Unit - 2

Fresh concrete

Q1) What is fresh concrete?

A1)

- Concrete is called sparkling while the placing and hardening manner has now no longer but started.

- Fresh concrete may be deformed and poured because of this that it may be transported or pumped and used to fill moulds and formwork. The traits of the shape and the concrete placement strategies decide the composition of the concrete whose consistency is then adjusted on the premise of the Abrams cone droop test.

- Workability is crucial so as for the concrete to absolutely fill the moulds and formwork, whose form can be complex, and to be able to efficaciously cowl the reinforcement. Workability is prompted through many parameters: the character and percentage of the cement, the form of the mixture particles, the share of water and using additives.

Q2) Explain batching in detail.

A2)

- Batching of Concrete stands for the technique of estimating and combining the specified concrete elements with each weight or quantity consistent with the combinationture layout and transplanting them into the combinationture to create a regular fine of concrete.

- Batching of Concrete is typically completed with quantity. Precision may be very crucial in batching. It is higher to do weight batching in preference to quantity batching. Before creating a concrete mixture, the concrete fabric need to be well and correctly batched or proportioned to gain the brilliant fine of the concrete.

- Concrete Batching enables enhance the practicality of concrete to reap a clean floor of concrete and boom the rate of creation and decrease the wastage of concrete additives. Thus, batch making of concrete additives is an important method while making concrete

Q3) What is Mechanical mixer?

A3)

- A concrete mixer mixes cement, aggregates and water and produce concrete mechanically. There are various types of concrete mixers available which makes concrete production quick and economical.

- Non- tilting drum mixers aren't allowed to tilt and the drum rotates approximately its horizontal axis. For the release of concrete a chute is organized in willing function on the way to gets the concrete blend from drum and discharges out. In this case, the drum is opened at ends and is composed blades insides whilst substances are poured via one cease and blend is accrued via any other cease.

- Rapid discharge of concrete isn't feasible on this case. Due to this delay, the concrete can be susceptible to segregation. The large length mixture isn't discharged without problems with the blend. So, length of mixture mot greater than 7.5cm is most effective for this kind of mixers. So, this kind of mixers are commonly used for small projects.

- Reversing drum mixers are much like non-tilting kind mixers however in this situation reversal of rotation takes area for distinctive action. The drum has openings, one give up is for pouring substances and different give up is for discharge of mix. The drum rotates approximately its horizontal axis. The rotation of drum takes area in a single route for blending and in contrary route for discharging. Two distinctive set of blades are organized for blending and discharging. They are appropriate for dry concrete mixes.

Q4) Explain automatic batching and mixing plants.

A4)

- Automatic batching plant via way of means of affords a fee-powerful entire concrete generating solution.

- The progressive layout of the plant with a pan mixer and additionally reversible kind affords clean and low-fee transportation and mobility for the entire unit. Automatic batch blend flora rent computer-aided manage to help in speedy, unique dimension of enter factors in addition to tie collectively the diverse elements and add-ons for coordinated, stable overall performance for longer purposeful life.

- The robust production of the concrete processing gadget allows in keeping a low fee of manufacturing and least utilization of exertions requirement via way of means of our clients. With our computerized batching plant, you may efficiently do away with the surprising production issues and unexpected fee overruns that might postpone your assignment start-up dates and lift the deliberate budget.

- The batch blend plant is pre-assembled and manufacturing facility examined earlier than shipment; thus, the assured manner to speedy on-webweb page setup and startup. Automatic Batching Plant is used to move the substances for making concrete or to put together concrete for similarly processing. Operated automatically, the output of those flora may be up to twenty cum in keeping with hour.

- For higher mobility, this plant is supplied with pneumatic wheels. Its computerized water dispenser is a tremendous gain in coping with most excellent water spraying at some stage in the concrete mixing. For clean discharging to concrete pump and difficult rider, a appropriate discharge peak is maintained.

- With its hydraulic components, the entire processing appears easy whilst coping with complicated tasks. Our batch blend plant comes with four bin hopper, capability as much as 8m3 Modern concrete plant manage structures are normally capable of save a big wide variety of blend designs, having a reminiscence of specifics of every batch produced, combine admix and moisture probes to allow unique blend manage, and in a few instances interface with accounting and different software.

- The addition of protection switches to save you unintended operation reduces dangers on your personnel and might even lessen coverage rates. One of many crucial issues while buying a manage device is the extent of knowledge the representative, dealer, or producer promoting the product has in its operation and setup.

Q5) What is efficiency of mixing?

A5)

- Mixing performance is the ratio of the internet alternate in ability strength to the strength expended in generating the combination. Parameterizations of performance and of associated blending coefficients are had to estimate diapycnal diffusivity from measurements of the turbulent dissipation price. Comparing diffusivities from microstructure profiling with the ones inferred from the thickening price of 4 simultaneous tracer releases has verified, inside observational accuracy, 0.2 as the combination coefficient over a 30-fold variety of diapycnal diffusivities.

- Although a few blending coefficients may be expected from pycnocline measurements, at gift blending performance need to be acquired from channel flows, laboratory experiments, and numerical simulations.

- Reviewing the distinctive procedures demonstrates that estimates and parameterizations for blending performance and coefficients aren't converging past the at-sea comparisons with tracer releases, main to pointers for a network method to deal with this essential issue.

Q6) Explain workability measurement.

A6)

- Workability of concrete is the convenience and homogeneity of labor with freshly blended concrete or mortar. In different words, if concreting procedure which includes mixing, placing, compacting and completing may be completed effortlessly in freshly blended concrete; that is known as workability of the concrete.

