sp2 hybridized that means there is 4 valence electron in their outermost shell as in the diamond the all 4 valence electron are covalently bonded while in graphite the 3 electron makes a covalent bond while the remaining 1 electron are free. The interconnection of these carbon atoms forms the hexagonal structure. The C-C bond bond length is 1.42 Angstrom. This hexagonal layer attached toward each other by weak Vander Wall forces at a distance of 3.35 Angstrom. This is the reason why graphite is soft.

Properties:

Conducting Property: As the carbon of Graphite are sp2 hybridized that means the p orbital remain vacant of the carbon atom this tend to overlapping of the vacant P-orbital. This overlapping of the vacant orbital is responsible for the movement of electrons in parallel on their vacant orbital that is why Graphite shows the conducting property.

Q-9Mention the applications of graphites.

Applications:

1-Graphite can be used as the solid lubricant

2-Graphite can be used as conductor.

3-Graphite can be used as the electrodes.

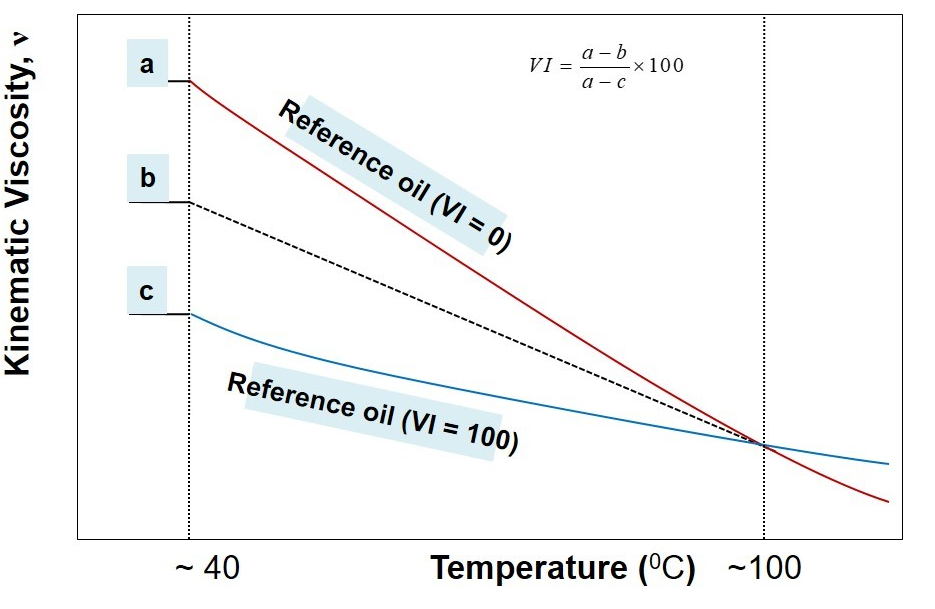

Q-10What is viscosity index?

The rate at which viscosity of a lubricant changes with temperature is measured by any arbitrary scale is known as viscosity index. Viscosity of liquid is decreases with increasing temperature so that lubricating oil become thinner as the operating temperature is raised, and lubricant can be squeezed out from the subbing parts.

A stepwise procedure to estimate viscosity index, VI, may be outlined as below:

- Measure kinematic viscosity of the unknown oil at 40o C and 100oC.

- Identify two reference oils whose kinematic viscosity at 100oC coincides with the kinematic viscosity of the unknown oil (from the look-up chart of ASTM standard).

- Pick-up the kinematic viscosity of two identified reference oils at 40oC

- In reference to illustration above, now a, b, and c are known.

- Use the following formula to calculate viscosity index

VI=(a-b)/(a-c) *100

Q-11What is aniline point?

The minimum temperature at which oil is miscible with equal amount of aniline. It is the measure of aromatic content of the lubricating oil. The low aniline point have high aromatic content which attacks rubber seals. The higher the aniline point means the lower percentage of hydrocarbons. Thus Aniline point is used as an indication of possible deterioration of rubber sealing.

Determination of Aniline Point:

Aniline + Sample oil Homogenous Solution Cloudiness