- Simply speaking, workability of concrete is all approximately how effortlessly freshly blended concrete may be blended, placed, consolidated and completed with minimum lack of homogeneity. Or technically speaking, workability of concrete is the quantity of beneficial inner paintings essential to supply 100% compaction. Sometimes, the word ‘consistency’ is likewise used to explain workability of freshly blended concrete.

- Workability measures a fluidity or mobility of concrete. It is stated that moist concrete is extra conceivable than the dry concrete. The preferred workability of concrete for a specific production exercise varies consistent with the paintings condition, climate condition, form of paintings, mode of compaction etc.

- There are commonly 3 main elements affecting the workability of concrete – water/cement ratio, form and length of mixture and admixtures. Workability is defined as very low, low, medium, excessive and really excessive. And, there are numerous concrete workability exams to be had to degree it.

Q7) Explain slump cone test

A7)

- The word ―workability or plausible concrete indicates an awful lot wider and deeper which means than the alternative terminology ―consistency frequently used loosely for workability. Consistency is a popular time period to suggest the diploma of fluidity or the diploma of mobility.

- The elements supporting concrete to have greater lubricating impact to lessen inner friction for supporting clean compaction are : (a) Water Content (b) Mix Proportions (c) Size of Aggregates (d) Shape of Aggregates (e) Surface Texture of Aggregate (f) Grading of Aggregate (g) Use of Admixtures. Slump take a look at is the maximum usually used technique of measuring consistency of concrete which may be hired both in laboratory or at web website online of work.

- It isn't a appropriate technique for extremely moist or very dry concrete. It does now no longer degree all elements contributing to workability, nor it's far continually consultant of the placeability of the concrete. It shows the feature of concrete similarly to the stoop fee.

- If the concrete slumps flippantly it's far known as genuine stoop. If one 1/2 of the cone slides down, it's far known as shear stoop. In case of a shear stoop, the stoop fee is measured because the distinction in peak among the peak of the mildew and the common fee of the subsidence.

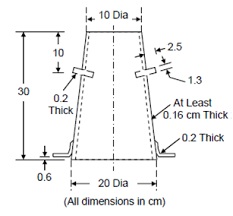

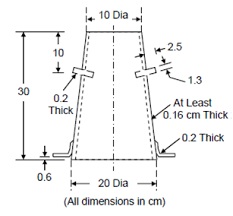

Fig 1: Slump cone test apparatus

- Fig. 1: Schematic Slump Cone Apparatus: The Slump Cone equipment for accomplishing the stoop check basically includes a metal mold withinside the shape of a frustum of a cone having the inner dimensions as : Bottom diameter : 20 cm, Top diameter : 10 cm, Height : 30 cm and the thickness of the metal sheet for the mildew must now no longer be thinner than 1.6 mm.

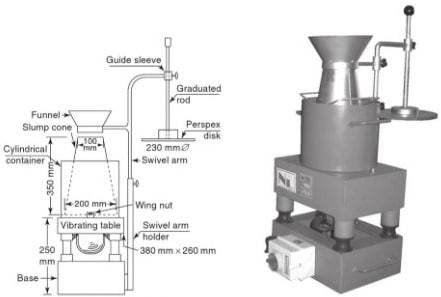

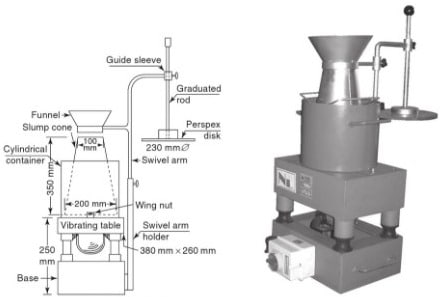

Fig 2: Slump cone test apparatus

- Fig. 2: Slump Cone Apparatus The Slump Cone equipment at the side of Tamper (sixteen mm in diameter and six hundred mm length.

- The tamping cease of rod will be rounded to a hemispherical tip), Ruler, etc. Conforming to IS 7320:1974 Specifications for Concrete Slump Test Apparatus (Fourth revision). Reaffirmed- Dec 2013.

Q8) What is compacting factor test?

A8)

- The pattern of concrete to be examined will be located lightly withinside the higher hopper, the use of the hand scoop. The hopper will be stuffed degree with its brim and the trap-door will be opened in order that the concrete falls into the decrease hopper.

- Certain mixes will be inclined to paste in a single or each of the hoppers. If this occurs, the concrete can be helped via with the aid of using pushing the rod lightly into the concrete from the pinnacle. During this technique, the cylinder will be included with the aid of using the trowels. Immediately after the concrete has come to rest, the cylinder will be uncovered, the trap-door of the decrease hopper opened, and the concrete allowed to fall into the cylinder.

- The extra of concrete ultimate above the extent of the pinnacle of the cylinder shall then be reduce off with the aid of using keeping a trowel in every hand, with the aircraft of the blades horizontal, and shifting them concurrently one from every facet throughout the pinnacle of the cylinder, on the identical time retaining them pressed at the pinnacle fringe of the cylinder.

- The outdoor of the cylinder shall then be wiped clean. The above operation will be performed at an area loose from vibration or shock. The weight of the concrete withinside the cylinder shall then be decided to the closest 10 g. The extra of concrete ultimate above the extent of the pinnacle of the cylinder shall then be reduce off with the aid of using keeping a trowel in every hand, with the aircraft of the blades horizontal, and shifting them concurrently one from every facet throughout the pinnacle of the cylinder, on the identical time retaining them pressed at the pinnacle fringe of the cylinder.

- The outdoor of the cylinder shall then be wiped clean. This whole technique will be performed at an area loose from vibration or shock. This weight will be called the load of in part compacted concrete.

- The cylinder will be refilled with concrete from the identical pattern in layers about five cm deep, the layers being closely rammed or ideally vibrated with a purpose to reap complete compaction. The pinnacle floor of the absolutely compacted concrete will be cautiously struck off degree with the pinnacle of the cylinder. The outdoor of the cylinder shall then be wiped clean.

- Observation

The compacting factor is defined as the ratio of the weight of partially compacted concrete to the weight of fully compacted concrete. It shall normally be stated to the nearest second decimal place.

Workability | Compaction Factor | Slump (mm) |

Very Low | 0.78 | 0 - 25 |

Low | 0.85 | 25 - 50 |

Medium | 0.92 | 50 - 100 |

High | 0.95 | 100 - 175 |

Q9) What is flow table?

A9)

Sr. No. | Description | Sample 1 | Sample 2 | Sample 3 |

1 | Weight of Empty Cylinder (W1) |

|

|

|

2 | Weight of Empty Cylinder + Free Fall Concrete(W2) |

|

|

|

3 | Weight of Empty Cylinder + Hand Compacted Concrete (W3) |

|

|

|

4 | Weight of Partially Compacted Concrete(WP = W2 - W1) |

|

|

|

5 | Weight of Fully Compacted Concrete(WF = W3 - W1) |

|

|

|

6 | Compaction Factor = WP/ WF |

|

|

|

Q10) Explain Vee-Bee consistometer

A10)

Fig 3: Vee-Bee consistometer

- The workability of clean concrete is a composite property, which incorporates the various necessities of stability, mobility, compactability, placeability and finishability.

- There are distinctive techniques for measuring the workability. Each of them measures best a specific element of it and there may be sincerely no specific check, which measures workability of concrete in its totality. This check offers a demonstration of the mobility and to a degree of the compactibility of freshly combined concrete.

- The check measures the relative attempt required to extrade a mass of concrete from one particular form to another (i.e., from conical to cylindrical) through vibration. The quantity of attempt (referred to as remoulding attempt) is taken because the time in seconds, required to finish the extrade.

- The consequences of this check are of cost whilst analyzing the mobility of the hundreds of concrete made with various quantities of water, cement and with numerous varieties of grading of aggregate. The time required for whole remoulding in seconds is taken into consideration as a degree of workability and is expressed because the variety of Vee-Bee seconds. The approach is appropriate for dry concrete. For concrete of hunch in extra of 50mm, the remoulding is so short that the time can't measured.

Q11) Explain Factor affecting workability

A11)

- The term ‘Workability of Concrete’ is described because the assets of freshly blended concrete which determines the convenience and homogeneity with which it is able to be blended placed, consolidated and finished.

- A perfect water-cement ratio on my own isn't always going to present most strength. 100% compaction of concrete is a critical parameter for contributing to the most strength. Insufficient compaction will bring about presence of air voids which has unfavourable impact on strength.

- Generally to compact the concrete absolutely a better water-cement ratio is adopted. The water characteristic as a lubricant withinside the concrete which eases the compaction process. Thus water is needed for Handling concrete without segregation. For setting without lack of homogeneity. Effort of compaction is needed to finish. The nice of concrete pleasurable a lot of these necessities is named as practicable concrete.

- Water Content: The quantity of water content material to be had in a extent of concrete may have a enormous impact at the workability of concrete. The better the water content material in step with cubic meter of concrete the better will be the fluidity of the concrete. In fashionable to growth the workability sure quantity of extra water is brought in concrete at site. However it must be referred to that growing the water content material of concrete may have a few impact on energy of the concrete. Besides, every time greater water is brought a sure quantity of cement is likewise brought in order that water-cement ratio stays constant.

- Mix Proportions: In preferred combination-cement ratio is likewise a critical issue which impacts the workability. If the combination-cement ratio is better, the tilt concrete is formed. In this example much less amount of paste is to be had for supplying lubrication, subsequently workability is decreased. Whereas if the combination-cement ratio is decrease the wealthy blend is formed. In this example extra paste is to be had to offer lubrication, subsequently higher workability of concrete is observed.

- Size of Aggregates: The larger the scale of the aggregates the lesser is the floor place subsequently much less quantity of water is needed for wetting the floor. Hence much less paste is needed for lubricating the concrete floor to lessen inner friction, consequently we will say that the larger length of aggregates will provide better workability. Reduction in length of aggregates will lessen the workability.

- Shape of Aggregates: The form of aggregates additionally have great have an effect on at the workability of concrete. Compared to rounded aggregates or cubical fashioned aggregates the angular, elongated or flaky aggregates makes the concrete very harsh. Thus rounded fashioned aggregates have higher workability. This is because of rounded combination can have much less floor place and much less voids than an angular or flaky combination. In addition, rounded combination has the decreased frictional resistance and that is a cause why river sand and combination offer extra workability of concrete than beaten sand and combination. Besides the form of aggregates additionally has a good sized impact on energy and overall performance of concrete. In latest instances utilization of herbal sand turned into confined consequently new system turned into designed to yield properly fashioned and properly graded aggregates.

- Surface Texture of Aggregates: The floor texture of the combination additionally has a good sized impact at the workability of concrete. The overall floor place of approximately textured combination is extra than the floor place of easily rounded combination of the equal volume. Thus it could be inferred that more or less textured combination will display negative workability and clean or glassy texture combination will provide higher workability of concrete. The discount of inter-particle frictional resistance presented via way of means of clean aggregates additionally contributes to better workability of concrete.

Q12) What is setting time?

A12)

- Moisture performs a important function in curing time for concrete. If there isn't always enough water withinside the blend, the concrete will therapy too fast, ensuing in weaker typical power.

- Too a whole lot moisture, regularly used withinside the completing step will weaken the pinnacle layer and reason flaking. Hot ambient temperatures and wind boost up the evaporation of moisture–rushing concrete placing time. The blend layout has lots to do with concrete placing time. Some jobs would require accelerants due to the fact the region desires to be usable as quickly as possible.

- The accelerant will do its task and accelerate the concrete placing time. Accelerant mixes will display a weaker typical power withinside the end, however will nevertheless meet power requirements.

Fig 4: Initial and setting time of cement

- Initial putting time offers a concept approximately how rapid cement can begin dropping its plasticity and the very last putting time of cement offers an concept approximately how a good deal cement takes to lose its complete plasticity and advantage a few energy to face up to pressure. Significance of Initial and Final Setting Time of Cement It is needed that cement does now no longer lose its plasticity too early or too overdue.

- If cement set too early, there's inadequate time for transportation and area concrete. If cement set too overdue then there's a put off in production work. Also, concrete will now no longer get enough energy early and the formwork elimination system delayed.

- The right putting time required for the stiffening of cement paste to a described consistency. It is circuitously associated with the chemical response of cement with water to shape an aluminum–silicate compound. Initial putting time is an essential time to recognise for concrete transportation, placing, and curing. Initial putting time additionally applied to put off the system of hydration or hardening.

- The very last putting time applied for the secure elimination of scaffolding or form

Q13) Explain W/C Law

A13)

- The water–cement ratio is the ratio of the load of water to the load of cement utilized in a concrete blend. A decrease ratio ends in better electricity and durability, however can also additionally make the combinationture hard to paintings with and form.

- Workability may be resolved with the usage of plasticizers or super-plasticizers. Often, the ratio refers back to the ratio of water to cementitious substances, w/cm. Cementitious substances encompass cement and supplementary cementitious substances which include fly ash, floor granulated blast-furnace slag, silica fume, rice husk ash and herbal pozzolans. Supplementary cementitious substances are introduced to bolster concrete.

- The belief of water–cement ratio changed into first evolved through Duff A. Abrams and posted in 1918. Refer to concrete hunch test. The 1997 Uniform Building Code specifies a most of 0.five ratio while concrete is uncovered to freezing and thawing in a wet situation or to de-icing chemicals, and a most of 0.forty five ratio for concrete in a extreme or very extreme sulfate situation. Concrete hardens because of the chemical response among cement and water (called hydration, this produces warmness and is known as the warmth of hydration). For each pound (or kilogram or any unit of weight) of cement, approximately 0.35 pounds (or 0.35 kg or corresponding unit) of water is wanted to completely whole hydration reactions.

- However, a combination with a ratio of 0.35 might not blend thoroughly, and might not glide nicely sufficient to be placed. More water is consequently used than is technically essential to react with cement.

- Water–cement ratios of 0.forty to 0.60 are extra commonly used. For better-electricity concrete, decrease ratios are used, in conjunction with a plasticizer to growth flowability.

- Too a good deal water will bring about segregation of the sand and mixture additives from the cement paste. Also, water that isn't always fed on through the hydration response can also additionally go away concrete because it hardens, ensuing in microscopic pores (bleeding) in an effort to lessen very last electricity of concrete.

- A blend with an excessive amount of water will revel in extra shrinkage as extra water leaves, ensuing in inner cracks and seen fractures (specifically round internal corners), which once more will lessen the very last electricity.

Q14) Give significance of w/c ratio

A14)

- In concrete, the unmarried maximum widespread affect on maximum or all the houses is the quantity of water used withinside the blend. In concrete blend design, the ratio of the quantity of water to the quantity of cement used (each with the aid of using weight) is known as the water to cement ratio (w/c).

- These substances are accountable for binding the whole thing together. The water to cement ratio in large part determines the electricity and sturdiness of the concrete whilst it's far cured properly. The w/c ratio refers back to the ratio of the weights of water and cement used withinside the concrete blend. A w/c ratio of 0.four way that for each one hundred lbs of cement used withinside the concrete, forty lbs of water is added.

- Typical Water-Cement Ratios in Concrete Mixes Typical w/c ratios are as follows: Normal for everyday concrete (sidewalks and driveways): 0.6 to 0.7 Specified if a better nice concrete is desired: 0.four The realistic variety of the w/c ratio is from approximately 0.three to over 0.eight. A ratio of 0.three could be very stiff (except superplasticizers are used). A ratio of 0.eight makes a moist and pretty vulnerable concrete. Typical compressive strengths whilst concrete is well cured are: 0.four w/c ratio –> 5600 psi 0.eight w/c ratio –> 2000 psi.

Q15) What is cohesiveness?

A15)

- Cohesiveness is the detail of workability which shows whether or not a combination is harsh, sticky, or plastic. Plasticity is a acceptable assets in concrete, indicating that a combination may be molded and preserve a form whilst formed.

- A harsh blend lacks plasticity and the elements might also additionally generally tend to separate. Harshness may be due to an extra or deficiency of blending water (excessive- or low-droop mixes), a deficiency of cement (lean mixes), or a deficiency of great mixture particles.

- Harshness will also be due to an extra of rough, angular, flat, or elongated mixture particles.

- Harsh mixes can now and again be stepped forward through air entrainment or through growing the great mixture or cement content, however modifications should be made to the general blend to preserve the right percentage of all elements.

- A sticky blend might also additionally have a excessive cement content (fats mixes) or big quantities of rock dust, great sand, or comparable great materials (over sanded mixes). Sticky mixes do now no longer segregate without difficulty, however due to the fact they require numerous water to acquire even minimum workability, sticky mixes frequently expand immoderate shrinkage cracking.

- A plastic blend is cohesive without being both sticky or harsh, and the elements do now no longer without difficulty segregate until the concrete is dealt with improperly.

Unit - 2

Fresh concrete

Q1) What is fresh concrete?

A1)

- Concrete is called sparkling while the placing and hardening manner has now no longer but started.

- Fresh concrete may be deformed and poured because of this that it may be transported or pumped and used to fill moulds and formwork. The traits of the shape and the concrete placement strategies decide the composition of the concrete whose consistency is then adjusted on the premise of the Abrams cone droop test.

- Workability is crucial so as for the concrete to absolutely fill the moulds and formwork, whose form can be complex, and to be able to efficaciously cowl the reinforcement. Workability is prompted through many parameters: the character and percentage of the cement, the form of the mixture particles, the share of water and using additives.

Q2) Explain batching in detail.

A2)

- Batching of Concrete stands for the technique of estimating and combining the specified concrete elements with each weight or quantity consistent with the combinationture layout and transplanting them into the combinationture to create a regular fine of concrete.

- Batching of Concrete is typically completed with quantity. Precision may be very crucial in batching. It is higher to do weight batching in preference to quantity batching. Before creating a concrete mixture, the concrete fabric need to be well and correctly batched or proportioned to gain the brilliant fine of the concrete.

- Concrete Batching enables enhance the practicality of concrete to reap a clean floor of concrete and boom the rate of creation and decrease the wastage of concrete additives. Thus, batch making of concrete additives is an important method while making concrete

Q3) What is Mechanical mixer?

A3)

- A concrete mixer mixes cement, aggregates and water and produce concrete mechanically. There are various types of concrete mixers available which makes concrete production quick and economical.

- Non- tilting drum mixers aren't allowed to tilt and the drum rotates approximately its horizontal axis. For the release of concrete a chute is organized in willing function on the way to gets the concrete blend from drum and discharges out. In this case, the drum is opened at ends and is composed blades insides whilst substances are poured via one cease and blend is accrued via any other cease.

- Rapid discharge of concrete isn't feasible on this case. Due to this delay, the concrete can be susceptible to segregation. The large length mixture isn't discharged without problems with the blend. So, length of mixture mot greater than 7.5cm is most effective for this kind of mixers. So, this kind of mixers are commonly used for small projects.

- Reversing drum mixers are much like non-tilting kind mixers however in this situation reversal of rotation takes area for distinctive action. The drum has openings, one give up is for pouring substances and different give up is for discharge of mix. The drum rotates approximately its horizontal axis. The rotation of drum takes area in a single route for blending and in contrary route for discharging. Two distinctive set of blades are organized for blending and discharging. They are appropriate for dry concrete mixes.

Q4) Explain automatic batching and mixing plants.

A4)

- Automatic batching plant via way of means of affords a fee-powerful entire concrete generating solution.

- The progressive layout of the plant with a pan mixer and additionally reversible kind affords clean and low-fee transportation and mobility for the entire unit. Automatic batch blend flora rent computer-aided manage to help in speedy, unique dimension of enter factors in addition to tie collectively the diverse elements and add-ons for coordinated, stable overall performance for longer purposeful life.

- The robust production of the concrete processing gadget allows in keeping a low fee of manufacturing and least utilization of exertions requirement via way of means of our clients. With our computerized batching plant, you may efficiently do away with the surprising production issues and unexpected fee overruns that might postpone your assignment start-up dates and lift the deliberate budget.

- The batch blend plant is pre-assembled and manufacturing facility examined earlier than shipment; thus, the assured manner to speedy on-webweb page setup and startup. Automatic Batching Plant is used to move the substances for making concrete or to put together concrete for similarly processing. Operated automatically, the output of those flora may be up to twenty cum in keeping with hour.

- For higher mobility, this plant is supplied with pneumatic wheels. Its computerized water dispenser is a tremendous gain in coping with most excellent water spraying at some stage in the concrete mixing. For clean discharging to concrete pump and difficult rider, a appropriate discharge peak is maintained.

- With its hydraulic components, the entire processing appears easy whilst coping with complicated tasks. Our batch blend plant comes with four bin hopper, capability as much as 8m3 Modern concrete plant manage structures are normally capable of save a big wide variety of blend designs, having a reminiscence of specifics of every batch produced, combine admix and moisture probes to allow unique blend manage, and in a few instances interface with accounting and different software.

- The addition of protection switches to save you unintended operation reduces dangers on your personnel and might even lessen coverage rates. One of many crucial issues while buying a manage device is the extent of knowledge the representative, dealer, or producer promoting the product has in its operation and setup.

Q5) What is efficiency of mixing?

A5)

- Mixing performance is the ratio of the internet alternate in ability strength to the strength expended in generating the combination. Parameterizations of performance and of associated blending coefficients are had to estimate diapycnal diffusivity from measurements of the turbulent dissipation price. Comparing diffusivities from microstructure profiling with the ones inferred from the thickening price of 4 simultaneous tracer releases has verified, inside observational accuracy, 0.2 as the combination coefficient over a 30-fold variety of diapycnal diffusivities.

- Although a few blending coefficients may be expected from pycnocline measurements, at gift blending performance need to be acquired from channel flows, laboratory experiments, and numerical simulations.

- Reviewing the distinctive procedures demonstrates that estimates and parameterizations for blending performance and coefficients aren't converging past the at-sea comparisons with tracer releases, main to pointers for a network method to deal with this essential issue.

Q6) Explain workability measurement.

A6)

- Workability of concrete is the convenience and homogeneity of labor with freshly blended concrete or mortar. In different words, if concreting procedure which includes mixing, placing, compacting and completing may be completed effortlessly in freshly blended concrete; that is known as workability of the concrete.

- Simply speaking, workability of concrete is all approximately how effortlessly freshly blended concrete may be blended, placed, consolidated and completed with minimum lack of homogeneity. Or technically speaking, workability of concrete is the quantity of beneficial inner paintings essential to supply 100% compaction. Sometimes, the word ‘consistency’ is likewise used to explain workability of freshly blended concrete.

- Workability measures a fluidity or mobility of concrete. It is stated that moist concrete is extra conceivable than the dry concrete. The preferred workability of concrete for a specific production exercise varies consistent with the paintings condition, climate condition, form of paintings, mode of compaction etc.

- There are commonly 3 main elements affecting the workability of concrete – water/cement ratio, form and length of mixture and admixtures. Workability is defined as very low, low, medium, excessive and really excessive. And, there are numerous concrete workability exams to be had to degree it.

Q7) Explain slump cone test

A7)

- The word ―workability or plausible concrete indicates an awful lot wider and deeper which means than the alternative terminology ―consistency frequently used loosely for workability. Consistency is a popular time period to suggest the diploma of fluidity or the diploma of mobility.

- The elements supporting concrete to have greater lubricating impact to lessen inner friction for supporting clean compaction are : (a) Water Content (b) Mix Proportions (c) Size of Aggregates (d) Shape of Aggregates (e) Surface Texture of Aggregate (f) Grading of Aggregate (g) Use of Admixtures. Slump take a look at is the maximum usually used technique of measuring consistency of concrete which may be hired both in laboratory or at web website online of work.

- It isn't a appropriate technique for extremely moist or very dry concrete. It does now no longer degree all elements contributing to workability, nor it's far continually consultant of the placeability of the concrete. It shows the feature of concrete similarly to the stoop fee.

- If the concrete slumps flippantly it's far known as genuine stoop. If one 1/2 of the cone slides down, it's far known as shear stoop. In case of a shear stoop, the stoop fee is measured because the distinction in peak among the peak of the mildew and the common fee of the subsidence.

Fig 1: Slump cone test apparatus

- Fig. 1: Schematic Slump Cone Apparatus: The Slump Cone equipment for accomplishing the stoop check basically includes a metal mold withinside the shape of a frustum of a cone having the inner dimensions as : Bottom diameter : 20 cm, Top diameter : 10 cm, Height : 30 cm and the thickness of the metal sheet for the mildew must now no longer be thinner than 1.6 mm.

Fig 2: Slump cone test apparatus

- Fig. 2: Slump Cone Apparatus The Slump Cone equipment at the side of Tamper (sixteen mm in diameter and six hundred mm length.

- The tamping cease of rod will be rounded to a hemispherical tip), Ruler, etc. Conforming to IS 7320:1974 Specifications for Concrete Slump Test Apparatus (Fourth revision). Reaffirmed- Dec 2013.

Q8) What is compacting factor test?

A8)

- The pattern of concrete to be examined will be located lightly withinside the higher hopper, the use of the hand scoop. The hopper will be stuffed degree with its brim and the trap-door will be opened in order that the concrete falls into the decrease hopper.

- Certain mixes will be inclined to paste in a single or each of the hoppers. If this occurs, the concrete can be helped via with the aid of using pushing the rod lightly into the concrete from the pinnacle. During this technique, the cylinder will be included with the aid of using the trowels. Immediately after the concrete has come to rest, the cylinder will be uncovered, the trap-door of the decrease hopper opened, and the concrete allowed to fall into the cylinder.

- The extra of concrete ultimate above the extent of the pinnacle of the cylinder shall then be reduce off with the aid of using keeping a trowel in every hand, with the aircraft of the blades horizontal, and shifting them concurrently one from every facet throughout the pinnacle of the cylinder, on the identical time retaining them pressed at the pinnacle fringe of the cylinder.

- The outdoor of the cylinder shall then be wiped clean. The above operation will be performed at an area loose from vibration or shock. The weight of the concrete withinside the cylinder shall then be decided to the closest 10 g. The extra of concrete ultimate above the extent of the pinnacle of the cylinder shall then be reduce off with the aid of using keeping a trowel in every hand, with the aircraft of the blades horizontal, and shifting them concurrently one from every facet throughout the pinnacle of the cylinder, on the identical time retaining them pressed at the pinnacle fringe of the cylinder.

- The outdoor of the cylinder shall then be wiped clean. This whole technique will be performed at an area loose from vibration or shock. This weight will be called the load of in part compacted concrete.

- The cylinder will be refilled with concrete from the identical pattern in layers about five cm deep, the layers being closely rammed or ideally vibrated with a purpose to reap complete compaction. The pinnacle floor of the absolutely compacted concrete will be cautiously struck off degree with the pinnacle of the cylinder. The outdoor of the cylinder shall then be wiped clean.

- Observation

The compacting factor is defined as the ratio of the weight of partially compacted concrete to the weight of fully compacted concrete. It shall normally be stated to the nearest second decimal place.

Workability | Compaction Factor | Slump (mm) |

Very Low | 0.78 | 0 - 25 |

Low | 0.85 | 25 - 50 |

Medium | 0.92 | 50 - 100 |

High | 0.95 | 100 - 175 |

Q9) What is flow table?

A9)

Sr. No. | Description | Sample 1 | Sample 2 | Sample 3 |

1 | Weight of Empty Cylinder (W1) |

|

|

|

2 | Weight of Empty Cylinder + Free Fall Concrete(W2) |

|

|

|

3 | Weight of Empty Cylinder + Hand Compacted Concrete (W3) |

|

|

|

4 | Weight of Partially Compacted Concrete(WP = W2 - W1) |

|

|

|

5 | Weight of Fully Compacted Concrete(WF = W3 - W1) |

|

|

|

6 | Compaction Factor = WP/ WF |

|

|

|

Q10) Explain Vee-Bee consistometer

A10)

Fig 3: Vee-Bee consistometer

- The workability of clean concrete is a composite property, which incorporates the various necessities of stability, mobility, compactability, placeability and finishability.

- There are distinctive techniques for measuring the workability. Each of them measures best a specific element of it and there may be sincerely no specific check, which measures workability of concrete in its totality. This check offers a demonstration of the mobility and to a degree of the compactibility of freshly combined concrete.

- The check measures the relative attempt required to extrade a mass of concrete from one particular form to another (i.e., from conical to cylindrical) through vibration. The quantity of attempt (referred to as remoulding attempt) is taken because the time in seconds, required to finish the extrade.

- The consequences of this check are of cost whilst analyzing the mobility of the hundreds of concrete made with various quantities of water, cement and with numerous varieties of grading of aggregate. The time required for whole remoulding in seconds is taken into consideration as a degree of workability and is expressed because the variety of Vee-Bee seconds. The approach is appropriate for dry concrete. For concrete of hunch in extra of 50mm, the remoulding is so short that the time can't measured.

Q11) Explain Factor affecting workability

A11)

- The term ‘Workability of Concrete’ is described because the assets of freshly blended concrete which determines the convenience and homogeneity with which it is able to be blended placed, consolidated and finished.

- A perfect water-cement ratio on my own isn't always going to present most strength. 100% compaction of concrete is a critical parameter for contributing to the most strength. Insufficient compaction will bring about presence of air voids which has unfavourable impact on strength.

- Generally to compact the concrete absolutely a better water-cement ratio is adopted. The water characteristic as a lubricant withinside the concrete which eases the compaction process. Thus water is needed for Handling concrete without segregation. For setting without lack of homogeneity. Effort of compaction is needed to finish. The nice of concrete pleasurable a lot of these necessities is named as practicable concrete.

- Water Content: The quantity of water content material to be had in a extent of concrete may have a enormous impact at the workability of concrete. The better the water content material in step with cubic meter of concrete the better will be the fluidity of the concrete. In fashionable to growth the workability sure quantity of extra water is brought in concrete at site. However it must be referred to that growing the water content material of concrete may have a few impact on energy of the concrete. Besides, every time greater water is brought a sure quantity of cement is likewise brought in order that water-cement ratio stays constant.

- Mix Proportions: In preferred combination-cement ratio is likewise a critical issue which impacts the workability. If the combination-cement ratio is better, the tilt concrete is formed. In this example much less amount of paste is to be had for supplying lubrication, subsequently workability is decreased. Whereas if the combination-cement ratio is decrease the wealthy blend is formed. In this example extra paste is to be had to offer lubrication, subsequently higher workability of concrete is observed.

- Size of Aggregates: The larger the scale of the aggregates the lesser is the floor place subsequently much less quantity of water is needed for wetting the floor. Hence much less paste is needed for lubricating the concrete floor to lessen inner friction, consequently we will say that the larger length of aggregates will provide better workability. Reduction in length of aggregates will lessen the workability.

- Shape of Aggregates: The form of aggregates additionally have great have an effect on at the workability of concrete. Compared to rounded aggregates or cubical fashioned aggregates the angular, elongated or flaky aggregates makes the concrete very harsh. Thus rounded fashioned aggregates have higher workability. This is because of rounded combination can have much less floor place and much less voids than an angular or flaky combination. In addition, rounded combination has the decreased frictional resistance and that is a cause why river sand and combination offer extra workability of concrete than beaten sand and combination. Besides the form of aggregates additionally has a good sized impact on energy and overall performance of concrete. In latest instances utilization of herbal sand turned into confined consequently new system turned into designed to yield properly fashioned and properly graded aggregates.

- Surface Texture of Aggregates: The floor texture of the combination additionally has a good sized impact at the workability of concrete. The overall floor place of approximately textured combination is extra than the floor place of easily rounded combination of the equal volume. Thus it could be inferred that more or less textured combination will display negative workability and clean or glassy texture combination will provide higher workability of concrete. The discount of inter-particle frictional resistance presented via way of means of clean aggregates additionally contributes to better workability of concrete.

Q12) What is setting time?

A12)

- Moisture performs a important function in curing time for concrete. If there isn't always enough water withinside the blend, the concrete will therapy too fast, ensuing in weaker typical power.

- Too a whole lot moisture, regularly used withinside the completing step will weaken the pinnacle layer and reason flaking. Hot ambient temperatures and wind boost up the evaporation of moisture–rushing concrete placing time. The blend layout has lots to do with concrete placing time. Some jobs would require accelerants due to the fact the region desires to be usable as quickly as possible.

- The accelerant will do its task and accelerate the concrete placing time. Accelerant mixes will display a weaker typical power withinside the end, however will nevertheless meet power requirements.

Fig 4: Initial and setting time of cement

- Initial putting time offers a concept approximately how rapid cement can begin dropping its plasticity and the very last putting time of cement offers an concept approximately how a good deal cement takes to lose its complete plasticity and advantage a few energy to face up to pressure. Significance of Initial and Final Setting Time of Cement It is needed that cement does now no longer lose its plasticity too early or too overdue.

- If cement set too early, there's inadequate time for transportation and area concrete. If cement set too overdue then there's a put off in production work. Also, concrete will now no longer get enough energy early and the formwork elimination system delayed.

- The right putting time required for the stiffening of cement paste to a described consistency. It is circuitously associated with the chemical response of cement with water to shape an aluminum–silicate compound. Initial putting time is an essential time to recognise for concrete transportation, placing, and curing. Initial putting time additionally applied to put off the system of hydration or hardening.

- The very last putting time applied for the secure elimination of scaffolding or form

Q13) Explain W/C Law

A13)

- The water–cement ratio is the ratio of the load of water to the load of cement utilized in a concrete blend. A decrease ratio ends in better electricity and durability, however can also additionally make the combinationture hard to paintings with and form.

- Workability may be resolved with the usage of plasticizers or super-plasticizers. Often, the ratio refers back to the ratio of water to cementitious substances, w/cm. Cementitious substances encompass cement and supplementary cementitious substances which include fly ash, floor granulated blast-furnace slag, silica fume, rice husk ash and herbal pozzolans. Supplementary cementitious substances are introduced to bolster concrete.

- The belief of water–cement ratio changed into first evolved through Duff A. Abrams and posted in 1918. Refer to concrete hunch test. The 1997 Uniform Building Code specifies a most of 0.five ratio while concrete is uncovered to freezing and thawing in a wet situation or to de-icing chemicals, and a most of 0.forty five ratio for concrete in a extreme or very extreme sulfate situation. Concrete hardens because of the chemical response among cement and water (called hydration, this produces warmness and is known as the warmth of hydration). For each pound (or kilogram or any unit of weight) of cement, approximately 0.35 pounds (or 0.35 kg or corresponding unit) of water is wanted to completely whole hydration reactions.

- However, a combination with a ratio of 0.35 might not blend thoroughly, and might not glide nicely sufficient to be placed. More water is consequently used than is technically essential to react with cement.

- Water–cement ratios of 0.forty to 0.60 are extra commonly used. For better-electricity concrete, decrease ratios are used, in conjunction with a plasticizer to growth flowability.

- Too a good deal water will bring about segregation of the sand and mixture additives from the cement paste. Also, water that isn't always fed on through the hydration response can also additionally go away concrete because it hardens, ensuing in microscopic pores (bleeding) in an effort to lessen very last electricity of concrete.

- A blend with an excessive amount of water will revel in extra shrinkage as extra water leaves, ensuing in inner cracks and seen fractures (specifically round internal corners), which once more will lessen the very last electricity.

Q14) Give significance of w/c ratio

A14)

- In concrete, the unmarried maximum widespread affect on maximum or all the houses is the quantity of water used withinside the blend. In concrete blend design, the ratio of the quantity of water to the quantity of cement used (each with the aid of using weight) is known as the water to cement ratio (w/c).

- These substances are accountable for binding the whole thing together. The water to cement ratio in large part determines the electricity and sturdiness of the concrete whilst it's far cured properly. The w/c ratio refers back to the ratio of the weights of water and cement used withinside the concrete blend. A w/c ratio of 0.four way that for each one hundred lbs of cement used withinside the concrete, forty lbs of water is added.

- Typical Water-Cement Ratios in Concrete Mixes Typical w/c ratios are as follows: Normal for everyday concrete (sidewalks and driveways): 0.6 to 0.7 Specified if a better nice concrete is desired: 0.four The realistic variety of the w/c ratio is from approximately 0.three to over 0.eight. A ratio of 0.three could be very stiff (except superplasticizers are used). A ratio of 0.eight makes a moist and pretty vulnerable concrete. Typical compressive strengths whilst concrete is well cured are: 0.four w/c ratio –> 5600 psi 0.eight w/c ratio –> 2000 psi.

Q15) What is cohesiveness?

A15)

- Cohesiveness is the detail of workability which shows whether or not a combination is harsh, sticky, or plastic. Plasticity is a acceptable assets in concrete, indicating that a combination may be molded and preserve a form whilst formed.

- A harsh blend lacks plasticity and the elements might also additionally generally tend to separate. Harshness may be due to an extra or deficiency of blending water (excessive- or low-droop mixes), a deficiency of cement (lean mixes), or a deficiency of great mixture particles.

- Harshness will also be due to an extra of rough, angular, flat, or elongated mixture particles.

- Harsh mixes can now and again be stepped forward through air entrainment or through growing the great mixture or cement content, however modifications should be made to the general blend to preserve the right percentage of all elements.

- A sticky blend might also additionally have a excessive cement content (fats mixes) or big quantities of rock dust, great sand, or comparable great materials (over sanded mixes). Sticky mixes do now no longer segregate without difficulty, however due to the fact they require numerous water to acquire even minimum workability, sticky mixes frequently expand immoderate shrinkage cracking.

- A plastic blend is cohesive without being both sticky or harsh, and the elements do now no longer without difficulty segregate until the concrete is dealt with improperly.